Patents

Literature

31results about How to "Low heat loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

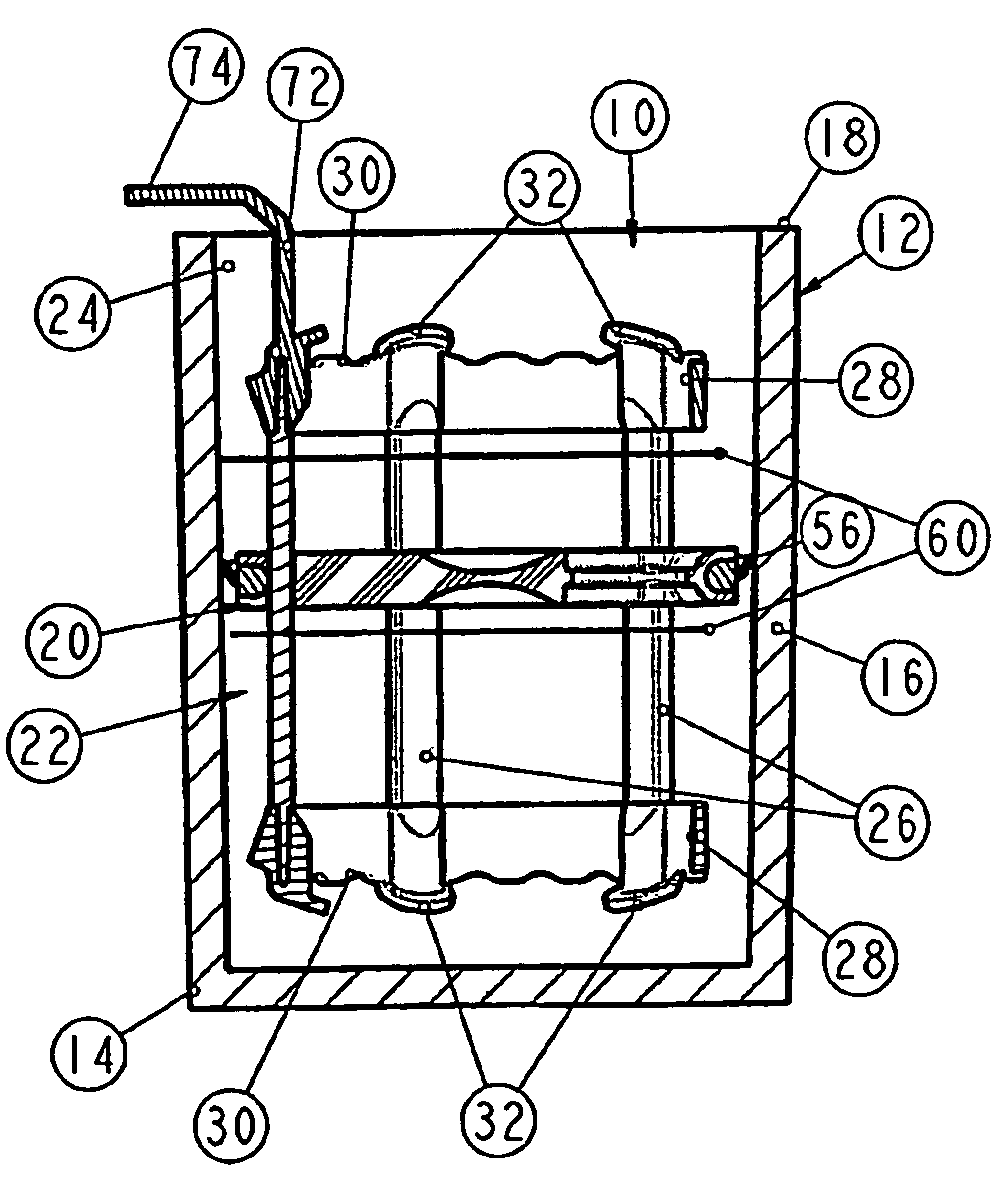

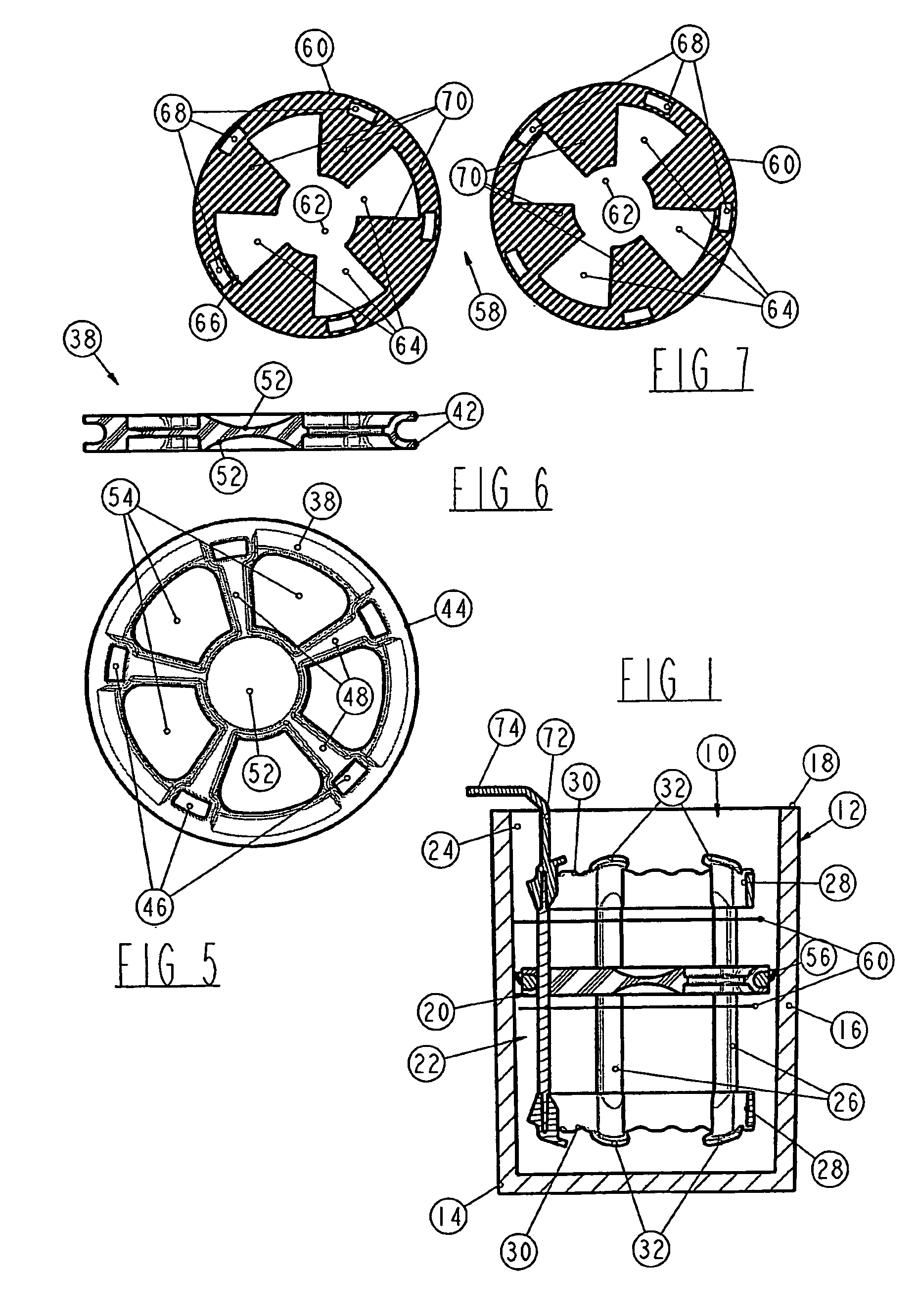

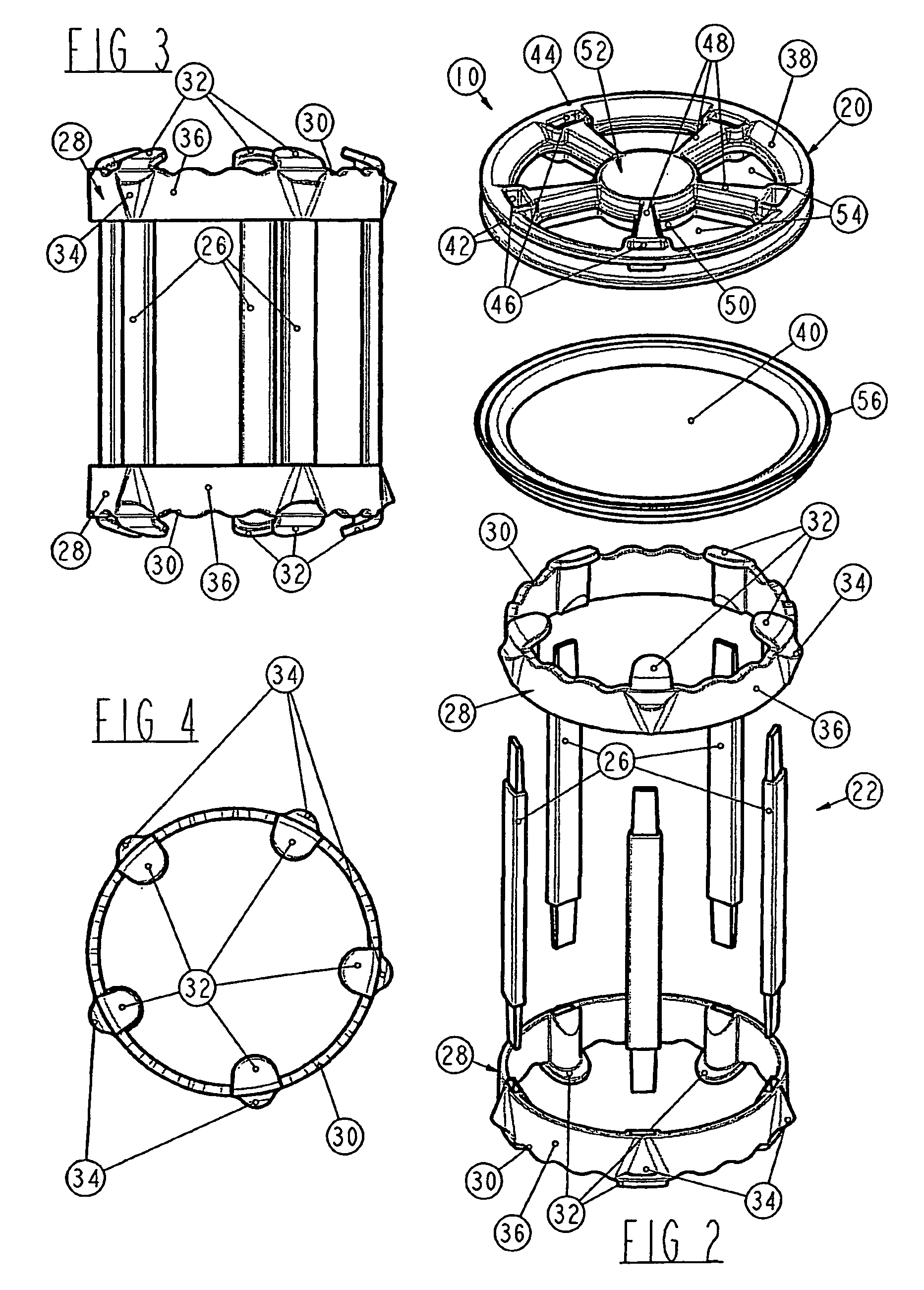

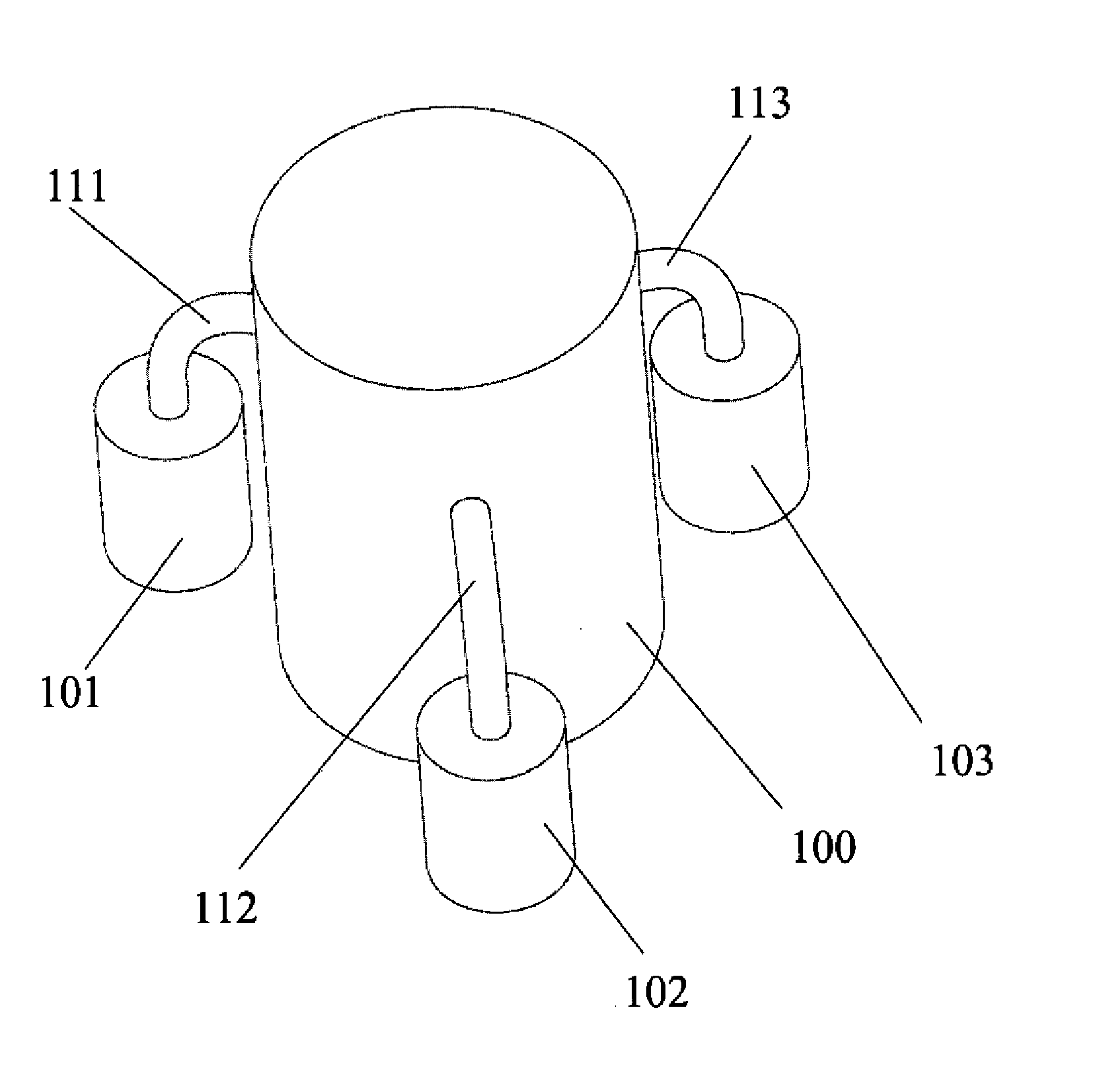

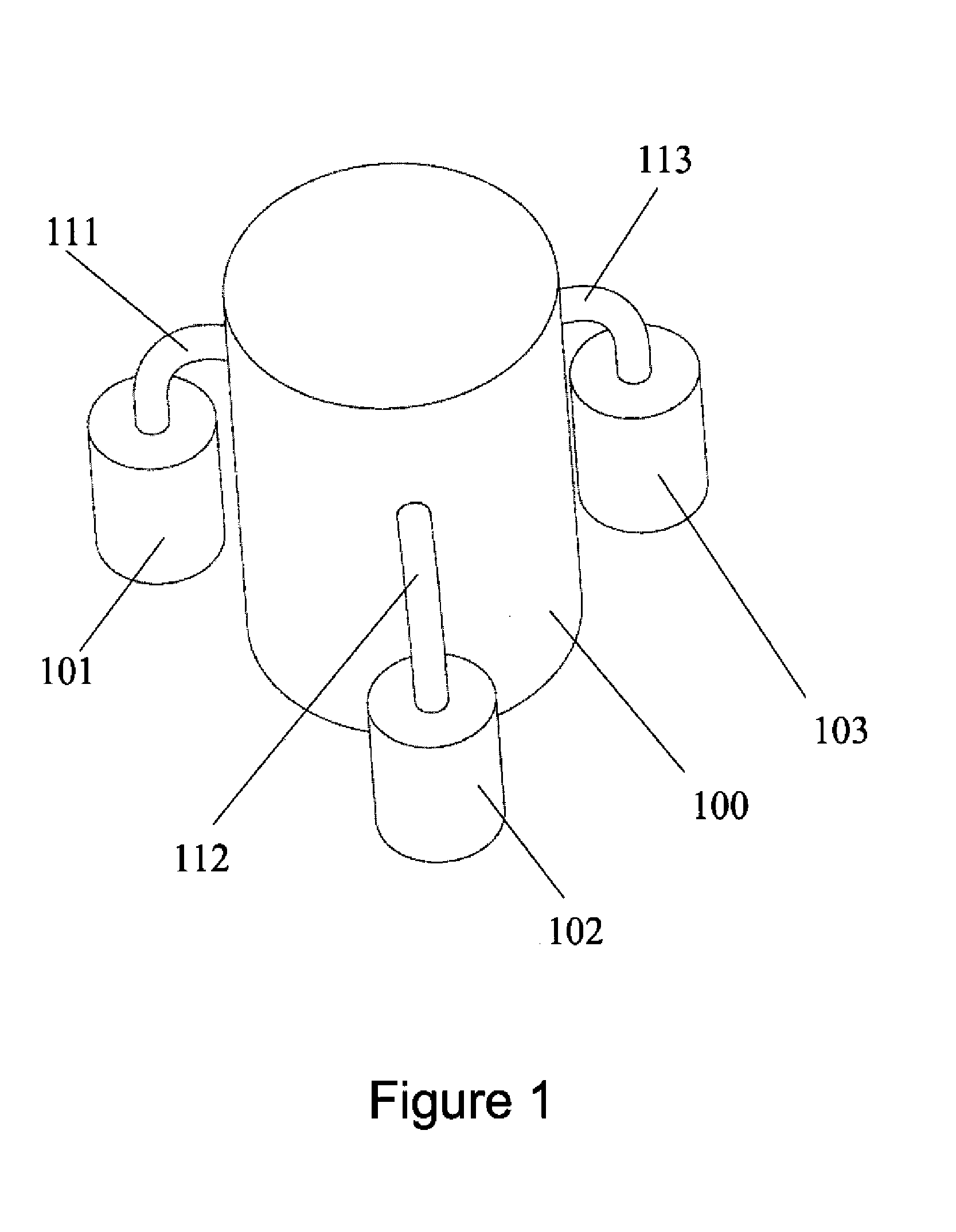

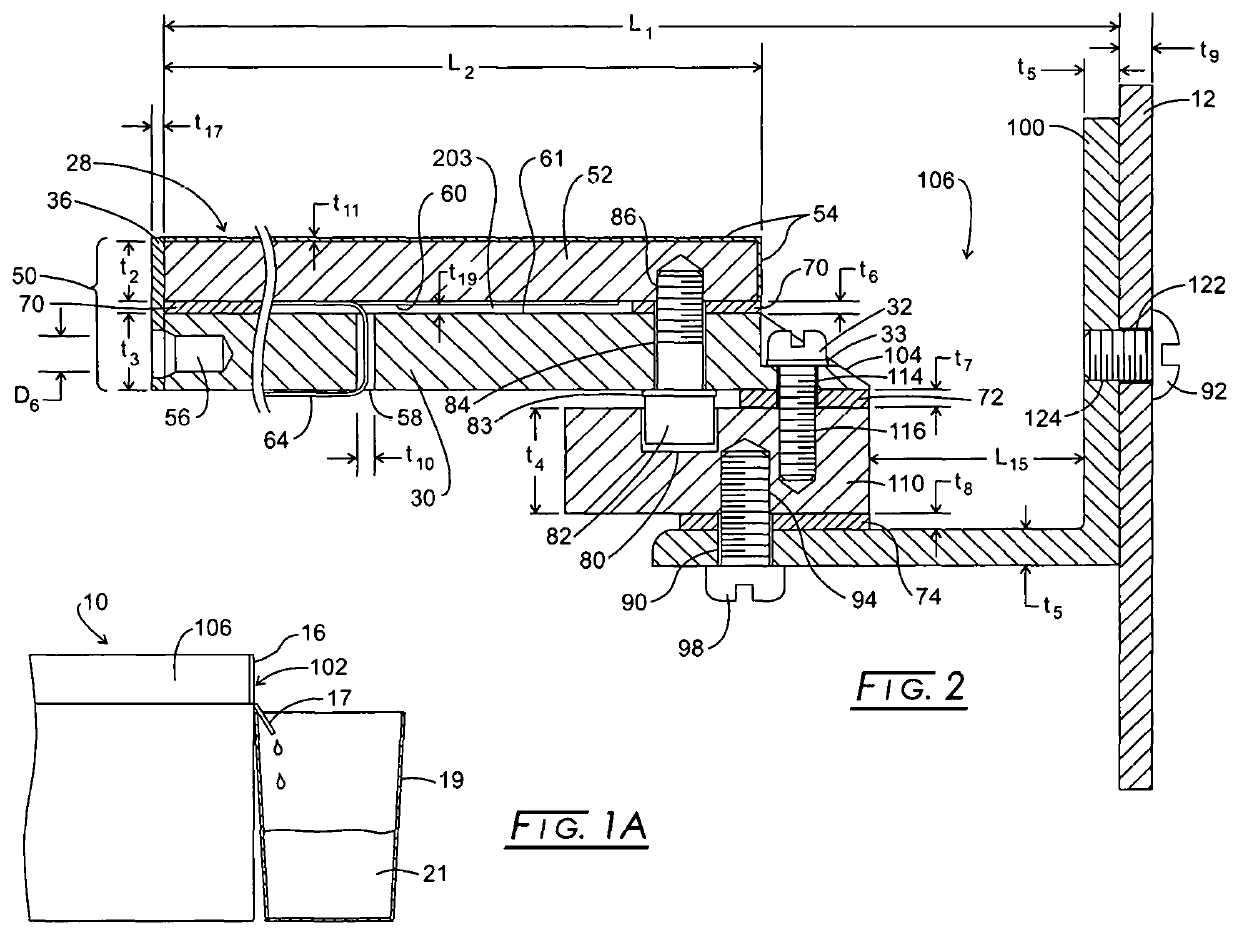

Plunger for brewing a drink

InactiveUS6964223B2Quickly and conveniently makingSimple and inexpensiveBeverage vesselsFood preparationHeat lossesEngineering

Plunger (10) for brewing a drink in a cup (12) includes two main components, a filter disc (20) and a frame (22). The filter disc (20) is shaped to extend across and abut an inside surface (24) of the cup (12). The frame (22) is dimensioned so that it can be wholly inserted into the cup (12) to be disposed below a mouth (18) of the cup. This allows a drink such as coffee or tea to be brewed in the cup from which it is to be consumed without the plunger (10) interfering with the drinking of the drink. The disc (20) is supported on the frame (22) to slide along upright posts (22). Thus the disc (20) can be pushed toward the bottom or (14) of the cup (12) that contain particulate materials such as coffee grounds or tea leaves used in brewing the drink. A heat shield (58) may be also supported on the frame (22) to minimise the rate of heat loss of a hot drink brewed in the cup (12) using the plunger (10).

