Liquid dispenser filter screen assembly and liquid dispenser

A liquid separator and filter screen technology, applied in refrigeration components, refrigeration and liquefaction, refrigerators, etc., can solve problems such as liquid hammer, and achieve the effect of preventing liquid hammer, reducing possibility and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

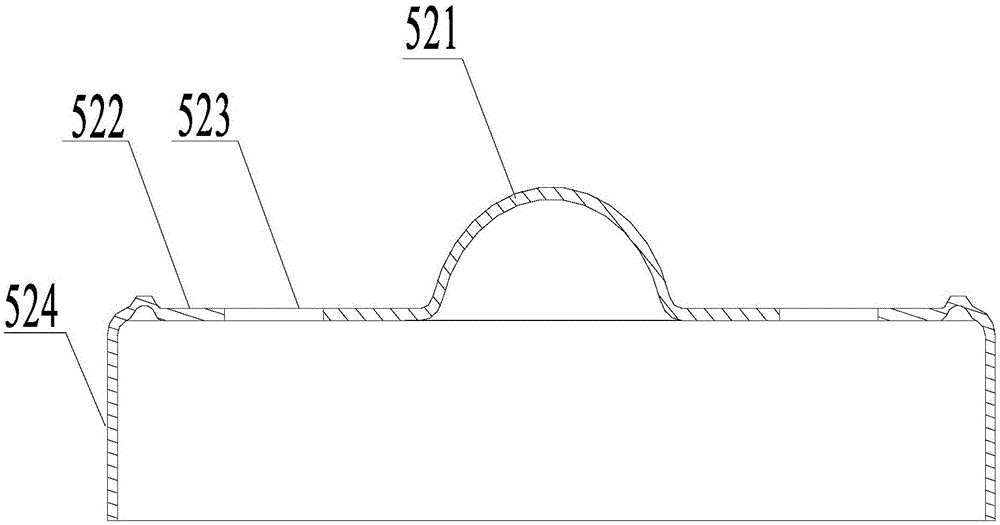

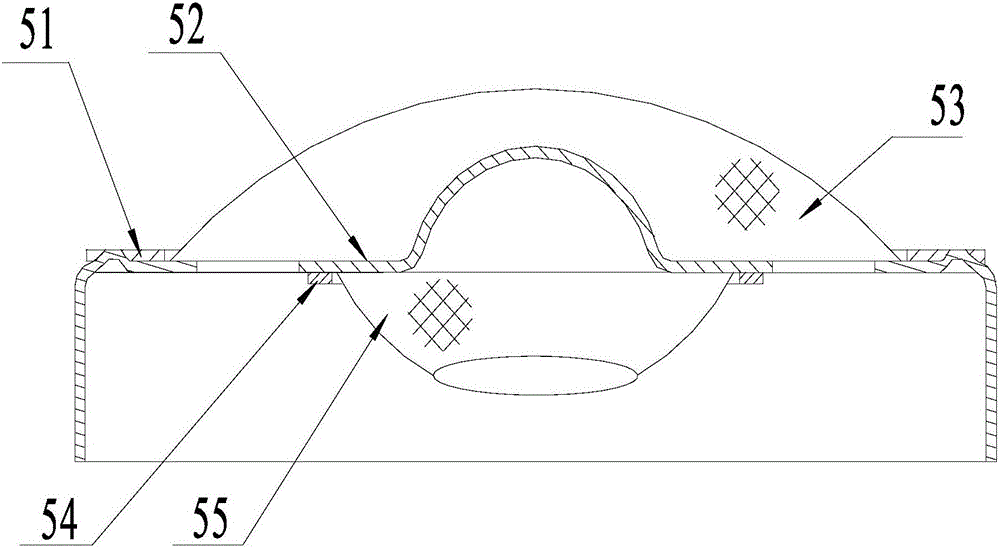

[0028] Such as figure 1 and figure 2 As shown, a filter screen assembly for a liquid separator includes a filter screen support 52, and the filter screen support 52 includes a connecting plate 522. A through hole is provided in the middle of the connecting plate 522, and a central support plate 521 is provided at the center of the through hole. An air intake channel 523 is provided between the outer edge of the support plate 521 and the inner edge of the connecting plate 522, an upper filter screen 53 is provided above the filter screen support 52, a lower filter screen 55 is provided below, and a connecting filter screen 55 is provided on the lower filter screen 55. mouth;

[0029] The upper filter screen 53 covers the central support plate 521 and the air intake channel 523, the edge of the upper filter screen 53 is connected with the top of the connecting plate 522, the central support plate 521 covered by the lower filter screen 55, and the edge of the lower filter scree...

Embodiment 2

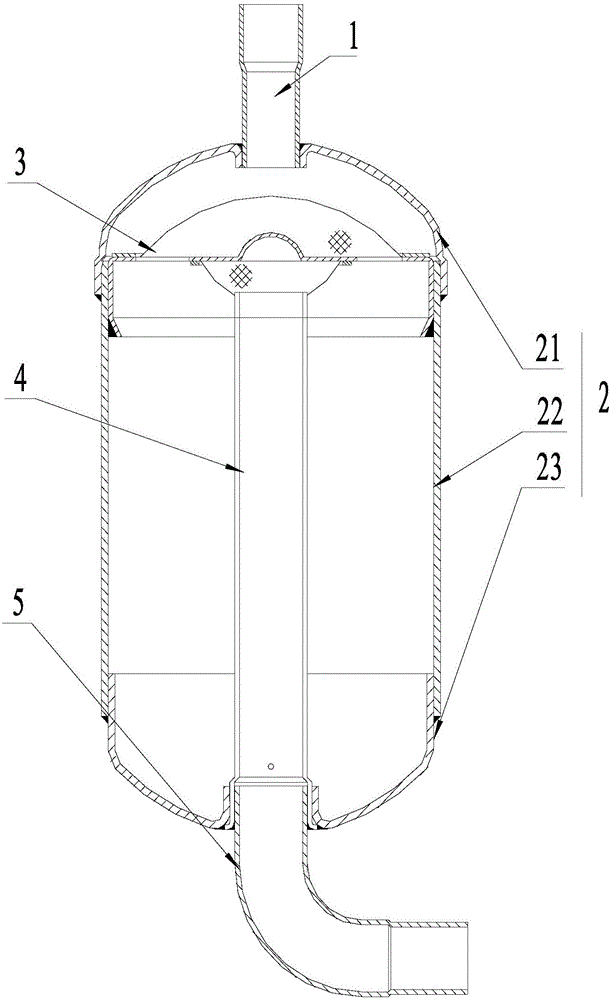

[0036] Such as image 3 and Figure 4 As shown, a liquid separator includes a cylinder 2, the top of the cylinder 2 is provided with a suction pipe 1, the bottom is provided with an exhaust pipe 5, and the cylinder 2 is provided with a steel pipe 4 and the liquid separator in Example 1. Filter screen assembly 3;

[0037] The bottom of the steel pipe 4 is connected with the exhaust pipe 5, the top is connected with the connecting port of the lower filter screen 55, and the upper filter screen 53 is set opposite to the suction pipe 1.

[0038] The liquid separator uses the liquid separator filter assembly 3 in Embodiment 1, which can realize the secondary filtration of the gas-liquid mixed refrigerant, wherein, during the secondary filtration, the original gas-liquid mixed refrigerant is not completely The filtered liquid refrigerant is filtered, and at the same time, the liquid refrigerant that is mixed into the gas refrigerant after the gas refrigerant enters the cylinder 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com