Refrigeration equipment and control method of air-cooled refrigeration workbench

A refrigeration equipment and air-cooled technology, which is used in the temperature stability control of air-cooled refrigeration workbenches, and the field of refrigeration equipment, can solve the problems of insufficient heat insulation, low temperature storage box temperature rise, leakage, etc., and achieve universal equipment. Strong performance, fast defrosting speed and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

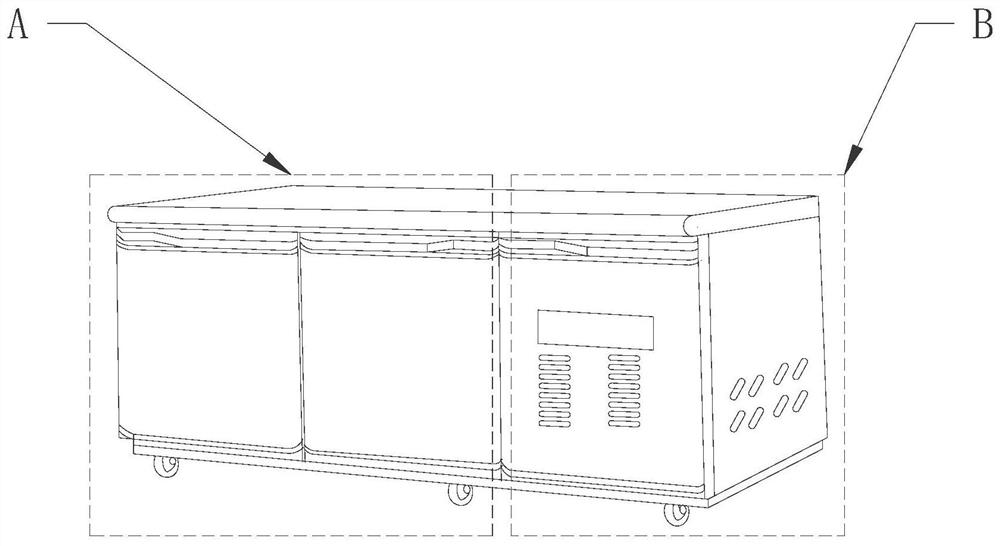

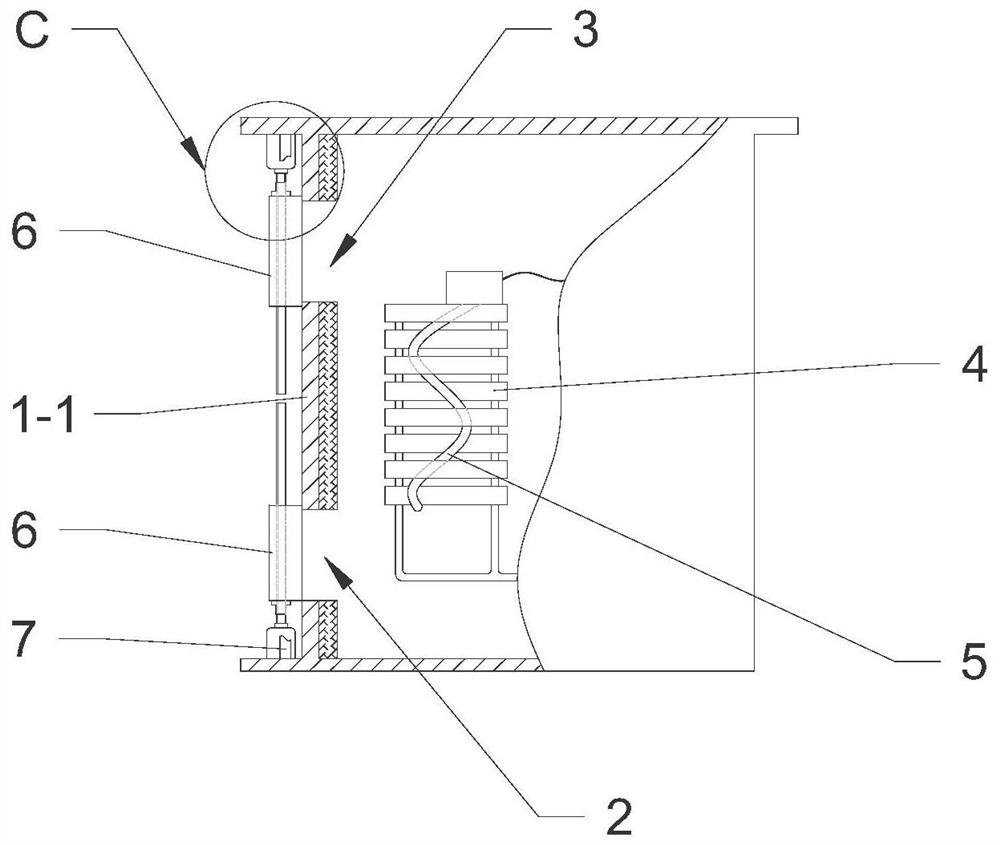

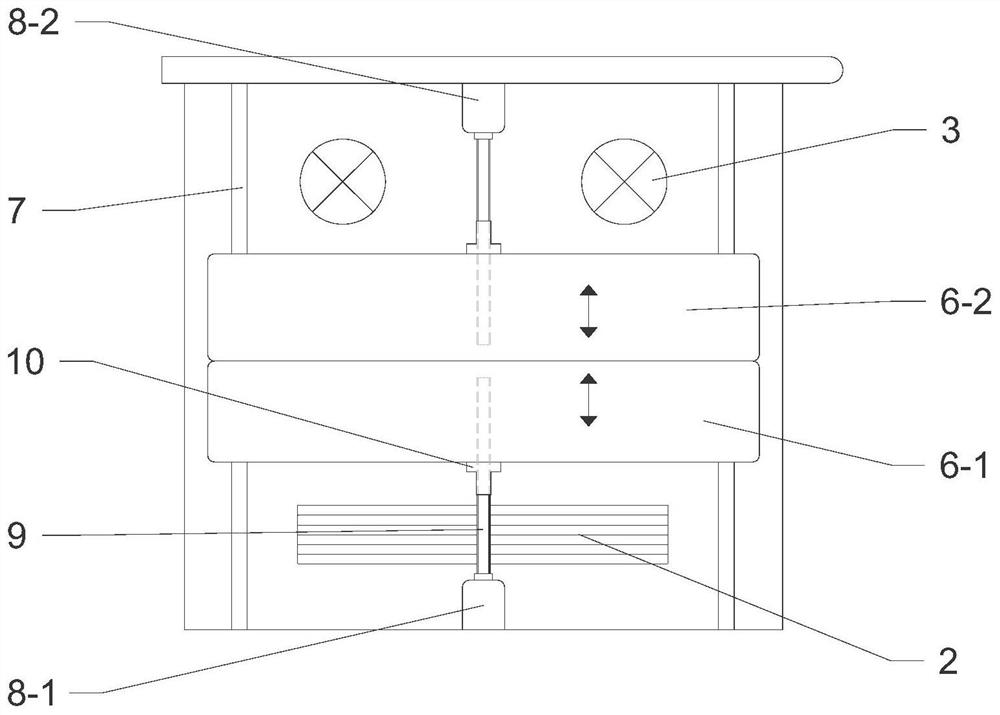

[0033] figure 1 A schematic diagram of a commercially available air-cooled freezing workbench is shown, in which the left side is the low-temperature storage box A, and the right side is the refrigeration equipment B. The improved refrigerating equipment B proposed by the present invention has a side view of the low-temperature storage box A refrigerating equipment B as figure 2 As shown, the low-temperature storage box A is shown opposite to the refrigeration equipment B, that is, the ventilation side panel 1-1. In general, the refrigeration equipment B of this embodiment includes an equipment box 1 and a refrigeration unit. The equipment box 1 has a ventilation side panel 1-1, and the ventilation side panel 1-1 is provided with an air inlet 2 and an air outlet 3 for refrigeration. The unit includes a compressor, an evaporator 4 and a defrosting heating device 5 installed on the evaporator 4 . A plurality of movable thermal insulation panels 6 are installed on the ventilat...

Embodiment 2

