Intelligent garbage classification robot

A garbage sorting and robot technology, applied in sorting and other directions, can solve the problems of people prone to fatigue, single sorting types, and expensive prices, and achieve the effects of improving sorting efficiency, ensuring continuous work, and reducing sorting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

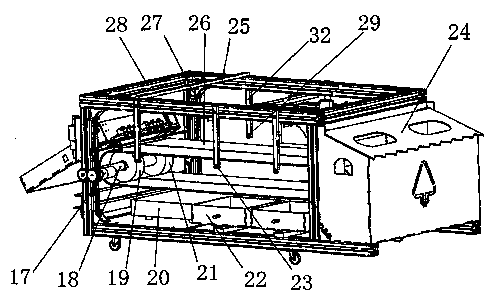

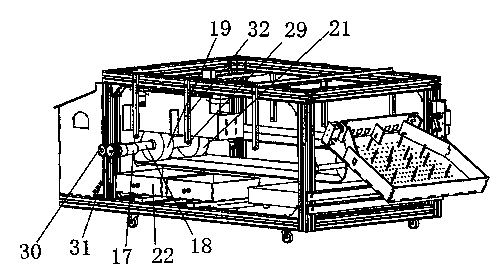

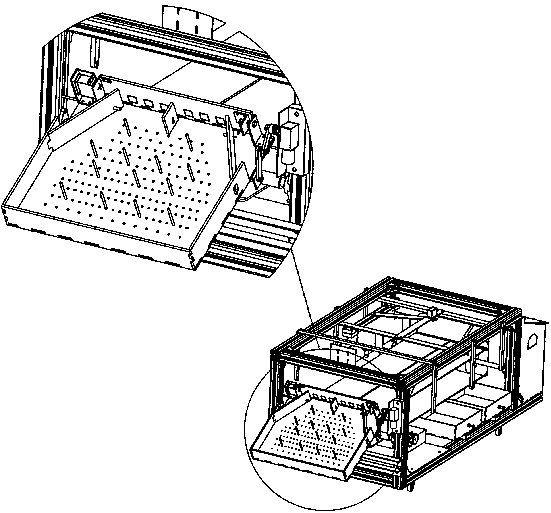

[0016] Such as figure 1 with figure 2 As shown, the present invention is achieved in this way, it includes a garbage separation device and a garbage classification device, the garbage separation device is composed of a garbage bucket and a crank rocker mechanism, wherein the garbage bucket includes a garbage baffle 1, a bottom plate 2, and a side plate 3 , laser emitting tube Ⅰ4, metal proximity switch 5, laser receiver Ⅰ6, partition 7, metal proximity switch bracket 8, rotating shaft 9, steering gear Ⅰ10, garbage separation column jack 11 and garbage separation column 12, crank rocker mechanism Including coupling 13, crank I14, DC geared motor I15 and connecting rod 16, the garbage sorting device includes DC geared motor II17, transmission shaft 18, driving sprocket 19, control system 20, driven sprocket 21, garbage bin 22, Laser emission tube Ⅱ23, solar panel 24, camera bracket 25, chain plate 26, camera 27, bracket body 28, laser receiver Ⅱ29, driven gear 30, driving gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com