Patents

Literature

69 results about "Chromium-Nickel Alloys" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The 80/20 nickel chromium alloy is often used for wrought and cast parts for high temperature applications, as it has better oxidation and hot corrosion resistance compared to cheaper iron-nickel-chromium alloys. This nickel chromium alloy is highly suited to applications that are subject to oxidation.

Spray coating material prepared by titanium-containing high-chromium-nickel alloy, preparation method and use thereof

InactiveCN101260487AExtended service lifeImprove anti-sulfur performanceMetal-working apparatusRheniumVulcanization

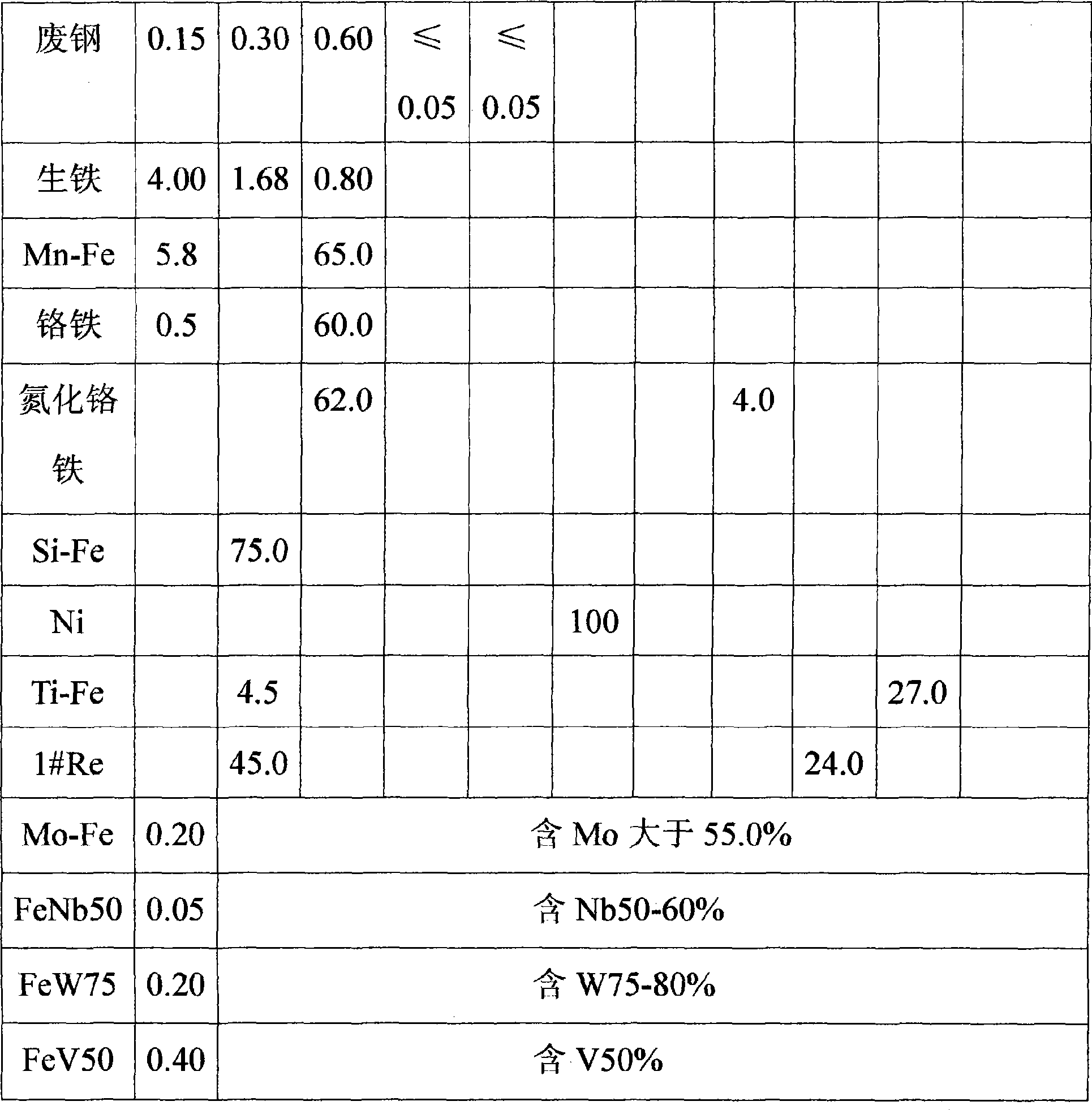

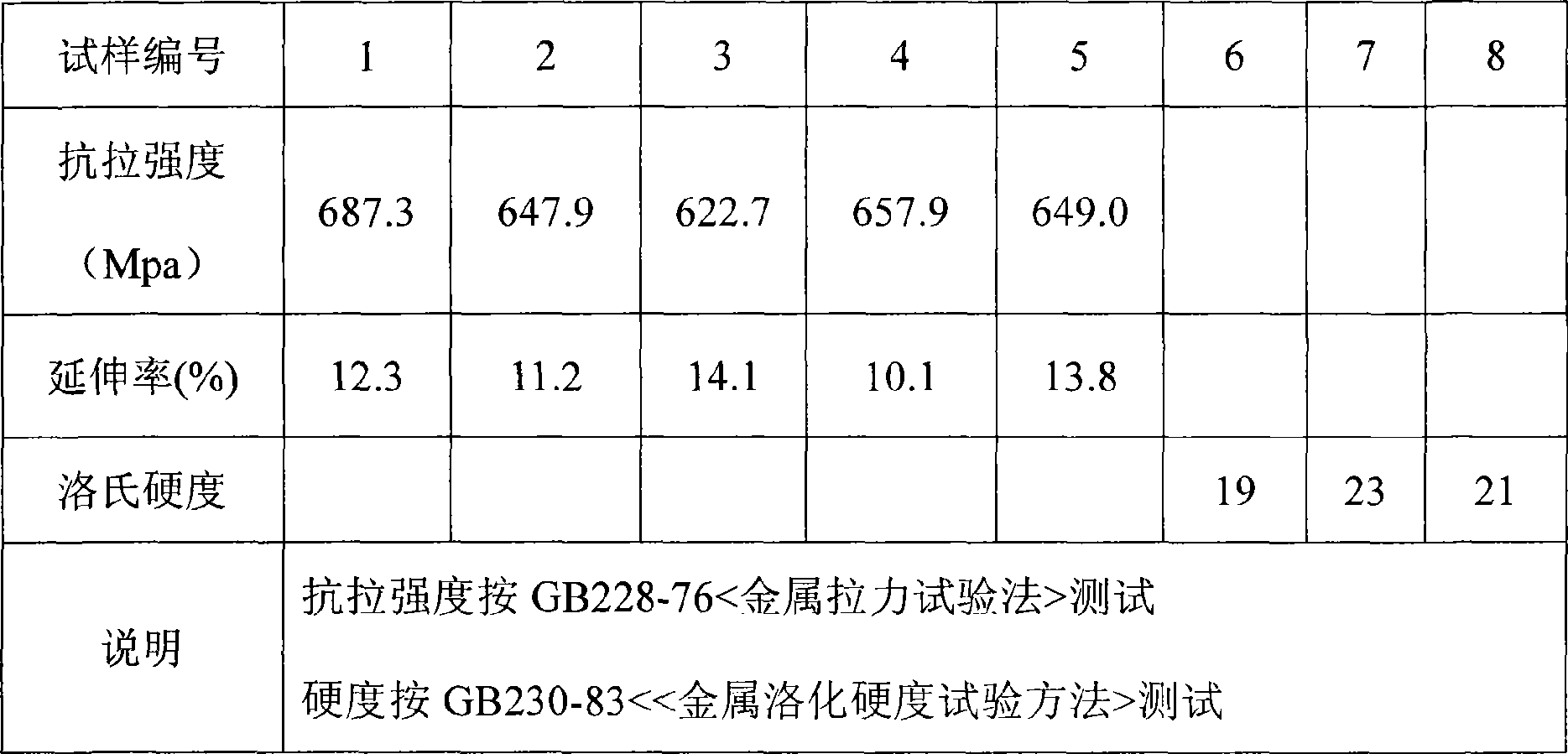

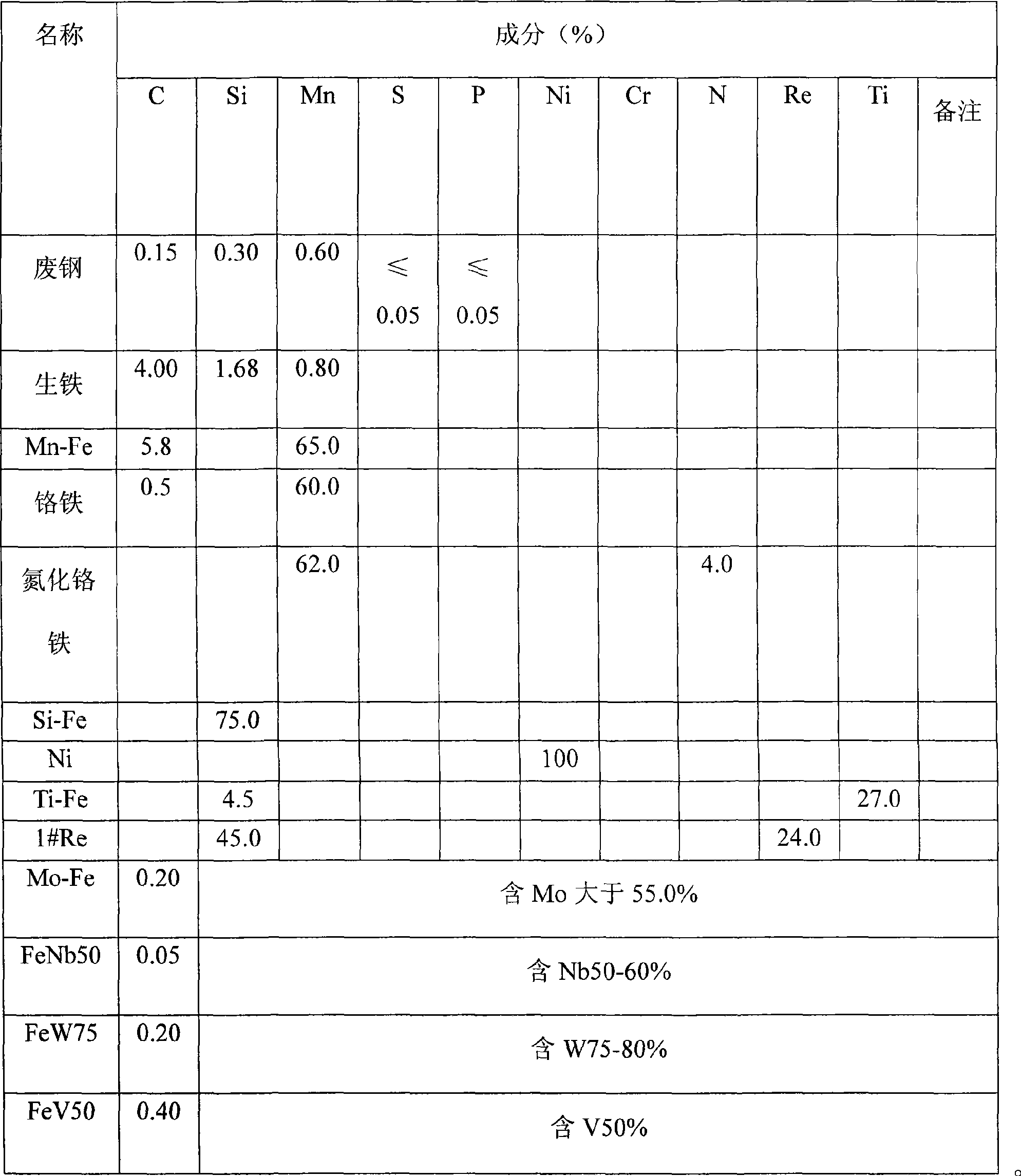

The invention relates to a titanium contained high chromel alloy and application thereof in spraying materials. The components of the alloy are (by weight percentage) as follows: the content of chromium is more than or equal to 15 percent and less than or equal to 25 percent, the content of titanium is more than or equal to 1 percent and less than or equal to 6 percent, the content of silicon is more than or equal to 1 percent and less than or equal to 6 percent, the content of carbon is more than or equal to 0 percent and less than or equal to 0.02 percent, the content of nickel is more than or equal to 20 percent and less than or equal to 55 percent, the content of rhenium is more than or equal to 0.5 percent and less than or equal to 6 percent, the content of aluminum is more than or equal to 0 percent and less than or equal to 6 percent, the content of sulfur is more than or equal to 0 percent and less than or equal to 0.035 percent, he content of phosphorus is more than or equal to 0 percent and less than or equal to 0.035 percent, the content of manganese is more than or equal to 0 percent and less than or equal to 0.2 percent, and the rest is iron. After the parts of working equipment are sprayed at high temperature oxidation and high temperature corrosion environments by the spraying material produced by the alloy, since the coating has good high temperature oxidation and vulcanization resistance and hot corrosion resistance performances, the service life of the parts can be greatly improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Trivalent Chromium Electroplating Solution and an Operational Method Thereof

InactiveUS20090211914A1Improve current efficiencyImprove efficiencyChromium-Nickel AlloysNickel salt

A trivalent chromium-based electroplating solution in accordance with the present invention a trivalent chromium salt, a bivalent nickel salt, a complex agent, a conductive salt, a buffering agent and an additive for electroplating a chromium-nickel alloy deposit on a component. By using the lowly toxic trivalent chromium to substitute highly toxic hexavalent chromium, an electroplating procedure with the present trivalent chromium-based electroplating solution has less pollution and high current efficiency to allow the electroplating performing at the room temperature.

