Multi-stage centrifugal concentration treatment device for waste slurry and use method thereof

A centrifugal concentration and treatment device technology, which is applied in water/sludge/sewage treatment, devices with reversed axial directions of swirling flow, centrifuges, etc., which can solve the problems of low water content, large device footprint, and high cost. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

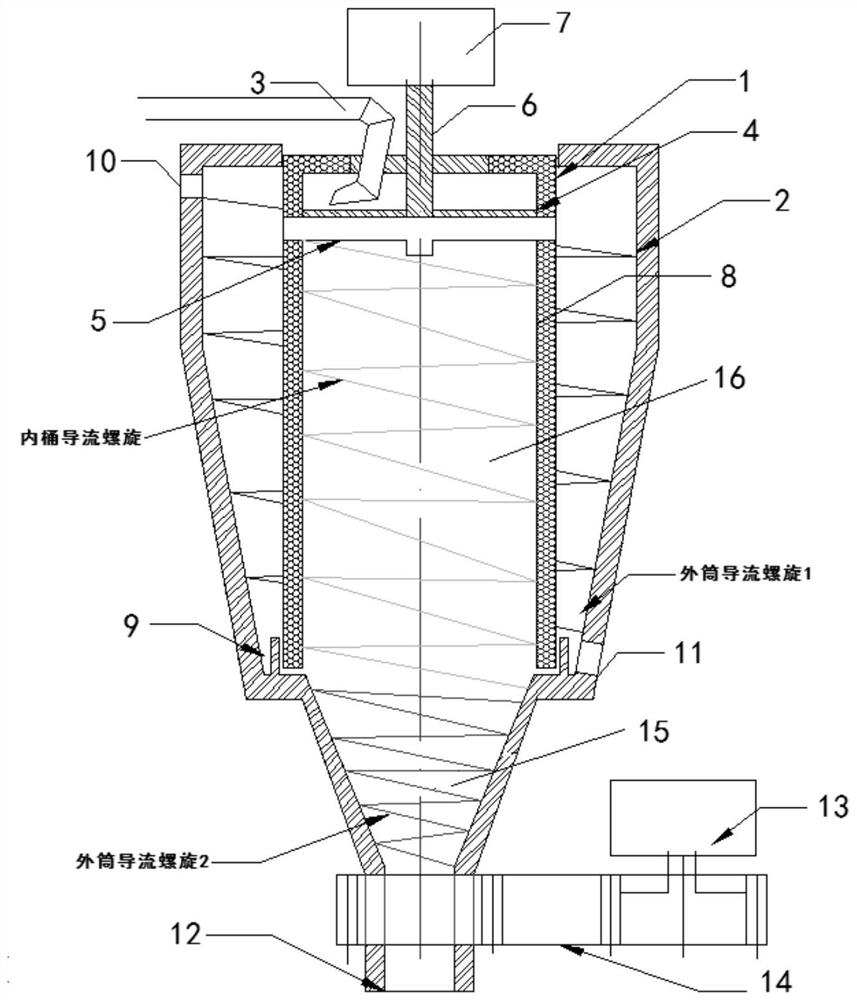

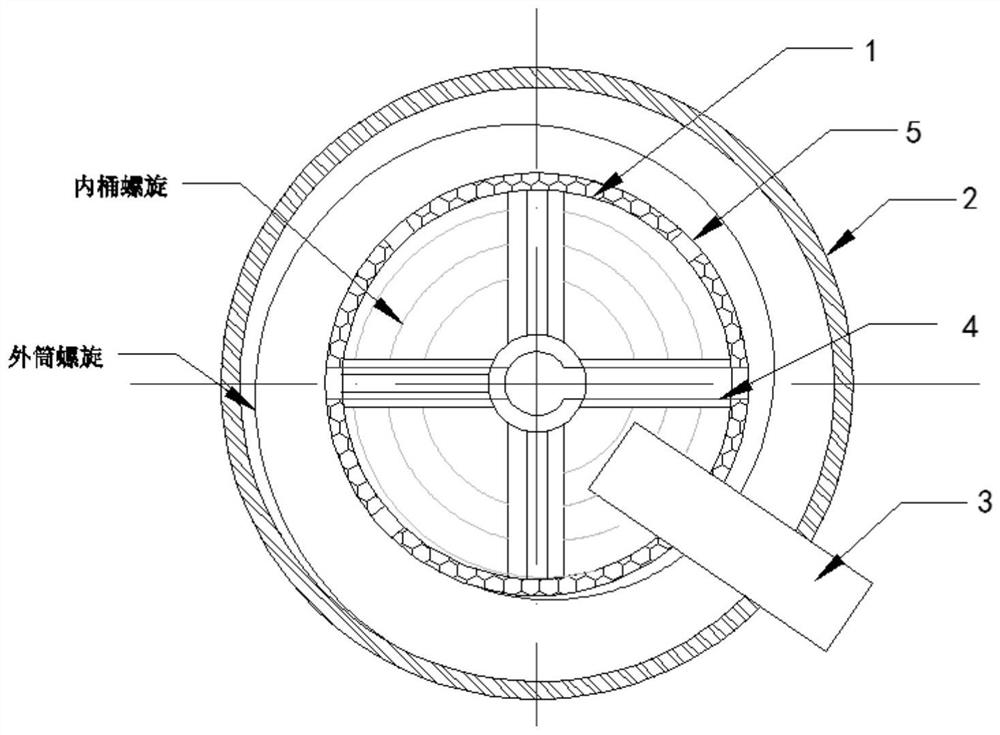

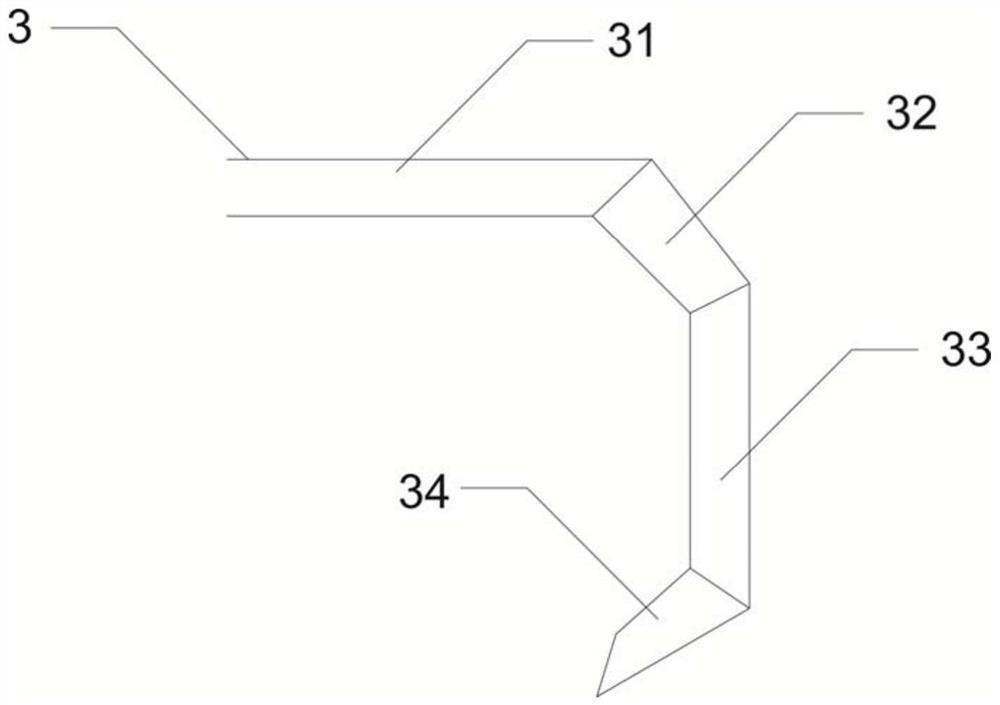

[0033] This example provides a multi-stage centrifugal concentration treatment device for waste slurry water, such as Figure 1-4 As shown, it includes an inner barrel 1 and an outer barrel 2. The inner barrel 1 is located inside the outer barrel 2. The shape of the barrel of the inner barrel 1 is straight and the width is 0.35m; the upper part of the inner barrel 1 is provided with a connecting rod 4, which is connected to the rotating motor The transmission shaft 6 of one 7 is connected, and the top of the inner barrel 1 is provided with a feeding mechanism 3, and the feeding structure includes a direct current pipeline 31, a corner pipeline 32, a direct current pipeline 2 33 and a corner outlet 34, and the upper part of the inner barrel 1 is provided with an inner barrel swirl outlet 5 , the inner barrel body 8 is a mesh structure, specifically composed of multi-layer screens, the aperture of which is 0.01-0.05mm; the total height of the outer cylinder 2 is 1.7m, and the wid...

Embodiment 2

[0036] This example provides a multi-stage centrifugal concentration treatment device for waste slurry water and its use method. The difference from Example 1 is that the height ratio of the upper, middle and lower parts of the outer cylinder is 2:5:2, and the remaining steps and parameters are the same.

Embodiment 3

[0038]This example provides a multi-stage centrifugal concentration treatment device for waste slurry water and its use method. The difference from Example 1 is that the height ratio of the upper, middle and lower parts of the outer cylinder is 2:5:5, and the remaining steps and parameters are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com