Double-layered vibrating fluidized-bed drying-classification apparatus

A vibrating fluidized bed and fluidized drying technology, applied in drying gas arrangement, drying solid materials, heating to dry solid materials, etc., can solve the problems of uneven fluidization, high cost of exhaust gas treatment, short circuit of hot gas flow, etc. The effect of reducing investment and operating energy consumption, high coal classification efficiency, and increasing processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

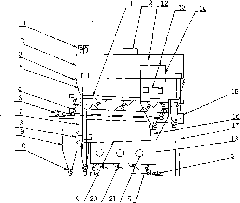

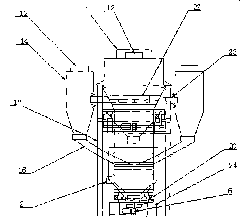

[0027] Such as figure 1 , 2The double-deck vibrating fluidized bed drying and classifying device shown in and 3 includes a coal inlet 1, an upper fluidized drying and classifying chamber 2 and a lower fluidized drying and classifying chamber 7, an inclined material baffle 4, a transmission device 5, and a driving motor 6. Fine-grained coal feed pipe 8, fine-grained coal buffer and sealed hopper 9, rotary unloader 10, air distribution plate 11 of the upper fluidized drying and classifying chamber and air distribution plate 19 of the lower fluidized drying and classifying chamber, outlet Tuyere 12, air outlet 13, air-material separation chamber 14, upper driving device base 15, lower driving device base 24, feeding conduit 16, supporting steel beam 17, equalizing air box 18, air inlet 21, fine particle Coal scraper 22, gas material conduit 23, air cap 25, and large-grained coal outlet 26; wherein the coal feeding port 1 is located at the top end side of the upper fluidized clas...

Embodiment 2

[0040] The double-deck vibrating fluidized bed drying and classifying device as described in embodiment 1, its difference is that the air distribution plate 11 of the fluidized drying and classifying chamber of the upper floor and the air distribution plate 19 of the fluidized drying and classifying chamber of the lower floor have a distance of 20 from the horizontal plane. ° Angle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com