Graphite thin film with heat collecting function

A technology of graphite and thin film, applied in the field of graphite thin film with heat collection function, can solve the problems of manpower consumption, serious heat loss, environmental pollution during the process, etc., so as to reduce heat loss, improve heat energy absorption rate, and avoid environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take by weighing expanded graphite 80kg, boron nitride 8kg, silicon carbide 10kg, wherein, expanded graphite is 300 orders, after above-mentioned three kinds of raw materials are mixed uniformly, be made into film shape through mechanical pressing, make graphite thin film.

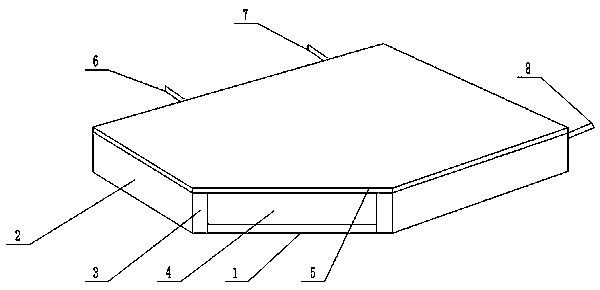

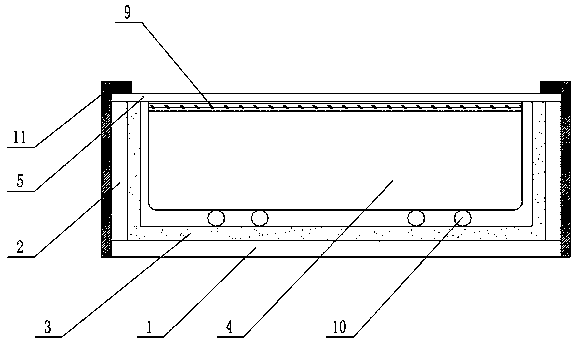

[0021] The above-mentioned graphite thin film is applied in the solar heat collecting device, such as Figure 1-2 As shown, it includes a base plate 1, an insulation layer 3, a side plate 2, an inner tank 4, and a transparent cover plate 5. Two U-shaped support frames 10 are fixed on the base plate 1, and the base plate 1 and the side plate 2 are connected and fixed to form a groove. , the inner wall of the groove is provided with a thermal insulation layer 3 made of ceramic fiber material, and an inner tank 4 is fixed on the support frame 10. The upward surface of the inner tank 4 is a high thermal conductivity graphite film 9, and the side and bottom surface of the inner tank 4 are made of stainles...

Embodiment 2

[0023] Take by weighing: expanded graphite 85kg, boron nitride 8kg, silicon carbide 8kg, wherein, expanded graphite is 400 mesh, after above-mentioned three kinds of raw materials are mixed uniformly, through mechanical pressing into film shape, make graphite film.

Embodiment 3

[0025] Take by weighing: expanded graphite 90kg, boron nitride 5kg, silicon carbide 5kg, graphene 20kg, wherein, expanded graphite is 350 mesh, after above-mentioned three kinds of raw materials are mixed uniformly, through mechanical pressing into film shape, make graphite film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com