A high heat dissipation concrete material

A technology of concrete and high heat dissipation, which is applied in the application field of graphite film, which can solve the problems of high cost of heat-conducting concrete, high heat loss rate, and rapid heat dissipation, so as to improve heat dissipation effect and use intensity, reduce production cost, and reduce heat loss rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

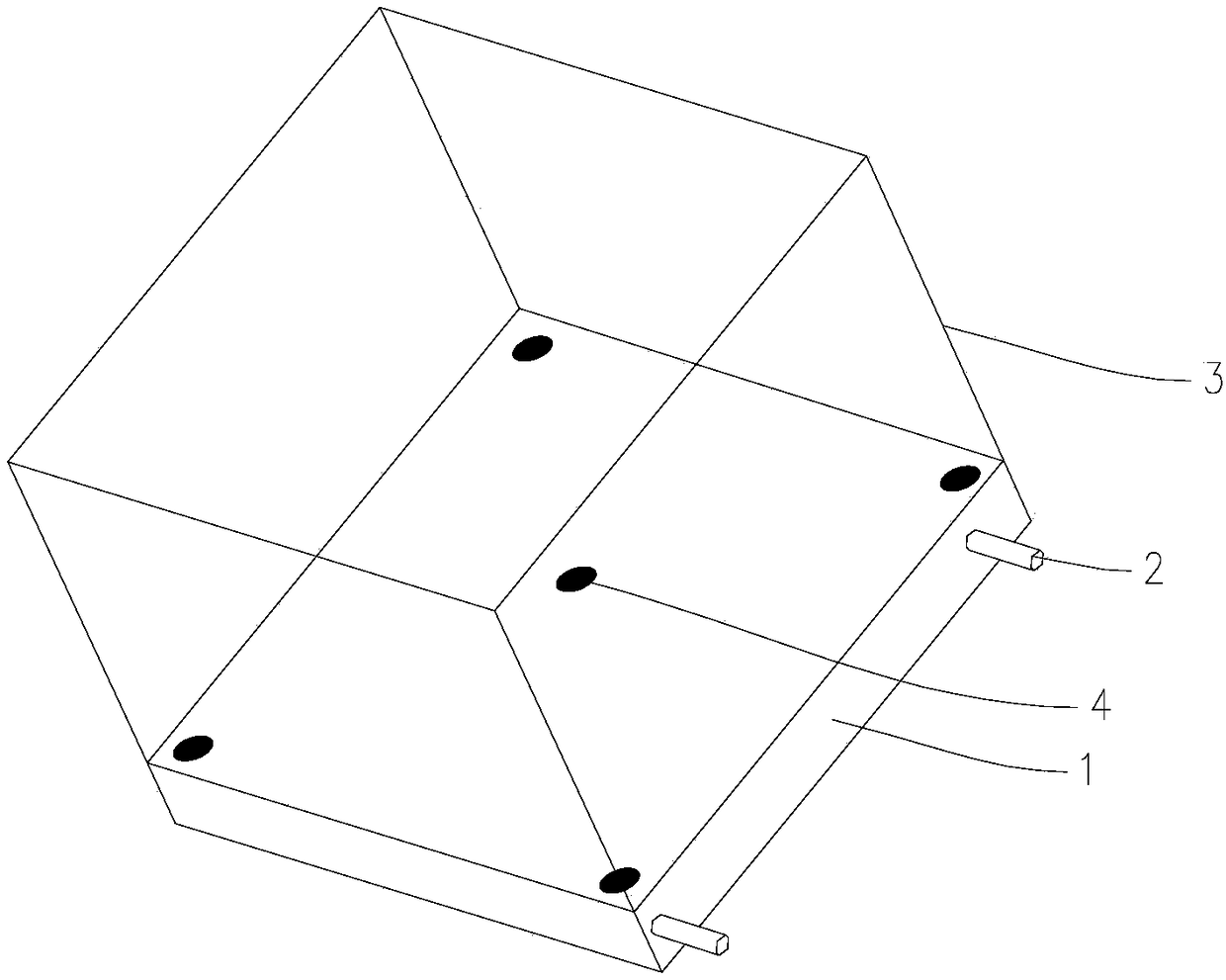

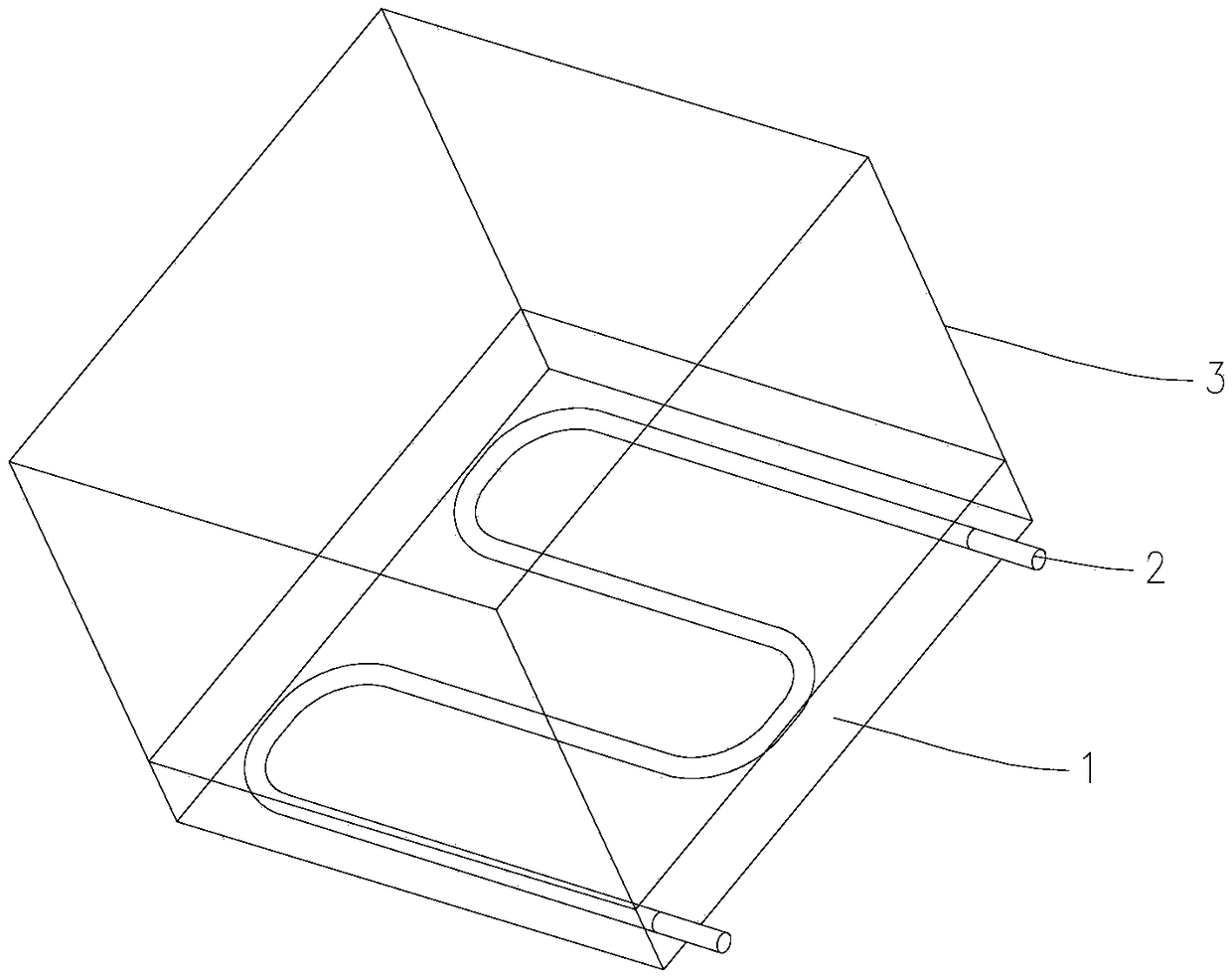

Image

Examples

Embodiment 1