Owner:OLOUGHLIN NICK

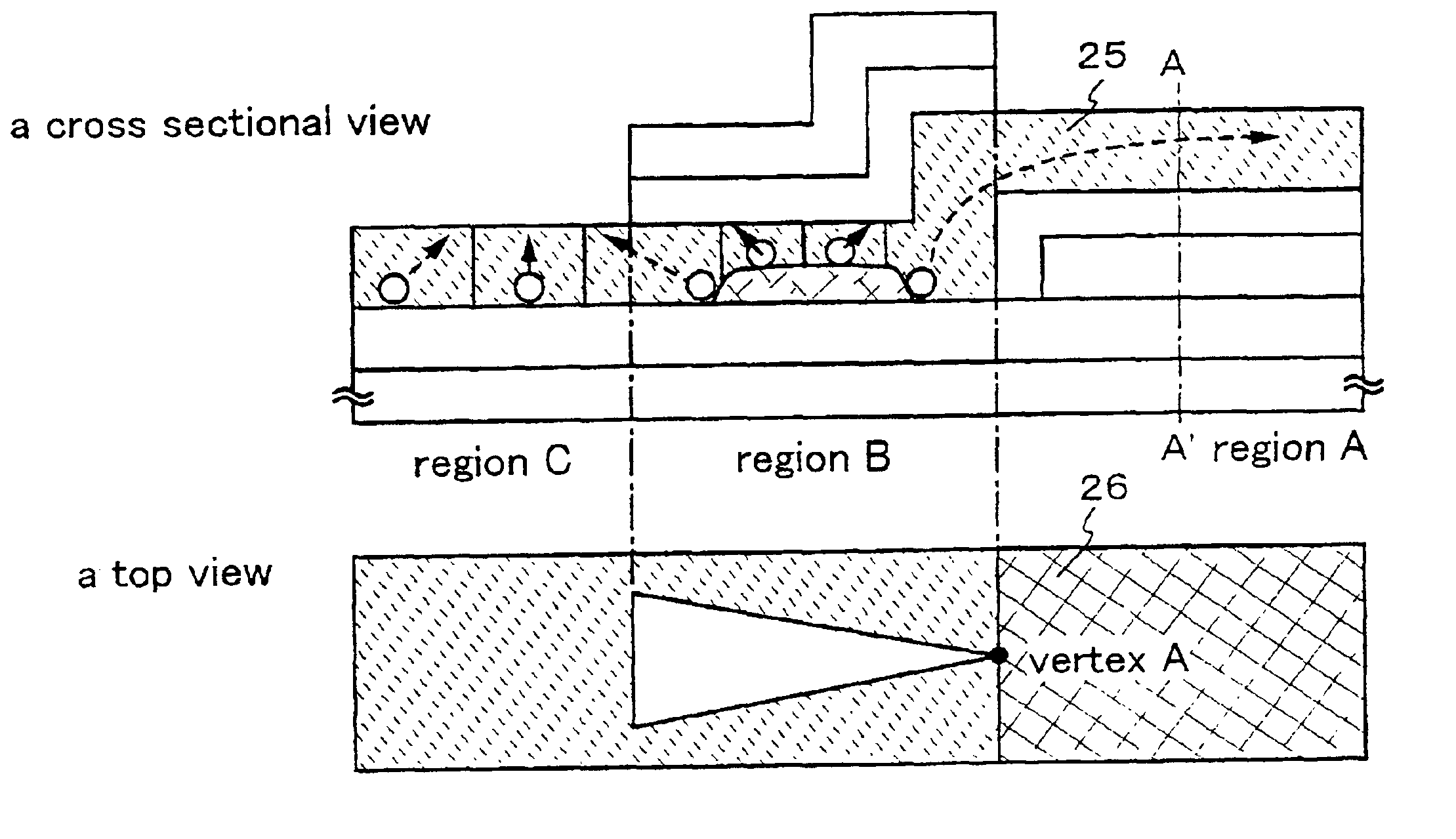

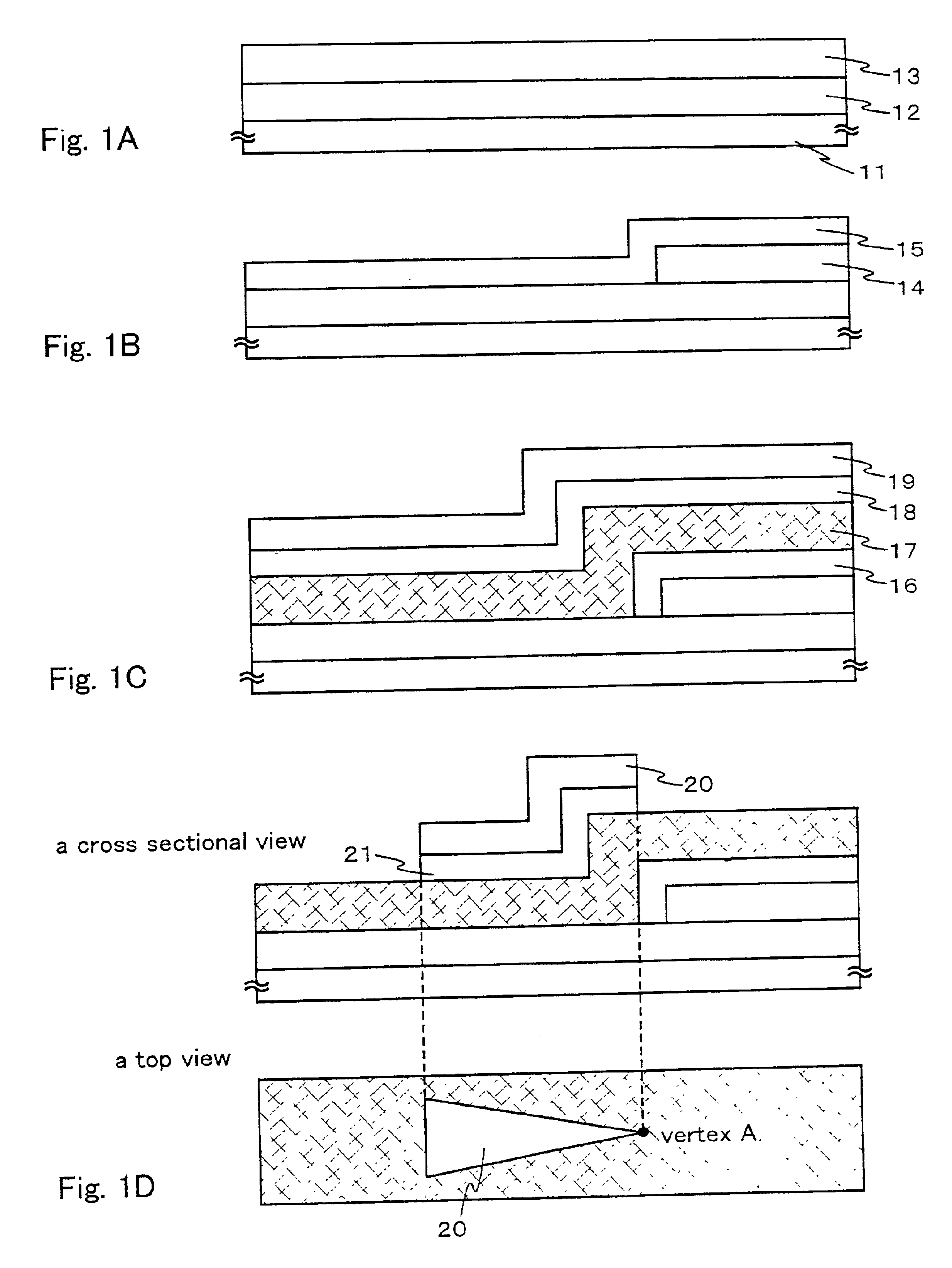

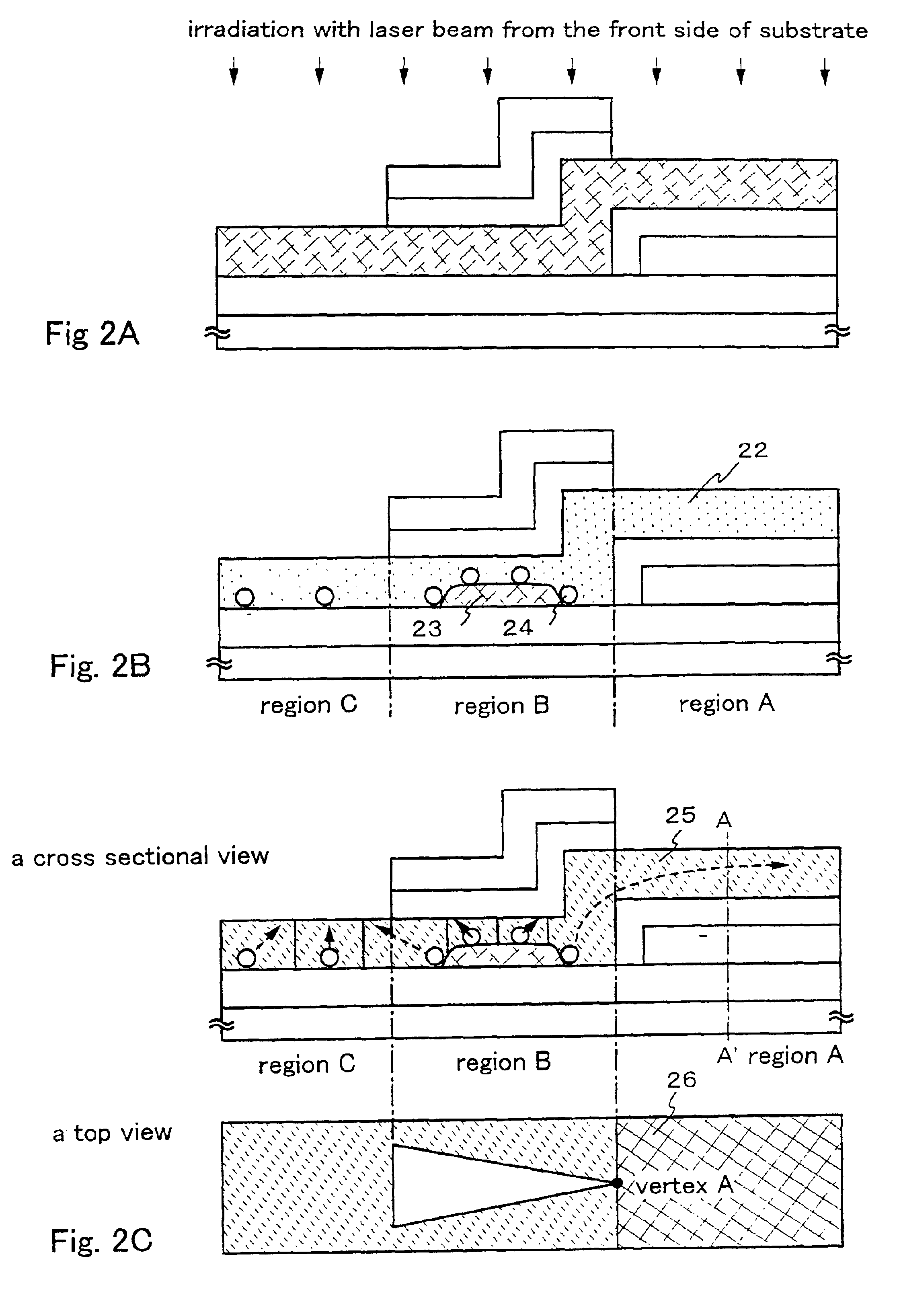

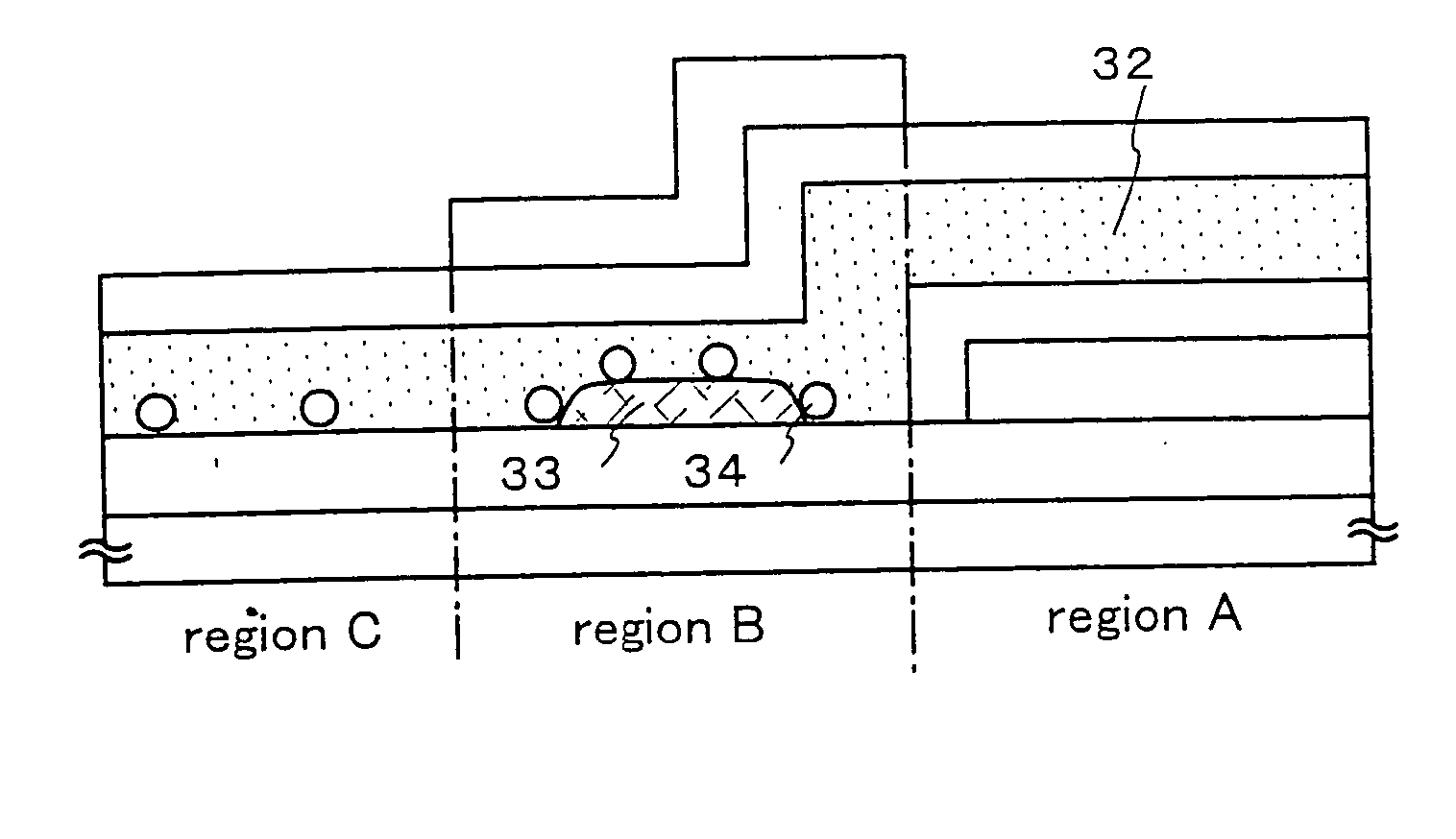

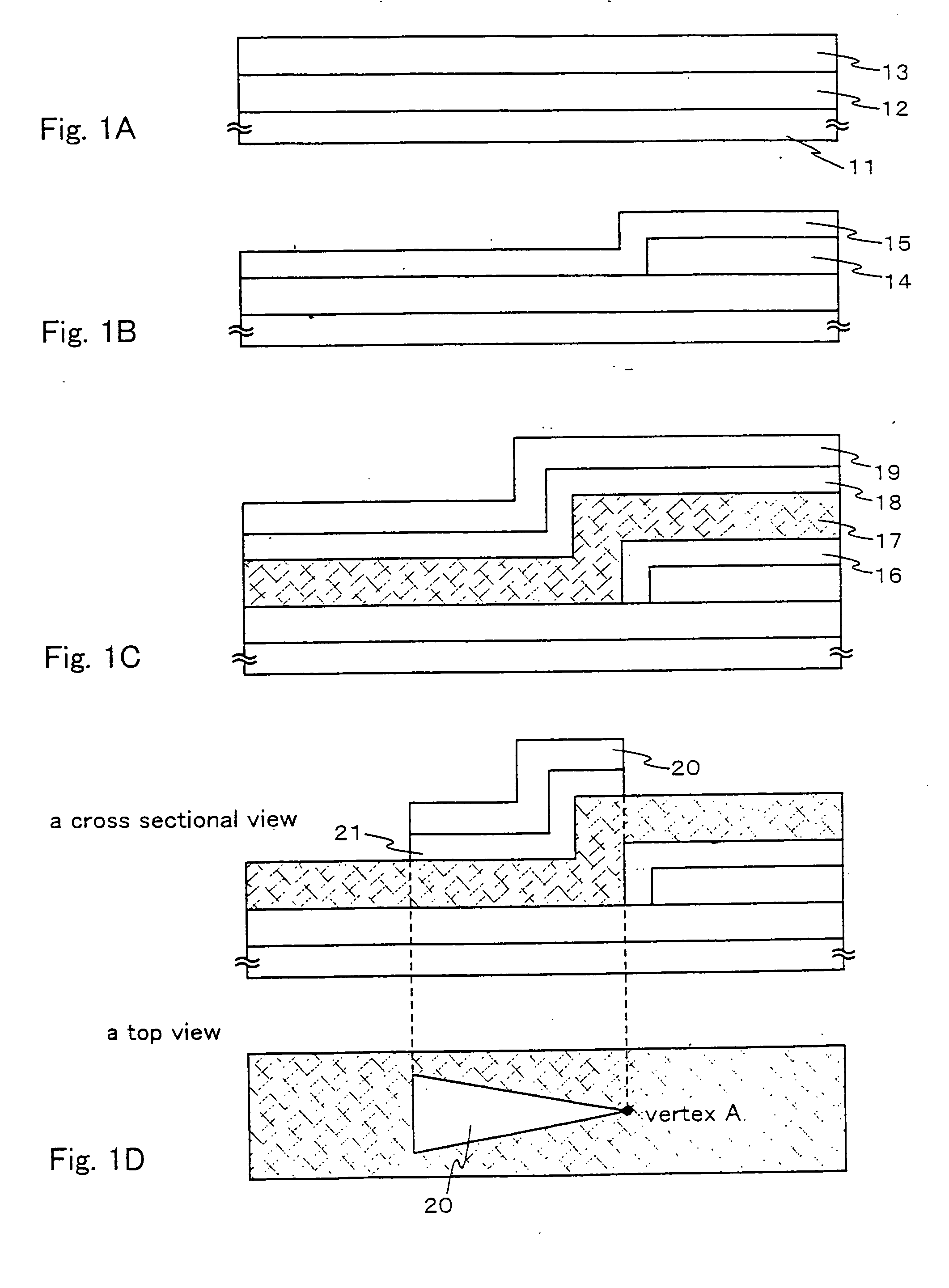

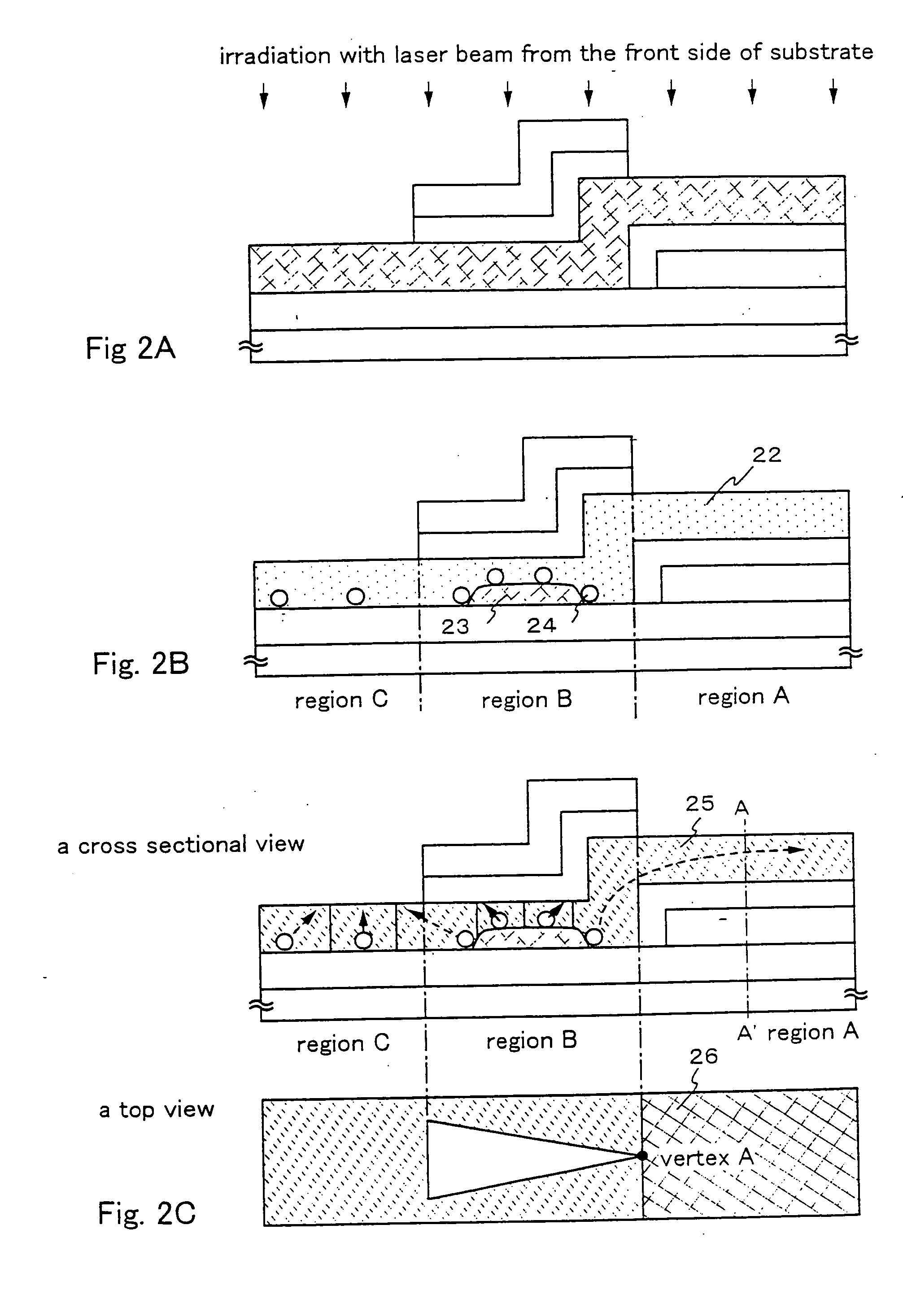

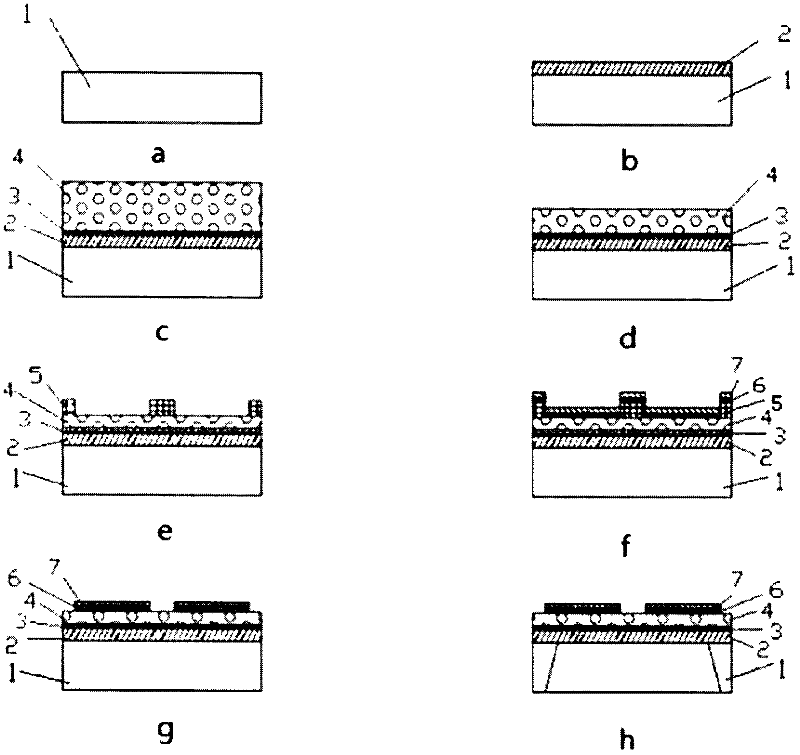

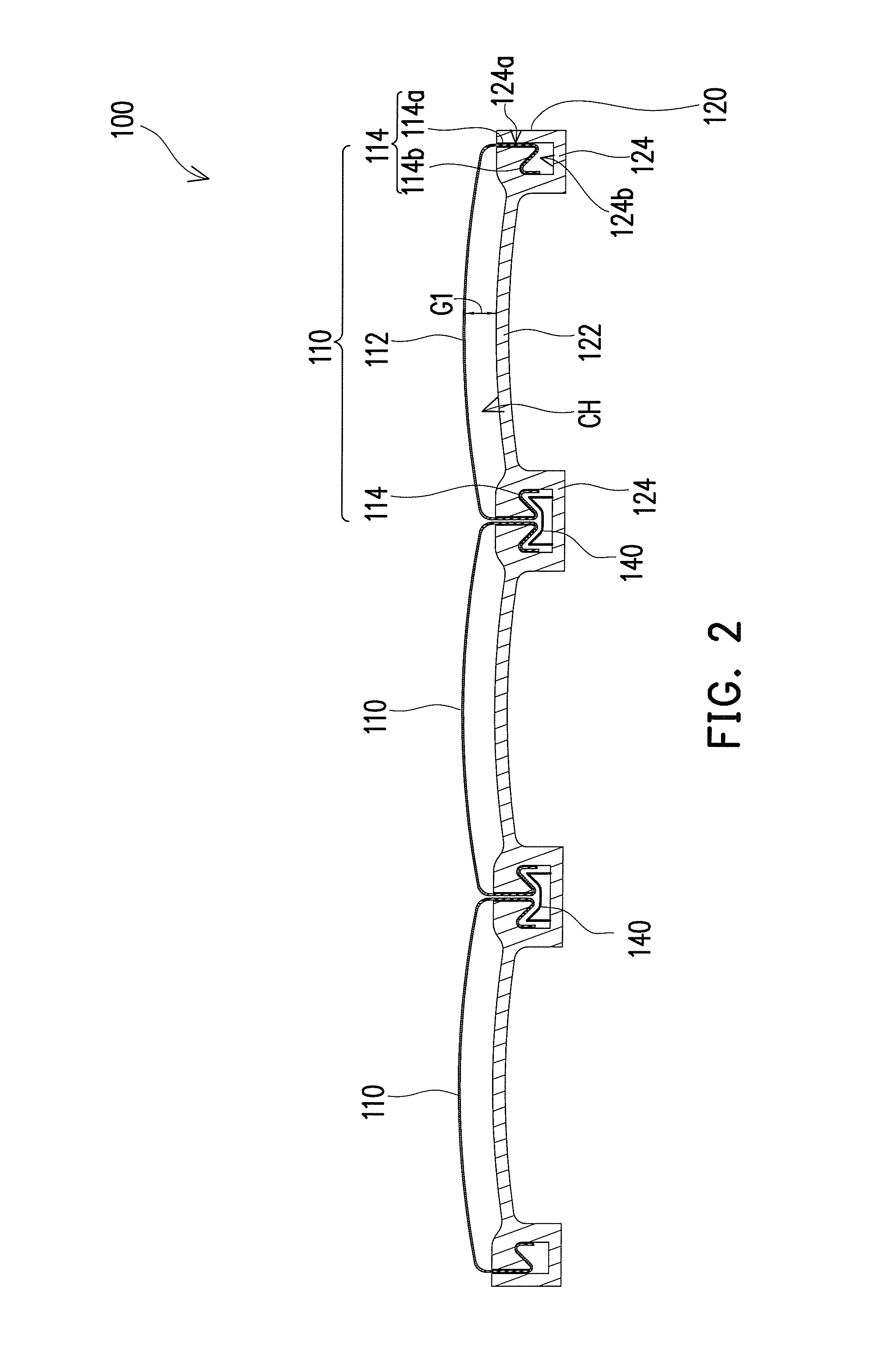

Semiconductor device and method of manufacturing the same

InactiveUS7078321B2Increase speedRun at high speedTransistorSolid-state devicesIrradiationLaser beams

A crystalline semiconductor film in which the position and the size of crystal grains are controlled is provided, and a TFT that can operate at high speed is obtained by forming a channel formation region of the TFT from the crystalline semiconductor film. A heat retaining film is formed on an insulating surface, a semiconductor film is formed to cover the heat retaining film, and a reflective film is formed to partially cover the semiconductor film. The reflective films and the semiconductor film are irradiated with a laser beam. The reflective film creates a distribution in effective irradiation intensity of laser beam on the semiconductor film. The distribution, with the heat retaining effect provided by the heat retaining film, generates a temperature gradient in the semiconductor film. Utilizing these, the position where crystal nuclei are to be generated and the direction in which crystal growth should advance can be controlled and crystal grains having a large grain size can be obtained.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device and method of manufacturing the same

A crystalline semiconductor film in which the position and the size of crystal grains are controlled is provided, and a TFT that can operate at high speed is obtained by forming a channel formation region of the TFT from the crystalline semiconductor film. A heat retaining film is formed on an insulating surface, a semiconductor film is formed to cover the heat retaining film, and a reflective film is formed to partially cover the semiconductor film. The reflective films and the semiconductor film are irradiated with a laser beam. The reflective film creates a distribution in effective irradiation intensity of laser beam on the semiconductor film. The distribution, with the heat retaining effect provided by the heat retaining film, generates a temperature gradient in the semiconductor film. Utilizing these, the position where crystal nuclei are to be generated and the direction in which crystal growth should advance can be controlled and crystal grains having a large grain size can be obtained.

