Premixed polyether, anti-ageing full-water type foam board and preparation method of anti-ageing full-water type foam board

A technology of combining polyether and sheet, applied in the field of combined polyether, can solve the problems of endangering human life, a large amount of toxic gas, immaturity, etc., and achieve the effects of good structural symmetry, improved skeleton strength, and good flame retardant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

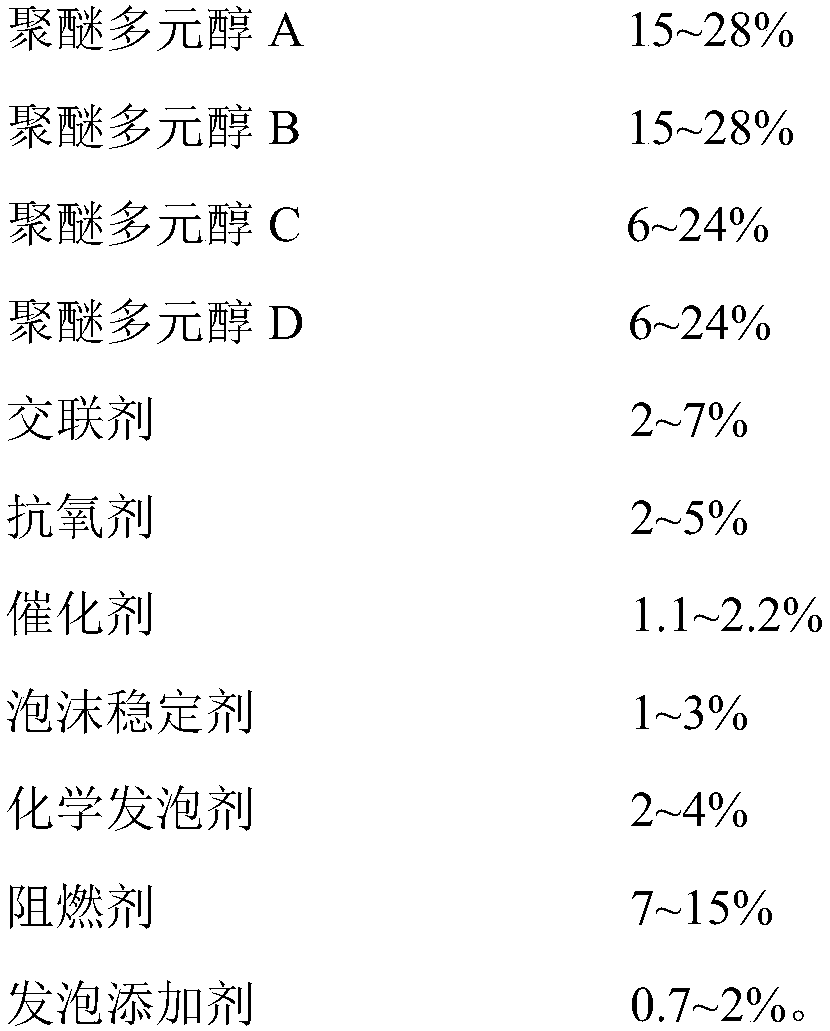

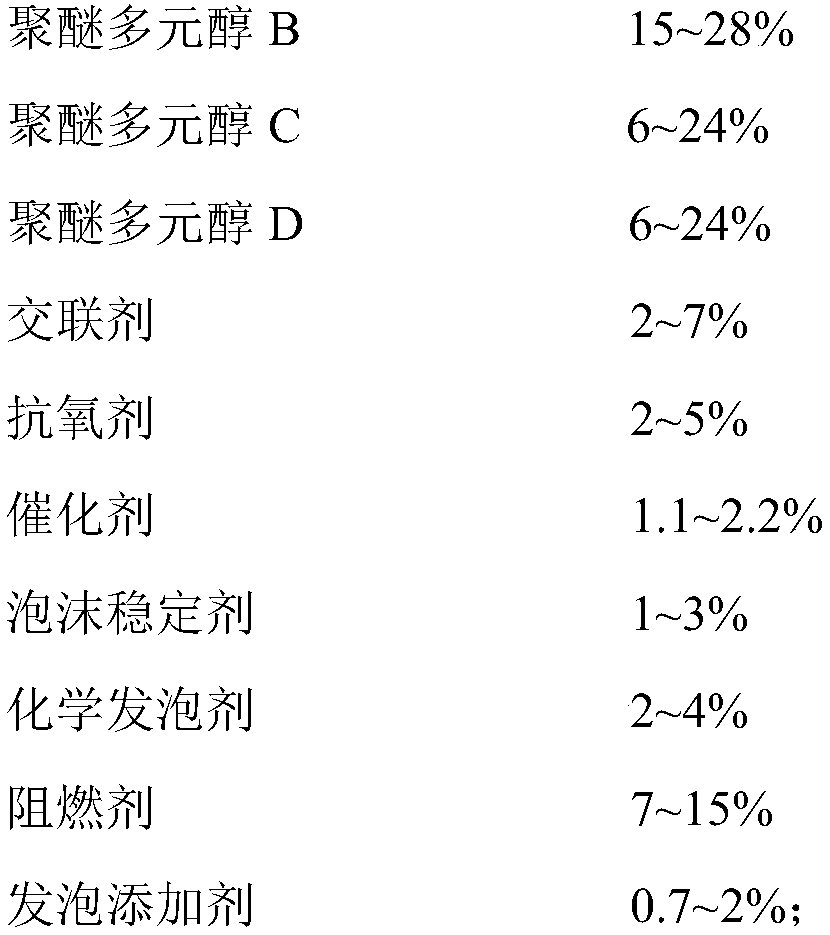

Method used

Image

Examples

Embodiment 1

[0038] (1) Prepare the premix, weigh polyether polyol A: TAE305 (Shanghai Gaoqiao Petrochemical): 40kg; polyether polyol B: GX9103 (Cardolite): 40kg; crosslinking agent: THPO (Hubei Xingfa Chemical Industry Co., Ltd. Group Corporation): 10kg; Antioxidant: Chinox 35 (Taiwan Double Bond): 5kg; Catalyst: dimethylaminopropylamine diisopropanol (Handels NP10) 0.6kg, tetramethyldipropylenetri Amine (Air Chemical PC15) 2kg; Foam stabilizer: AK8805 (Mesid): 2kg; Chemical blowing agent: Water: 3.4kg; Polyether polyol C: R370S (Shandong Yinuowei New Material Co., Ltd.): 10kg ; Polyether polyol D: R8336 (Shandong Yinuowei New Material Co., Ltd.): 10kg; sequentially added to the reaction kettle, stirred at room temperature for 0.5 hours, fully mixed and loaded into barrels to obtain a premix. At the same time, weigh the flame retardant: Exflam201 (Quzhou Jiajie Auxiliary Company): 20kg; foaming additive: FA188 (3M Company): 1.3kg; add the flame retardant and foaming additive to the premix...

Embodiment 2