Owner:CHANG GUNG UNIVERSITY

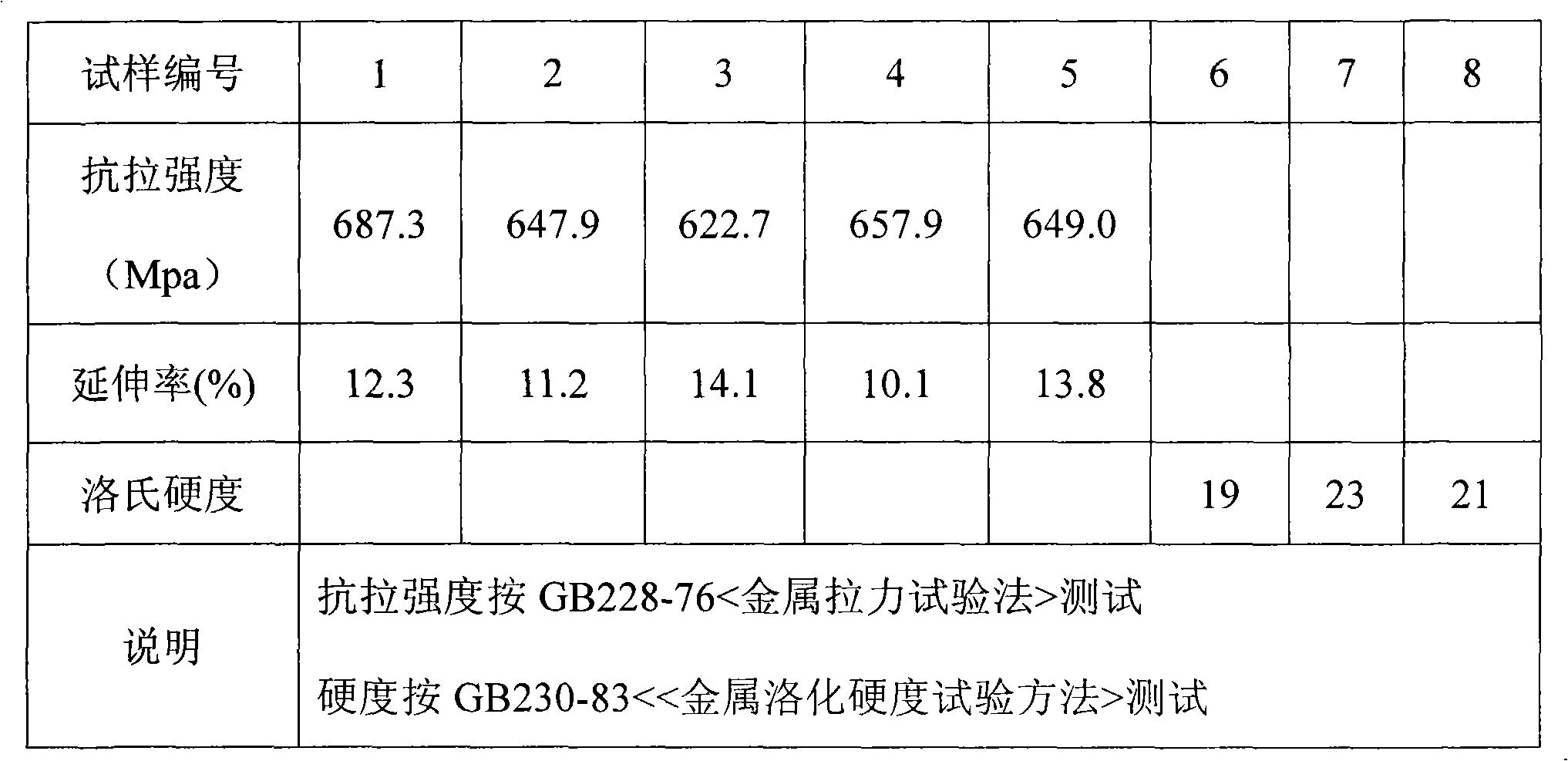

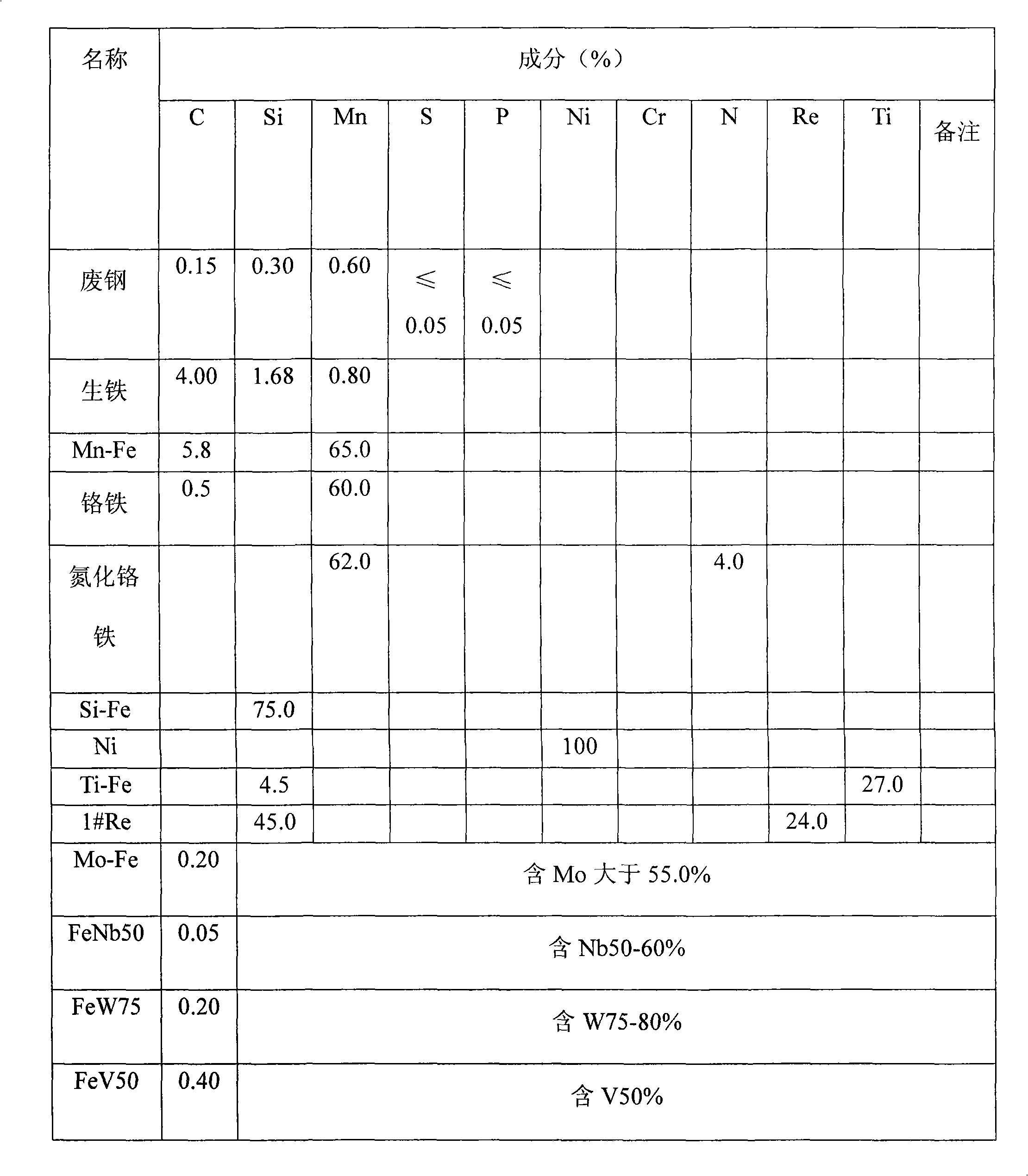

Fluidized bed furnace central drum alloy and production method thereof

InactiveCN101476087ASolve non-wearable technical problemsReduce tensionChromium-Nickel AlloysFluidized bed

The invention discloses a fluid-bed furnace center barrel alloy using the chromium-nickel alloy as the essential element. The alloy comprises the following components by weight percentage: C of 0.25-.60, Cr of 26.00-30.00, Ni of 9.00-12.00, Si of 0.80-1.50, Mn of 1.00-2.00, N of 0.15-0.30, Mo of 0.20-0.50, W of 0.50-1.00, Ti of 0.20-0.60, Nb of 0.20-0.60, V of 0.20-0.50, Re of 0.20-0.50, S<=0.04, P<=0.05, and Fe of the rest.The manufacturing process of the fluid-bed furnace center barrel comprises steps of moulding preparation, smelting and pouring and thermal treatment. The invention solves a technical problem that the existing fluid-bed furnace center barrel is non-wear-resistant and strain cracking under a high temperature, and the invention has three main advantages of high stretching and rigidity specific elongation index at normal temperature, strong oxidation resistance and antiwear quality at high temperature and service life longer than that of the existing products.

Owner:HENAN HONGYU SPECIAL CASTINGS

Chronium-nickel alloy element electric furnace smelting recovery method from stainless steel dedusting ash

InactiveCN101067180AReduce smelting costAchieve recyclingProcess efficiency improvementRecovery methodSteelmaking

