Floor with internal heat-conducting structure

A heat-conducting, flooring technology, applied in the field of flooring, can solve the problems of not saving space, high heat loss rate, and large floor thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

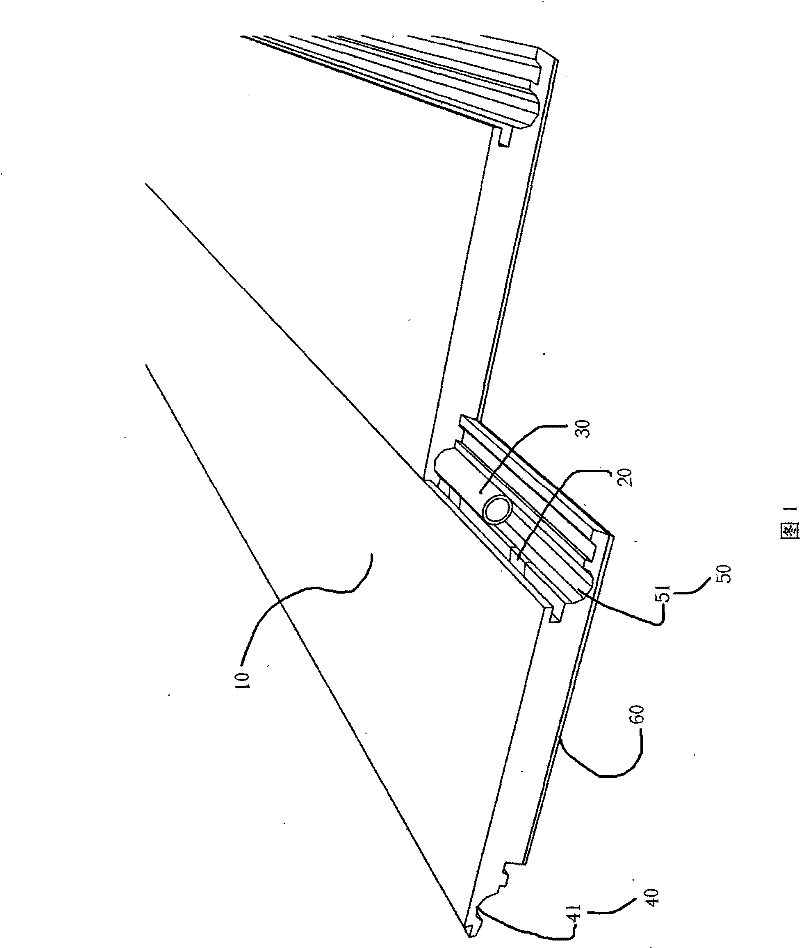

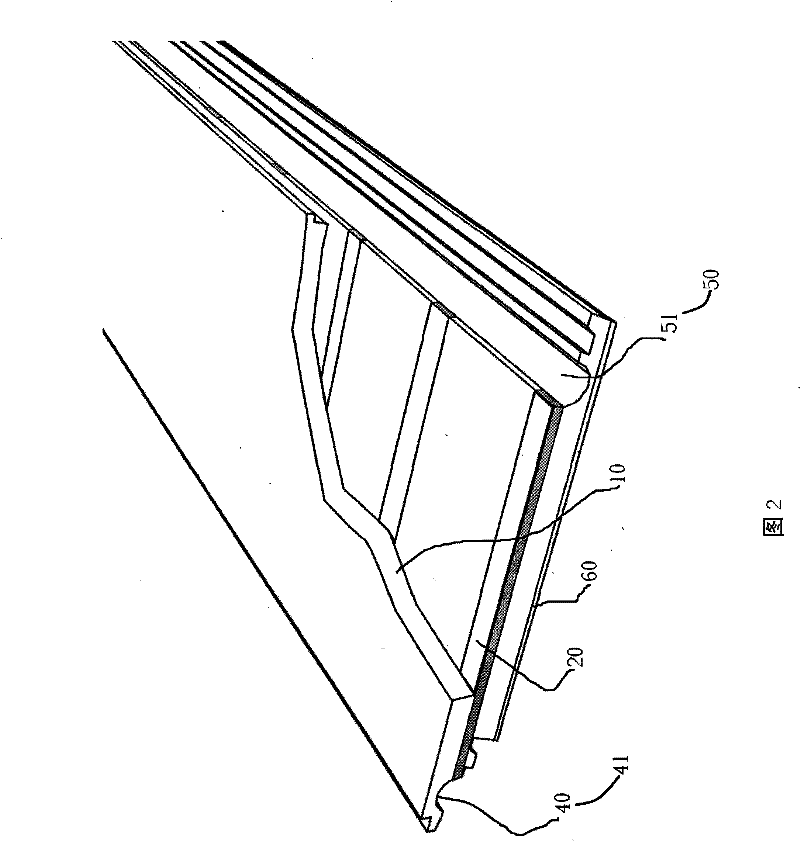

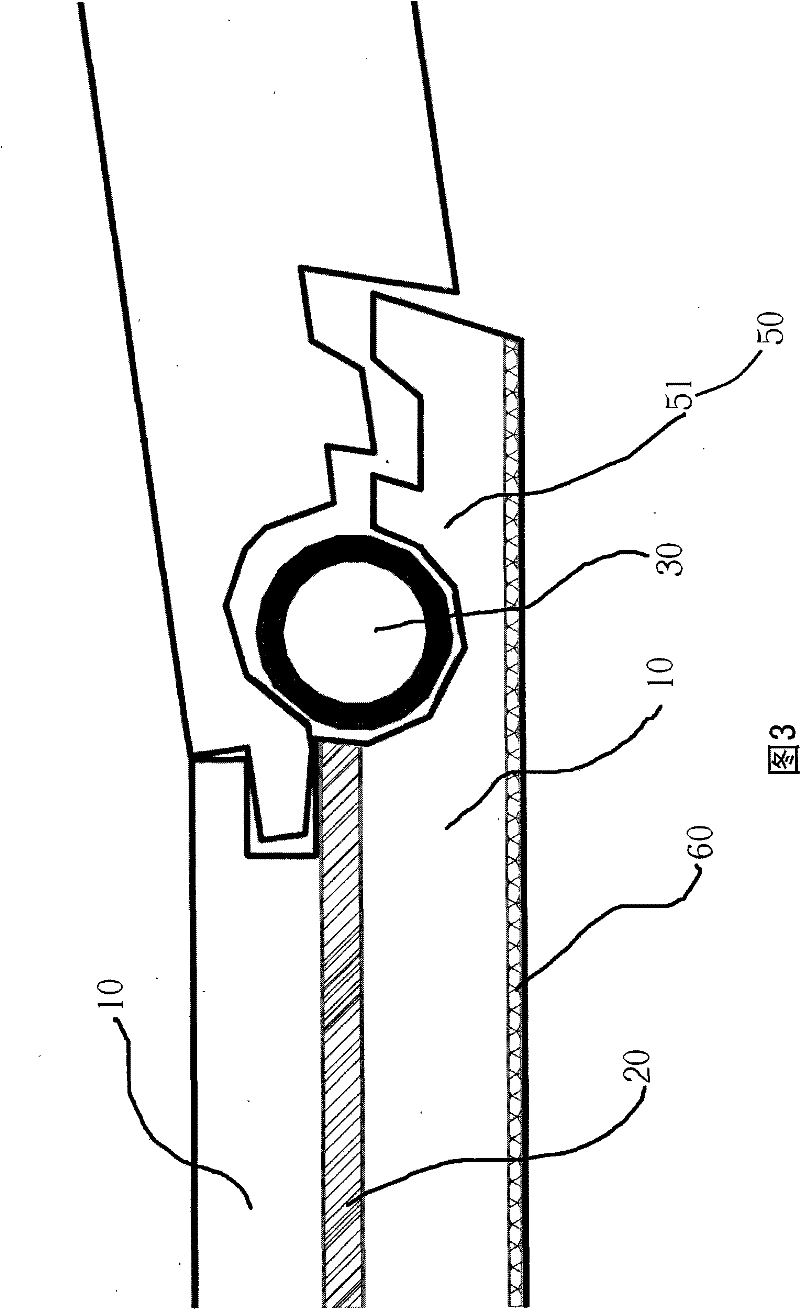

[0022] As shown in Figures 1 to 3, a preferred embodiment of a floor with an internal heat conduction structure is illustrated. The floor includes a floor body 10 , a plurality of heat-conducting medium objects 20 , a floor heating pipe 30 , an upper locking member 40 and a lower locking member 50 .

[0023] Each of the heat-conducting medium objects 20 is located laterally inside the floor body 10, and one end of each of the heat-conducting medium objects 20 is in contact with the floor heating pipe 30, so that the heat in the floor heating pipe 30 is directly Conduction and rapid distribution to various positions of the floor, avoiding the loss of the heat.

[0024] The upper locking member 40 is located on one side of the floor body 10, defining an upwardly convex upper support chamber 41, and the lower locking member 50 is located on the other side of the floor body 10, defining a A concave lower support cavity 51, wherein the floor heating pipe 30 is horizontally placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com