Owner:SEMICON ENERGY LAB CO LTD

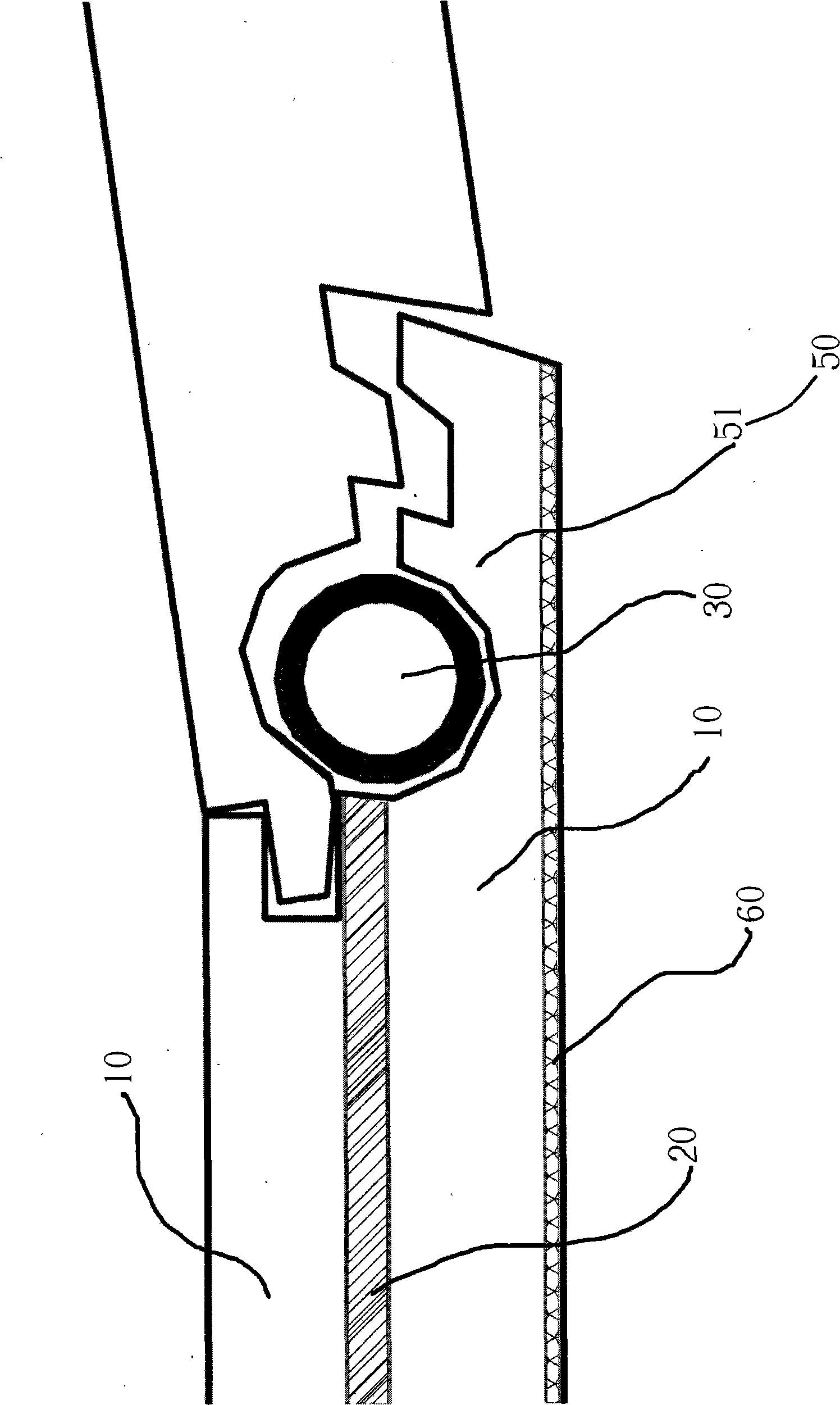

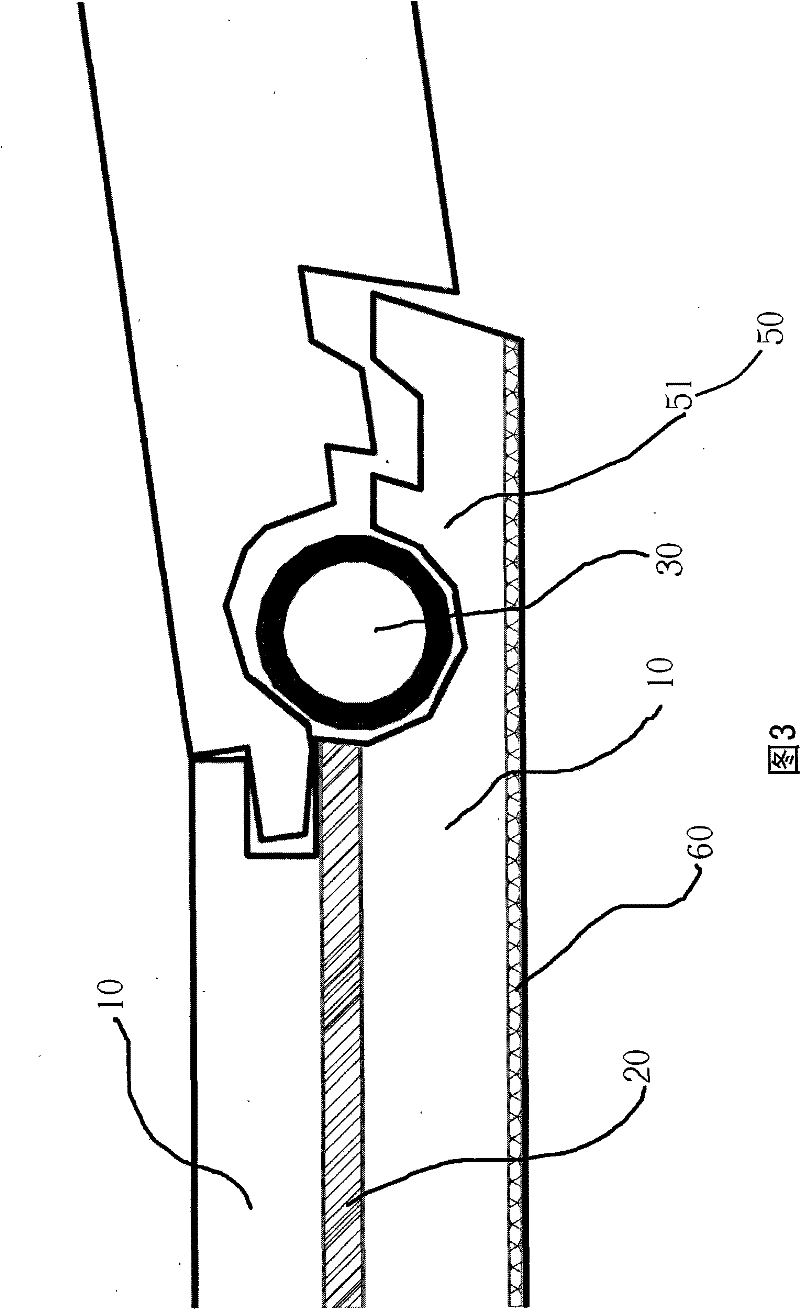

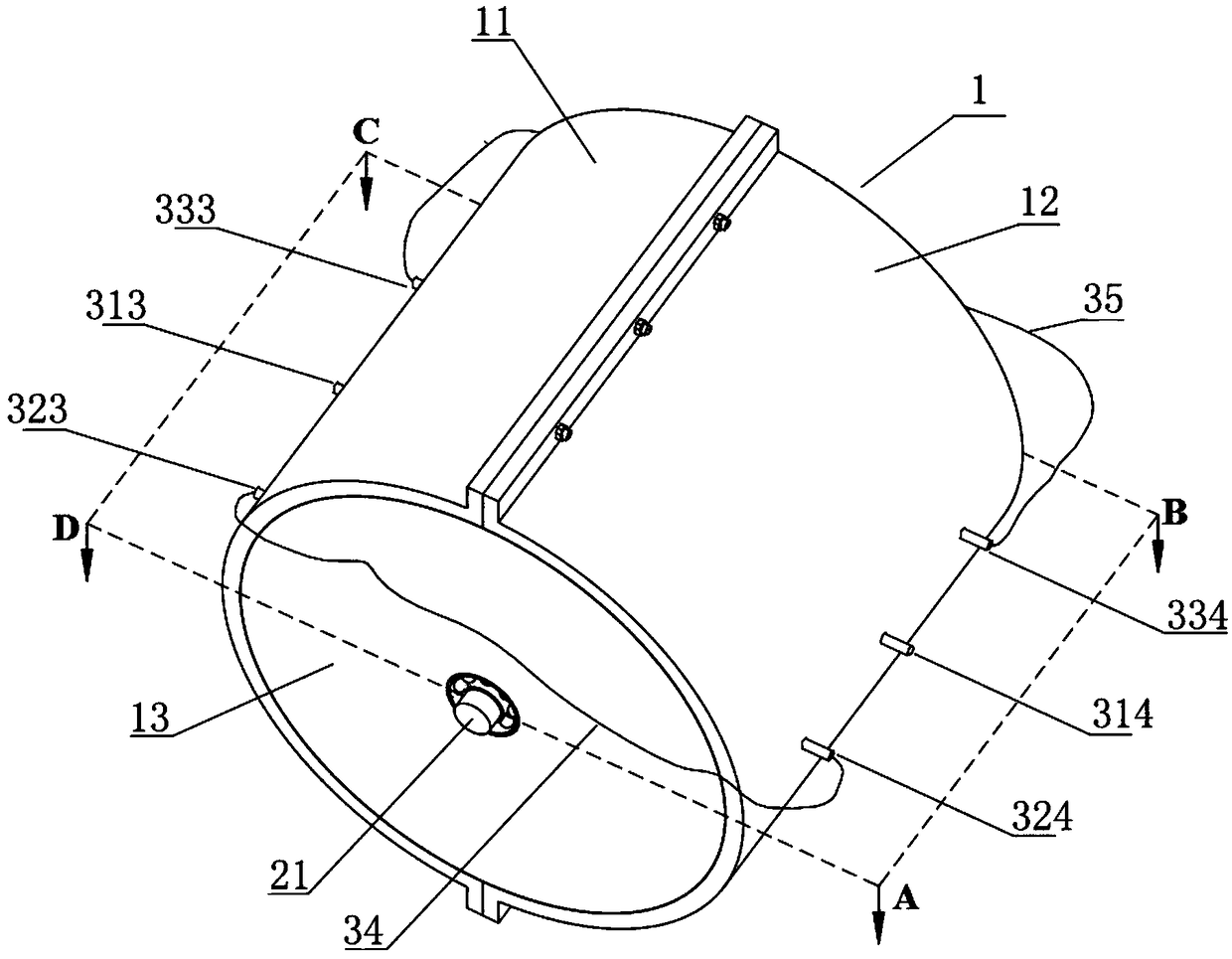

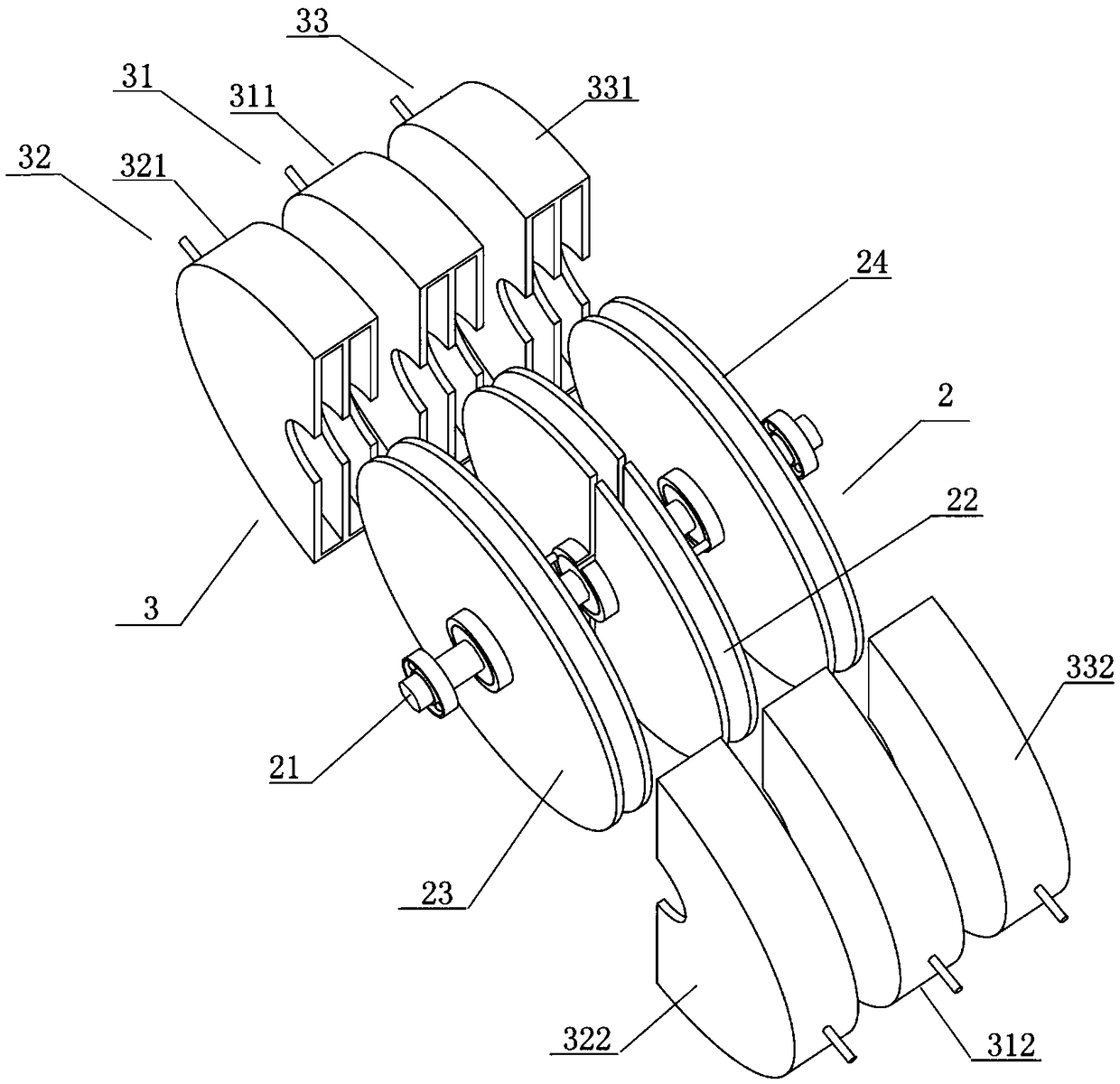

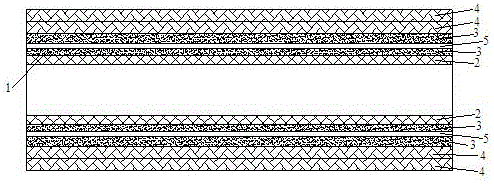

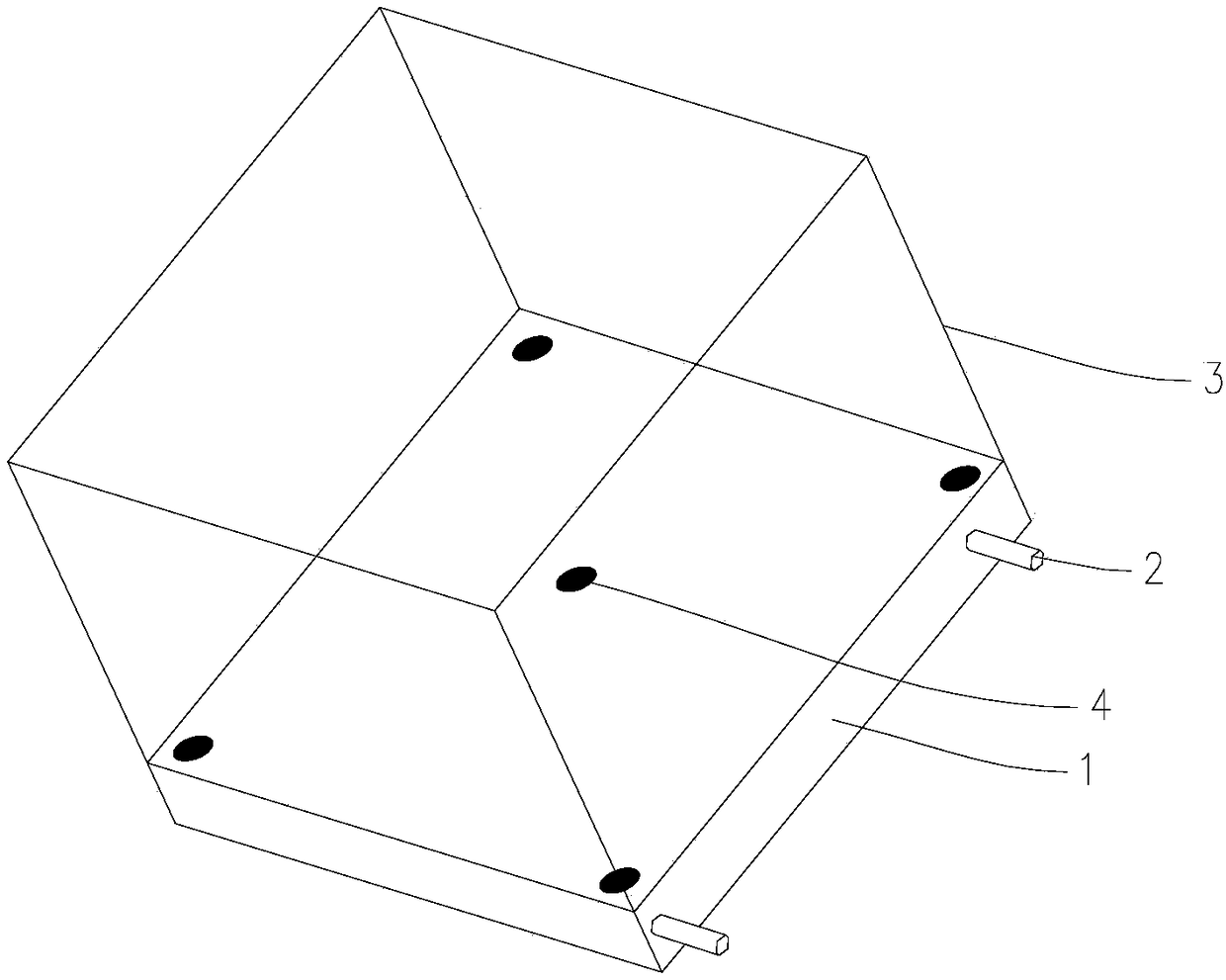

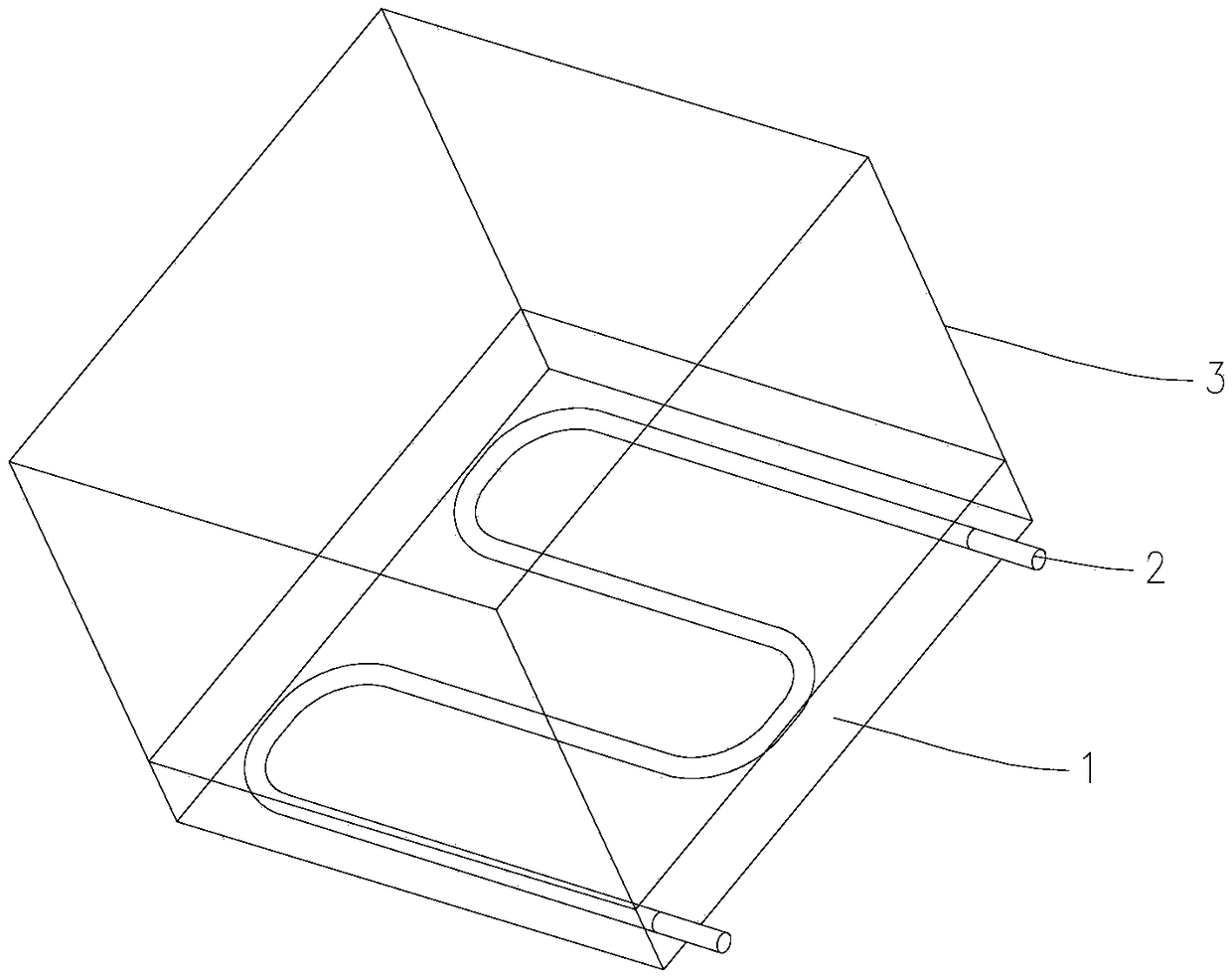

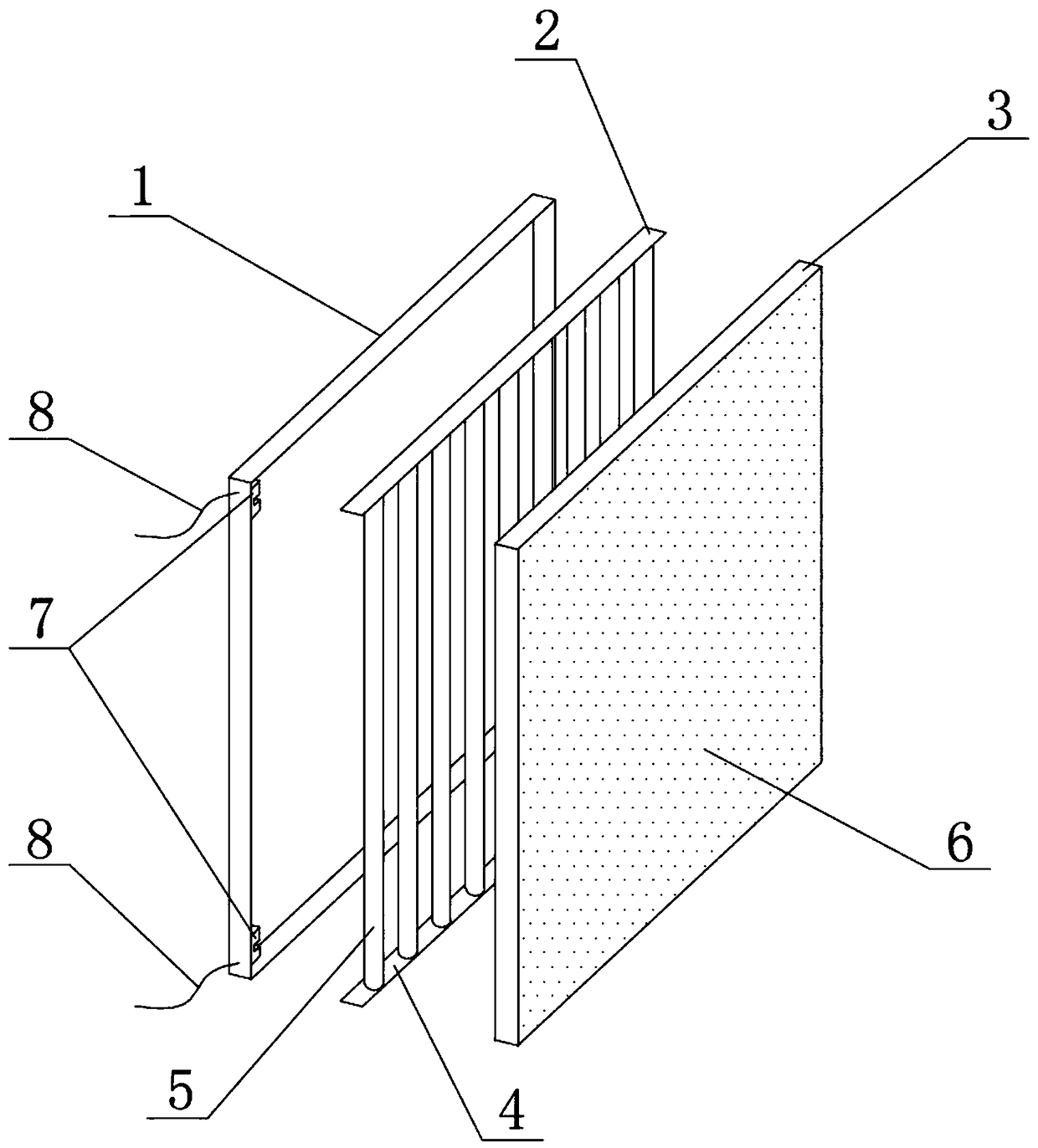

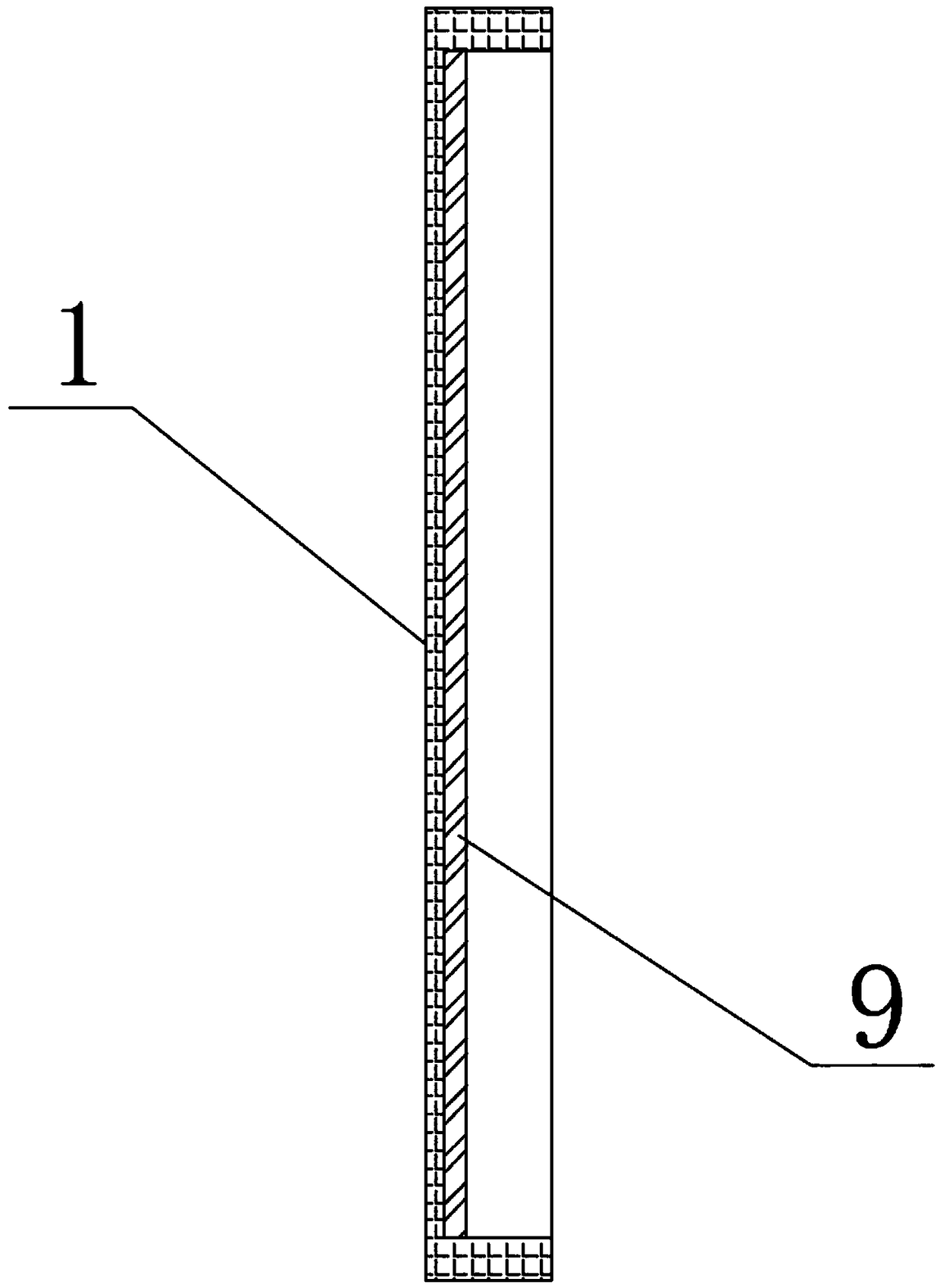

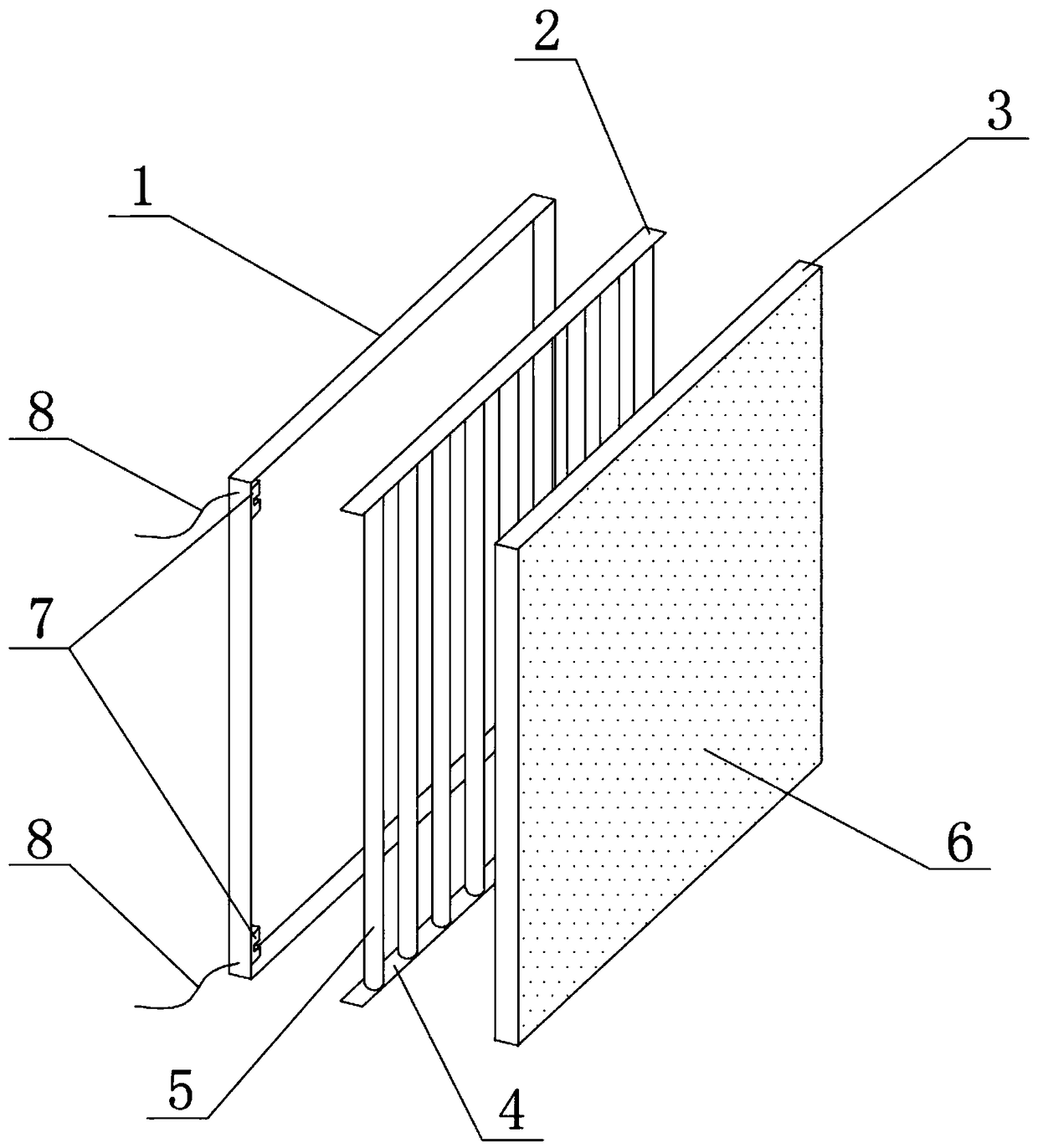

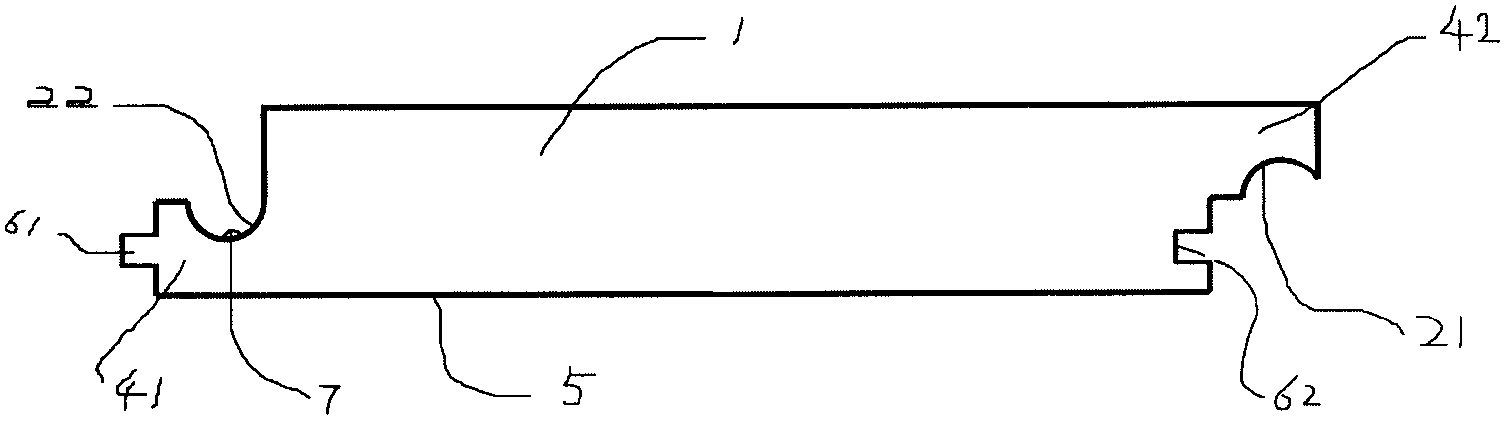

Floor with internal heat-conducting structure

InactiveCN101532332ALow heat lossReduce pavement thicknessLighting and heating apparatusFlooringHeat conductingHeat losses

The invention relates to a floor with an internal heat-conducting structure, comprising a floor body, a plurality of heat-conducting media, a ground-heating pipe, an upper locking fastener and a lower locking fastener. Each heat-conducting medium is horizontally positioned in the floor body and one end thereof is contacted with the ground-heating pipe. The upper locking fastener is positioned at one side of the floor body and defines an upper support cavity which is convex upward; the lower locking fastener is positioned at the other side of the floor body and defines a lower support cavity which is concave downward; wherein the ground-heating pipe is horizontally arranged in the lower support cavity. When the upper locking fastener of the floor is meshed with the lower locking fastener of the adjacent floor, the upper support cavity and the lower support cavity are matched to form a containing cavity; and the ground-heating pipe is contained in the containing cavity, therefore, the ground-heating pipe is embedded into two adjacent floors, not only the thickness of the paved floor is reduced, but also heat is directly transmitted to each heat-conducting medium from the ground-heating pipe, thus reducing the heat loss.

