Residual oil hydrogenation method

A technology for hydrogenation of residual oil and hydrogenation catalyst, which is applied in chemical instruments and methods, treatment with moving solid particles, chemical/physical processes, etc. Easy operation, flexible operation and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

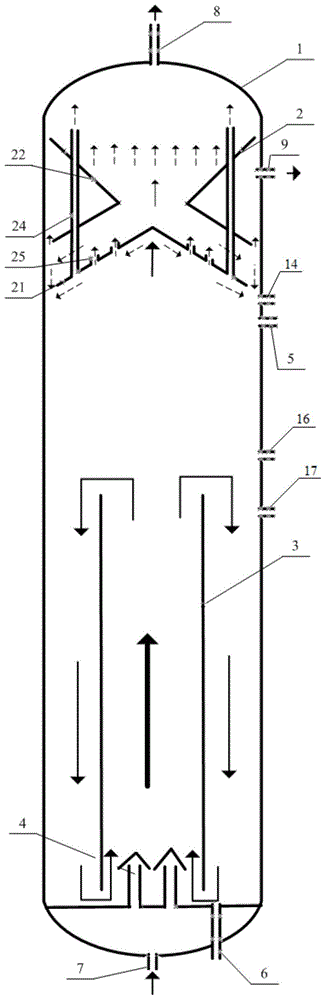

[0092] The specific dimensions of the ebullated bed reactor used in this example are shown in Table 1 below.

[0093] Table 1

[0094] code name

[0095] The above-mentioned ebullated bed reactor was used to carry out the cold model experiment, wherein the solid-phase catalyst added through the catalyst inlet 5 was a spherical catalyst with a particle size of 0.2 mm, and the solid-phase catalyst added through the catalyst inlet 17 was a spherical catalyst with a particle size of 0.3 mm , the colors of the two catalysts are different to facilitate experimental observation. The total catalyst storage is 60% of the effective volume of the reactor. The liquid phase uses straight-run kerosene, and the volume space velocity is 0.25-3.0h -1 . Nitrogen is used in the gas phase, and the gas-oil volume ratio is 20-150. Eight gas nozzles 10 are provided, and the gas volume injected into the gas nozzles accounts for 15% of the total gas volume. The experimental results in t...

Embodiment 2

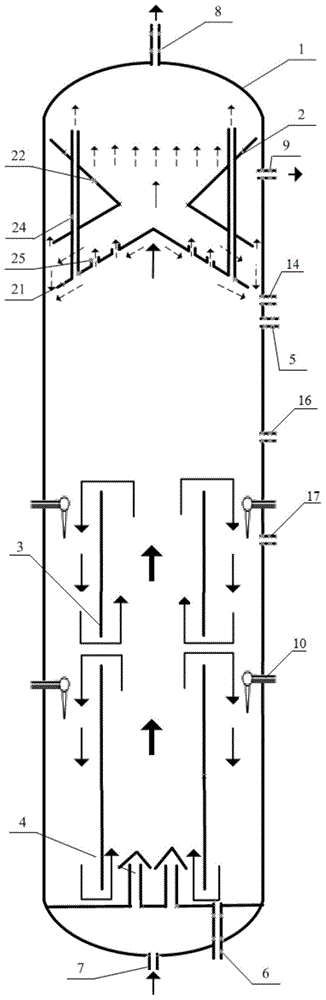

[0097] The specific dimensions of the ebullated bed reactor used in this example are shown in Table 2 below.

[0098] Table 2

[0099] code name

value

code name

value

d 1 / mm

300

h 1 / mm

3000

d 2 / mm

240

h 2 / mm

1500

d 3 / mm

280

h 3 / mm

900

d 4 / mm

260

α / °

60

d 5 / mm

150

β / °

60

d 6 / mm

285

ω / °

60

d 7 / mm

170

φ / °

60

d 8 / mm

285

The total opening area of the gas separation tube / mm 2

8000

d 9 / mm

160

The total opening area of the through hole / mm 2

15000

d 10 / mm

290

[0100] The above-mentioned ebullated bed reactor was used to carry out the cold model experiment, wherein the solid-phase catalyst added through the catalyst inlet 5 was a spherical catalyst with a particle size of 0.4 mm, and the solid-phase catalyst added through ...

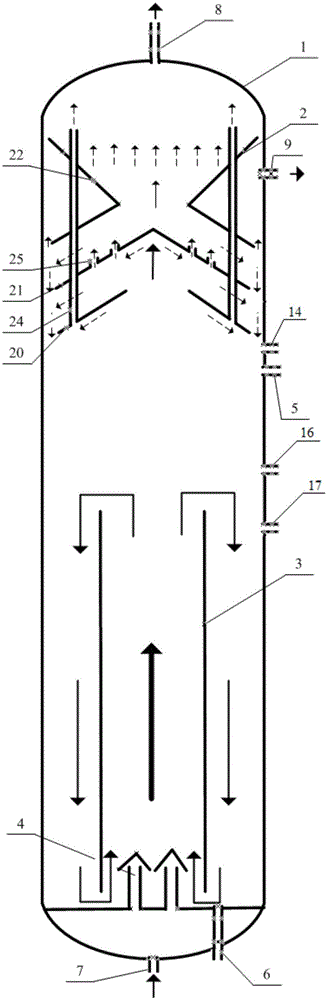

Embodiment 3-5

[0103]Embodiments 3 and 4 adopt the medium-sized thermal reactor made according to the ratio of embodiment 1, and embodiment 5 adopts the medium-sized thermal reactor made according to the ratio of embodiment 2, wherein, the solid-phase catalyst added through the catalyst inlet 5 and The physical and chemical properties of the solid-phase catalyst added through the catalyst inlet 17 are as shown in table 3, and two kinds of solid-phase catalyst loadings are 55% of the effective volume of the reactor, and the volume ratio of the consumption of two kinds of solid-phase catalysts is about 1: 1. The properties of residual oil raw materials are shown in Table 4. Table 5 shows the distillate oil carrying the suspended bed hydrogenation catalyst injected through the catalyst inlet 14 . The amount of gas injected through the nozzle 10 accounts for 20% by volume of the total gas amount. The reaction conditions and test results in the reactor are shown in Table 6.

[0104] table 3

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com