Barrel plating device and barrel plating automatic production line

A barrel plating and drum technology, applied in the direction of cells, electrolysis process, electrolysis components, etc., can solve the problems of large volume of tank liquid, large exhaust gas discharge, large waste water discharge, etc., and achieve the effect of reducing waste water and reducing consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

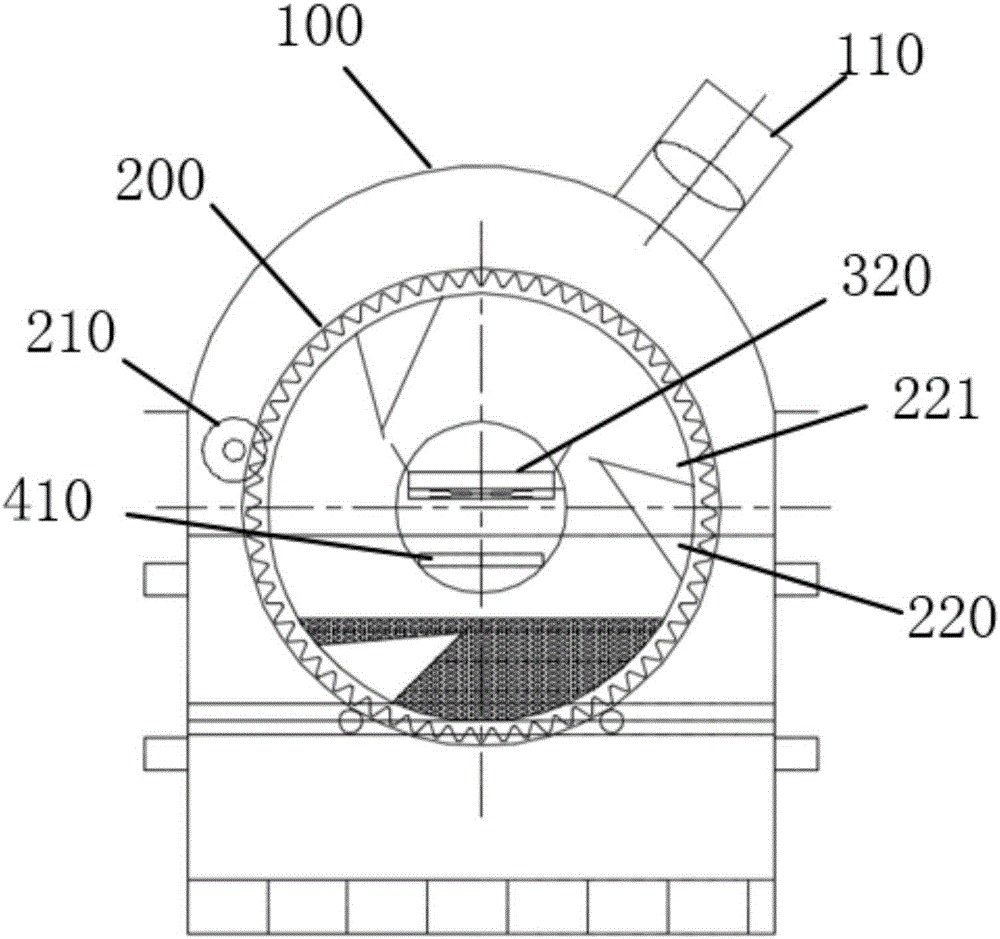

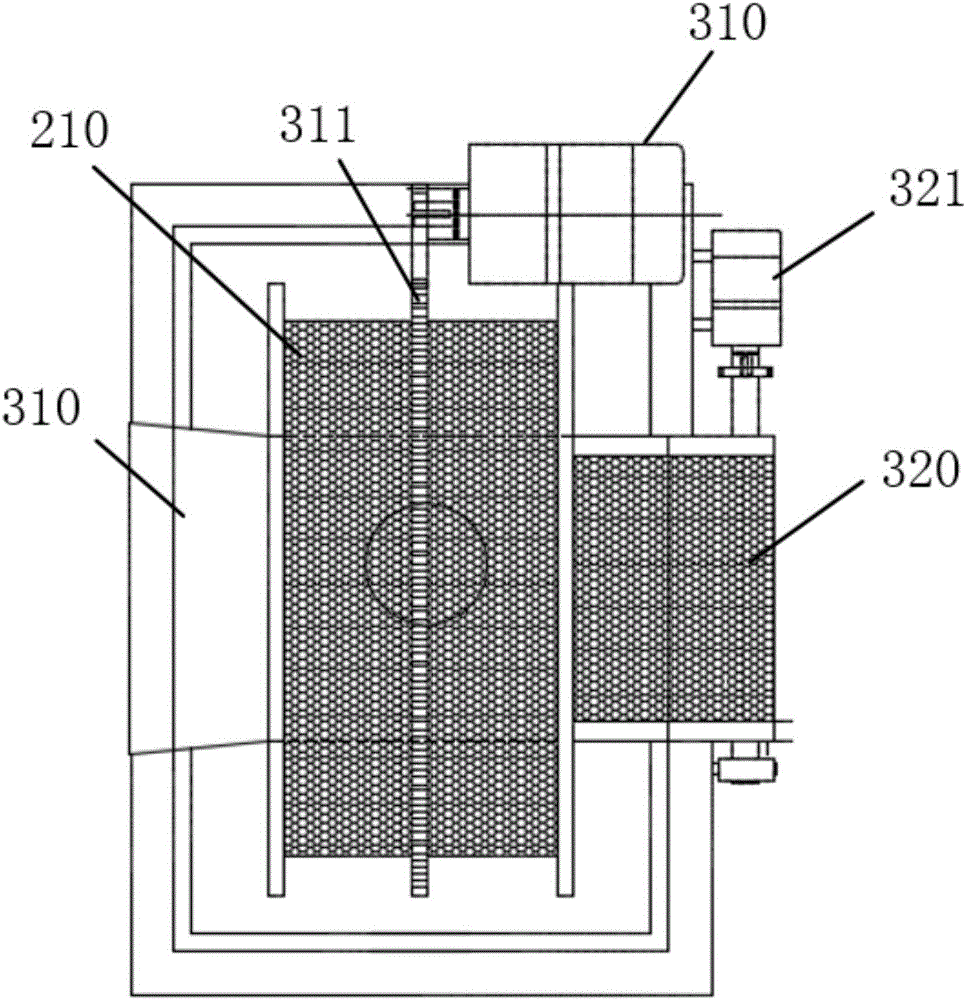

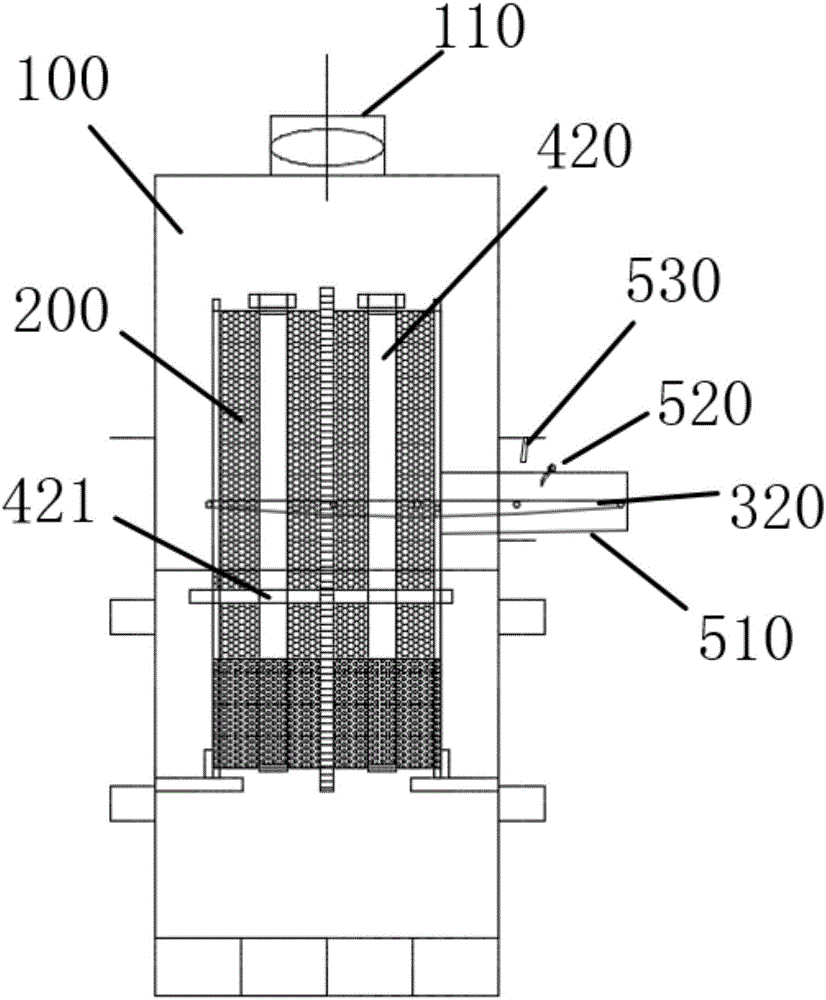

[0041] refer to Figure 1 to Figure 3 , in this embodiment, the barrel plating device provided by the present invention includes: a housing 100, a drum 200 rotatably arranged in the housing 100, a drum motor 210 connected to the drum 200 in transmission, for An input belt for receiving materials and an output belt for outputting materials, the input belt is arranged at the front end of the drum 200 along the axis direction, and the outlet belt is arranged at the rear of the drum 200 along the axis direction end.

[0042] In this embodiment, the rotation of the drum 200 toward the opening of the V-shaped dumping groove 221 is reverse rotation, and vice versa is forward rotation.

[0043] The working principle of the barrel plating device provided in this embodiment is as follows: bath liquid is placed in the housing 100 as required, and the parts enter the drum through the feeding belt and are soaked in the bath liquid. The parts are turned over by the rotation of the drum 20...

Embodiment 2

[0058] refer to Figure 4 , the barrel plating automatic production line provided in this embodiment includes: the chemical degreasing station S100, the hot water washing station S200, the weak corrosion station S300, the first cold water washing station S400, the neutralization station S500, the first The second cold water washing station S600, two cyanide galvanizing stations S700, two cyanide cadmium plating stations S800, and the third cold water washing station S900.

[0059] Each station is provided with the above-mentioned barrel plating device; in any two adjacent stations, the discharge belt of the barrel plating device on the upper station is connected with the input belt of the barrel plating device on the lower station. One or more spraying devices are arranged above the discharge belts of the chemical degreasing station S100 , the hot water washing station S200 and the third cold water washing station S900 . At the same time, on the cyanide galvanizing station S7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com