Owner:上海溢邦装饰建材有限公司

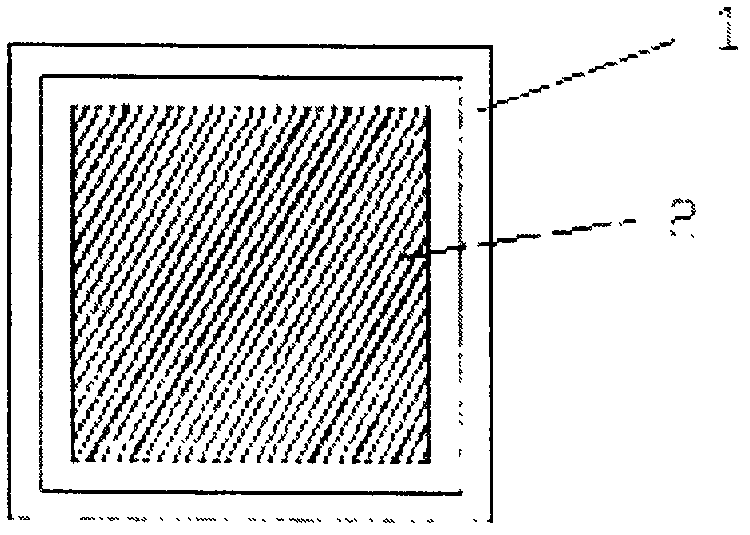

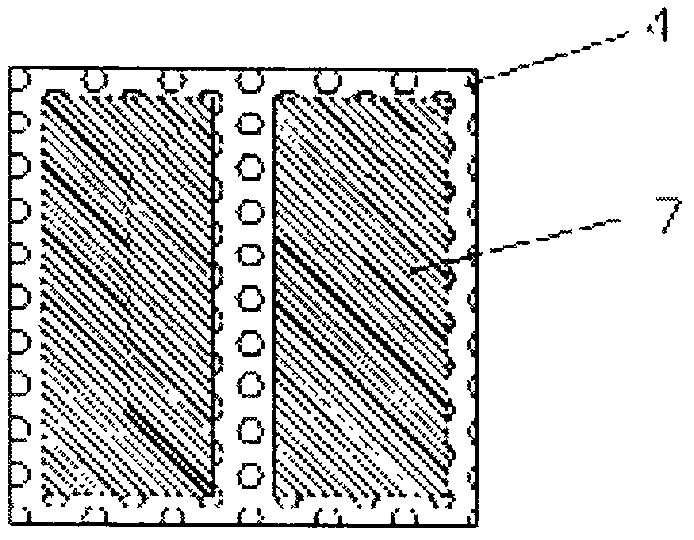

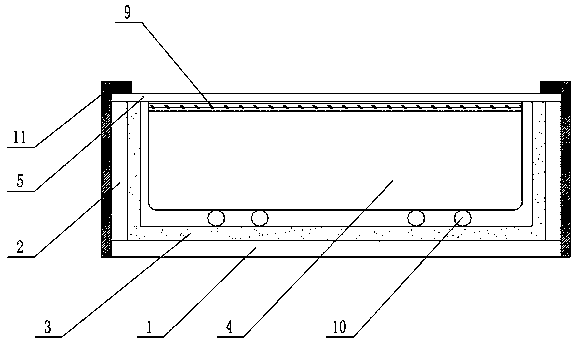

Pyroelectric infrared detector and preparation method thereof

InactiveCN102393249AEasy to processHigh material strengthPyrometry using electric radation detectorsPhysicsLarge capacity

The invention discloses a pyroelectric infrared detector implemented by a wafer bonding technology, and a preparation method for the pyroelectric infrared detector. The pyroelectric infrared detector comprises a silicon substrate (1), and a thermal insulating layer (2), a bonding layer (3), a pyroelectric material sheet (4), an upper electrode layer and an infrared absorption layer (7) which are arranged on the surface of the silicon substrate (1), wherein the thermal insulating layer (2) and the pyroelectric material sheet (4) are bonded through the bonding layer (3) in the preparation method. A pyroelectric wafer and the silicon substrate are combined and the completeness of the original wafer is ensured; and compared with a thin-film pyroelectric detector made of the same pyroelectric material, the pyroelectric infrared detector has the advantages of high processability, high material strength, simple achievement of thickness, high capacity of resisting influence of external serious environment, low heat loss and the like.

Owner:ZHONGBEI UNIV

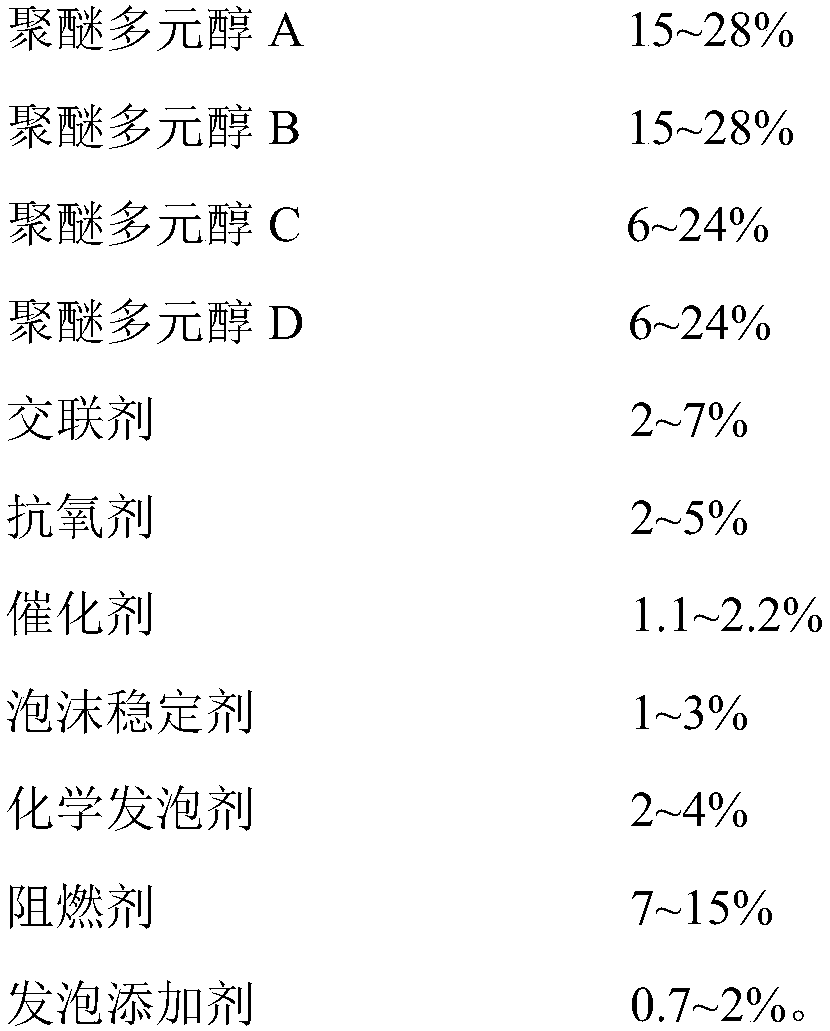

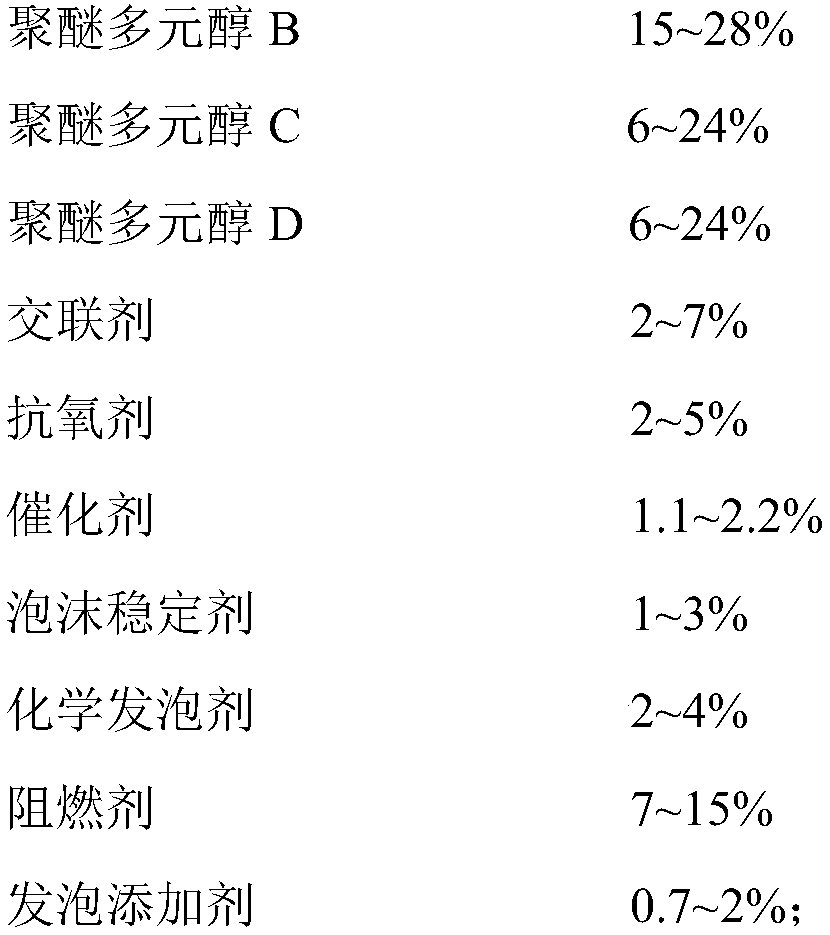

Premixed polyether, anti-ageing full-water type foam board and preparation method of anti-ageing full-water type foam board

The invention belongs to the technical field of premixed polyether, and particularly relates to premixed polyether, an anti-ageing full-water type foam board and a preparation method of the anti-ageing full-water type foam board. The premixed polyether is prepared from the following raw materials: polyether polyol A, polyether polyol B, polyether polyol C, polyether polyol D, a cross-linking agent, an antioxidant, a catalyst, a foam stabilizer, a chemical foaming agent, a flame retardant and a foaming additive. The full-water type foam board prepared from the premixed polyether, which is disclosed by the invention, is also processed at normal temperature and under normal pressure, is simple in process, is easy to operate, is low in volatilization, does not generate three wastes (waste gas,waste water and waste solid), and is short in production period, low in cost, high in efficiency and low in energy consumption.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

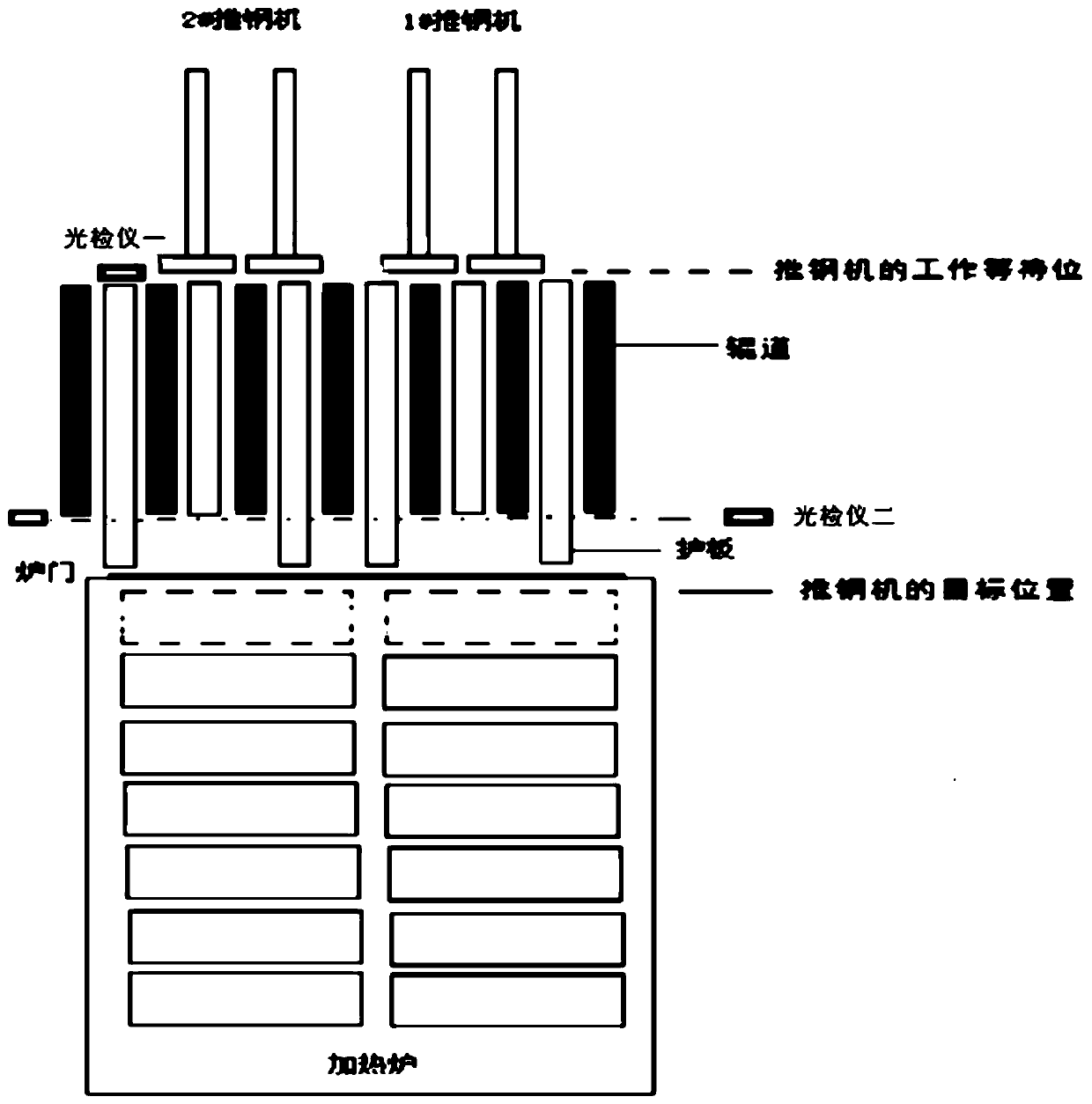

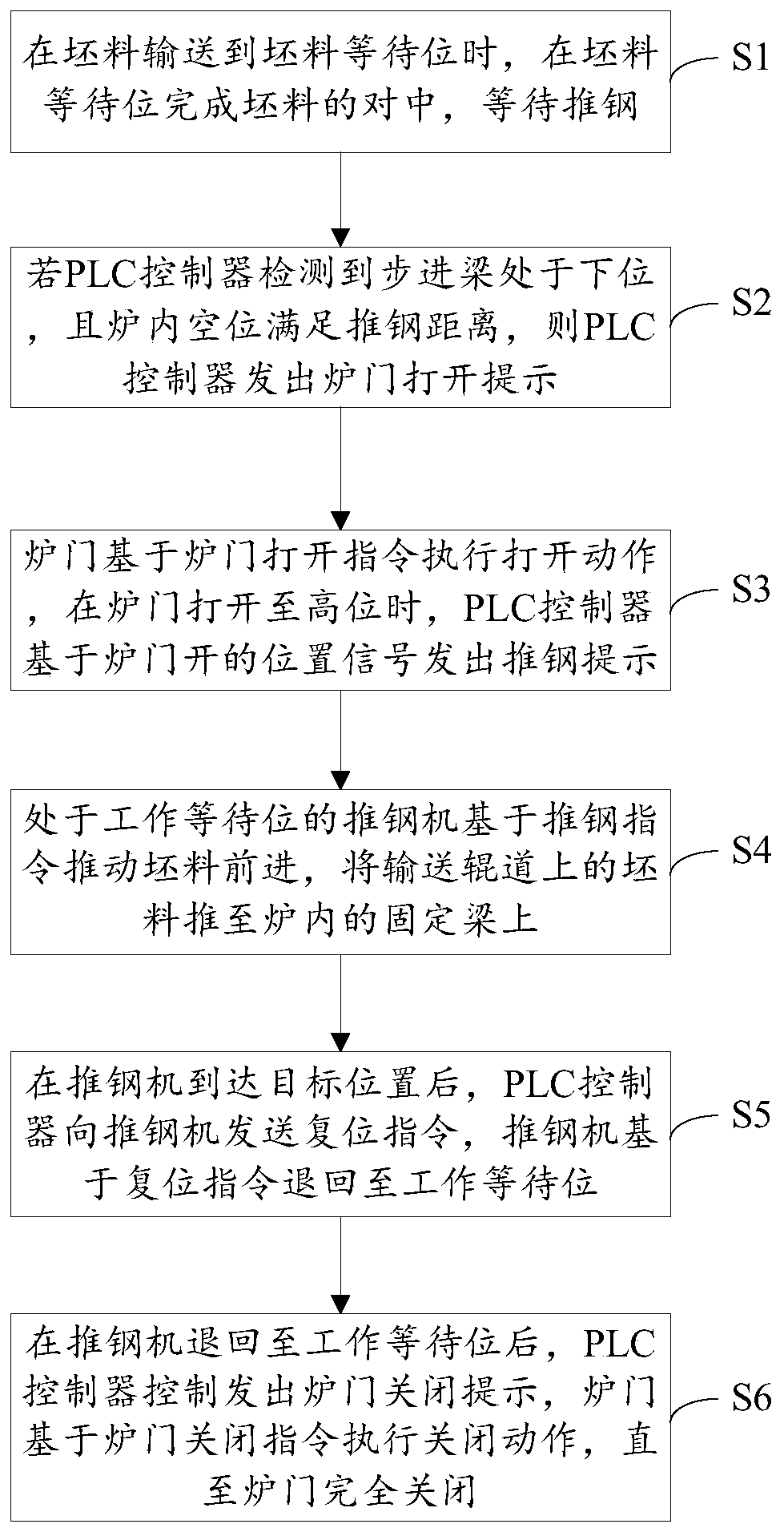

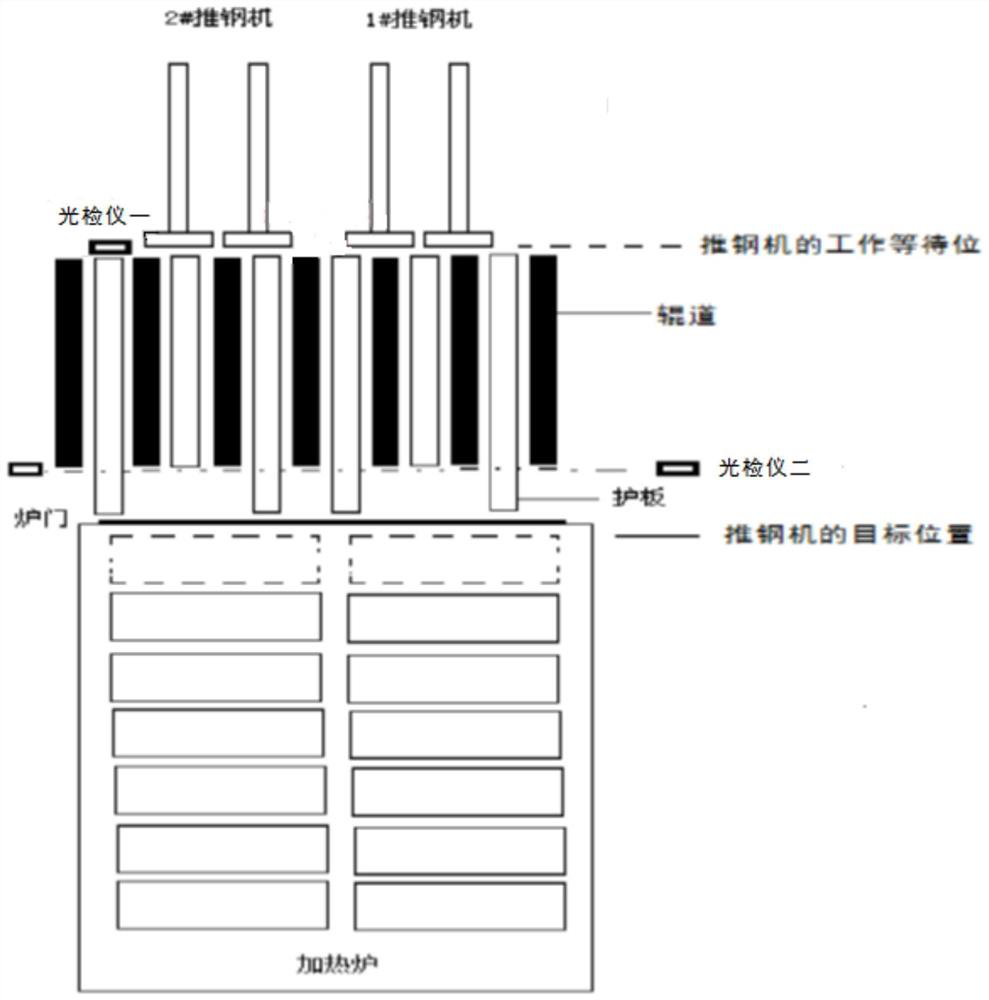

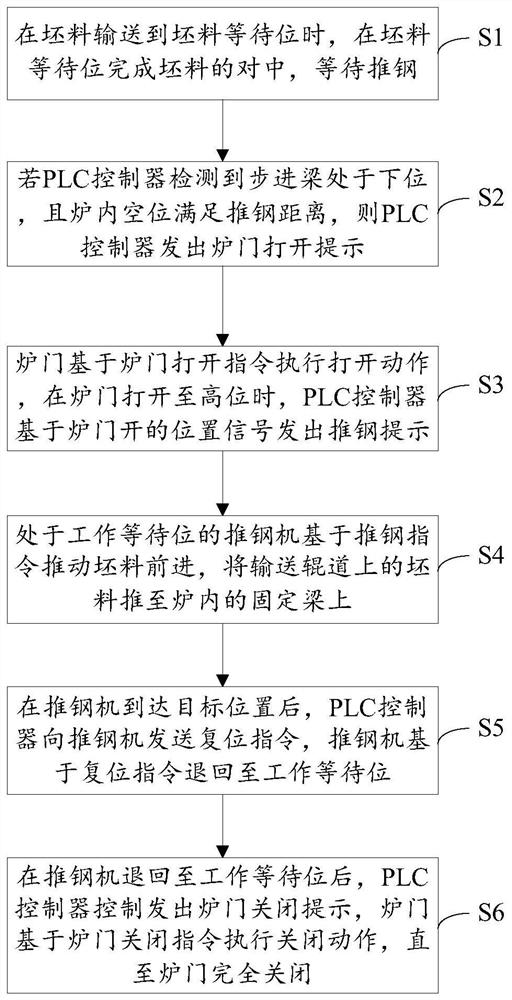

Control system and method for automatically pushing steel into furnace of steel pushing type stepping heating furnace

The invention discloses a control system and method for automatically pushing steel into a furnace of the steel pushing type stepping heating furnace. The method comprises the following steps of waiting for steel pushing after a blank is centered at a blank waiting station; sending out a furnace door opening prompt if a stepping beam is in a lower position and an empty space in the furnace meets asteel pushing distance; opening a furnace door to a high position based on a furnace door opening command, and sending out a steel pushing prompt based on a position signal of the opened furnace door; pushing, by a steel pushing machine in a work waiting station based on a steel pushing command, the blank to advance to push the blank on a conveying roller way onto a fixing beam in the furnace; sending a reset command to the steel pushing machine after the steel pushing machine reaches the target position, and retracting the steel pushing machine to the work waiting station; and sending out afurnace door closing prompt after the steel pushing machine retracts to the work waiting station, performing, by the furnace door based on a furnace door closing command, closing action till the furnace door is completely closed. The furnace door is in an opened state only in the process of pushing the steel into the furnace, and the furnace door is in a closed state in the other time, so that theheat efficiency loss is greatly reduced.

Owner:新余钢铁股份有限公司

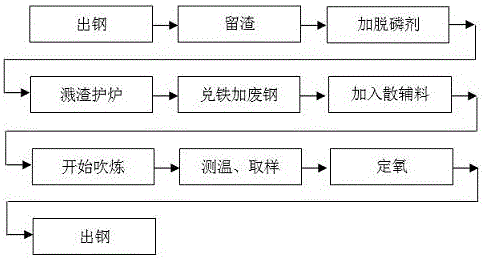

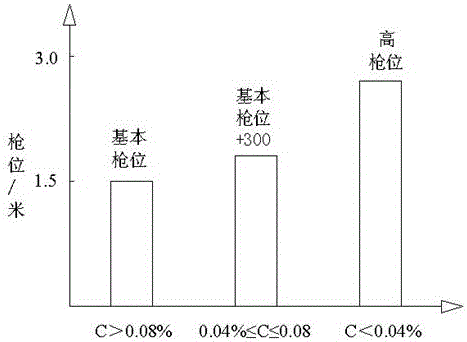

Dephosphorization method for oxygen top-blown converter slag remainder

InactiveCN106119459AReduce phosphorus contentReduce carryoverManufacturing convertersProcess efficiency improvementSmelting processHeat losses

The invention discloses a dephosphorization method for oxygen top-blown converter slag remainder. The dephosphorization method includes the steps that before slag-splashing for protection of a converter, a dephosphorization agent is added to the slag remainder in the converter after tapping, then inert gases are top-blown by an oxygen gun for the operation of slag-splashing for protection of the converter, and dephoshprized slag remainder serve as initial slag of the next melt of smelting. According to the method, the oxygen top-blown converter slag remainder operation is combined with the slag remainder dephosphorization process, the phosphorus content in the slag remainder can be lowered effectively, and the drag-in amount of phosphorus in the next melt of converter smelting process is lowered, so that the lime addition amount in the next melt of converter smelting process can be reduced, and the converter smelting cost is lowered. By the adoption of the dephosphorization method, part of the phosphorus element in the slag remainder in the converter can be removed, the slag amount is small in the smelting process, the heat loss is low, the iron loss is small, the converter slag dephosphorization effect is good, and the smelting cost is lowered remarkably.