The electric furnace smelting process for recovering Cr and Ni from stainless steel dust includes the following steps: 1. preparing mixed material through adding water in 4-6 wt% and adhesive in 3-5 wt% into stainless steel dust; 2. pelletizing the mixed material; 3.adding the pellet into steelmaking material in the added amount of 2.0-15.0 wt%; 4. smelting Ni-containing stainless steel in an electric furnace; and 5. tapping to obtain stainless steel. The electric furnace smelting process for recovering Cr and Ni from stainless steel dust is simple and low in cost.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

High-temperature wear resistant kilneye cap iron alloy and manufacturing method thereof

InactiveCN101476090ASolve non-wearable technical problemsReduce tensionFoundry mouldsFoundry coresChromium-Nickel AlloysWear resistant

The invention discloses a high-temperature wear-resistant kilneye protection iron alloy using the chromium-nickel alloy as the essential element. The kilneye protection iron alloy comprises the following components by weight percentage: C of 0.25-0.60, Cr of 26.00-30.00, Ni of 9.00- 12.00, Si of 0.80-1.50, Mn of 1.00-2.00, N of 0.15-0.30, Mo of 0.20-0.50, W of 0.50-1.00, Ti of 0.20-0.60, Nb of 0.20-0.60, V of 0.20-0.50, Re of 0.20-0.50, S<=0.04, P<=0.05, and Fe of the rest.The manufacturing process of the high-temperature wear-resistant kilneye protection iron alloy comprises steps of moulding preparation, smelting and pouring and thermal treatment. The invention solves the problem that the existing kilneye protection iron is un-wearable under a high temperature and the produced high-temperature wear-resistant kilneye protection iron alloy has three main advantages of high stretching and rigidity specific elongation index at normal temperature, strong oxidation resistance and antiwear quality at high temperature and service life longer than that of the existing products.

