Method for preparing steel smelting furnace materials from phosphorus-containing globulitic hematite

A technology of oolitic hematite and steelmaking furnace, which is applied in the field of utilization of phosphorus-containing oolitic hematite, can solve the problems of difficulty in phosphorus content in iron concentrate, poor dephosphorization effect, and large environmental pollution, and achieve metallization The effect of increasing the yield, improving the iron recovery rate, and reducing the content of harmful impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

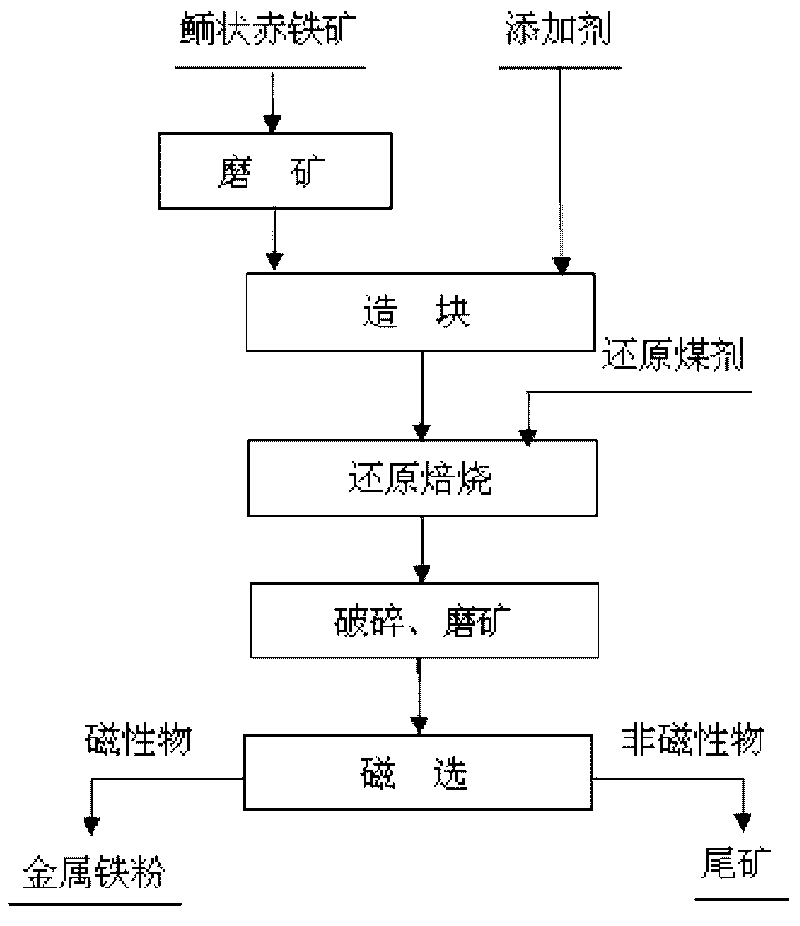

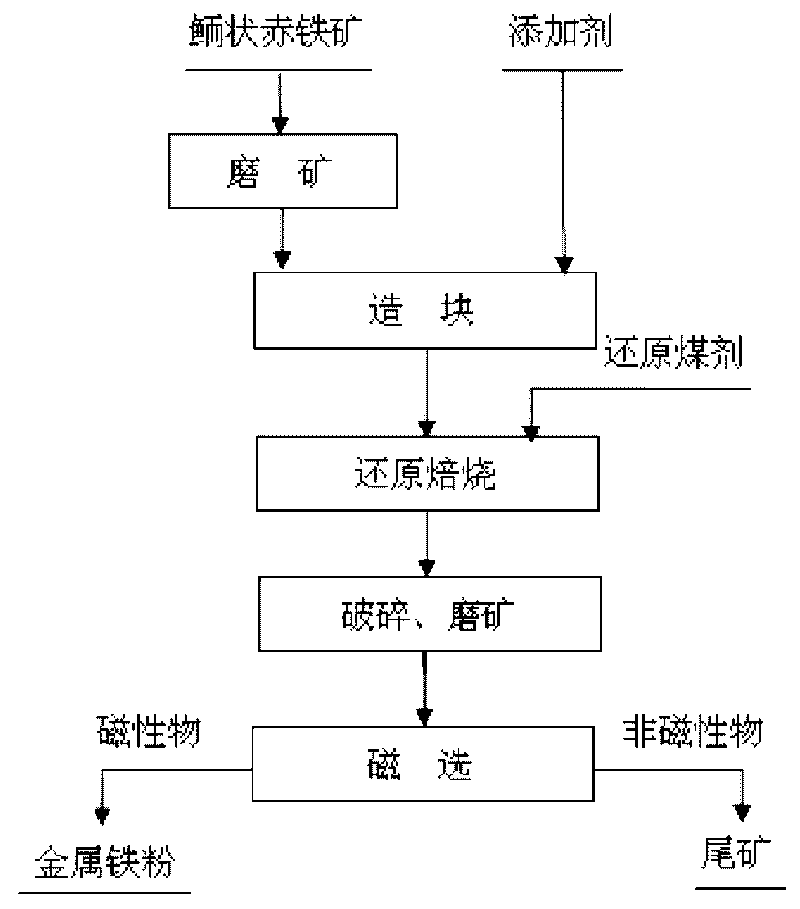

[0023] Embodiment 1: see figure 1, adding sodium huminate accounting for 8% of oolitic hematite mass percent, 1% of borax accounting for oolitic hematite mass percent, and 0.5% of oolitic hematite mass percent, accounting for oolitic hematite mass percent Sodium fulvic acid with a mass percentage of 1% of iron ore is pre-crushed and ground to less than 0.074mm in oolitic hematite with a mass percentage of 60%, mixed evenly, pelletized, dried, and then reduced and roasted with lignite, roasted The temperature is 1050°C, the roasting time is 1.5h, and the iron metallization rate reaches 96.2%. After cooling, the reduced pellets are crushed and ground to a mass percentage of less than 0.074mm, accounting for 80% of the mass percentage. Magnetic separation is carried out under a magnetic field of 0.1T. The iron grade of 93.84%, phosphorus content of 0.078%, Na 2 The metal iron powder product with O content of 0.18% has an iron recovery rate of 95.67% and a phosphorus removal rate...

Embodiment 2

