Method for operating a water circulation system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

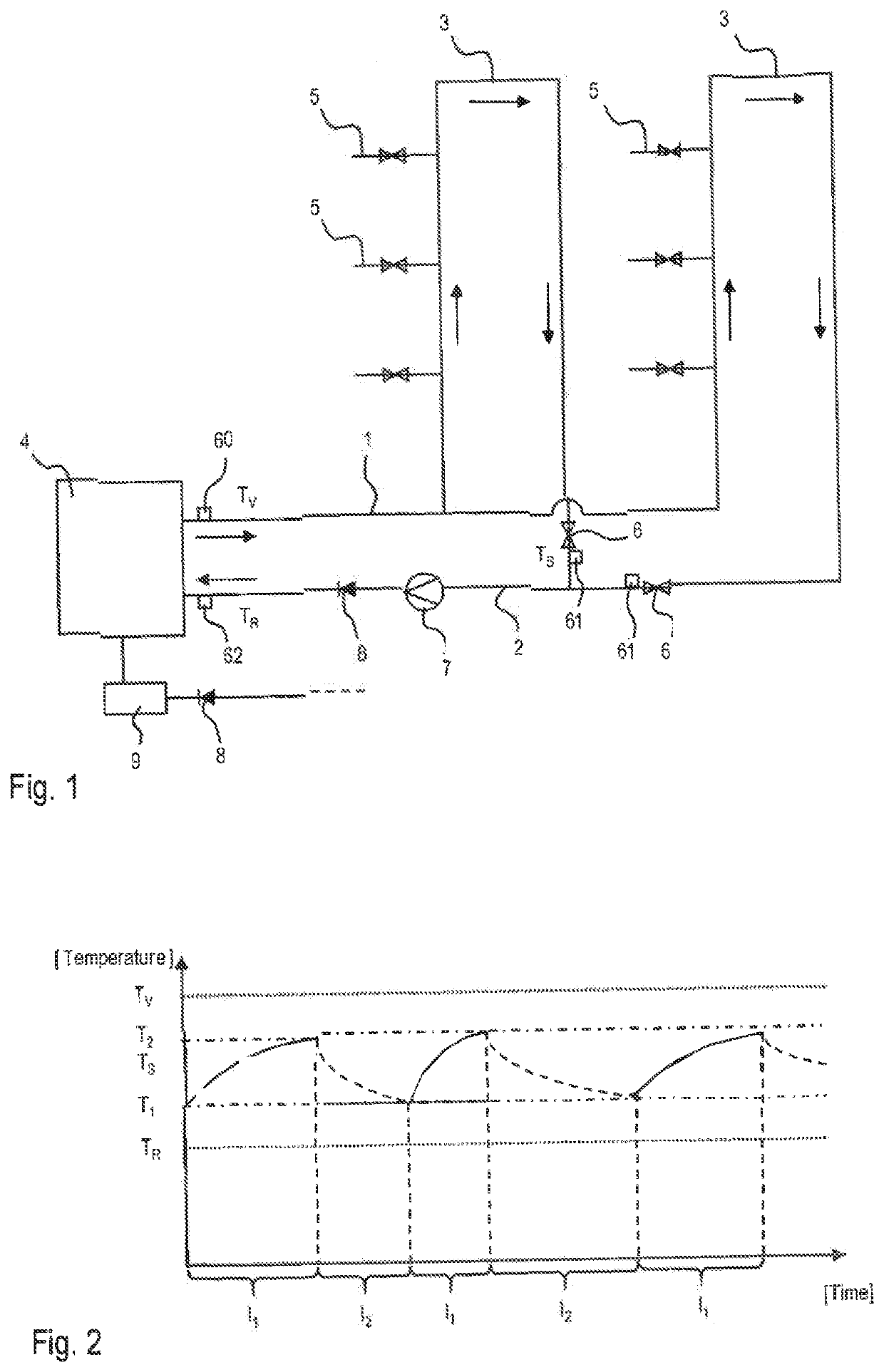

[0068]FIG. 1 shows a schematic representation of a water circulation system for carrying out the method according to the invention. The system comprises a supply line 1, a return line 2, two strand 3 which connect the supply line 1 to the return line 2. The system further comprises a temperature control unit 4, which connects the supply line 1 with the return line 2, whereby in one flow direction, water can circulate from the supply line 1, via the two strands 3, the return line 2 and the temperature control unit 4 back to the supply line 1. The system further comprises several consumers 5, which are arranged along the strand 3 and with which water can be drawn from the circulation system. In each strand 3, a valve 6 is provided, which is arranged in the region of the strand 3 which opens into the return line 2. I.e. the valve 6 is arranged in the region of the end of the strand 3. With each valve 6, the flow rate of the water in the respective strand can be changed. In the supply l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com