Owner:TANGSHAN IRON & STEEL GROUP

Nifuroxazide microcapsule powder and production method thereof

ActiveCN102657634AImprove solubilityImprove feedabilityAntibacterial agentsOrganic active ingredientsPolyethylene glycolSilicon dioxide

The invention discloses nifuroxazide microcapsule powder and a production method thereof. The nifuroxazide microcapsule powder is characterized by consisting of nifuroxazide, n-cyclohexylsulphamic acid, silicon dioxide micro powder and polyethylene glycol in a weight ratio of 1: (0.01-0.02): (1-3): (3-6). The production method comprises the following steps of: dissolving the n-cyclohexylsulphamicacid by using 95 percent ethanol, stirring with fine nifuroxazide powder to wet the fine nifuroxazide powder uniformly, adding the silicon dioxide micro powder to form a core material, mixing the core material and the polyethylene glycol 4000 or polyethylene glycol 6000 uniformly, performing interlayer heating at the temperature of between 75 and 80 DEG C to melt the mixture, cooling, curing, drying, crushing with airflow to form powder with the particle diameter of 90 to 100 meshes, and thus obtaining the nifuroxazide microcapsule powder. The nifuroxazide microcapsule powder is low in heat loss rate and high in flowability, has a good feeding effect, and facilitates industrialized production.

Owner:SHANGHAI E K M BIOTECH

Floor with internal heat-conducting structure

InactiveCN101532332BLow heat lossReduce pavement thicknessLighting and heating apparatusFlooringHeat conductingHeat losses

The invention relates to a floor with an internal heat-conducting structure, comprising a floor body, a plurality of heat-conducting media, a ground-heating pipe, an upper locking fastener and a lower locking fastener. Each heat-conducting medium is horizontally positioned in the floor body and one end thereof is contacted with the ground-heating pipe. The upper locking fastener is positioned at one side of the floor body and defines an upper support cavity which is convex upward; the lower locking fastener is positioned at the other side of the floor body and defines a lower support cavity which is concave downward; wherein the ground-heating pipe is horizontally arranged in the lower support cavity. When the upper locking fastener of the floor is meshed with the lower locking fastener of the adjacent floor, the upper support cavity and the lower support cavity are matched to form a containing cavity; and the ground-heating pipe is contained in the containing cavity, therefore, the ground-heating pipe is embedded into two adjacent floors, not only the thickness of the paved floor is reduced, but also heat is directly transmitted to each heat-conducting medium from the ground-heating pipe, thus reducing the heat loss.

Owner:上海溢邦装饰建材有限公司

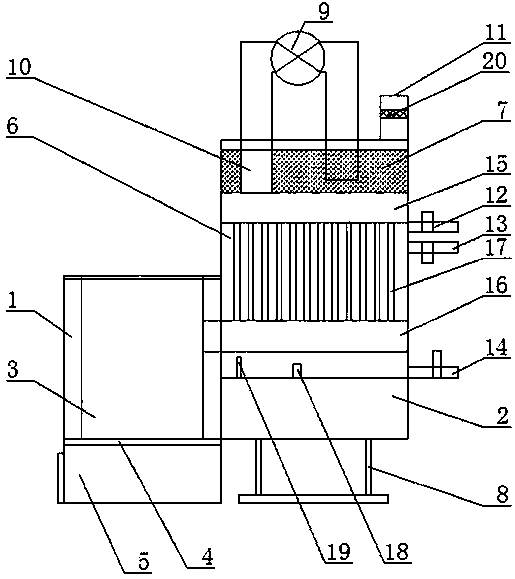

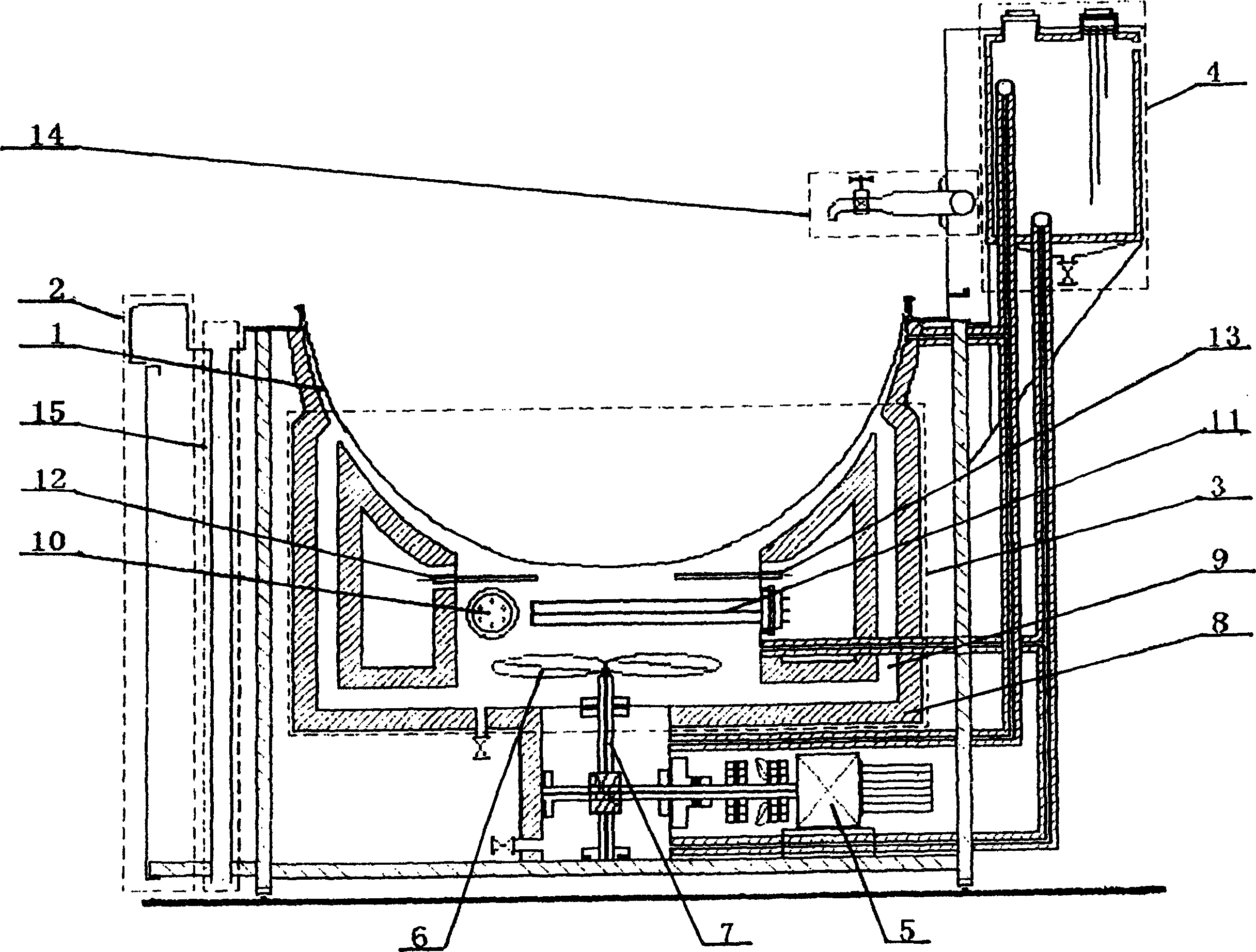

Energy-saving environmentally friendly civil boiler

PendingCN107781850ALow heat lossReduce pollutionLighting and heating apparatusStove/ranges for heating waterEnvironmentally friendlyCombustion chamber

An energy-saving environmentally friendly civil boiler comprises a left boiler body and a right boiler body, wherein the left boiler body is a combustion furnace; the right boiler body is a heat exchange filtering furnace; the left boiler body is connected with the right boiler body through a smoke and fire tube; a combustion cavity is formed in the middle of the inside of the left boiler body; afire grate is arranged at the bottom end of the combustion cavity; an ash chamber is formed in the lower end of the fire grate; a heat exchange cavity is arranged in the middle of the inside of the right boiler body; a filtering cavity is formed in the upper end of the inside of the right boiler body; the bottom end of the right boiler body is supported by a supporting base; the heat exchange cavity is connected with the filtering cavity through a smoke discharging tube with a smoke discharging fan; a tube at the right end of the smoke discharging tube is inserted into the filtering cavity; asmoke discharge tube is arranged on the right side of the top end of the filtering cavity; a heat exchange water inlet tube and a steam tube are arranged at the upper end of the right side of the heatexchange cavity; and a heat exchange water outlet tube is arranged at the lower end of the right side of the heat exchange cavity. By the energy-saving environmentally friendly civil boiler, heat energy generated by combustion of coal can be utilized effectively, furthermore, waste heat in smoke generated after combustion of the coal can be effectively used for heat exchange, and thus, heat lossratio is reduced.

