Electric heating stove

An electric heating pot and stove technology, applied in the field of stoves or stoves, can solve the problems of large heat loss, overheating, and high energy consumption cost, and achieve the effects of small heat loss, fast heating and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

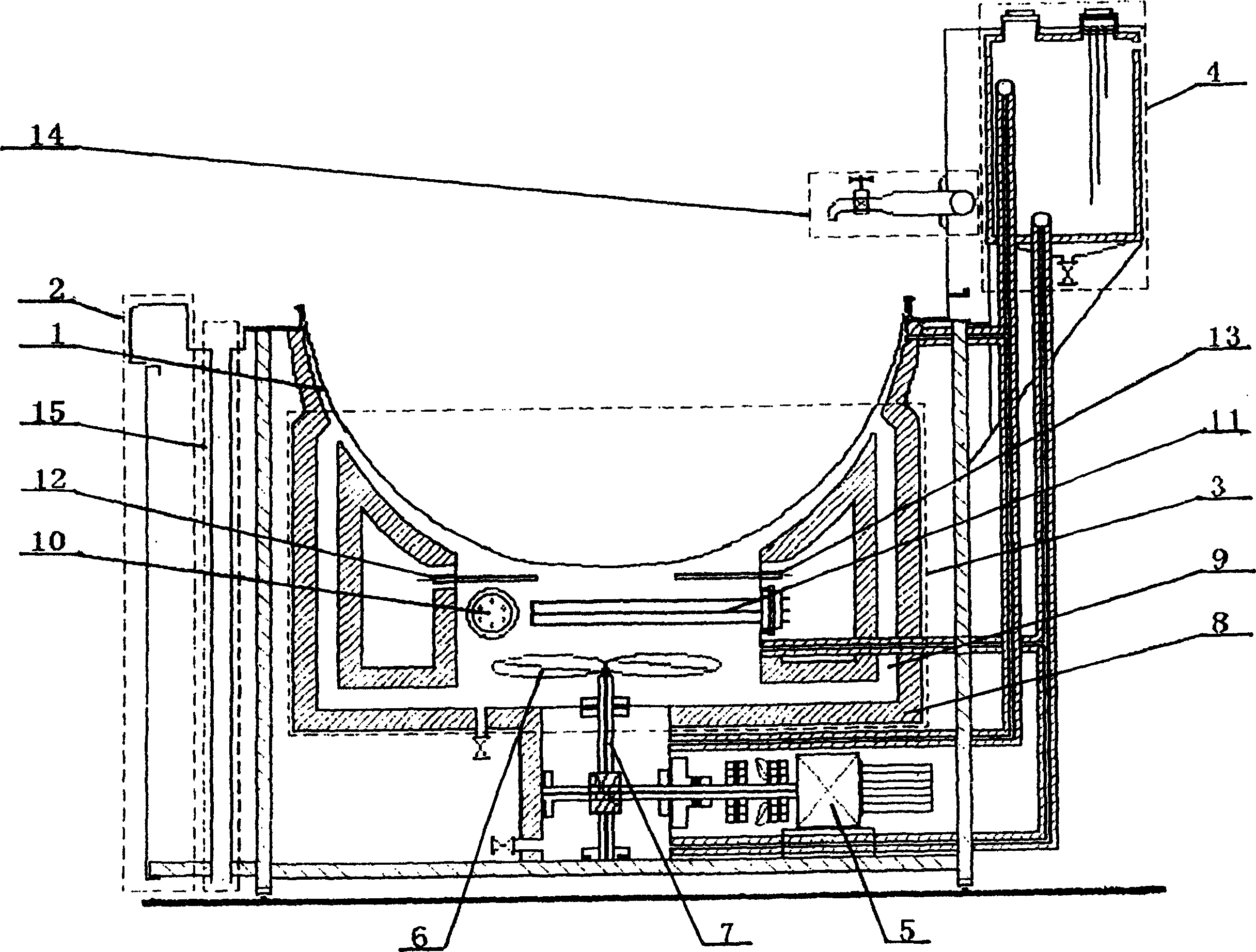

[0017] The present invention will be described below in combination with specific embodiments and with reference to the accompanying drawings.

[0018] The electric heating cooker for restaurants of the present invention comprises an electric heating element, a temperature control assembly, a spherical pot body 1 with a diameter of 80 cm, and a fixed stove 2, the stove 2 is placed on the periphery of the pot body 1, and the temperature The control assembly is adjacent to the electric heating element.

[0019] The cooker also includes a liquid heat conduction oil chamber 3 filled with liquid heat conduction oil, which is placed in the cooktop 2 and fits closely with the spherical pot body 1 to indirectly heat the pot body 1 . Both the electric heating element and the temperature control assembly are arranged in the liquid heat transfer oil cavity 3 .

[0020] The liquid heat transfer oil chamber 3 communicates with the high-level oil supply tank 4 (or oil supply pump), and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com