Pyroelectric infrared detector and preparation method thereof

A pyroelectric infrared and detector technology, which is applied in the field of infrared detection, can solve the problems of serious heat loss, insufficient material strength, and difficult thickness, and achieves the effects of strong influence ability, high material strength, and light heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

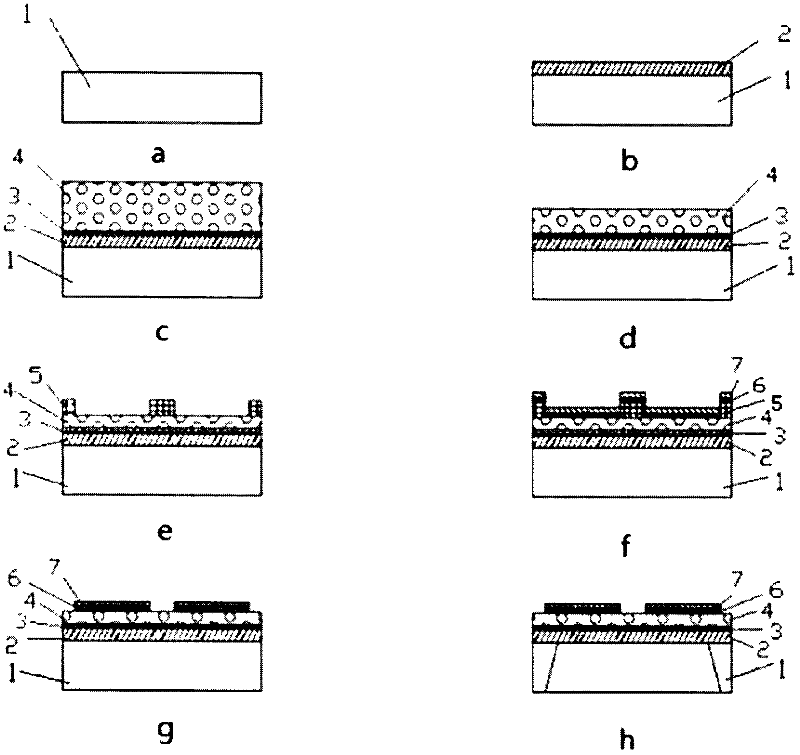

[0024] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

[0025] The invention discloses a pyroelectric infrared detector based on wafer bonding technology and a preparation method thereof. The bonding technology refers to a method of closely bonding two wafers that have been surface-treated to a certain degree of cleanliness and flatness without adding any adhesive. The main advantage of the wafer bonding technology is to overcome the interface defects, elastic stress and dislocation diffusion of the wafer during the growth process caused by the large thermal expansion coefficient difference and the large lattice coefficient mismatch difference to the whole material, so that different The materials stick together while preserving the integrity of the original wafer.

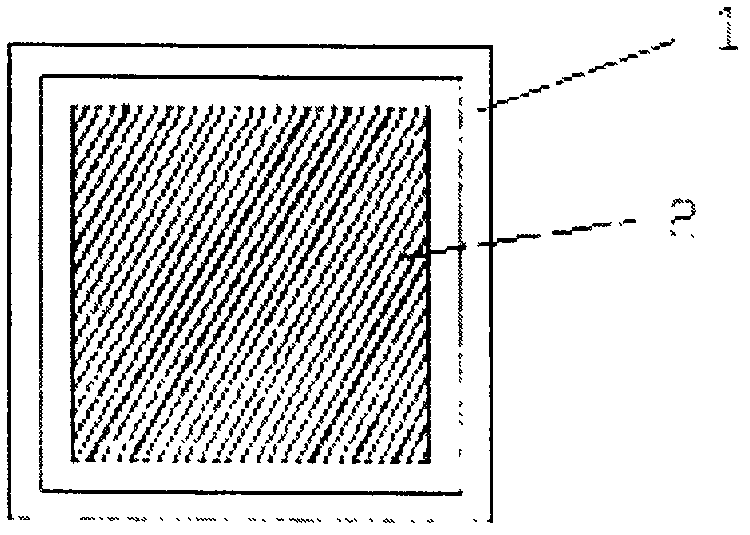

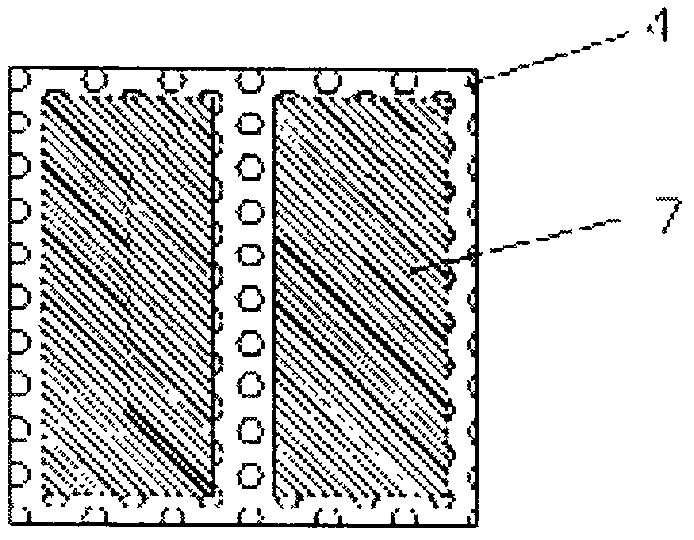

[0026] figure 1 It i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com