Owner:HENAN HONGYU SPECIAL CASTINGS

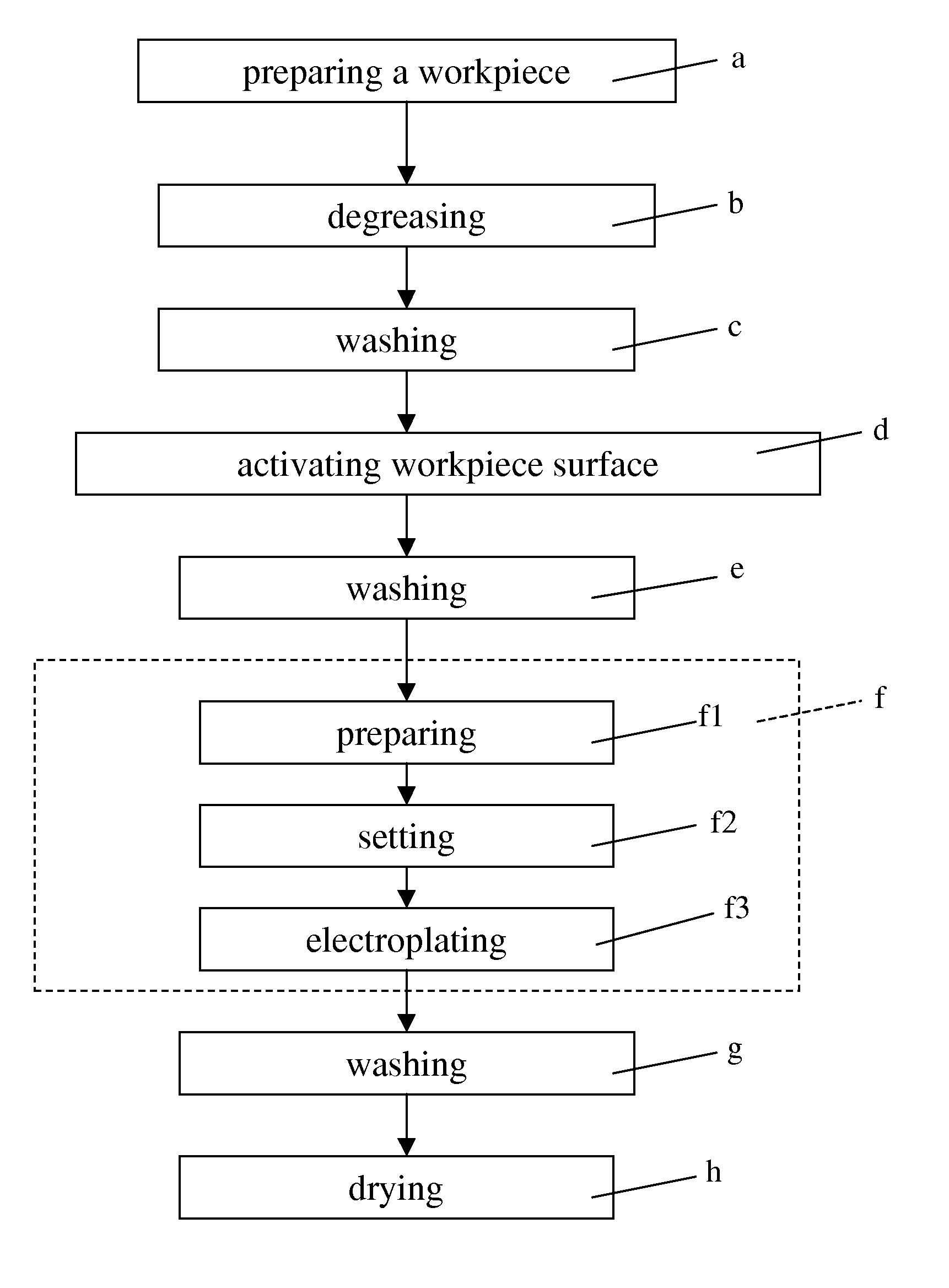

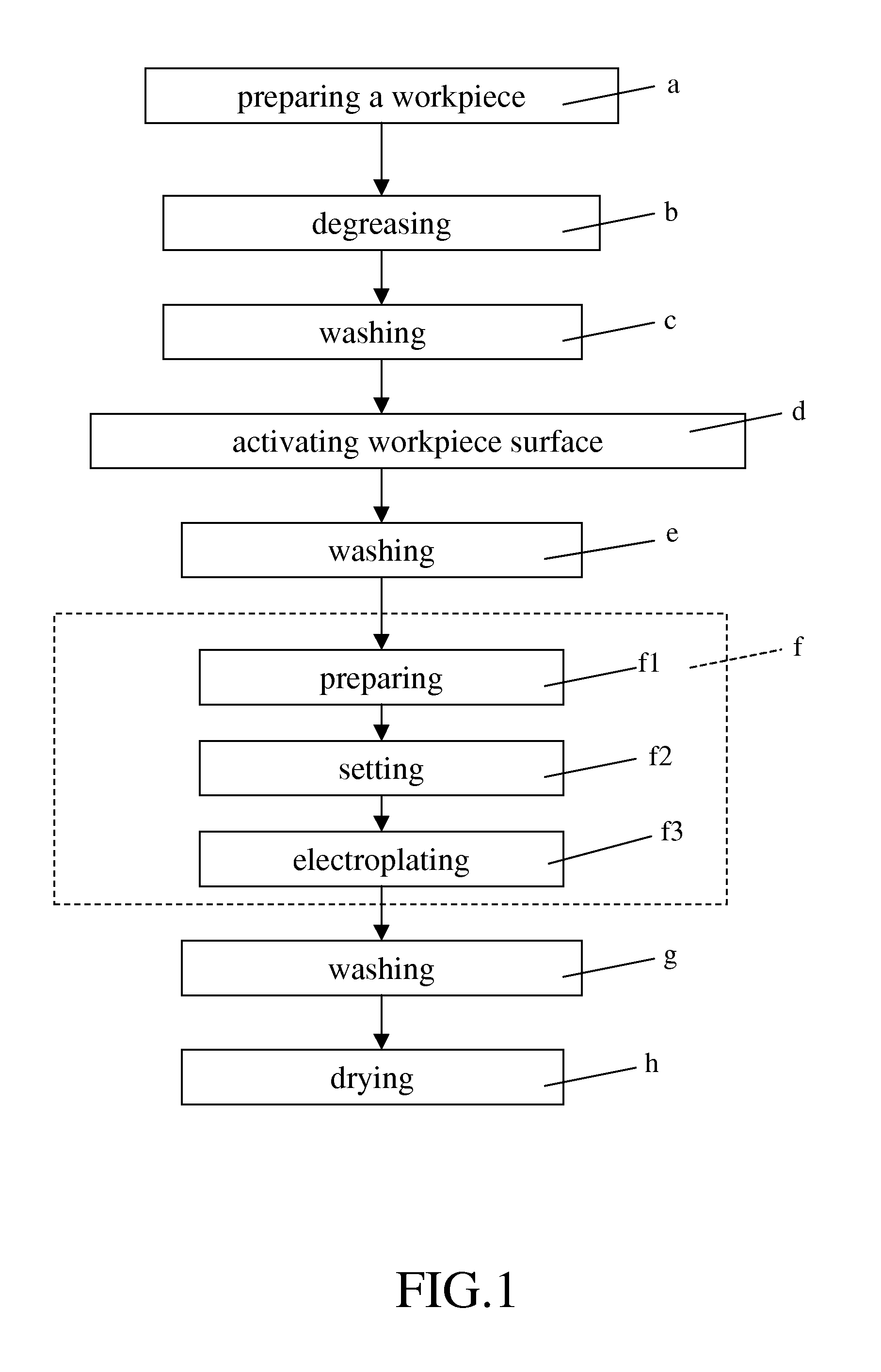

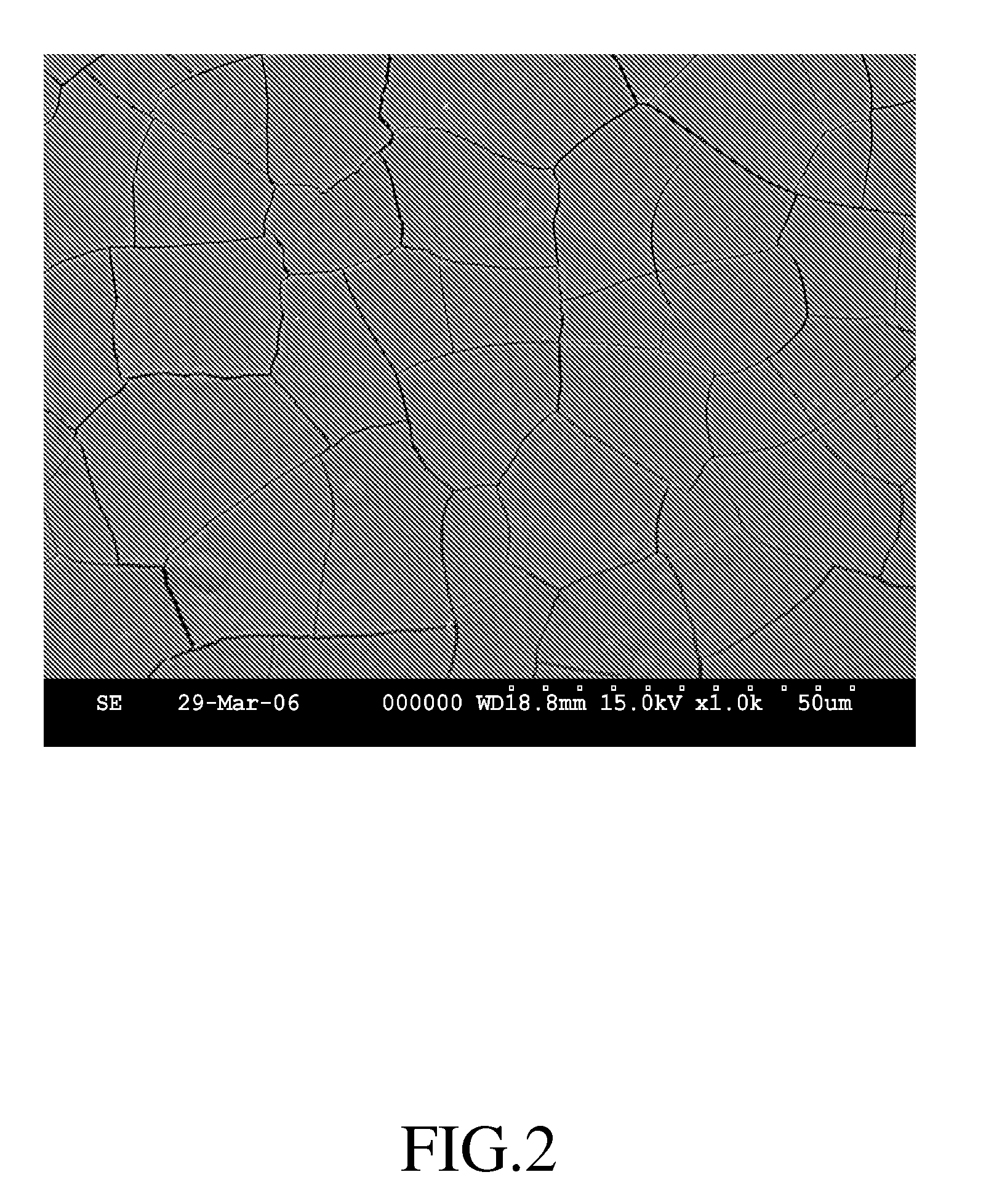

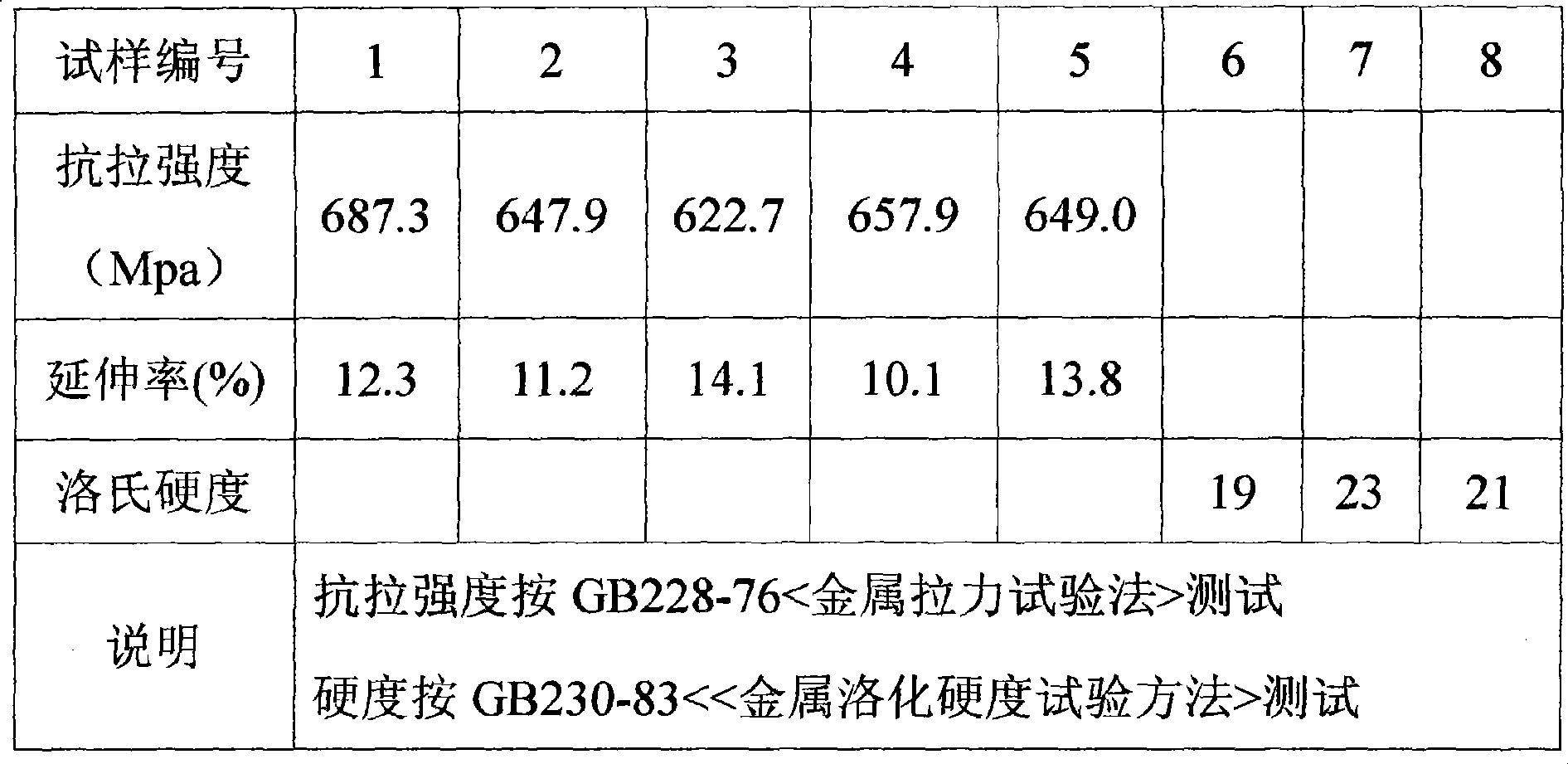

Method for electrodepositing nanocrystalline chromium-nickel alloy coating with carboxylic acid or its salt -urea impulse

A process for pulse electro-deposition nanometer Cr-Ni alloy plating of carboxylic acid or the salt-urea system of carboxylic acid is provided, which relates to the technology for surface engineering and surface treatment, comprises the pretreating and pulse electro-deposition treatment of the plating. The current efficiency of the plating solution system in the invention is up to 45.28%, about 35% higher than the 10% current efficiency in conventional trivalent Cr plating solution system; the toxicity of Cr3+ in the plating solution is only 1% of Cr6+, and the Cr content in the plating solution is only 1 / 7 of that in the plating solution of chromic acid. The invention is characterized by low toxicity and energy consumption, and greatly reduces the production cost of Cr-Ni plating and the environmental pollution during the production. The nanometer Cr-Ni plating prepared by the present invention is bright, intense, flat, and strongly bonded with the substrate, and is of excellent resistance to wear and corrosion in air. The invention is applicable for corrosion protection and decoration of metallic or metal alloy surfaces.

