Safety tank on oil outlet pipe of oil well oil pouring tank

A technology of oil outlet pipe and safety tank, which is applied in the field of oil well pouring, which can solve the problems of hidden safety hazards, prone to combustion, explosion, etc., and achieve the effects of preventing dissipation, avoiding fire hazards, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical solution of the present invention clearer, the present invention will be further described below with examples in conjunction with the accompanying drawings.

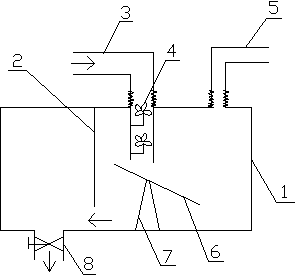

[0013] A safety tank on the oil outlet pipe of an oil well pouring tank. The safety tank body 1 is divided into two left and right tank body areas by a partition layer 2. There is a gap for crude oil flow at the lower end of the partition layer 2, and a tank body area is provided on the upper part of the tank body area. There are an oil inlet pipe 3 and an exhaust pipe 5, the oil inlet pipe 3 is provided with an electric stirring fan blade 4, the oil inlet pipe 3 is provided with a deflector 6 at the bottom of the nozzle in the tank, and the bottom of the other tank body area is provided with an outlet Oil pipe 8, the oil inlet pipe 3 threaded connections on the top of the tank body are connected to the oil outlet pipe of the oil well pouring oil tank. The above-mentioned oil inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com