Owner:HARBIN XINGYU RIVETING

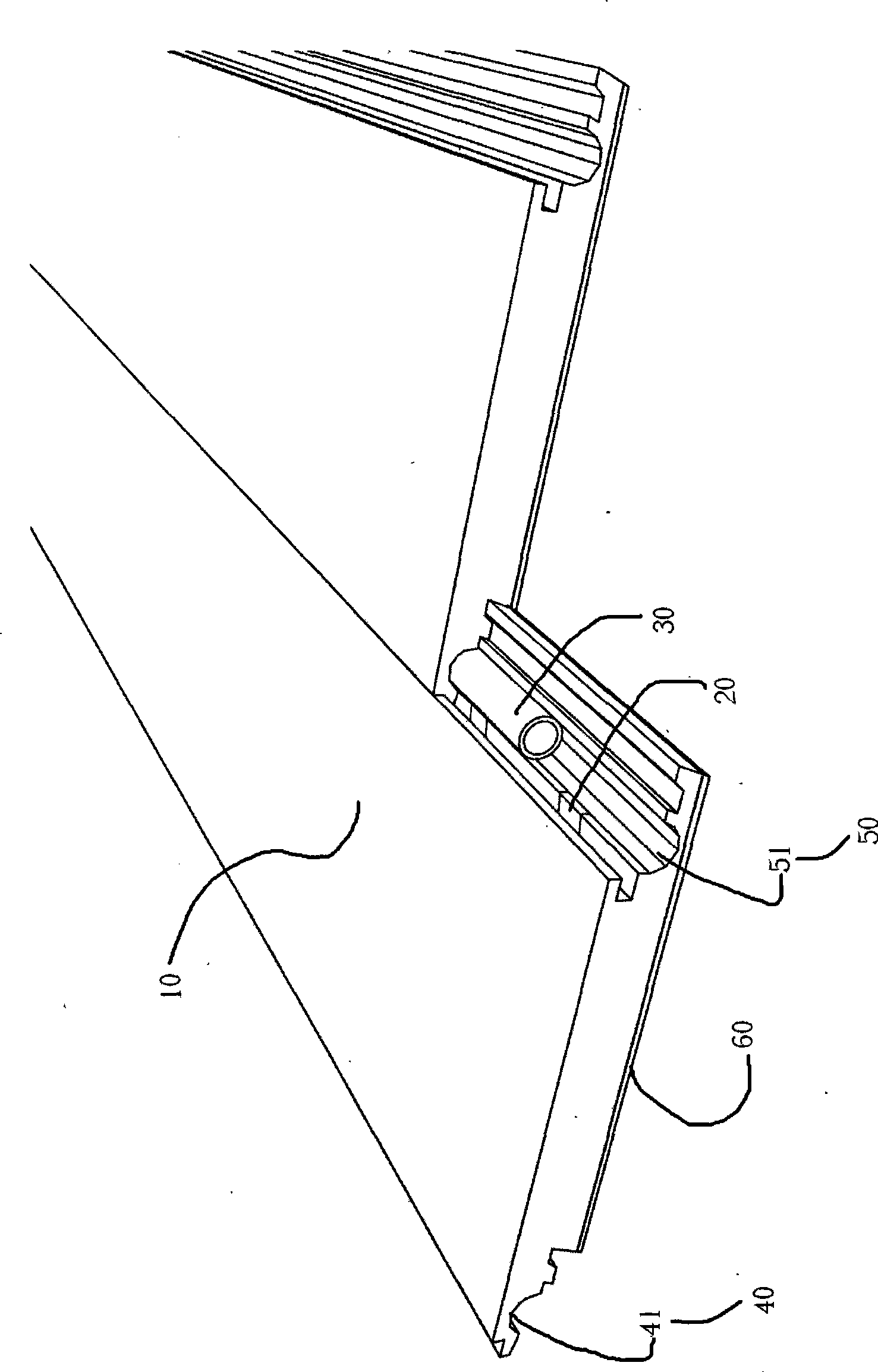

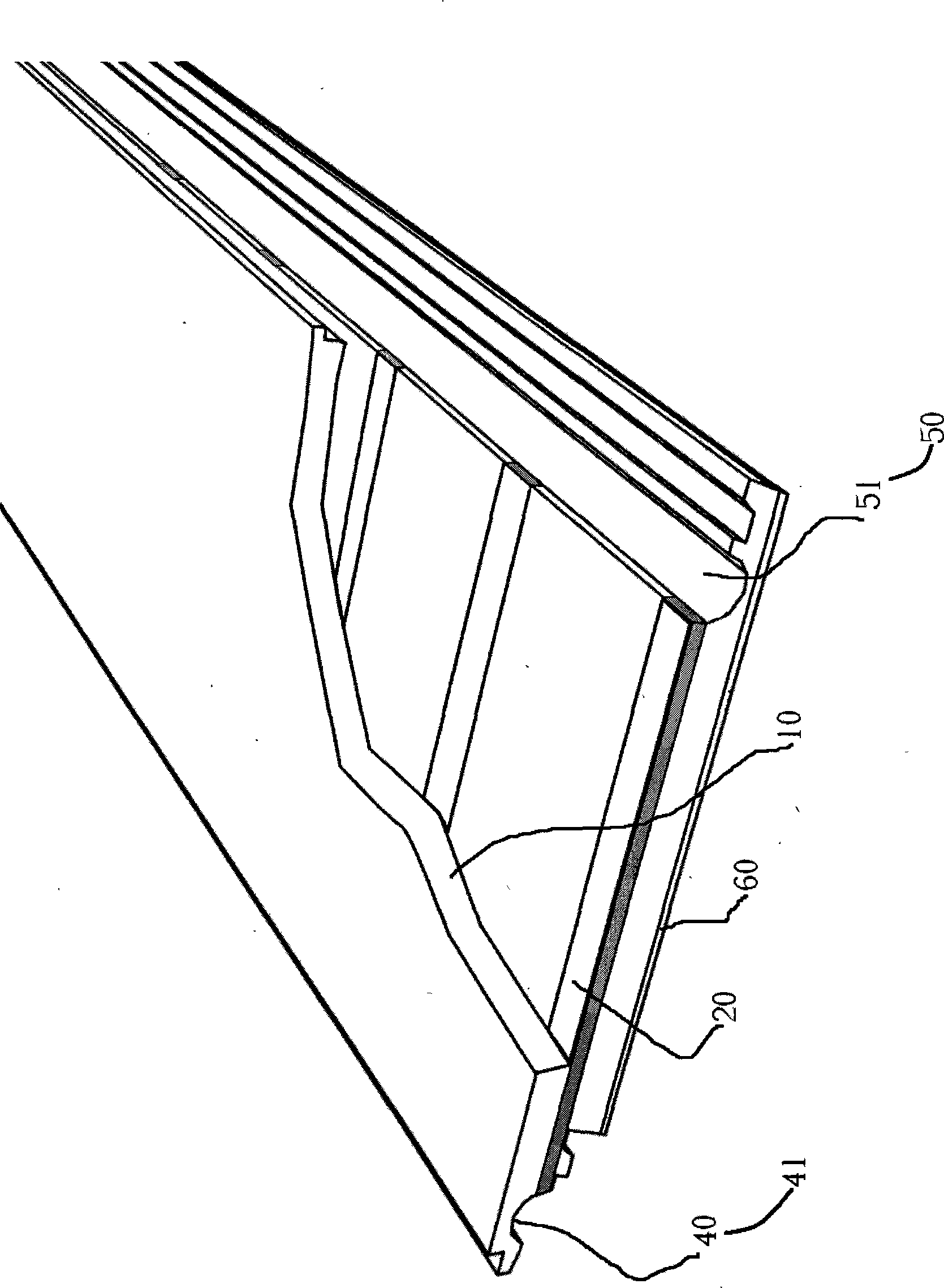

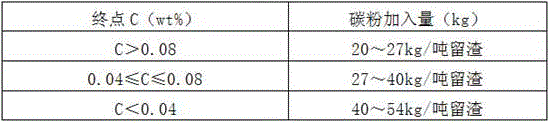

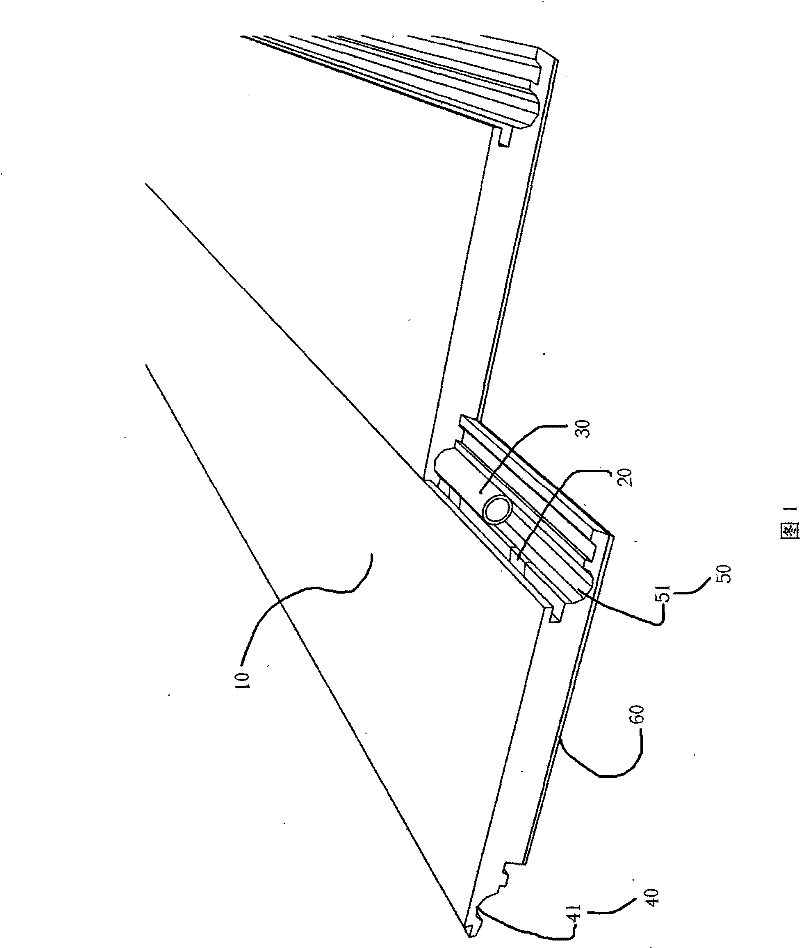

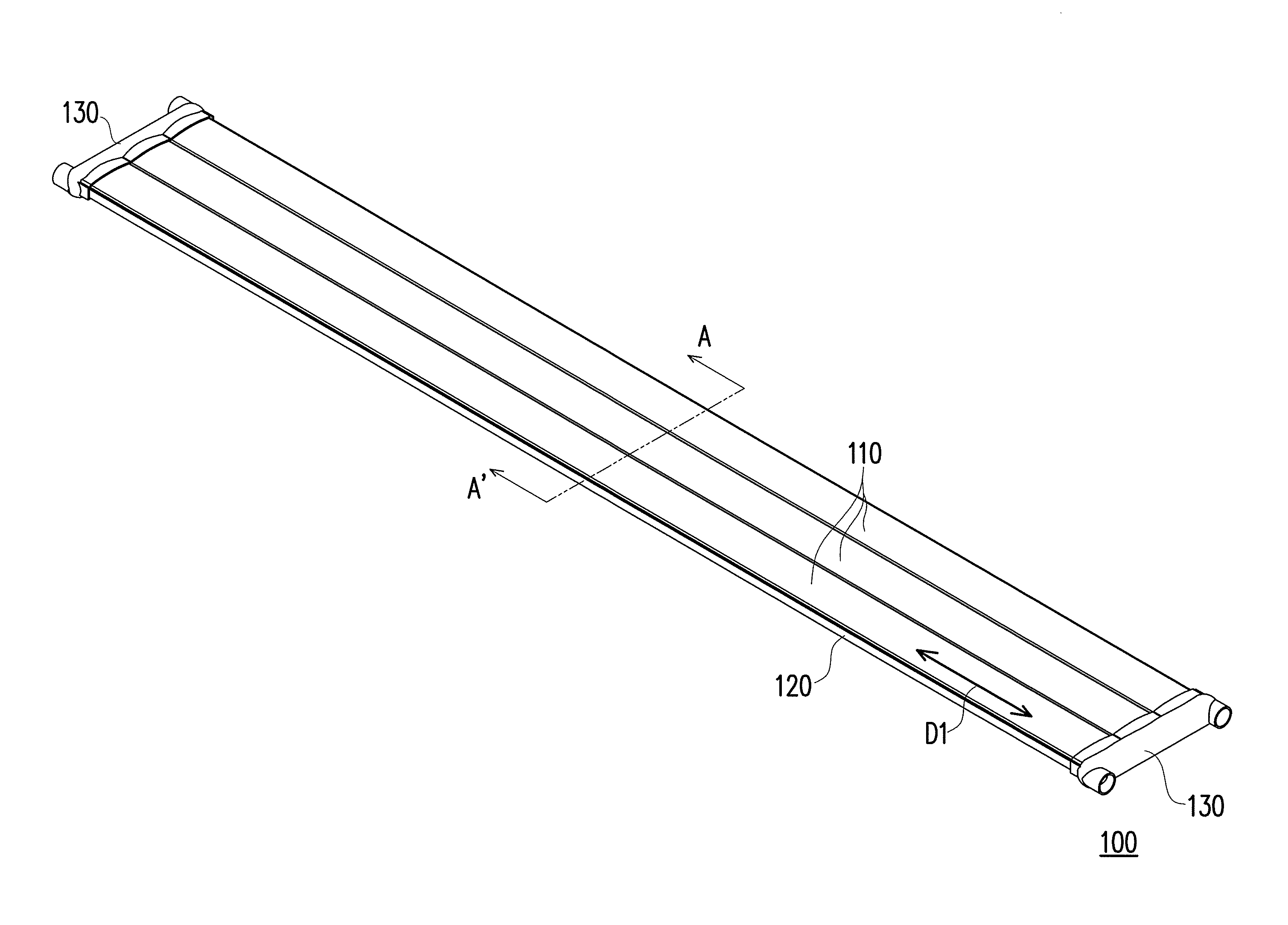

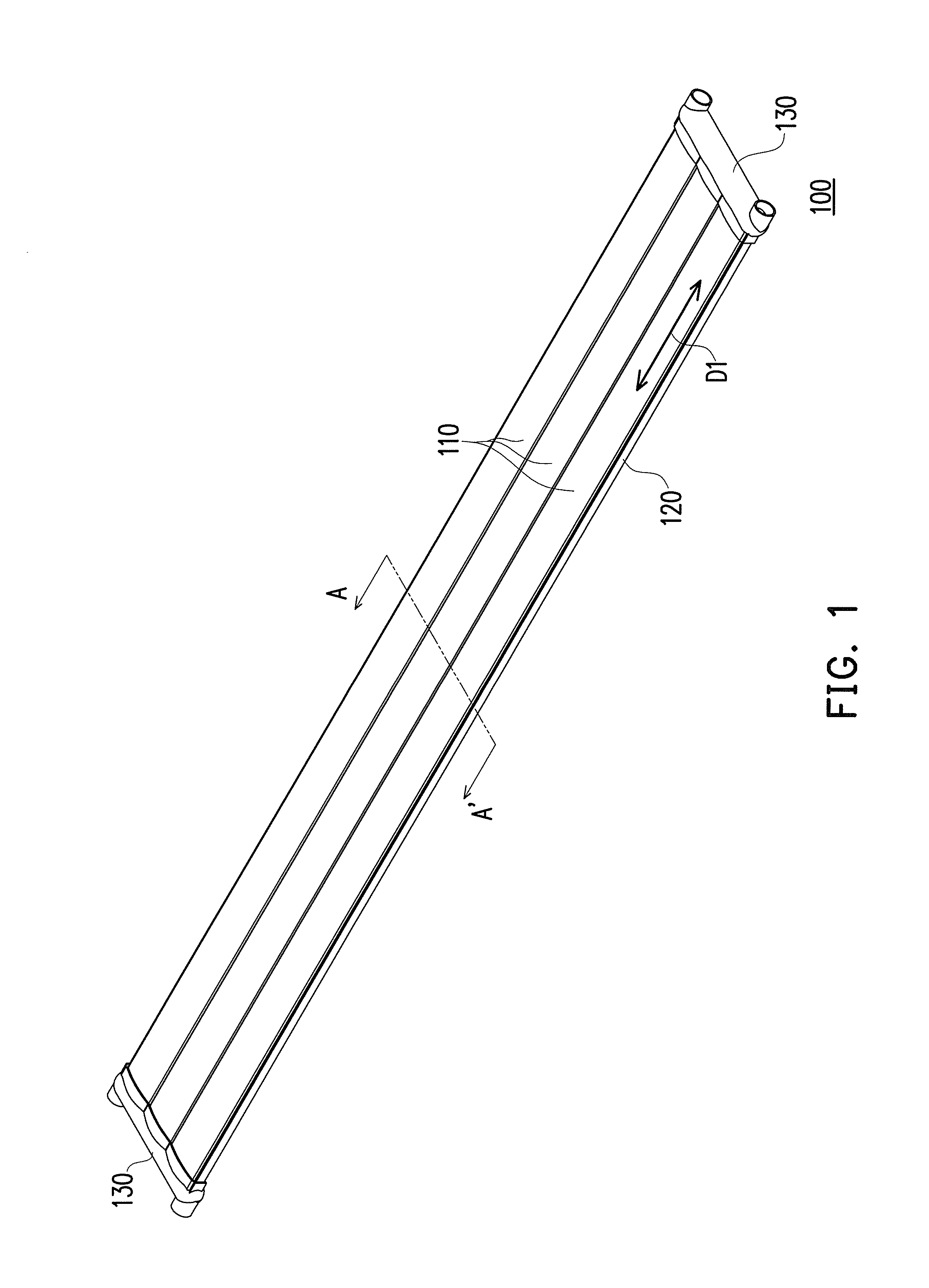

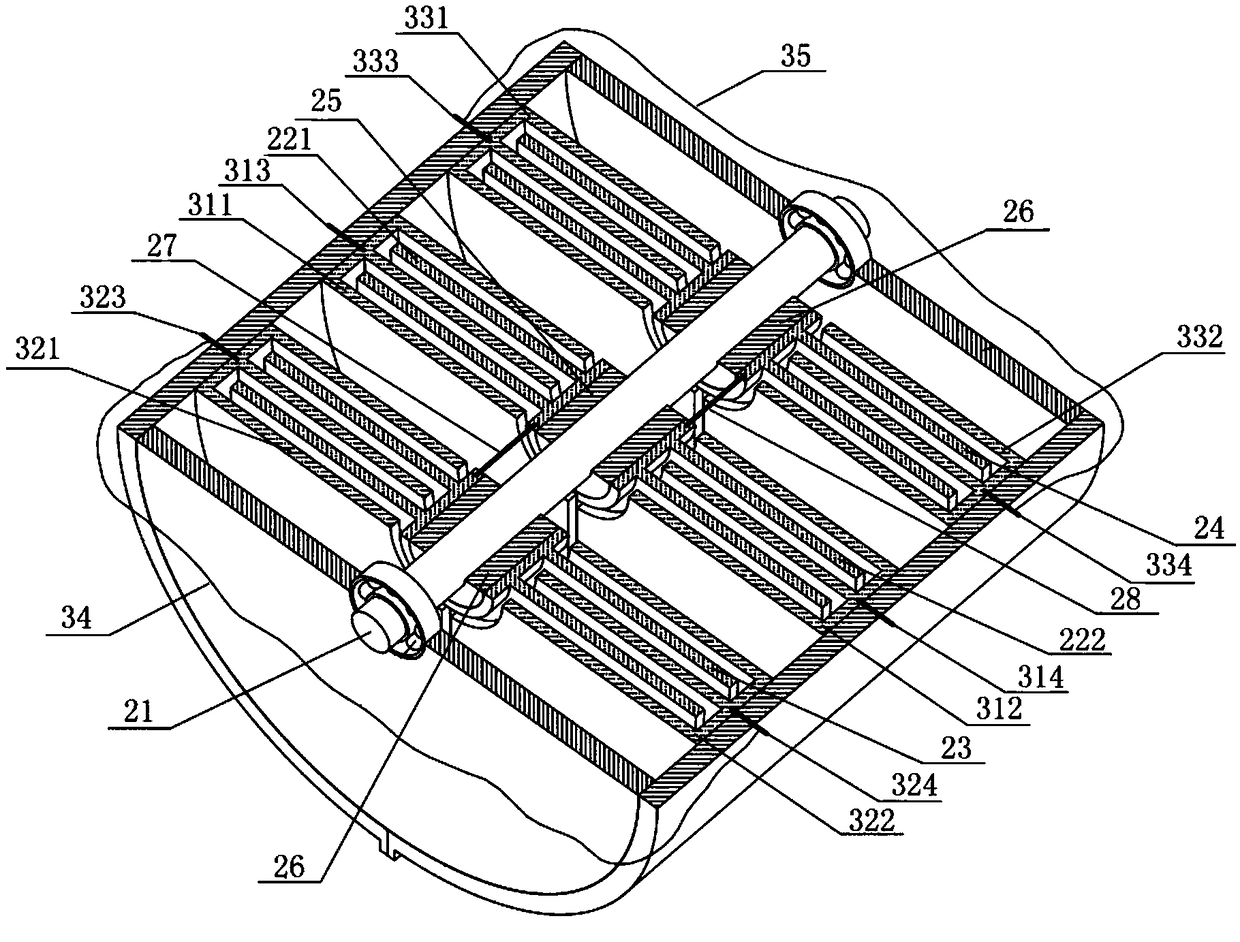

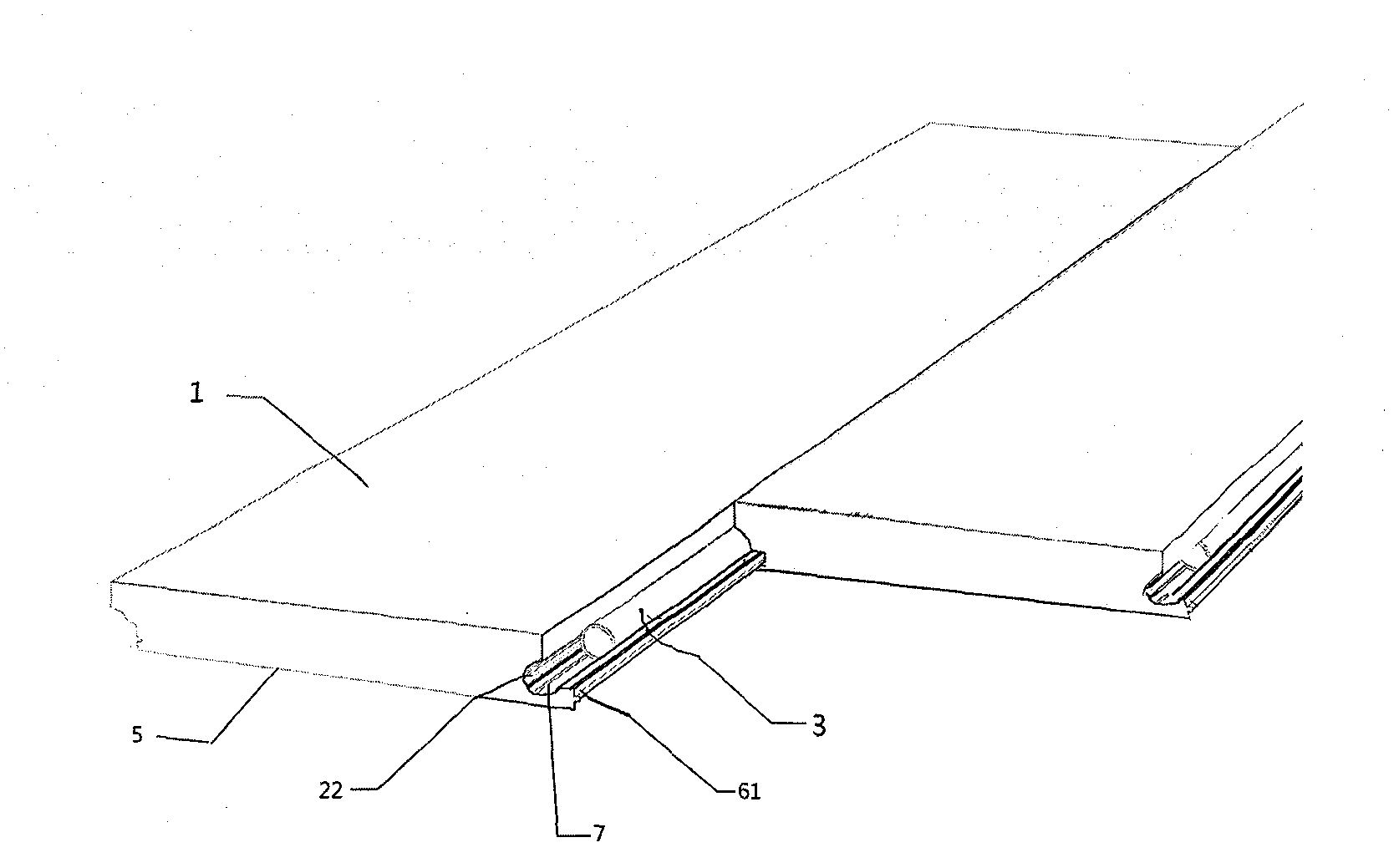

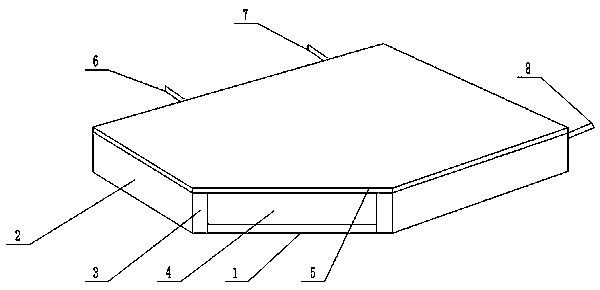

Solar thermal collector and building accessory structure

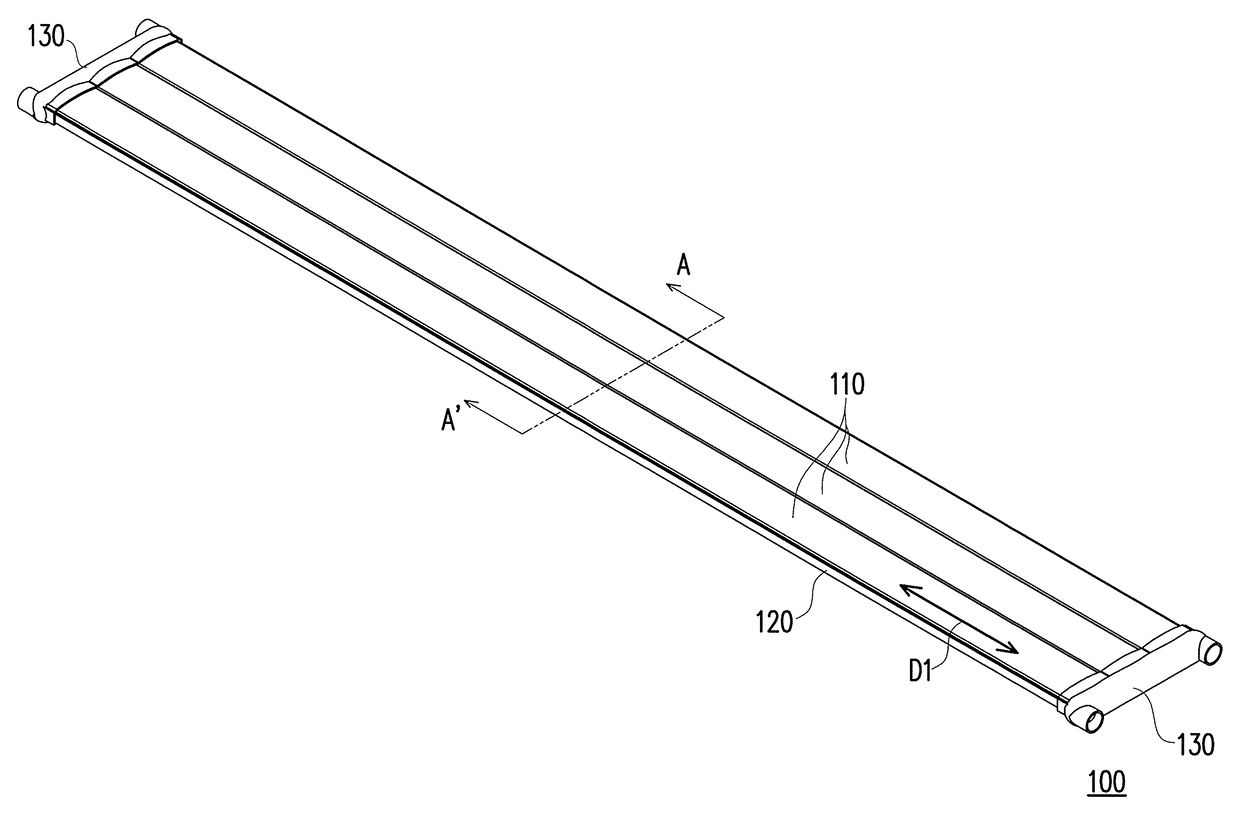

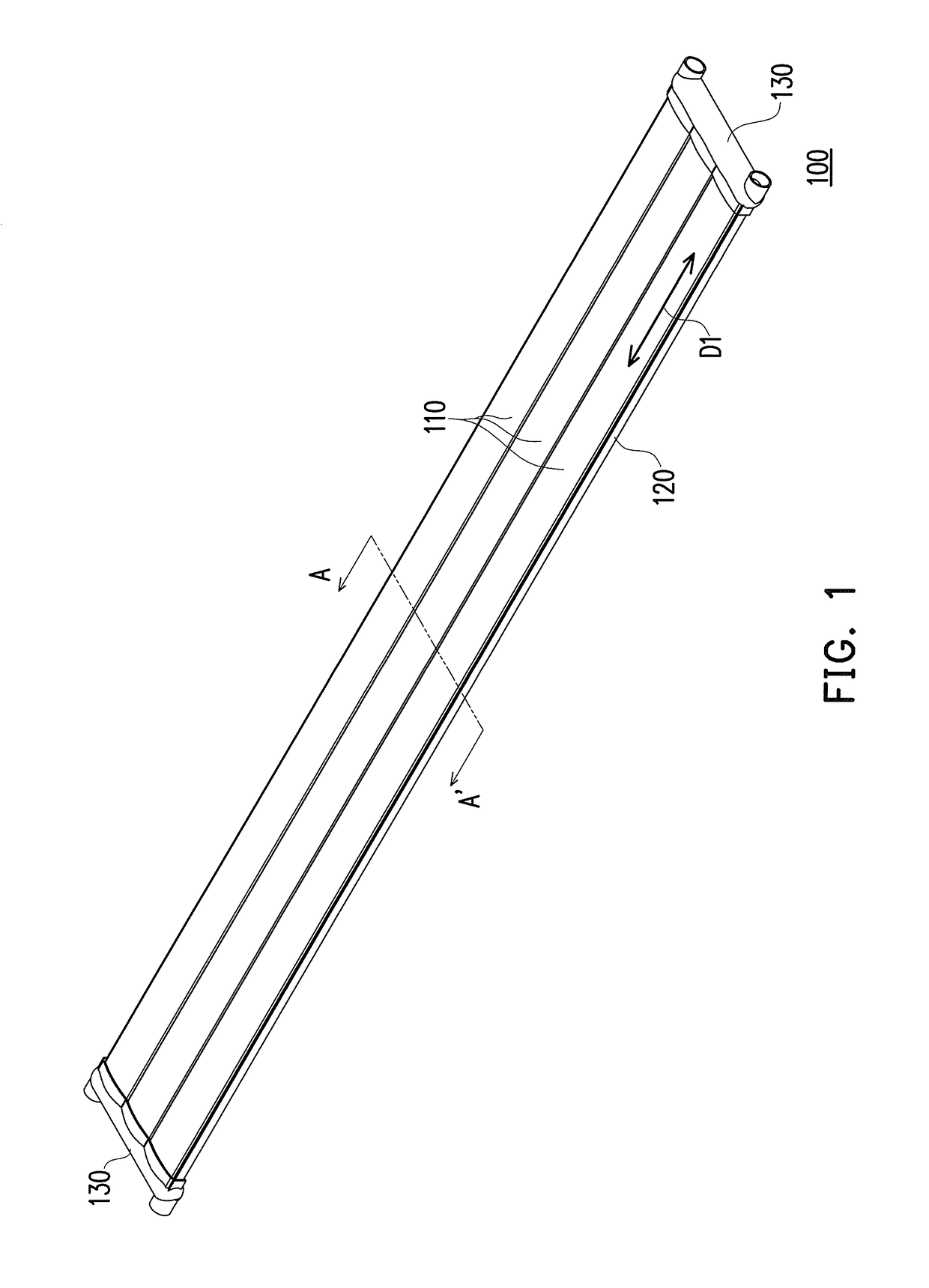

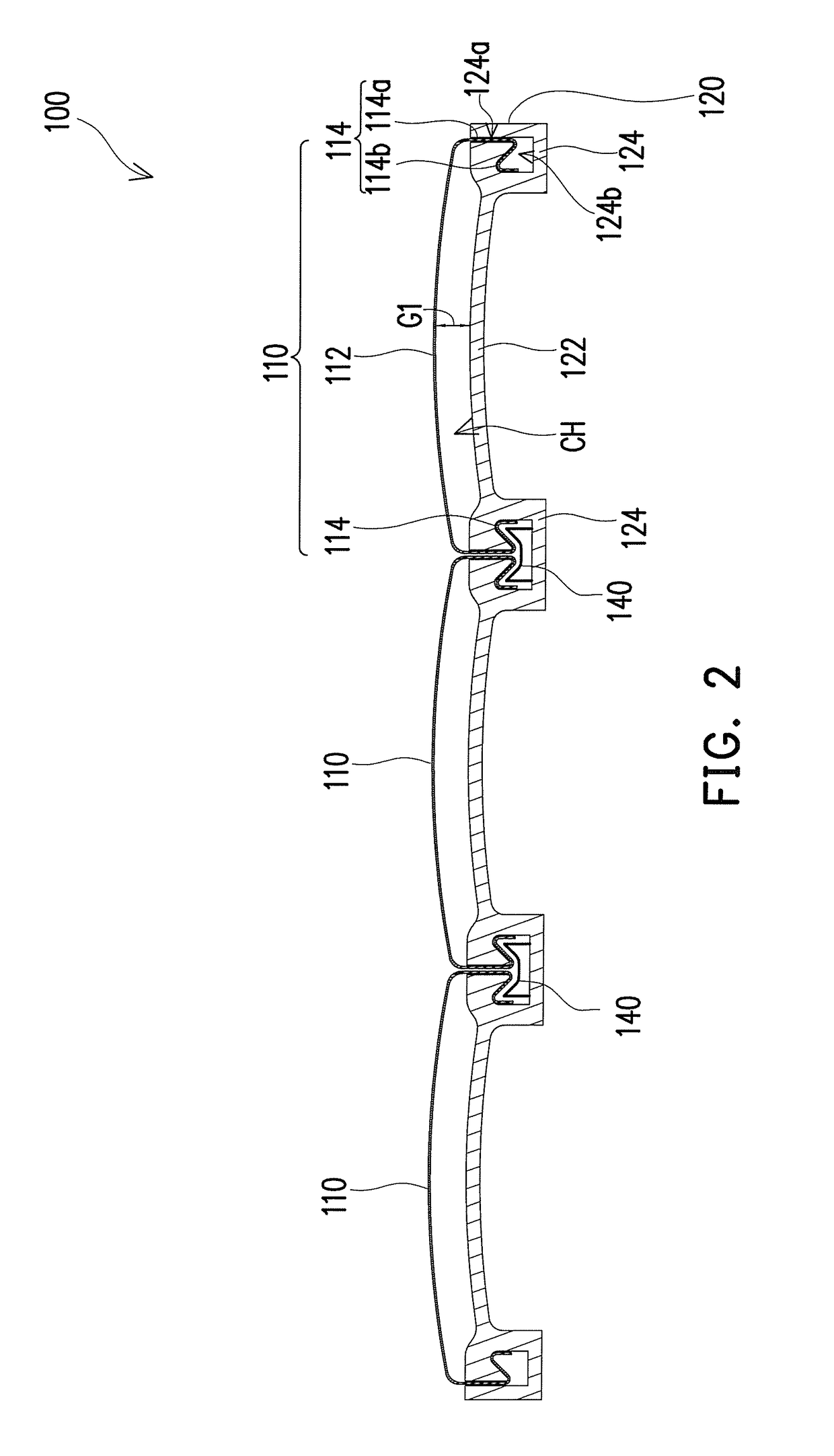

InactiveUS20160138831A1More rigid structureImprove design flexibilitySolar heating energySolar heat devicesThermal transmittanceHeat transfer fluid

A solar thermal collector and an accessory structure of a building are provided. The solar thermal collector includes at least one heat absorbing plate and at least one heat insulating plate. Each of the heat absorbing plate includes at least one first slab and first engaging parts connected with the first slab. Each of the heat insulating plate includes at least one second slab and second engaging parts connected with the second slab. The first engaging parts are respectively engaged with the second engaging parts, and a gap is maintained between the first slab and the second slab to define a heat collecting channel, through which a heat transfer fluid flows between the heat absorbing plate and the heat insulating plate. A heat conductivity of the heat absorbing plate is at least 30 times greater than a heat conductivity of the heat insulating plate.

Owner:HSIU LIN PENG

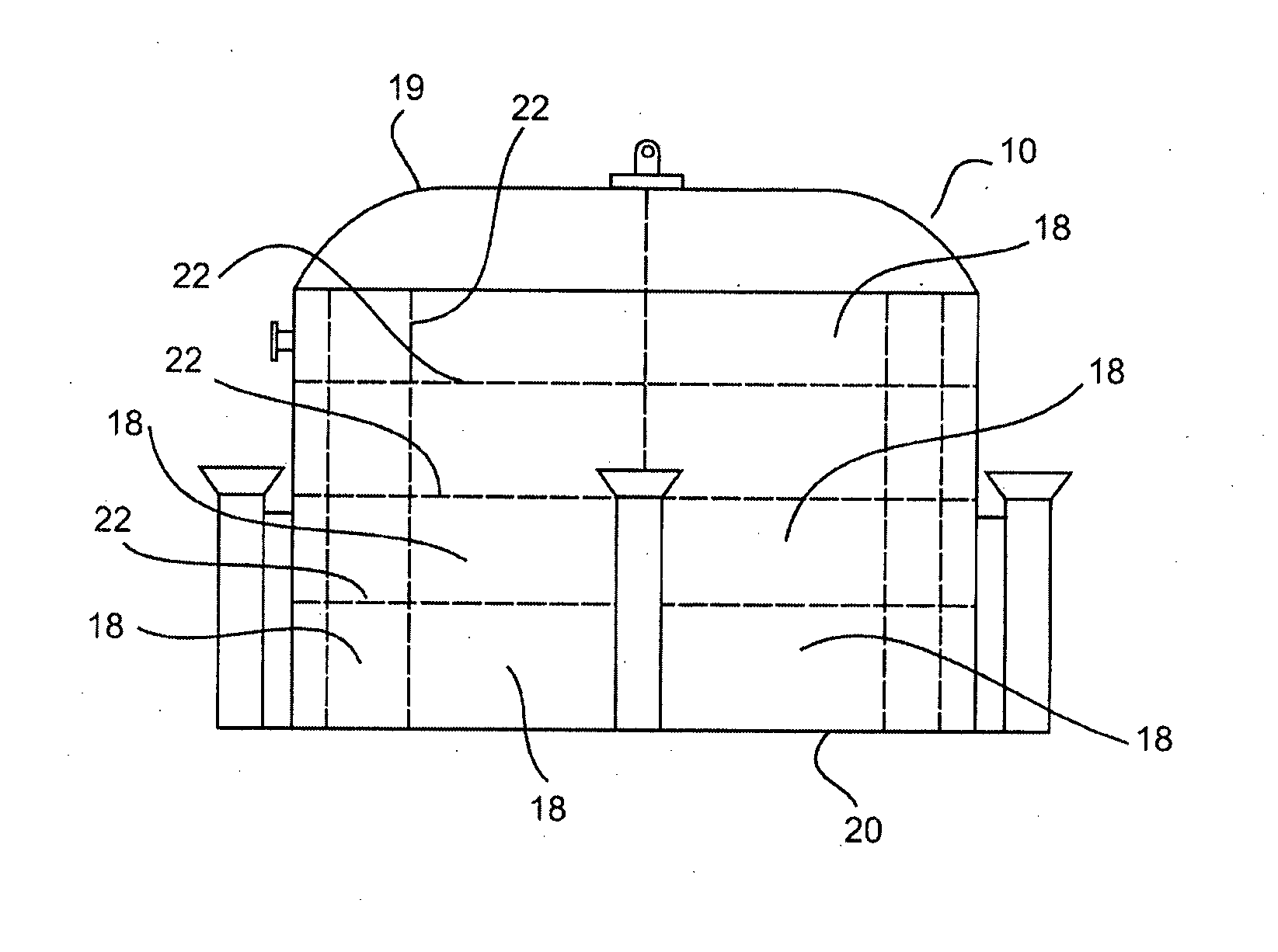

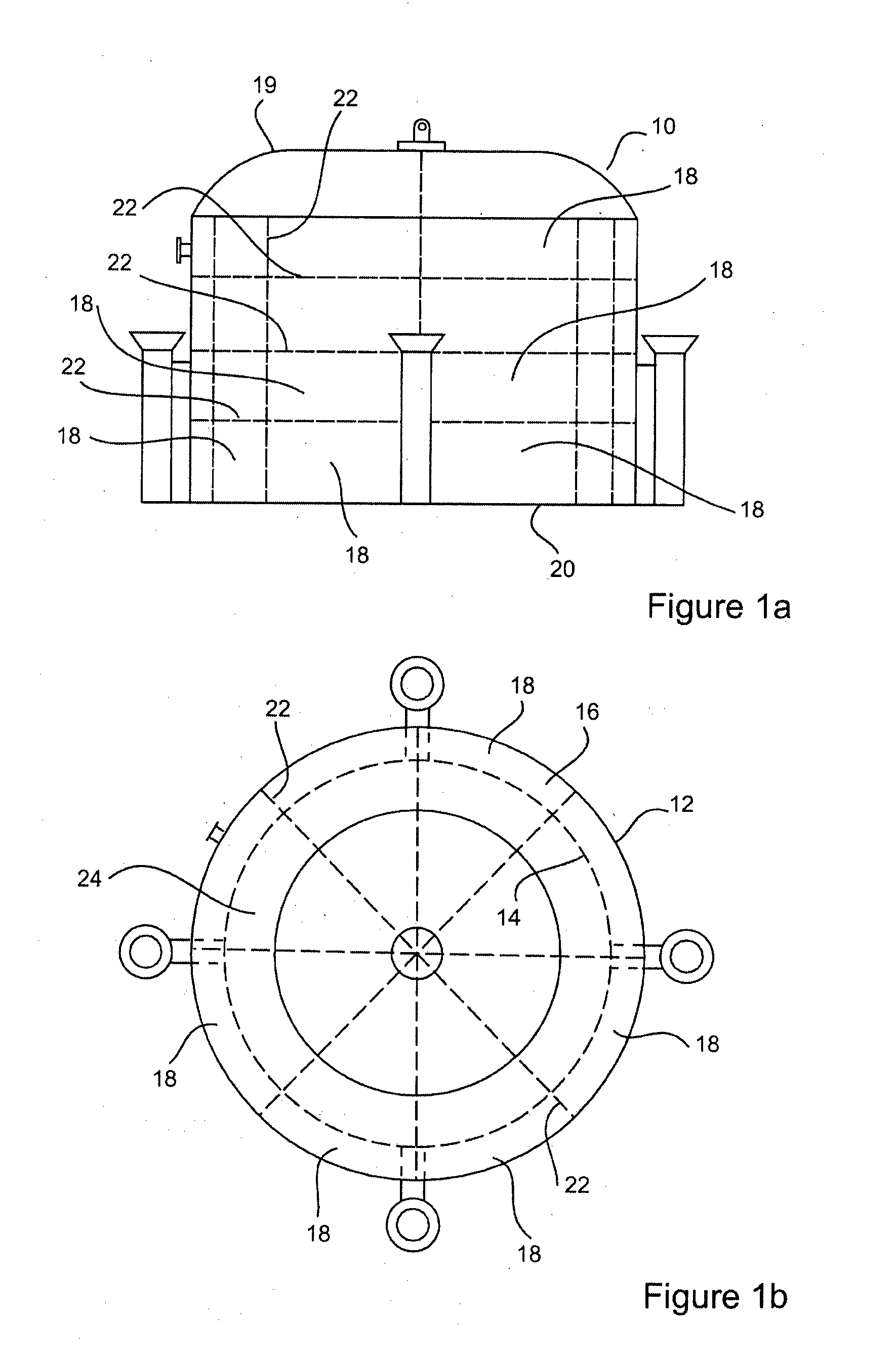

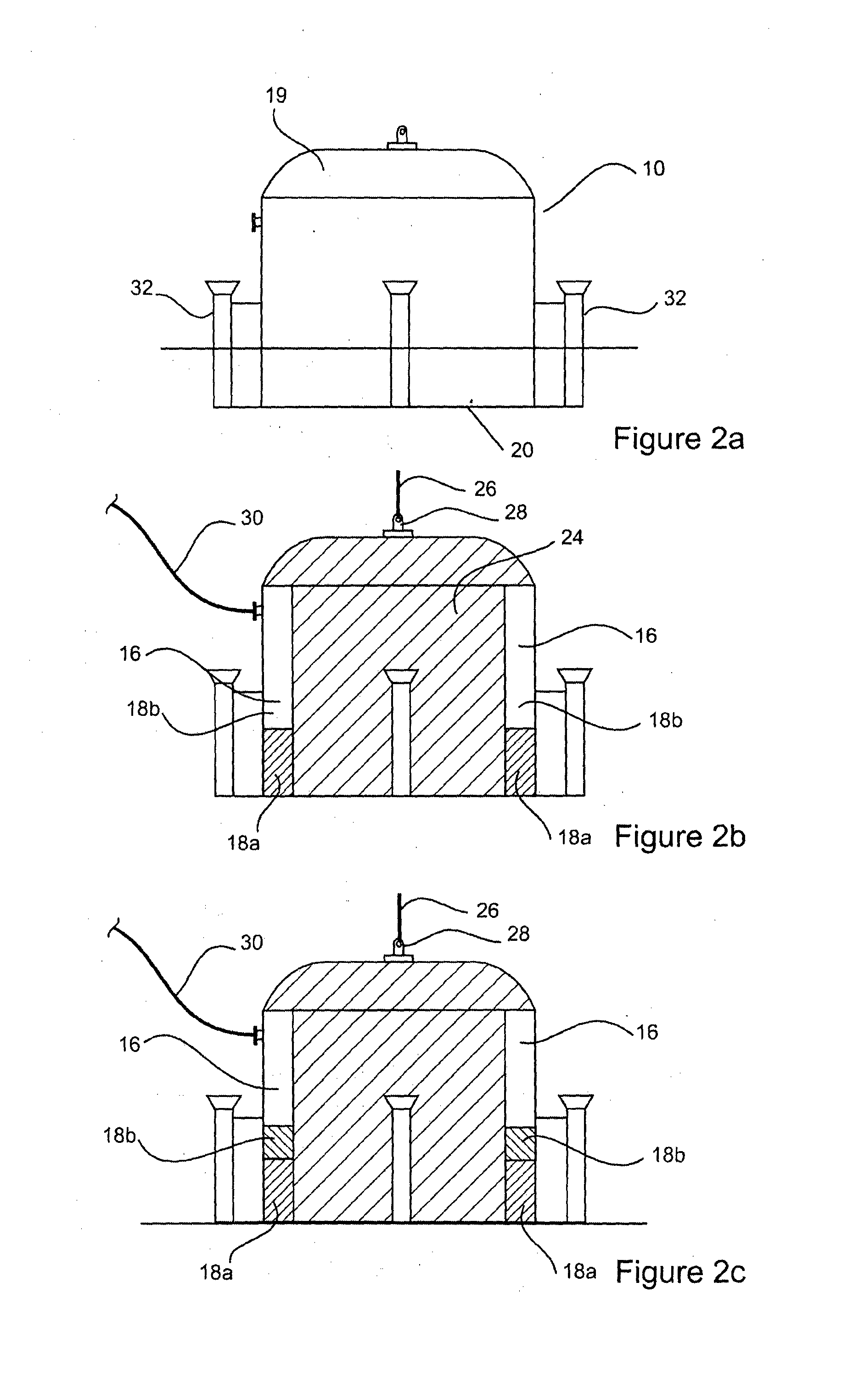

Tank

InactiveUS20150176764A1Reduce floodingReduce hydrostatic pressureLarge containersContainer/bottle contructionCisternNeutral buoyancy

A tank for storage of hydrocarbon liquids on the seabed, being of double hull construction which is compartmented to form a plurality of chambers, such that the tank may be safely towed from its build location or shipyard, to offshore deployment location as marine warranty compliant vessel, having appropriate intact and damaged stability characteristics. There is also provided a method for deploying a tank for storage of hydrocarbon liquids on the seabed, the method comprising the step of towing the tank having un-ballasted storage areas and compartments to the location of deployment; flooding at least partially the storage area to achieve substantial neutral buoyancy of the tank to allow decent of the tank up to a submerged equilibrium; allowing decent of the tank to the seabed and injecting air into at least one compartment for maintaining equilibrium between the pressure applied by the surrounding sea and the pressure inside compartments and storage area.

