Energy-saving environmentally friendly civil boiler

It is an energy-saving, environmental-friendly and civilian-use technology, which is applied in household stoves/stoves, applications, and household heating. It can solve the problems of resource waste, large heat loss, and single function, so as to meet the needs of use, reduce heat loss rate, and reduce pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

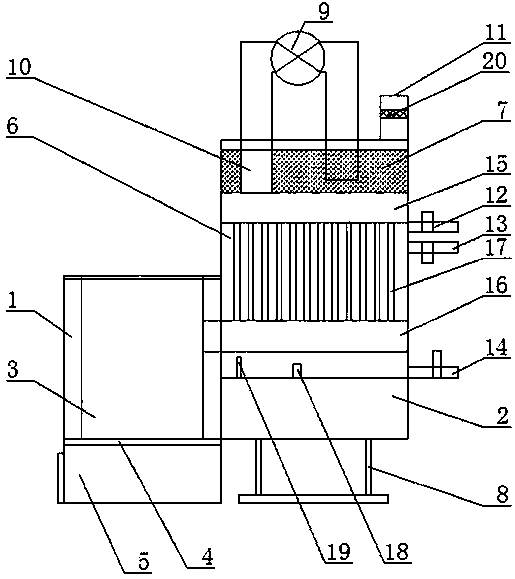

[0018] Such as figure 1 As shown, an energy-saving and environment-friendly civil boiler comprises a left furnace body 1 and a right furnace body 2, the left furnace body 1 is a combustion furnace; the right furnace body 2 is a heat exchange filter furnace; the left furnace body 1 and The right furnace body 2 is connected by a pyrotechnic pipe; the middle of the left furnace body 1 is equipped with a combustion chamber 3, and the bottom end of the combustion chamber 3 is equipped with a fire grate; the lower end of the fire grate 4 is an ash chamber 5; the right furnace The middle end of the body 2 is equipped with a heat exchange chamber 6, the upper end of the interior is equipped with a filter chamber 7, and the bottom end of the right furnace body 2 is supported by a support base 8; The smoke exhaust pipe 10 is connected, and the right end pipe body of the smoke exhaust pipe 10 is inserted into the inside of the filter chamber 7; a smoke discharge pipe 11 is installed on t...

Embodiment 2

[0020] Such as figure 1 As shown, the heat exchange chamber 6 is equipped with an upper smoke pipe 15, a lower smoke pipe 16, and a plurality of heat exchange tubes 17; the lower smoke pipe 16 is connected to the upper smoke pipe 15 through a plurality of heat exchange tubes 17 ; The upper end of the upper part of the smoke pipe 15 is connected to the smoke exhaust pipe 10 .

Embodiment 3

[0022] Such as figure 1 Shown, described filter chamber 7 internal installation alkaline water ponds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com