[0024] Example 2: see figure 1 , adding sodium huminate accounting for 5% of oolitic hematite mass percentage, borax accounting for 2% of oolitic hematite mass percentage, and 1.0% of oolitic hematite mass percentage, accounting for oolitic hematite mass percentage Sodium fulvic acid with a mass percentage of 0.5% of iron ore is pre-crushed and ground to less than 0.074mm in oolitic hematite with a mass percentage of 50%, mixed evenly, pressed into agglomerates, dried and then reduced and roasted with lignite, roasted The temperature is 1000°C, the roasting time is 2 hours, and the metallization rate of iron reaches 93.6%. After cooling, the reduced pellets are crushed and ground to a mass percentage of less than 0.074mm, accounting for 90% of the mass percentage, and are separated by magnetic separation under a magnetic field of 0.12T. Obtain iron grade 92.47%, phosphorus content 0.083%, Na 2 The metal iron powder product with O content of 0.23% has an iron recovery rate of ...

Embodiment 3

[0025] Embodiment 3: see figure 1 , adding sodium huminate accounting for 7% of oolitic hematite mass percentage, 1.5% of borax accounting for oolitic hematite mass percentage, 0.75% of oolitic hematite mass percentage, accounting for oolitic hematite mass percentage Sodium fulvic acid with a mass percentage of 0.75% of iron ore is crushed to less than 0.074mm in oolitic hematite with a mass percentage of 60%, mixed evenly, pelletized, dried and then reduced and roasted with lignite at a roasting temperature of 1050°C , the roasting time is 2h, the metallization rate reaches 97.6%; the reduced pellets after cooling are crushed and ground to less than 0.074mm, accounting for 90% by mass, and the iron grade is 94.19% obtained by magnetic separation under a magnetic field of 0.1T , phosphorus content 0.08%, Na 2 The metal iron powder product with O content of 0.20% has an iron recovery rate of 93.94% and a phosphorus removal rate of 95.94%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com