Method for separating mixed alcohol-water by continuous extractive rectification

A technology for extractive distillation and mixed alcohols, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of hydroxyl compounds, etc. It can solve the problems of immature membrane separation technology, large investment in azeotropic distillation equipment, and physical hazards of operators. To achieve the effect of improving equipment efficiency, convenient application, large economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

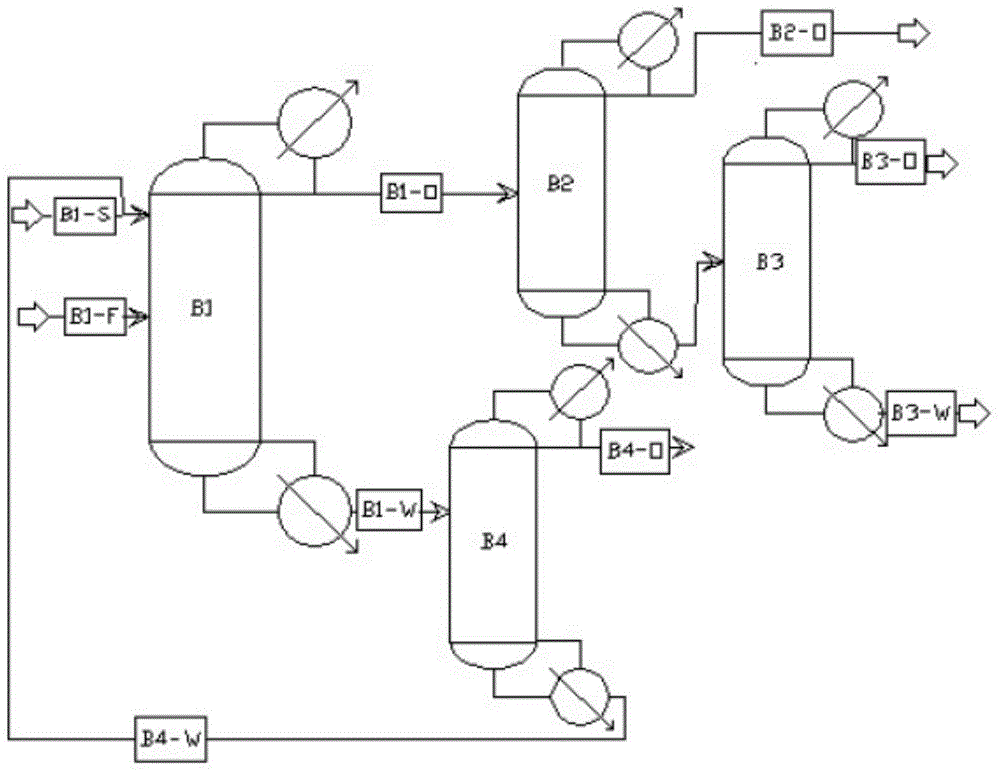

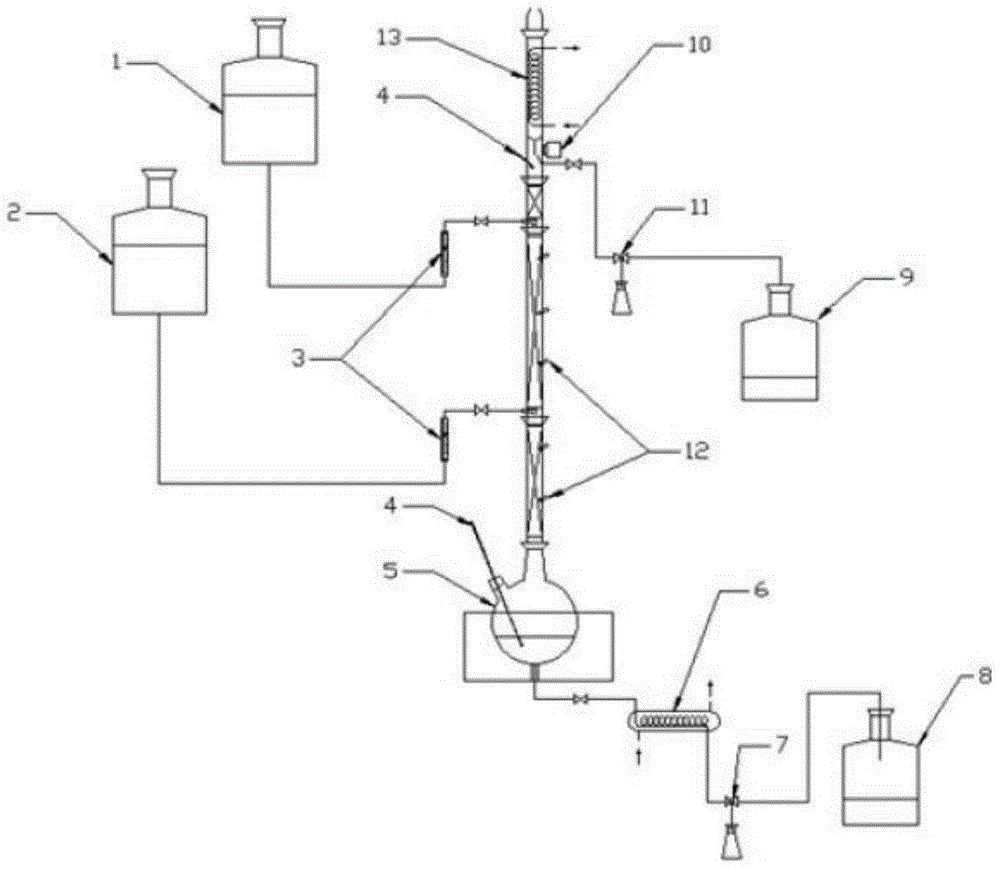

[0017] Example 1: continuous extraction rectification separation alcohol-water mixture flow process reference figure 1 , extractive distillation column reference figure 2 , the inner diameter of the tower is 25mm, the tower body packing is 03$3mm stainless steel 0-ring packing, the total height of the packing part is about 1.6m, and the number of theoretical plates is about 80. There are 3 and 2 sampling ports in the tower body, which are convenient for detecting the composition and content of the liquid phase. At the beginning of the experiment, first open the cooling water of the condenser at the top and bottom of the tower, close the valves at the top and bottom of the tower, and add 300ml of ethylene glycol and alcohol-containing waste liquid mixture with a solvent ratio of 4:1 into the tower kettle; Turn on the heating power of the tower kettle and heat to boiling until the tower body packing is wetted. Properly adjust the heating voltage and keep the full reflux for 1...

example 2

[0018] Example 2: substantially the same as Example 1, the ethylene glycol feed flow rate is set at 0.644ml / min, the alcohol-containing waste liquid feed flow rate is 0.279ml / min, and the set reflux ratio is 1~3.

example 3

[0019] Example 3: substantially the same as Example 1, the set reflux ratio is 1.35, the set ethylene glycol feed flow rate is 0.4~0.8ml / min, and the alcohol-containing waste liquid feed flow rate is 0.2ml / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com