Gas-liquid separator

A gas-liquid separator and separator technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., to achieve the effects of improved structure, improved processing capacity, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

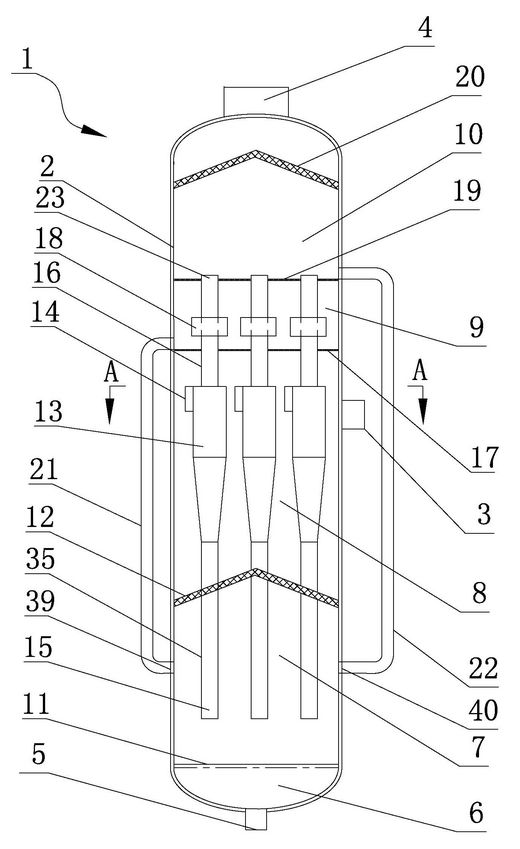

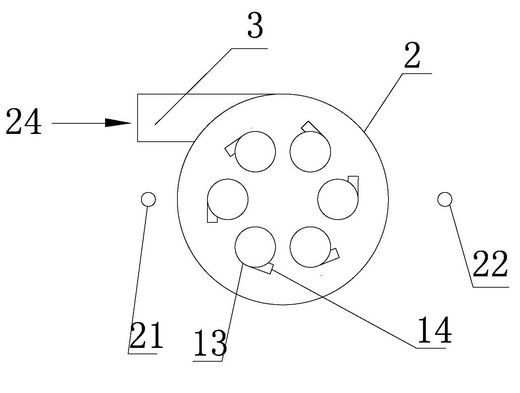

[0066] figure 1 It is a schematic diagram of the overall structure of the gas-liquid separator scheme 1 of the present invention, which adopts the gas-liquid separation process of the first-level cyclone separation, the second-level gas-lift pipe outlet ejection separation, and the third-level foam breaking net coalescence separation to realize the complete separation of gas and liquid;

[0067] The gas-liquid separator 1 includes a housing 2, a gas-liquid inlet pipe 3 arranged on the upper side wall of the housing, an exhaust pipe 4 at the top of the housing, and a liquid discharge pipe 5 at the bottom of the housing. The foam breaking net 12, the cyclone 13, the riser pipe separator 18 and the upper foam breaking net 20, the inner space of the shell is divided into a liquid collection area 6 from bottom to top, a coalescing area 7 for the exhaust liquid and tail gas of the cyclone, and a cyclone separation Zone 8, riser separation zone 9 and riser exhaust tail liquid coalesc...

Embodiment approach 2

[0084] Figure 8 It is a schematic diagram of the overall structure of the gas-liquid separator scheme 2 of the present invention, which uses the gas-liquid separation process of the first-level cyclone separation, the second-level eddy current separation at the outlet of the gas riser, and the third-level coalescence separation of the foam breaking net to achieve complete gas-liquid separation;

[0085] The gas-liquid separator 1 includes a housing 2, a gas-liquid inlet pipe 3 arranged on the upper side wall of the housing, an exhaust pipe 4 at the top of the housing, and a liquid discharge pipe 5 at the bottom of the housing. The foam breaking net 12, the cyclone 13, the riser pipe separator 18 and the upper foam breaking net 20, the inner space of the shell is divided into a liquid collection area 6 from bottom to top, a coalescing area 7 for the exhaust liquid and tail gas of the cyclone, and a cyclone separation Zone 8, riser separation zone 9 and riser exhaust tail liqui...

Embodiment approach 3

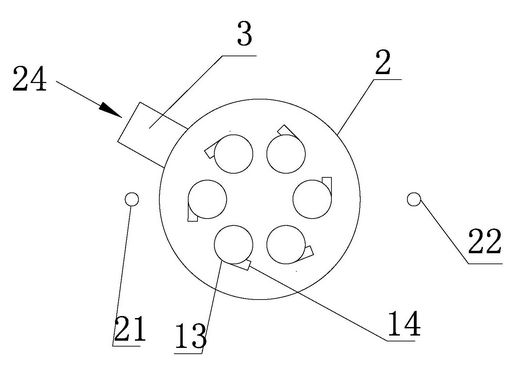

[0098] Figure 10 It is a schematic diagram of the overall structure of the third scheme of the gas-liquid separator of the present invention. The gas-liquid separation process of the first-level cyclone separation, the second-level eddy current separation at the outlet of the gas riser, and the third-level coalescence separation of the foam breaking net is used to achieve complete gas-liquid separation. The inlets are directly connected with the inlets of each cyclone, without partitions;

[0099] The gas-liquid separator 1 includes a housing 2, a gas-liquid inlet pipe 3 arranged on the upper side wall of the housing, an exhaust pipe 4 at the top of the housing, and a liquid discharge pipe 5 at the bottom of the housing. The foam breaking net 12, the cyclone 13, the riser pipe separator 18 and the upper foam breaking net 20, the inner space of the shell is divided into a liquid collection area 6 from bottom to top, a coalescing area 7 for the exhaust liquid and tail gas of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com