Owner:SEACAPTAUR IP

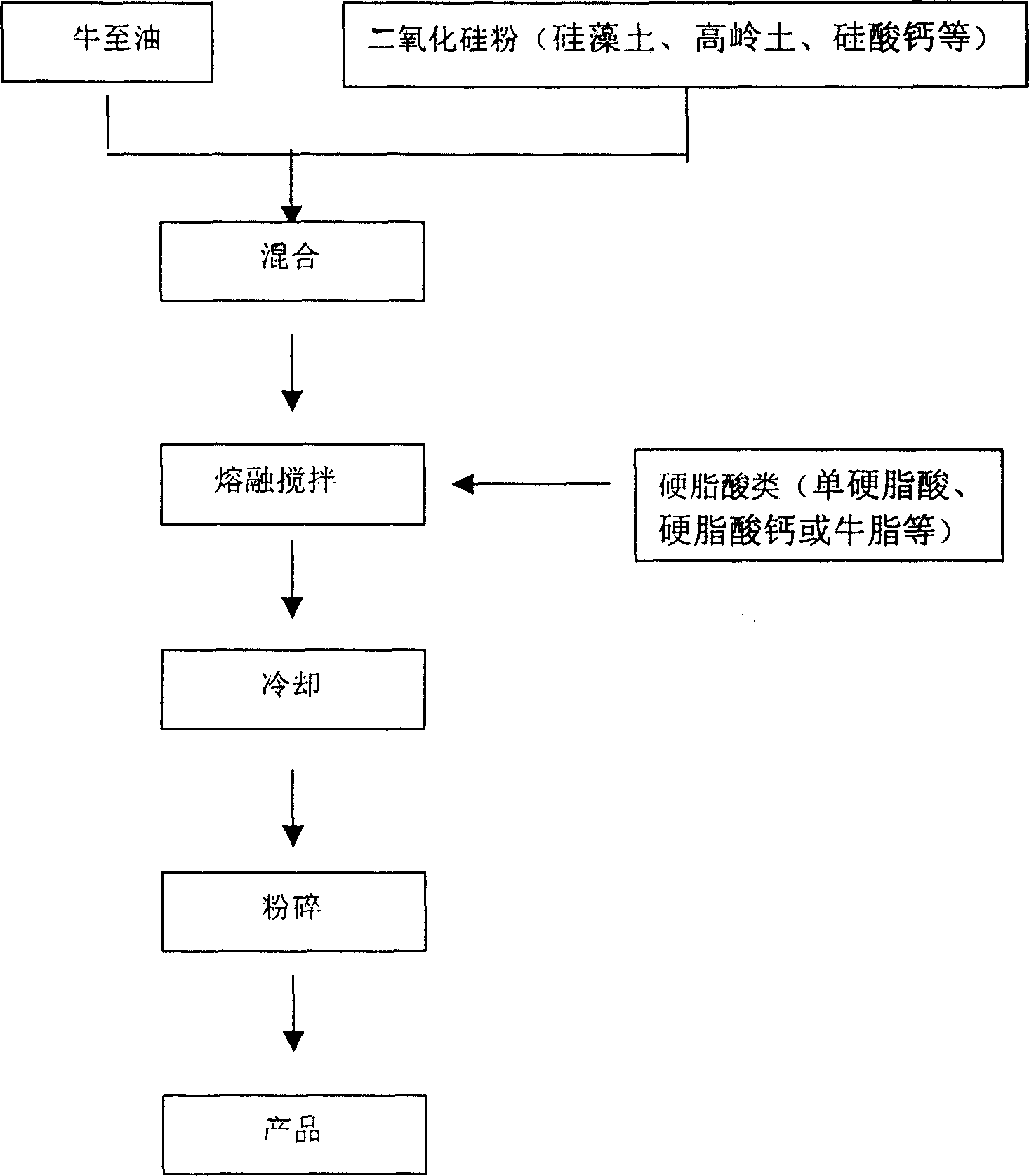

Method for preparing common origanum herb oil micro capsule powder for natural fodder germicide

InactiveCN1224331CIncrease contentImprove liquidityAnimal feeding stuffAccessory food factorsSoftgelStearic acid

An origanum herb oil softgel as antibacterial agent for feed is prepared from origanum herb oil extracted from origanum herb, stearic acid as well material and SiO2 particles as adsorbent through fusing and cooling.

Owner:FEED RESEARCH INSTITUTE CHINESE ACADEMY OF AGRICULTURAL SCIENCES

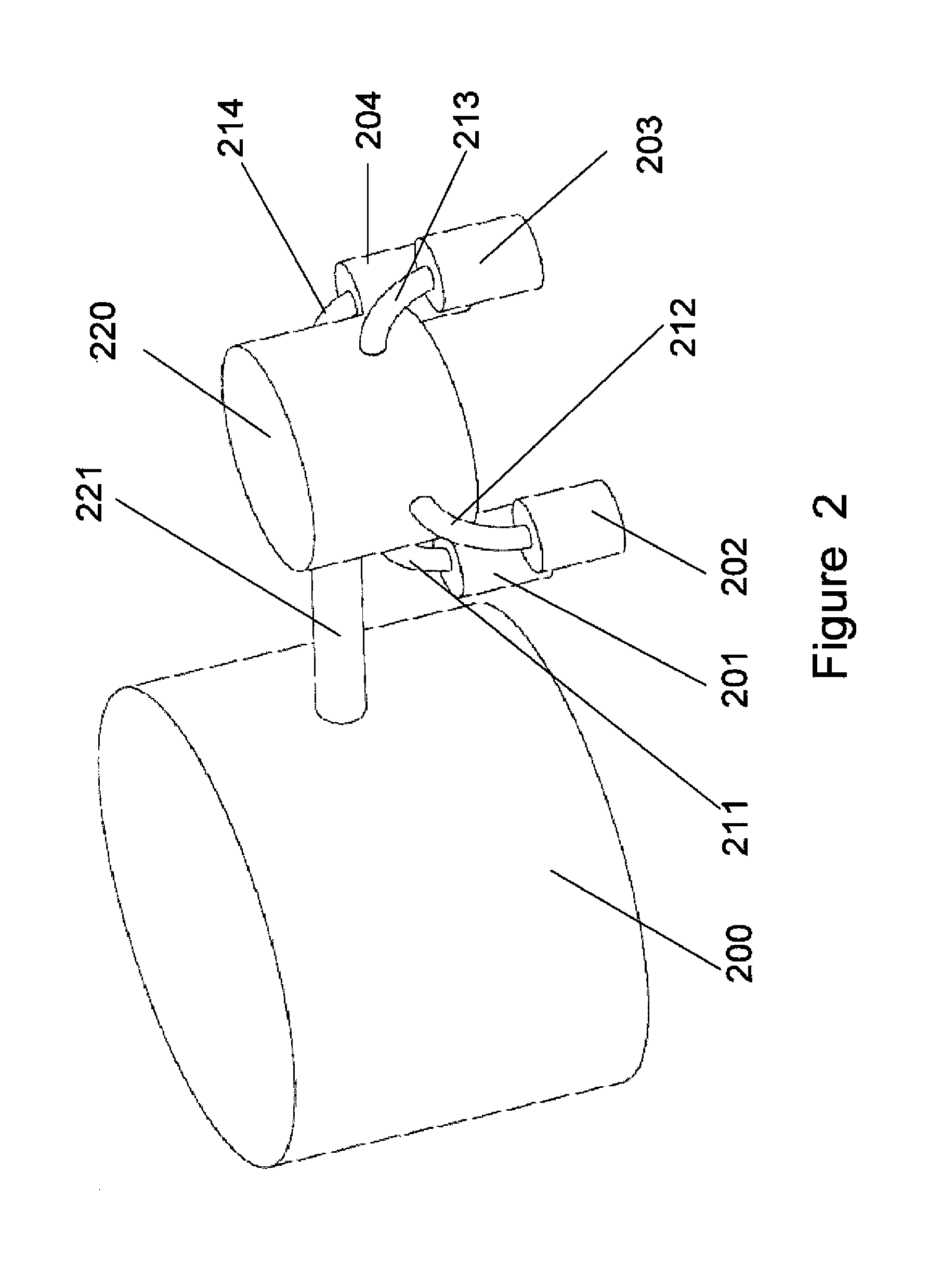

High Throughput Materials-Processing System

InactiveUS20090280029A1Improve system efficiencyImprove efficiencySequential/parallel process reactionsRotary stirring mixersHandling systemMaterials processing

The present invention discloses a materials-processing system, which comprises an inputting subsystem, a processing apparatus coupled to the inputting subsystem and a collecting subsystem coupled to the processing apparatus. The inputting subsystem comprises three or more sample vessels, which can be connected to the processing apparatus. Since the processing system includes multiple sample vessels, which can be grouped into different groups so that each group contains two or more of the multiple sample vessels. High throughput materials transport can be realized by sequentially connecting different groups of sample vessels to the processing apparatus, thereby overcoming a limitation of the prior art that cannot continuously perform multiple batches of materials processing and improving material processing efficiency.

Owner:ACCELERGY SHANGHAI R & D CENT CO LTD

Solar thermal collector and building accessory structure

InactiveUS9816728B2Structure moreIncrease flexibilitySolar heating energySolar heat devicesAccessory structureEngineering

A solar thermal collector and an accessory structure of a building are provided. The solar thermal collector includes at least one heat absorbing plate and at least one heat insulating plate. Each of the heat absorbing plate includes at least one first slab and first engaging parts connected with the first slab. Each of the heat insulating plate includes at least one second slab and second engaging parts connected with the second slab. The first engaging parts are respectively engaged with the second engaging parts, and a gap is maintained between the first slab and the second slab to define a heat collecting channel, through which a heat transfer fluid flows between the heat absorbing plate and the heat insulating plate. A heat conductivity of the heat absorbing plate is at least 30 times greater than a heat conductivity of the heat insulating plate.

Owner:HSIU LIN PENG

A static induction brushless alternator and a use method thereof

ActiveCN109217712AReduce power generation costsLow heat lossInfluence generatorsElectric heatingElectromagnetic induction

The embodiment of the invention discloses a static induction brushless alternator and a use method thereof, the generator includes an insulated casing and a rotor and stator disposed within the casing, the aforementioned rotor comprise a rotating shaft, An induction rotating sheet group is insulated and connected to the rotating shaft, A first pole rotating sheet and a second pole rotating sheet,the stator comprises a supply field stator set fixedly connected with the casing, a first pole plate group and a second pole plate group, Between that supply field fix sheet group and the induction rotating sheet group, Between that first pole fix plate group and the first pole rotating plate and between the second pole fix plate group and the second pole rotating plate, The electrostatic induction brushless alternator provided by the embodiment of the invention completes the output of electric energy through the electrostatic induction principle, does not need to set an electric brush, does not consume electric energy, has low power generation cost, has extremely low electric heating loss, has simpler structure, is easier to maintain, has longer motor working life, has less failure rate and has better stability than the electromagnetic induction generator.

Owner:刀春会

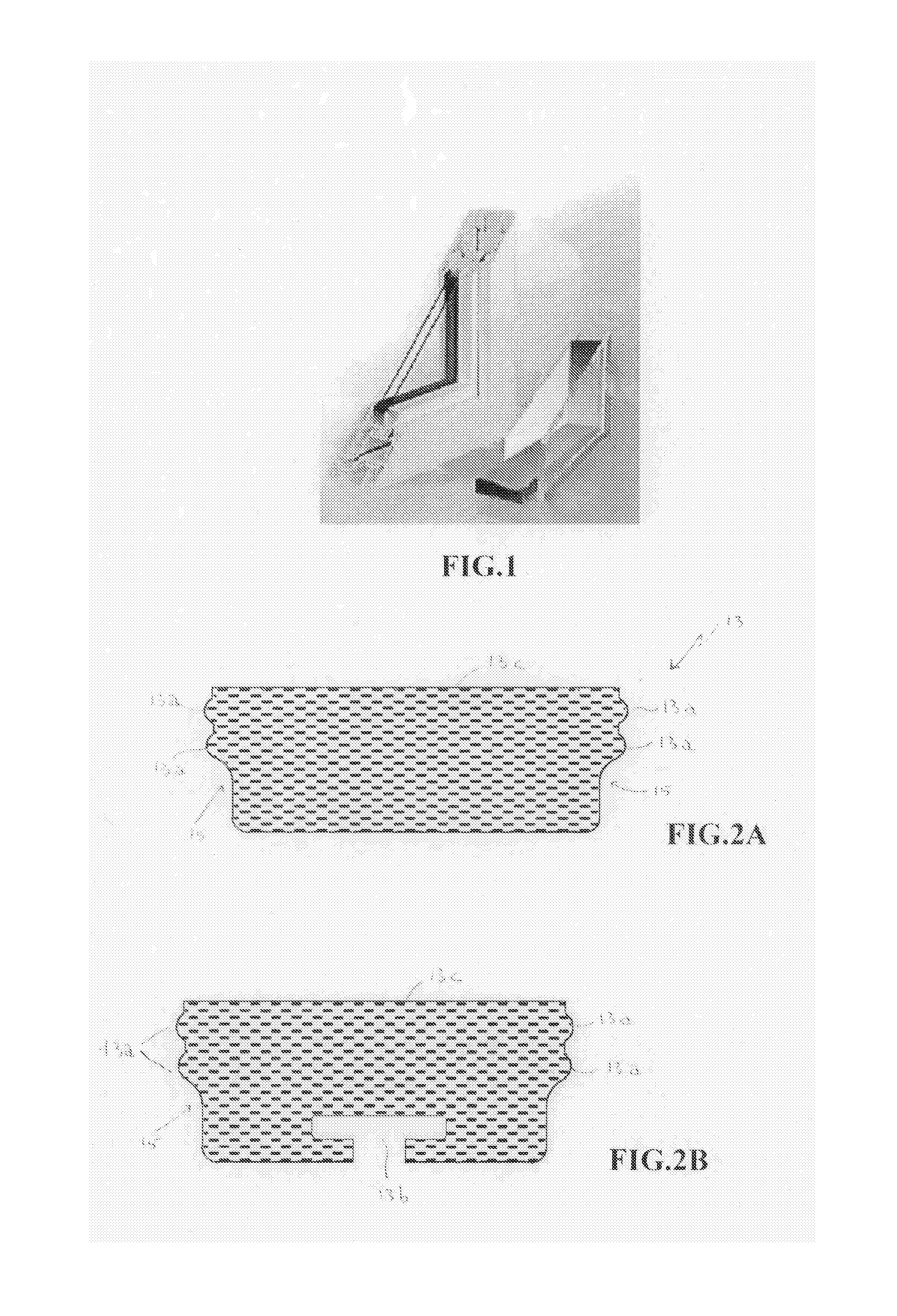

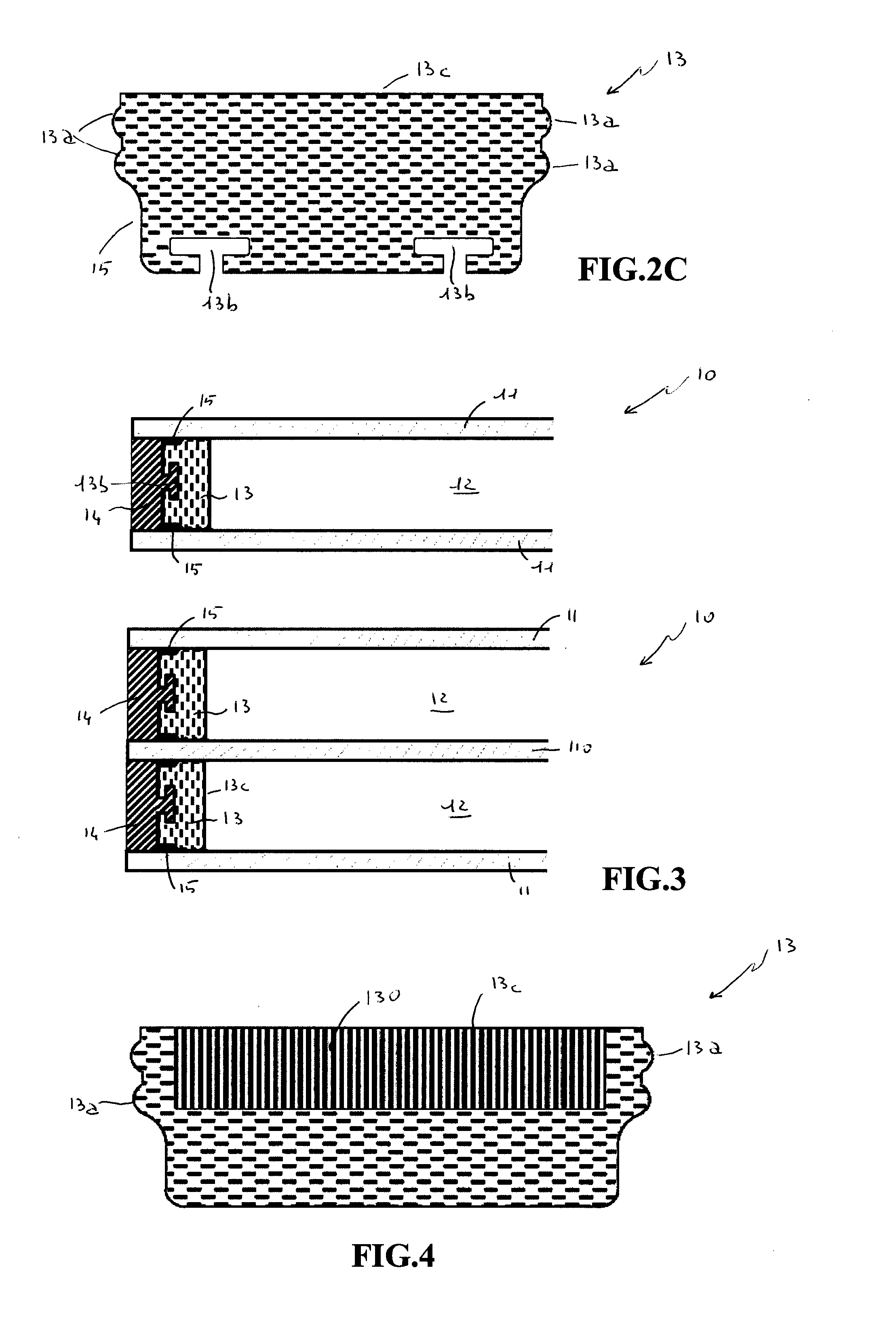

Flexible spacer for double-glazing

InactiveUS20160265265A1Low heat lossReduce thermal stressCorner/edge jointsUnits with parallel planesElastomerSulfur

A description is made of a flexible spacer for double glazing made of Polyisobutylene elastomer or butyl rubber IIR (simple or halogenated), suitably loaded with both reinforcing and inert fillers. The spacer can be cross-linked with sulphur or peroxides. The spacer is impermeable to moisture and has high low thermal conductivity gas sealing capacity, and incorporates moisture absorbing material. In particular, the spacer features—on each side wall—at least a small wave (13a) positioned immediately above the accumulation area of the internal or primary sealant (15) so as to ensure an optimal adhesion to the glass of the double / triple glazing unit within which the spacer is fitted and features at least one recess (13b), with a configuration such as to allow the external sealant to penetrate and create a strong mechanical bond between the two materials.

Owner:MERLO LUCA

Polyethylene foamed insulation pipeline

InactiveCN106481933AImprove insulation effectLow heat lossThermal insulationPipe protection by thermal insulationEngineeringHeat losses

The invention discloses a polyethylene foamed insulation pipeline. The polyethylene foamed insulation pipeline comprises a central steel pipe. An inner high-density polyethylene protective layer is arranged on the inner wall of the central steel pipe. A polyurethane insulation coating is arranged on the periphery of the central steel pipe. Two or more outer high-density polyethylene protective layers are arranged on the periphery of the polyurethane insulation coating. A leakage alarm line is buried inside the polyurethane insulation coating in the time delay direction of the central steel pipe. In this way, the polyethylene foamed insulation pipeline is good in insulation performance, low in heat loss rate, excellent in corrosion resistance, large in mechanical strength, and capable of supporting the central steel tube to bear a certain external load; and meanwhile, the insulation coating can be protected against erosion of underground water, leakage detection can be conducted, and the detection precision is high.

Owner:JIANGSU HAOSHENG PLASTIC IND TECH CO LTD

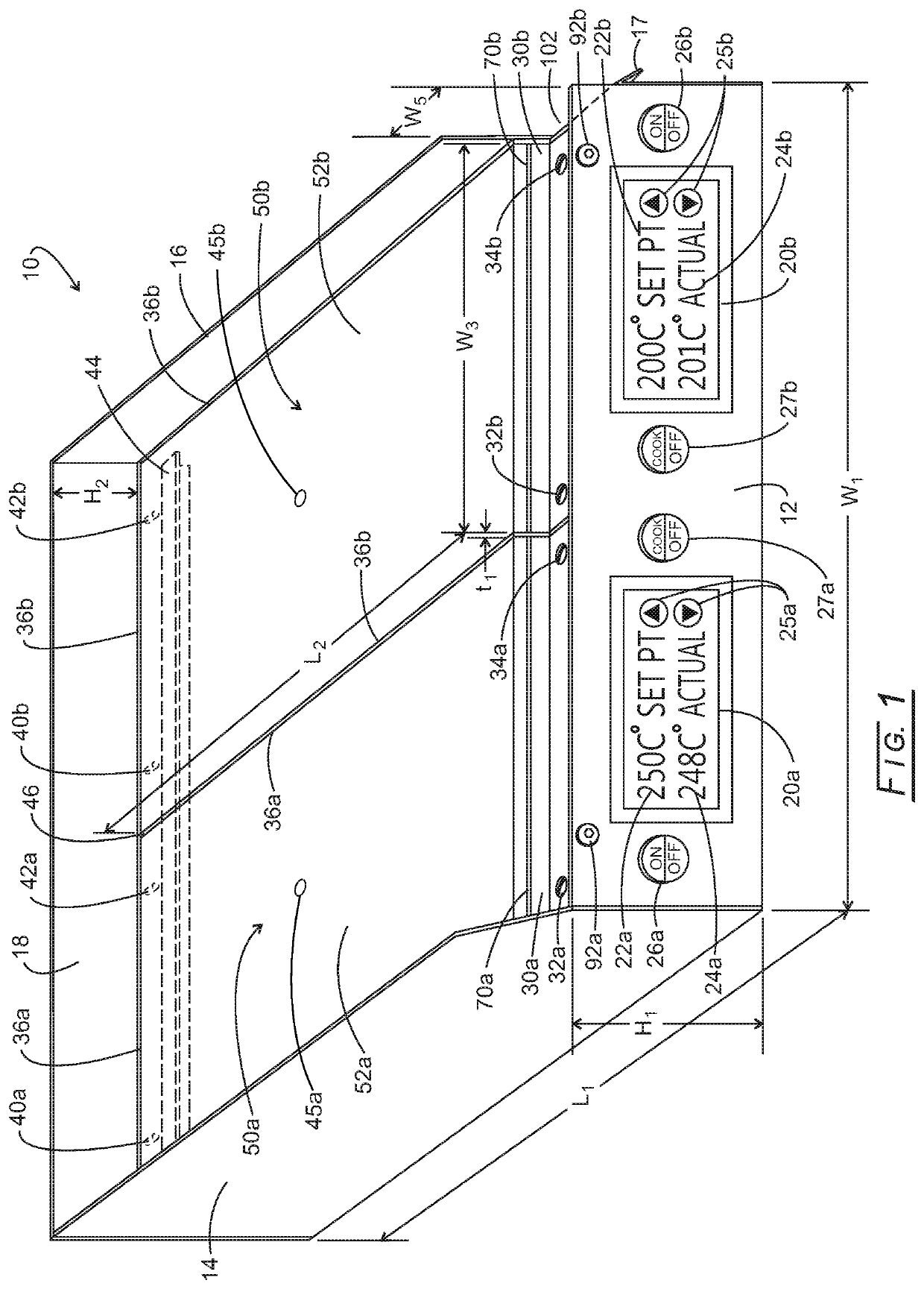

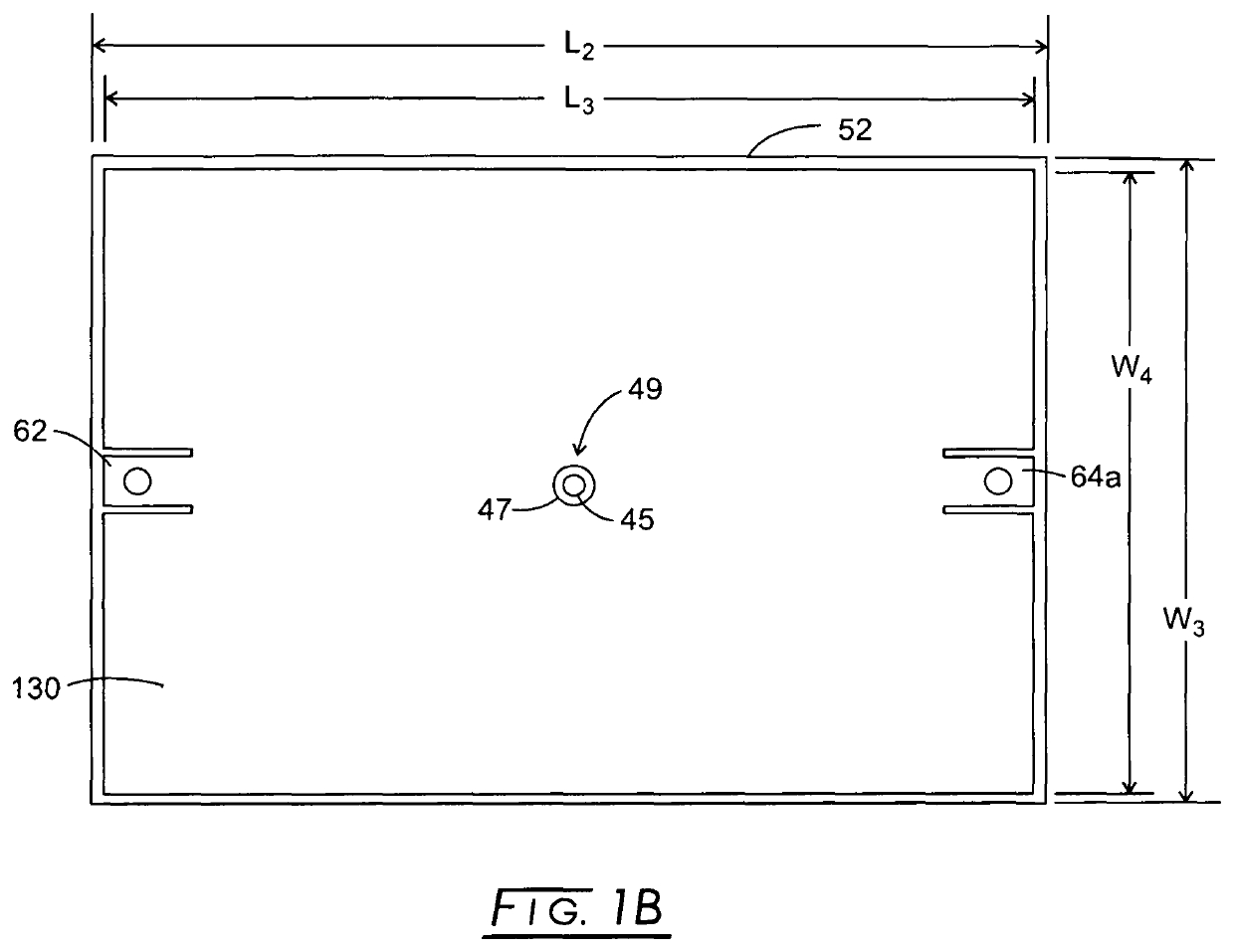

Isothermal cooking plate apparatus, system, and method of manufacture and use

ActiveUS10995959B2High hardnessImprove the lubrication effectDomestic stoves or rangesLighting and heating apparatusElectrical connectionAustenite

An isothermal cooking plate assembly is formed from a first plate of high thermal conductivity material having a back surface and an oppositely disposed top cooking surface. One or more heater circuit assemblies are disposed on the first plate back surface for forming a composite having a back surface. A controller is in electrical connection with the heater circuit assemblies for controlling temperature of the first plate of high thermal conductivity material. The first plate can be aluminum Type 1100 or aluminum Type 6061. The first plate can be a laminate formed from a clad bottom metal layer and clad top cooking surface metal layer, where the clad layers formed from the same material and having about the same thickness. The clad material can be austenitic stainless steel. A second plate of low thermal conductivity material can be attached to the composite back surface of first plate.

