Dephosphorization method for oxygen top-blown converter slag remainder

A technology of oxygen top blowing and slag retention, which is applied in the field of steelmaking, can solve the problems of limited popularization and application, failure to grasp the safety rules of slag retention operation, large spraying, etc., achieve low heat loss, reduce converter smelting costs, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

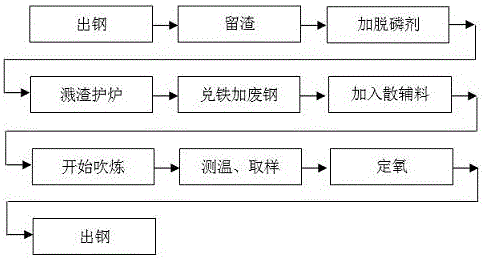

[0021] Example 1-9: The specific process of the dephosphorization method for slag retention in an oxygen top-blown converter is as follows.

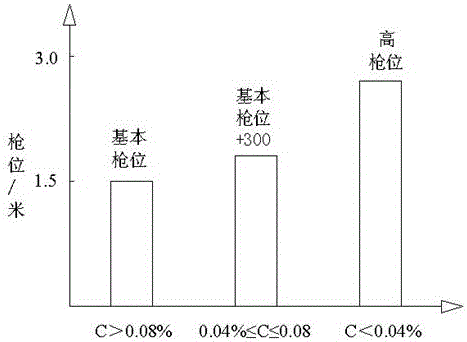

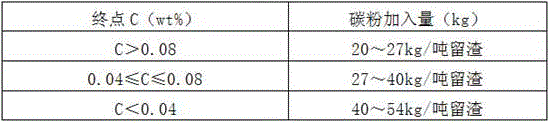

[0022] The smelting steel is low-alloy HRB400B, the molten iron loading amount is 70 tons, and the scrap steel loading amount is 5 tons; carbon pulling makes the carbon at the end point below 0.11wt%, with an average of 0.052wt%; the average temperature at the end point is 1663 ℃; the FeO content at the end point is greater than 15.15 wt%, the average is 17.48wt%; the average basicity is 2.2; the average addition amount of coke powder (carbon powder) is 144kg / furnace. The slag dephosphorization rate is between 31.02% and 43.42%, with an average value of 36%; the specific process parameters of each embodiment are shown in Table 2.

[0023] Table 2: Process parameters of each embodiment

[0024]

[0025] The 998mm in the slag splash gun position "998-1980" in Table 2 is the lower limit gun position of the oxygen lance.

[0026] After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com