[0042](1) Prepare the premix, weigh polyether polyol A: 466H (Shanghai Gaoqiao Petrochemical): 20kg; polyether polyol B: GX91001LV (Cardolite): 20kg; crosslinking agent: THPO (Hubei Xingfa Chemical Group Corporation): 3kg; Antioxidant: Chinox 35 (Taiwan Double Bond): 5kg; Catalyst: dimethylaminopropylamine diisopropanol (Handels NP10) 1kg, tetramethyldipropylenetriamine (Air Chemicals PC15) 0.4kg; Foam stabilizer: AK8805 (Meister): 3kg; Chemical foaming agent: Water: 4.2kg; Polyether polyol C: R370S (Shandong Yinuowei New Material Co., Ltd.): 30kg ; Polyether polyol D: R8336 (Shandong Yinuowei New Material Co., Ltd.): 30kg; sequentially added to the reaction kettle, stirred at room temperature for 0.5 hours, fully mixed and loaded into barrels to obtain a premix. At the same time, weigh the flame retardant: Exflam204 (Quzhou Jiajie Auxiliary Company): 10kg; foaming additive: FA188 (3M): 1.8kg; add the flame retardant and foaming additive to the premix before using the combined...

Embodiment 3

[0046] (1) Prepare the premix, weigh polyether polyol A: 466H (Shanghai Gaoqiao Petrochemical): 20kg; polyether polyol B: GX91001LV (Cardolite): 40kg; crosslinking agent: THPO (Hubei Xingfa Chemical Group Corporation): 5kg; Antioxidant: Chinox 35 (Taiwan Double Bond): 6kg; Catalyst: dimethylaminopropylamine diisopropanol (Handels NP10) 0.6kg, tetramethyldipropylenetri Amine (Air Chemical PC15) 0.6kg; Foam stabilizer: AK8805 (Mesid): 3.5kg; Chemical blowing agent: Water: 4.3kg; Polyether polyol C: R370S (Shandong Yinuowei New Material Co., Ltd.) : 20kg; polyether polyol D: R8336 (Shandong Yinuowei New Material Co., Ltd.): 20kg; sequentially added to the reaction kettle, stirred at room temperature for 0.5 hours, fully mixed and loaded into barrels to obtain a premix. At the same time, weigh the flame retardant: Exflam204 (Quzhou Jiajie Auxiliary Company): 13kg; foaming additive: FA188 (3M): 2.1kg; add the flame retardant and foaming additive to the premix before using the combi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com