Device and method for continuously rectifying and purifying trifluoromethanesulfonyl fluoride

A technology for purifying trifluoromethanesulfonyl fluoride and purifying trifluoromethanesulfonyl fluoride is applied in the field of purification of trifluoromethanesulfonyl fluoride, and can solve the problem of hydrogen leakage and explosion, poor separation effect of hydrogen fluoride and trifluoromethanesulfonyl fluoride, and purification There are many problems such as many steps, so as to avoid the wasted time of hot and cold switching, be conducive to industrialized and stable production, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

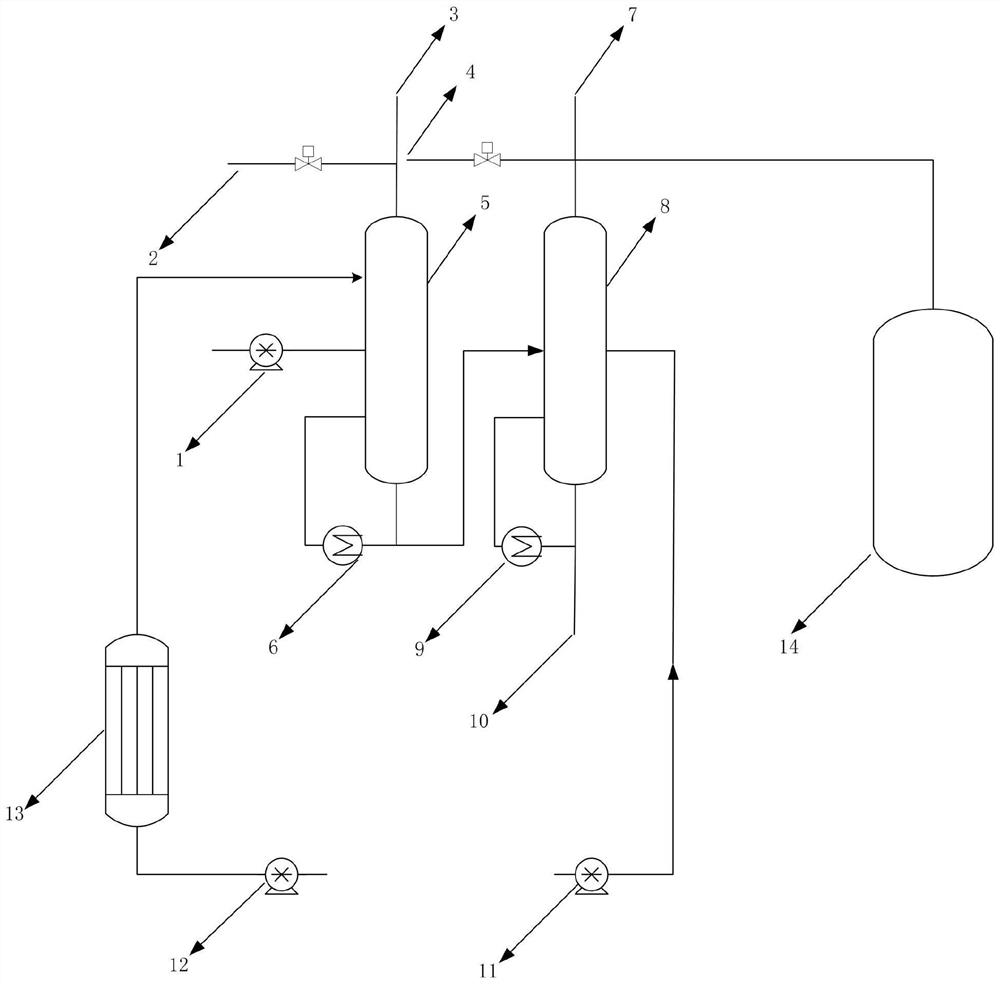

[0036] like figure 1 As shown, the device for continuous rectification and purification of trifluoromethanesulfonyl fluoride in this embodiment includes a first fluid conveying device 1, and a delight tower 5 is connected to the outlet of the first fluid conveying device 1. The top of the light tower 5 is provided with a light removal tower discharge port 3, the upper part of the light removal tower 5 is connected with a hydrogen fluoride cooler 13, and the bottom discharge port of the light removal tower 5 is connected with a weight removal tower 8. The top discharge port of the heavy tower 8 is connected with a fine-quality tank 14; the bottom of the light-removing tower 5 is connected with a light-removing tower reboiler 6, and the bottom of the weight-removing tower 8 is connected with a weight-removing tower reboiler 9, The top of the weight-removing tower 8 is further provided with a light component discharge port 7, and the bottom of the weight-removing tower 8 is also ...

Embodiment 2

[0041] The present embodiment adopts the method for continuous rectification and purification of trifluoromethanesulfonyl fluoride by the device in embodiment 1, comprising the following steps:

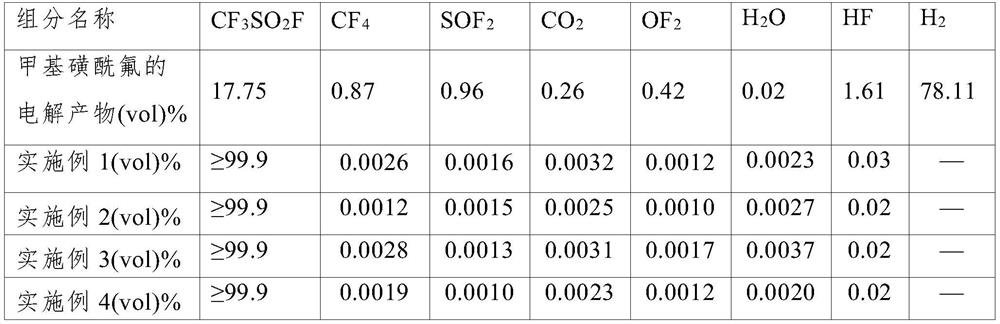

[0042] S1, at first the whole device in Example 1 is evacuated to -0.1MPa, then the electrolysis product of methylsulfonyl fluoride is passed into the light-removing tower 5 at a flow rate of 30kg / h through the first fluid conveying device 1, and the Hydrogen fluoride is transported into the hydrogen fluoride cooler 13 through the third fluid conveying device 12, and is passed into the upper part of the light-removing tower 5 at a temperature of -70 ° C and a flow rate of 3.6 kg / h, and then in the light-removing tower 5. Carry out rectification, described light-removing tower 5 tower tops produce light-component impurities, carry out sampling detection analysis in light-removing tower sampling port 2, detect in light-component impurities, trifluoromethanesulfonyl fluoride (CF 3 SO 2 ...

Embodiment 3

[0048] The present embodiment adopts the method for continuous rectification and purification of trifluoromethanesulfonyl fluoride by the device in embodiment 1, comprising the following steps:

[0049] S1, first vacuumize the whole device in Example 1 to -0.1MPa, then pass the electrolysis product of methylsulfonyl fluoride into the light-removing tower 5 at a flow rate of 300kg / h through the first fluid conveying device 1, and the Hydrogen fluoride is transported into the hydrogen fluoride cooler 13 through the third fluid conveying device 12, and is passed into the upper part of the light-removing tower 5 under the condition that the temperature is -40 ° C and the flow rate is 90 kg / h, and then carried out in the light-removing tower 5. Rectification, the light component impurities are produced at the top of the light-removing tower 5, and the sampling port 2 of the light-removing tower is sampled for detection and analysis to detect that in the light component impurities, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com