Pressure pipeline leaking stoppage device

A technology for pressure pipes and pipes, applied in pipe elements, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of poor pipe sealing, inconvenient use of devices, easy leakage of pipes, etc., and achieve good sealing performance, The effect of convenient operation and easy operation of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

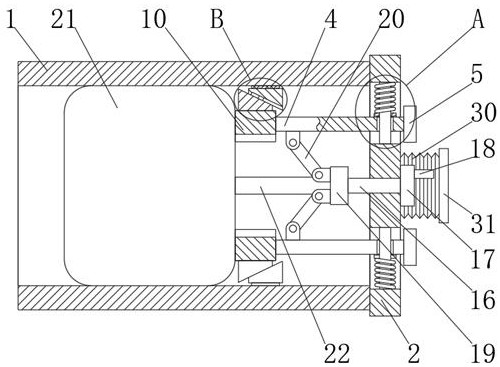

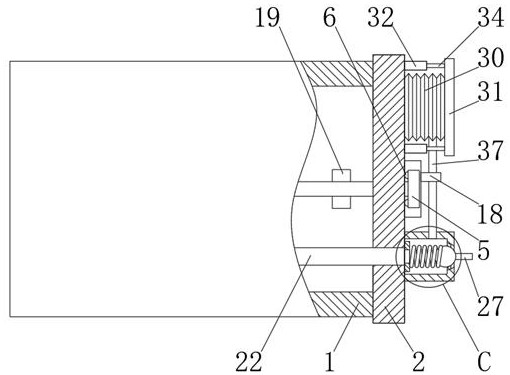

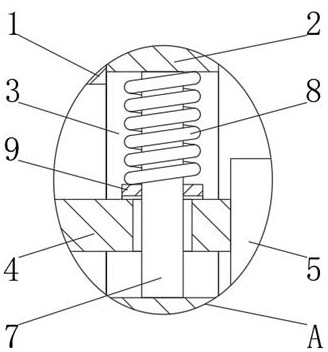

[0027] A pressure pipe leak plugging device, comprising a pipe 1, one end of the pipe 1 is contacted with a support plate 2, and a chute 3 is opened in the support plate 2, and there are two chute 3, and the two The chute 3 is symmetrically distributed in the support plate 2, the chute 3 is slidably connected with a support rod 4, one end of the support rod 4 is welded with a stopper 5, and a guide rod 7 is arranged in the chute 3, so The guide rod 7 is welded on the support plate 2, the first spring 8 is arranged on the outside of the guide rod 7, the outer side of the guide rod 7 is slidingly sleeved with a backing plate 9, and the outer side of the guide rod 7 is slidingly sleeved There is a support rod 4 , the backing plate 9 is in contact with the support bar 4 , one end of the first spring 8 is bonded to the support plate 2 , and the other end is bonded to the backing plate 9 .

[0028] Wherein, a bump 6 is welded on the stopper 5 , and the outer side of the bump 6 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com