Functional floor board with embedded cooling and heating pipe

A functional and flooring technology, applied to floors, insulation layers, buildings, etc., can solve the problems of large amount of materials and high energy loss rate in the gap between conductive media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

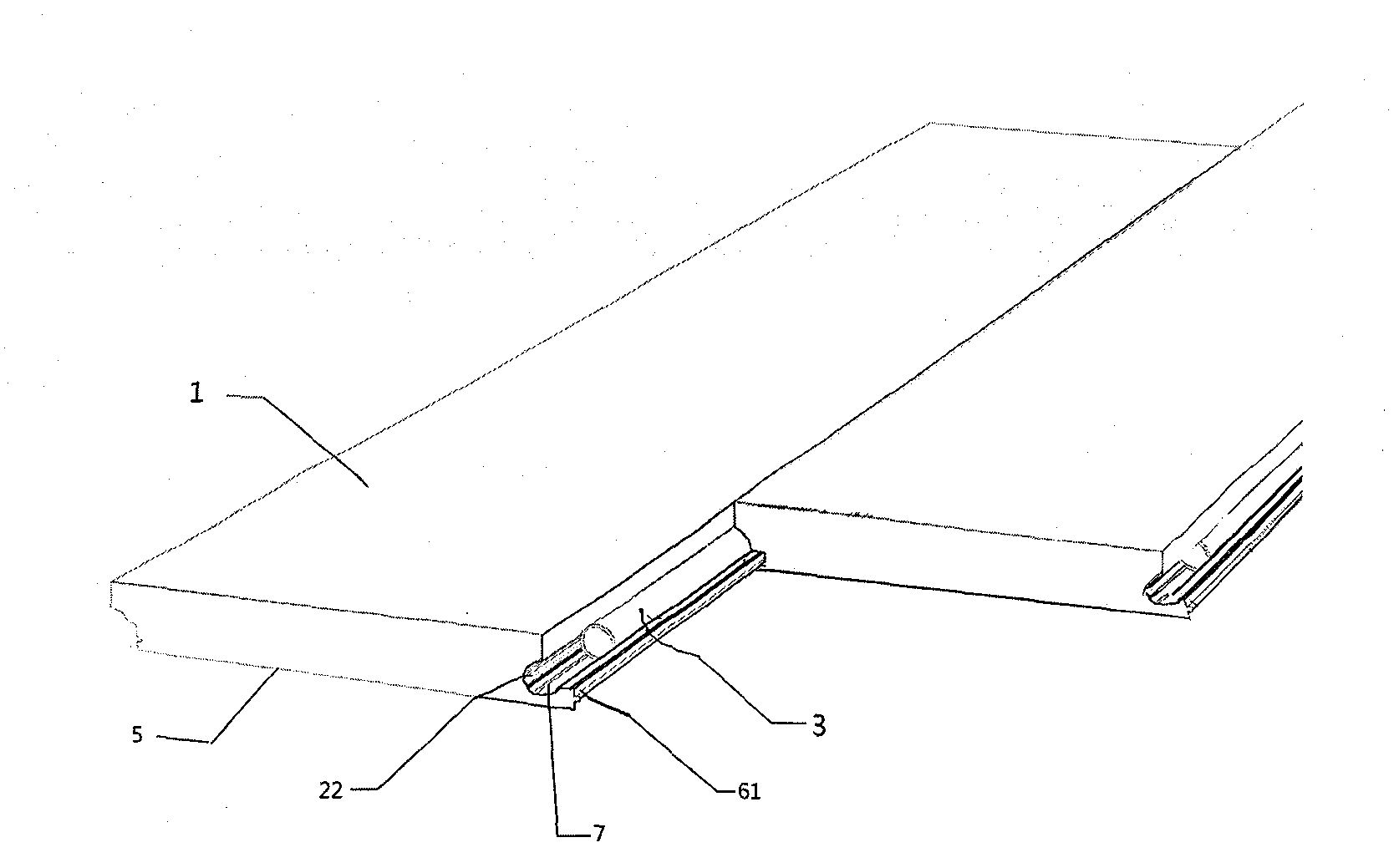

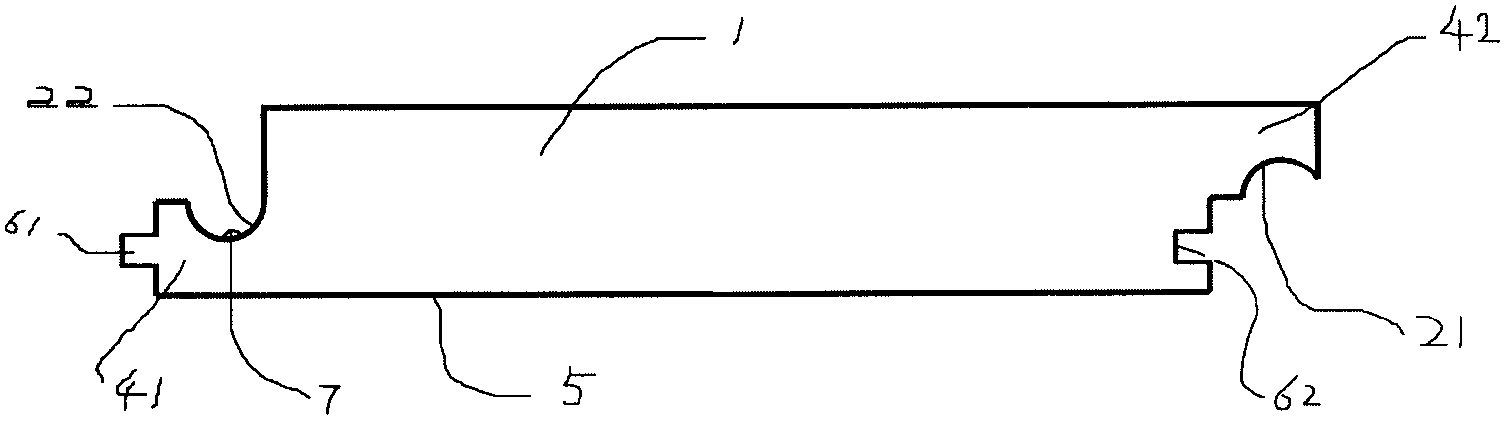

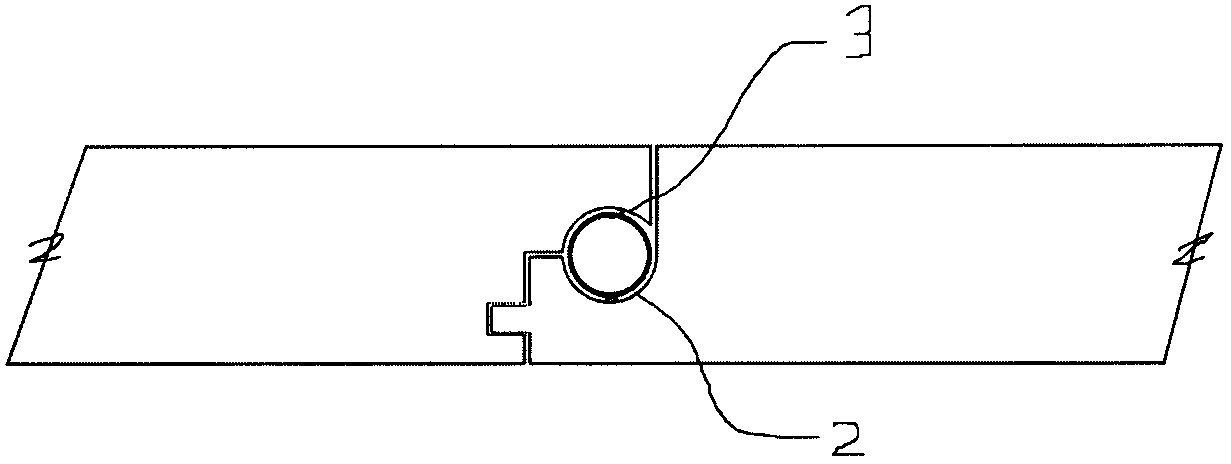

[0021] Such as Figures 1 to 2 As shown, a preferred embodiment of a functional floor with built-in heating and cooling pipelines is described. The floor includes a body 1, a groove 21 on the side of the floor body, a groove 22 under the floor body, and the upper and lower grooves to form an accommodating chamber 2, a floor heating pipe 3, a protrusion 41 on the side of the floor body, a The lower protrusion 42 on the side of the floor body, a heat insulation layer 5 of the floor body, tenon edges 61 and 64 of the floor body, groove edges 62 and 63 of the floor body, and vertical ribs 7 of the lower groove of the floor body.

[0022] The functional floor accommodating cavity 2 embedded with heating and cooling pipes is in contact with the floor heating pipe 3, so that the energy in the floor heating pipe 30 is directly conducted and quickly distributed to various positions of the floor. This installation method It avoids laying pipes in the ground, saves a lot of labor costs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com