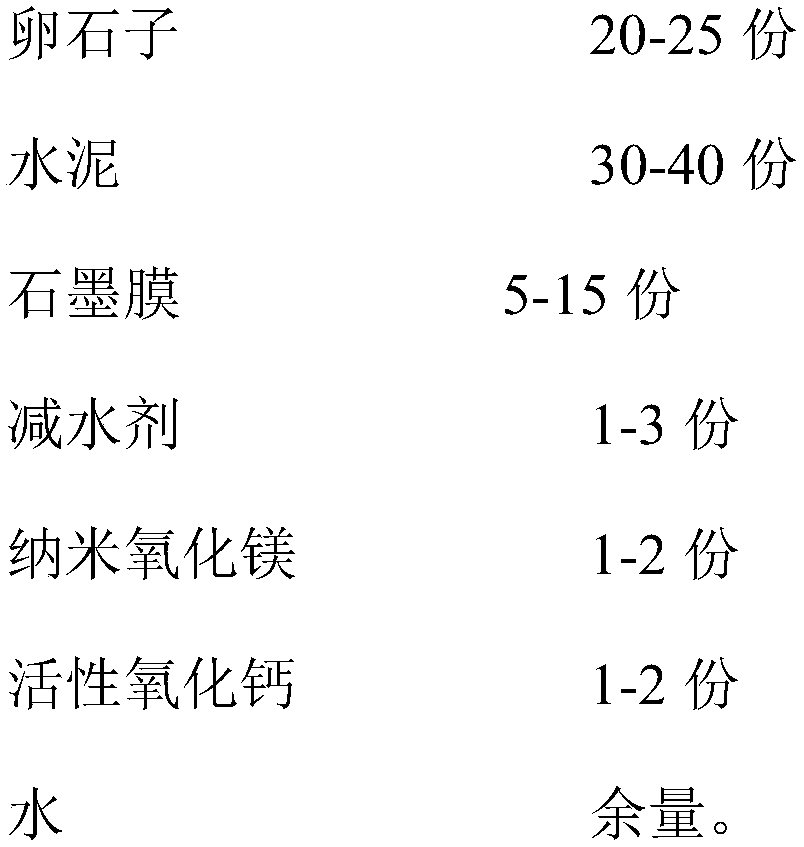

[0024] A high heat dissipation concrete material, comprising the following components, each component is by weight:

[0025]

[0026] Among them, the activated calcium oxide is prepared by calcination of limestone, the particle size of limestone is 80 μm, the temperature of calcination is 960° C., and the time of calcination is 40 minutes.

Embodiment 2-6

[0027] Embodiment 2-6, other conditions are the same as embodiment 1, difference is in table 1.

[0028] Table 1:

[0029]

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com