[0037] On the basis of Example 1, in order to further prevent the heat of the refrigeration equipment B from leaking to the low-temperature storage box A during defrosting, the inside and / or outside of the ventilation side panel 1-1 are covered with thermal insulation materials 1-2 . As a preferred solution, considering factors such as service life, movable thermal insulation board 6 easy installation, such as image 3 As shown, the thermal insulation material 1-2 is preferably laid on the inner side of the ventilation side panel 1-1. The thickness of the thermal insulation material 1-2 is 5-35mm, preferably 8-20mm. After many experiments, a variety of thermal insulation materials within this thickness range can have greater thermal insulation capabilities, avoiding the waste of materials caused by over-thick paving and the compression of refrigeration unit space. As a specific product, for example, a 10 mm thick EPS foam board can be used.

Embodiment 3

[0039] This embodiment shows an air-cooled freezing workbench using the refrigeration equipment B of the foregoing Embodiment 1 and / or 2. In this embodiment, the low-temperature storage box A and the refrigeration equipment B are arranged side by side, the ventilation side plate 1-1 of the refrigeration equipment B faces the low-temperature storage box A, and the air inlet 2 and the air outlet 3 communicate with the low-temperature storage box A. Such placement is the same as that of corresponding equipment in the prior art, such as figure 1 shown. That is to say, the refrigerating device B of the present invention can be used in conjunction with the commercially available low-temperature storage box A, and has extremely high flexibility and convenience.

[0040] In a more specific situation, the low-temperature storage box A is not provided with a vertical panel corresponding to the refrigeration equipment B, that is, the low-temperature storage box A is an incompletely clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com