Owner:EGGERS & ASSOC LLC

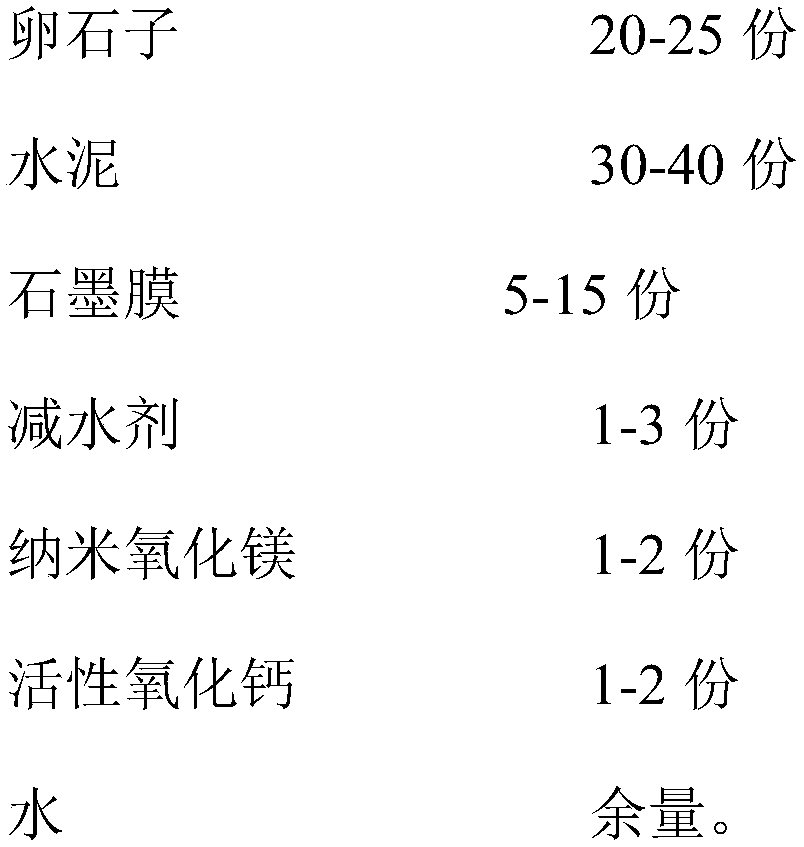

A high heat dissipation concrete material

The invention belongs to the technical field of graphite membrane application, and relates to a concrete material high in heat dissipation performance and used for the field having heat dissipation requirements such as underfloor heating and industrial pipeline. The concrete material includes, by weight, 20-25 parts of pebbles, 30-40 parts of cement, 5-15 parts of a graphite membrane, 1-3 parts of a water reducer, 1-2 parts of nanometer magnesium oxide and 1-2 parts of active calcium oxide, with the balance being water. The objective of the invention is to provide the concrete material high in heat dissipation performance. The strip-shaped, sheet or irregular-shaped graphite membrane is added into the concrete, and heat of a heat source can be rapidly dissipated on the graphite membrane, and therefore the overall heat of the concrete tends to be uniform, and temperatures of the concrete near the heat source and concrete far away from the heat source are homogenized.

Owner:SHANGHAI JIEYUAN ENVIRONMENTAL SCI & TECH

Nifuroxazide microcapsule powder and production method thereof

ActiveCN102657634BImprove solubilityImprove feedabilityAntibacterial agentsOrganic active ingredientsPolyethylene glycolSilicon dioxide

The invention discloses nifuroxazide microcapsule powder and a production method thereof. The nifuroxazide microcapsule powder is characterized by consisting of nifuroxazide, n-cyclohexylsulphamic acid, silicon dioxide micro powder and polyethylene glycol in a weight ratio of 1: (0.01-0.02): (1-3): (3-6). The production method comprises the following steps of: dissolving the n-cyclohexylsulphamicacid by using 95 percent ethanol, stirring with fine nifuroxazide powder to wet the fine nifuroxazide powder uniformly, adding the silicon dioxide micro powder to form a core material, mixing the core material and the polyethylene glycol 4000 or polyethylene glycol 6000 uniformly, performing interlayer heating at the temperature of between 75 and 80 DEG C to melt the mixture, cooling, curing, drying, crushing with airflow to form powder with the particle diameter of 90 to 100 meshes, and thus obtaining the nifuroxazide microcapsule powder. The nifuroxazide microcapsule powder is low in heat loss rate and high in flowability, has a good feeding effect, and facilitates industrialized production.

Owner:SHANGHAI E K M BIOTECH

Anti-kick far-infrared heating element installation protection structure

InactiveCN109462903APlay a protective effectIncrease the heating areaOhmic-resistance heating detailsHeating element shapesThermal insulationEngineering

The invention discloses an anti-kick far-infrared heating element installation protection structure. The far-infrared heating element installation protection structure comprises a shell and a heatingelement installed in the shell; wherein the heating element comprises a plurality of far-infrared heating tubes arranged horizontally or vertically; one side of the shell is arranged as a mesh surface, and the other side facing the mesh surface is set as a board; and the side of the board facing the mesh surface is covered with high temperature resistant thermal insulation cotton. The far-infraredheating element installation protection structure has high safety performance and good heat generation performance.

Owner:安徽金生金世电子科技有限公司

Electric heating stove

InactiveCN1313773CReduce volumeZero pollutionDomestic stoves or rangesLighting and heating apparatusElectricityTemperature control

This invention is an electro thermal kitchen range, including the heater, the temperature control block, the hollowware and the hearth. The electrical heater and the temperature control block are set in the heat-guiding oil chamber that is apt for the wall of the hollowware and filled with liquid heat-guiding oil, in the oil chamber is the stirring device; the oil chamber has the return pipe of the heat-guiding oil and the expanding port. The design of this invention is fancy, the structure is delicate. It has the strong points of high temperature, fast temperature rising, energy saving, low heat loss and noise. Because the liquid heat-guiding oil only expands but not vaporizes after being heated, so it is safe and reliable, and non environmental pollution, and the size of the hearth and oil chamber can be relatively smaller. Especially the matching hollowware surface is well-proportioned, so it will not appear partially over heating and quencher situation. This invention is not only suitable for the bittern food but also for the fried dishes. It is widely used in the cooking equipment for braising, frying, stewing, and etc.

Owner:李少平

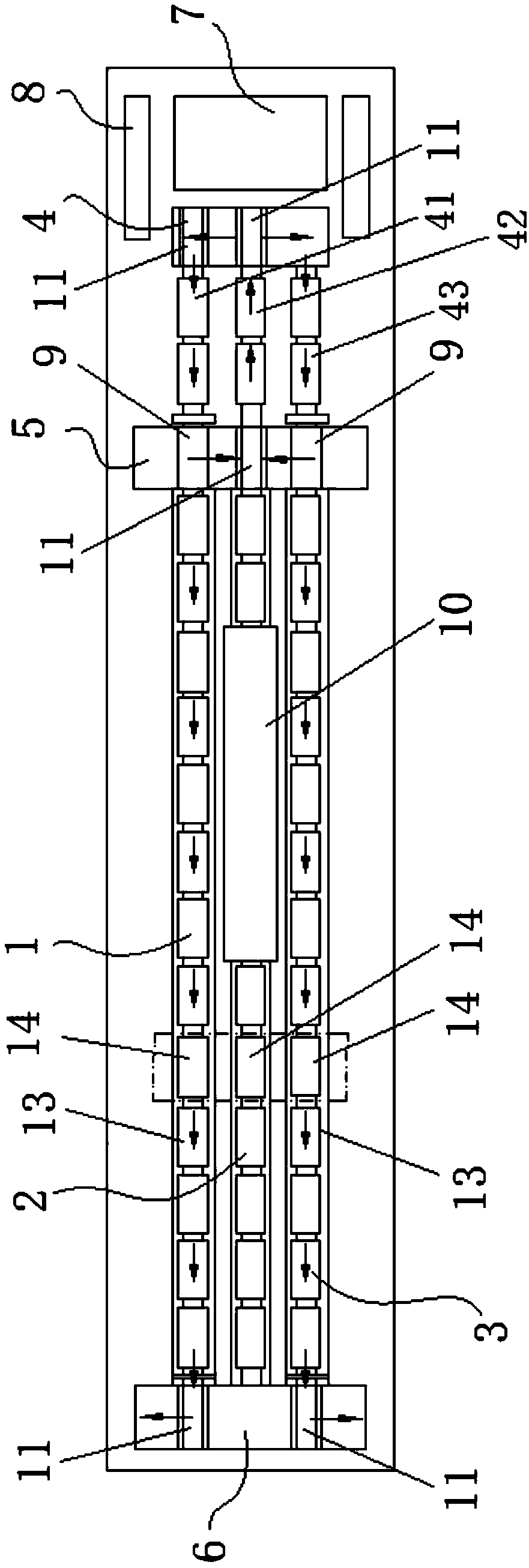

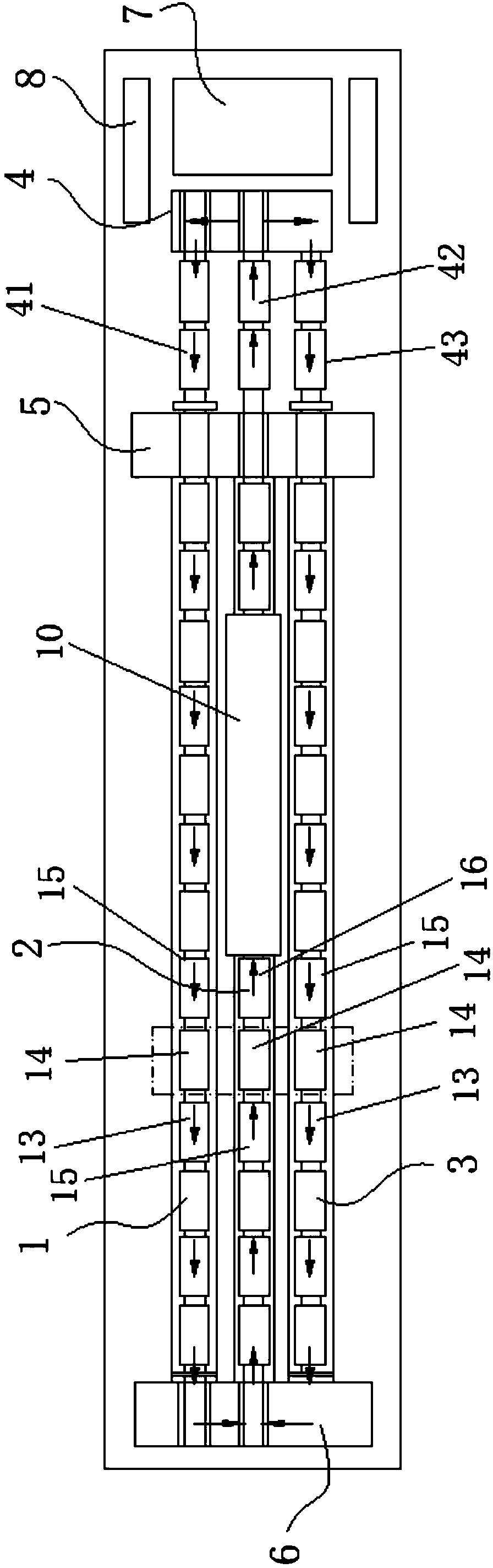

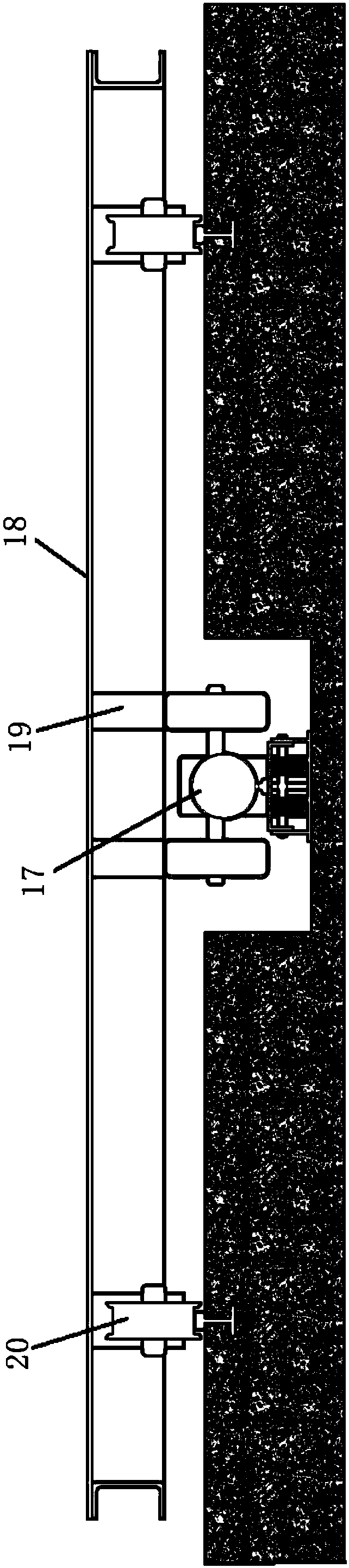

Three-dimensional production system for prefabricated components

ActiveCN105773827BReasonable useIncreased production flexibilityCeramic shaping plantsProduction lineKiln

The invention involves the production field of prefabricated components. Specifically, it is a three -dimensional production system of a prefabricated component, including the prefabricated component production area, the maintenance area of the lower layer, and the wheeled module.Moving operating area and edge model cleaning the operating area. The maintenance area has a straight -line maintenance kiln. The components are carried on the production line of the prefabricated component production area through the wheelmine platform and the straight -line maintenance kiln in the maintenance area of the maintenance area.There is a modation station crossing station, and a model platform lift and horizontal movement device is provided on the modeling station of the module ferry. The component prefabricated operating area has a special production line and production sub -line.The translation of the drive wheel module of the lifting device is connected to the production sideline.The invention has improved the prefabricated component production system in all aspects, which can achieve a variety of production methods, make production more flexible, and greatly improve production efficiency.

Owner:国新德

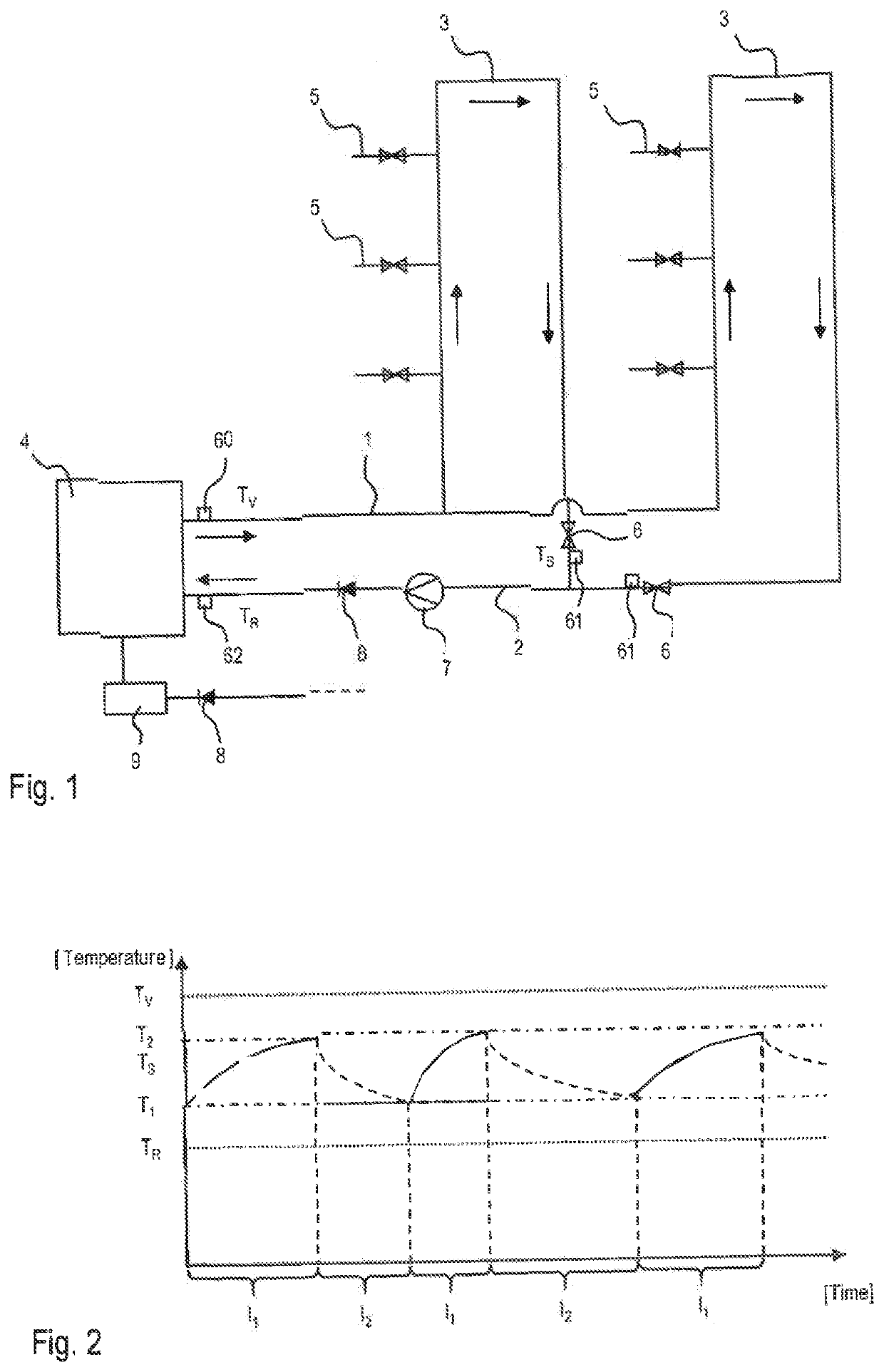

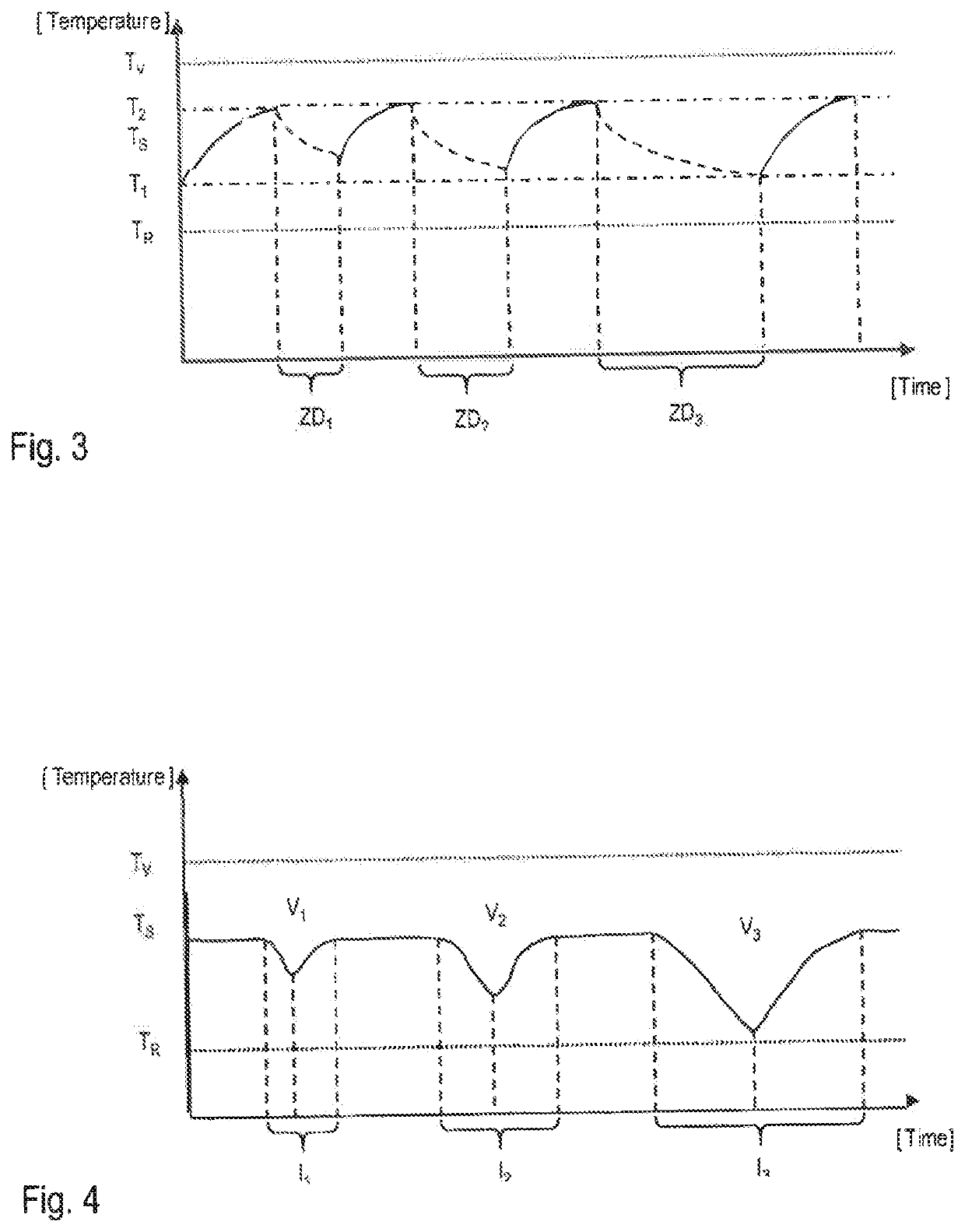

Method for operating a water circulation system

PendingUS20210270472A1More energy efficientEnergy efficiencyDomestic cooling apparatusLighting and heating apparatusWater circulationEngineering

A method for operating a water circulation system having at least one valve and at least one temperature sensor; determining a first temperature and a second temperature; determining a period of time; detecting the water temperature using at least one temperature sensor; detecting the opening time during which the at least one valve is at least partially open at least partially opening the at least one valve if the detected water temperature exceeds the value of the first temperature or if the opening time reaches the period of time; and completely closing the at least one valve if the detected water temperature reaches the value of the second temperature.

Owner:OBLAMATIK AG

Safety protection type far infrared heating element structure

InactiveCN109219173APlay a protective effectIncrease the heating areaOhmic-resistance heating detailsHeating element shapesEngineeringFar infrared

The invention discloses a safety protection type far-infrared heating element structure. The safety protection type far-infrared heating element structure comprises a shell and a heating element installed in the shell. Wherein the heating element comprises a plurality of far infrared heating tubes arranged horizontally or vertically, one side of the housing is arranged as a mesh surface, and the other side facing the mesh surface is arranged as a plate surface. The safety protection type far-infrared heating element has high safety performance and good heat generation.

Owner:安徽金生金世电子科技有限公司

Automatic push steel into furnace control system and method for push steel walking heating furnace

The invention discloses a control system and method for automatically pushing steel into the furnace of a pushing steel-type walking heating furnace. The method is as follows: after the billet is centered at the billet waiting position, wait for the steel to be pushed; if the walking beam is in the lower position, and When the vacancy in the furnace satisfies the steel pushing distance, a furnace door opening prompt is issued; the furnace door is opened to a high position based on the furnace door opening finger, and a steel pushing prompt is issued based on the position signal of the furnace door opening; the steel pushing machine in the working waiting position is based on the steel pushing command Push the billet forward, and push the billet on the conveying roller table to the fixed beam in the furnace; after the pusher reaches the target position, send a reset command to the pusher, and the pusher returns to the working waiting position; After reaching the working waiting position, a furnace door closing prompt is issued, and the furnace door performs a closing action based on the furnace door closing command until the furnace door is completely closed. The furnace door is only open when the steel is pushed into the furnace, and it is closed at other times, which greatly reduces the heat loss.

Owner:新余钢铁股份有限公司

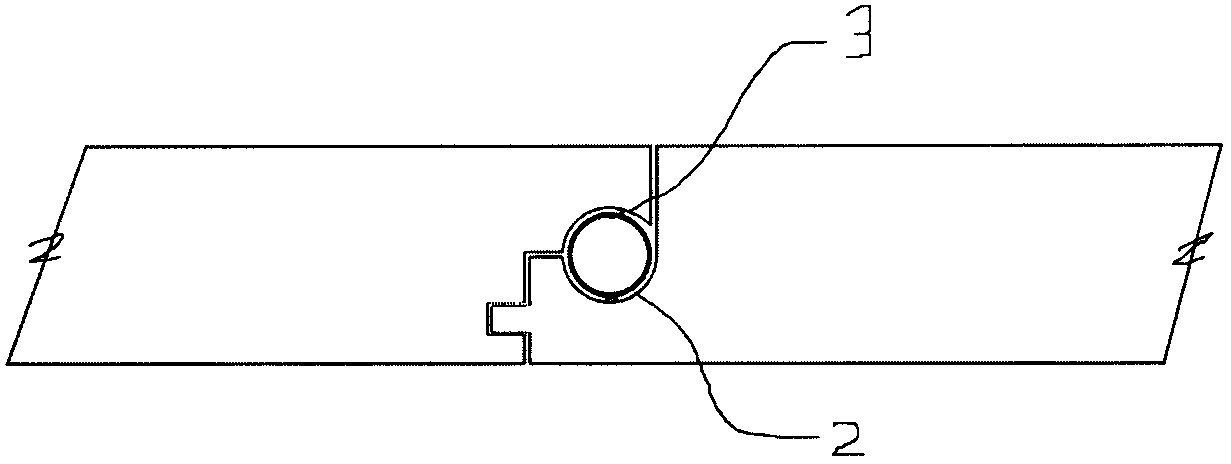

Functional floor board with embedded cooling and heating pipe

InactiveCN103774823ALow heat lossEasy to installFlooring insulationsEngineeringMechanical engineering

Disclosed is a functional floor board with an embedded cooling and heating pipe. The functional floor board with the embedded cooling and heating pipe comprises a floor board body, an accommodating cavity and a floor heating pipe. The accommodating cavity is arranged on the side edge of the floor board body, the upper portion of one side edge end of the floor board body is protruded, and the bottom of the side edge end of the floor board body is provided with a longitudinal groove; the bottom of the other side edge end of the floor board body is protruded and is provided with a longitudinal groove; the longitudinal grooves correspond to each other vertically to form an integrated accommodating cavity; a one-side notch which is arranged inside a neighboring floor board defines a longitudinal snapping groove, and the floor heating pipe is horizontally arranged inside the longitudinal snapping groove. When one floor board is matched with the groove of a neighboring floor board on one side, the two neighboring floor boards form the internal accommodating cavity, the floor heating pipe is accommodated inside the internal accommodating cavity, so that the floor boards and the floor heating pipe are connected into a whole, further a floor heating function and a floor board function are integrated together, heat can be transferred to the floor boards directly through the floor heating pipes and energy losses of floor cooling and heating can be reduced.

Owner:郭兆军

Graphite thin film with heat collecting function

InactiveCN109000380AImprove absorption rateEasy to processSolar heating energyCarbon compoundsHeat conductingGraphite

The invention discloses a graphite thin film with a heat collecting function, and relates to the technical field of new graphite materials. The graphite thin film comprises the following raw materialsof, by weight, 80-90 parts of expansion graphite, 5-10 parts of boron nitride and 5-10 parts of silicon carbide. The graphite thin film is formed by the three raw materials which are evenly mixed andthen pressed. The graphite thin film with the heat collecting function can directly serve as a heat absorbing plate to be applied to a solar device and can directly make contact with a heat absorbingmedium, the heat loss is reduced, the heat conducting efficiency is reinforced, the complex machining process of a traditional heat absorbing plate is simplified, and the environmental pollution problem brought in the spraying process of the traditional heat absorbing plate is avoided; and compared with the traditional heat absorbing plate or heat absorbing coating, the heat energy absorption rate is increased, and the heat loss rate is decreased.

Owner:山西臣功新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com