Owner:CENT SOUTH UNIV

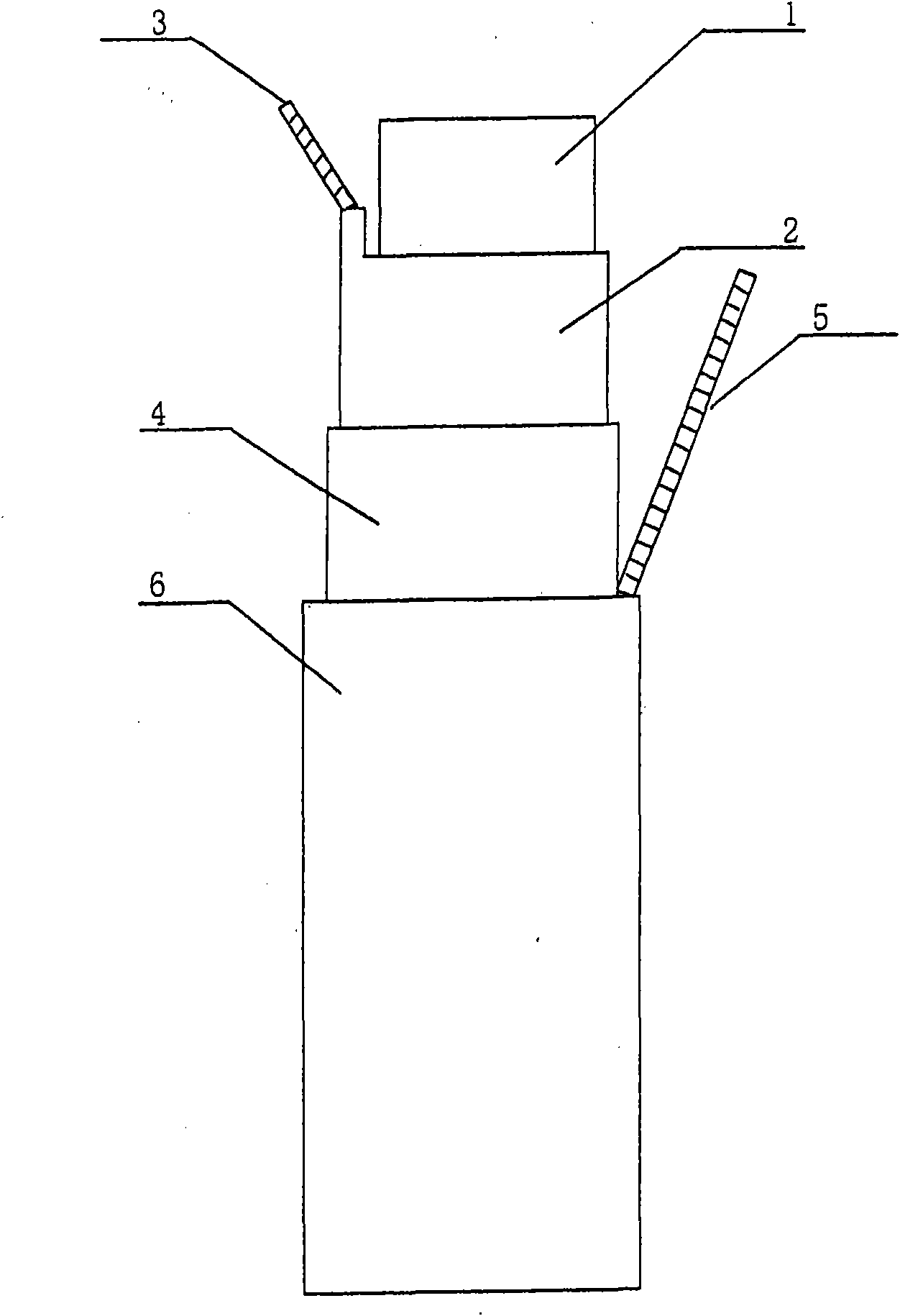

Method for recycling stainless steel pickling wastewater

InactiveCN108928953AReduce the amount addedImprove responseSludge treatment by pyrolysisCalcium/strontium/barium fluoridesChromium-Nickel AlloysSludge

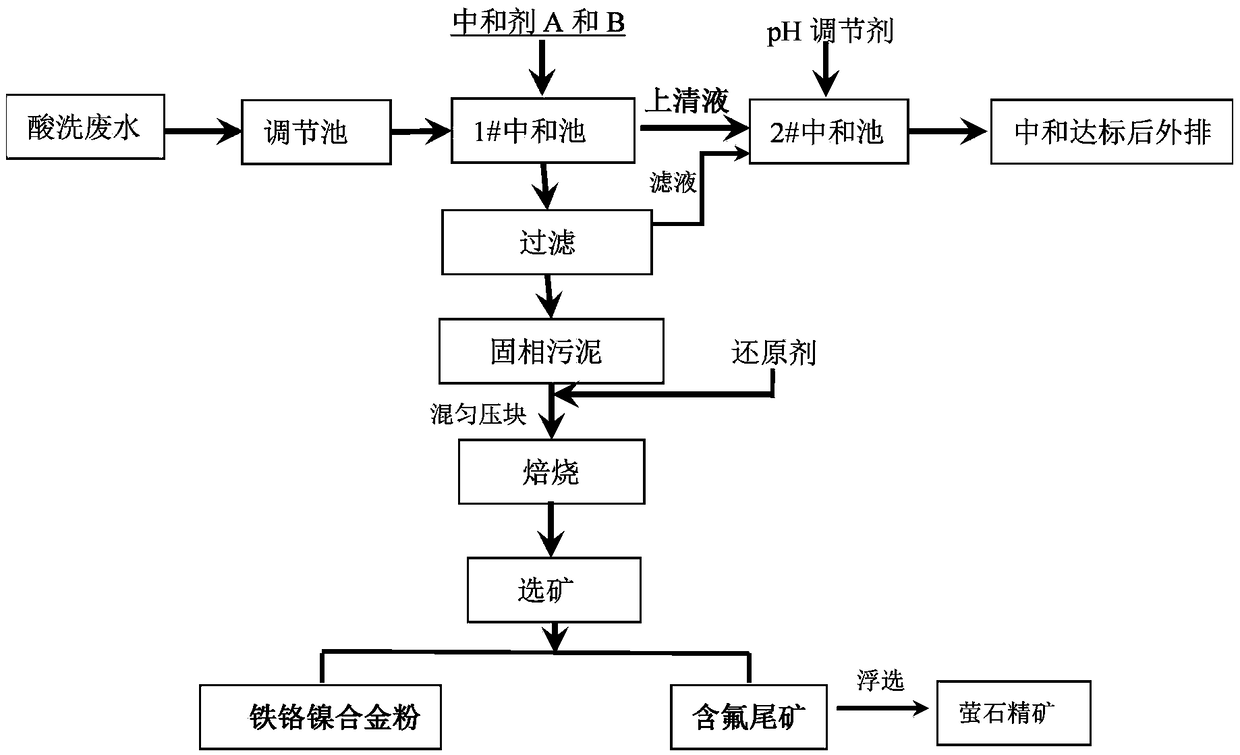

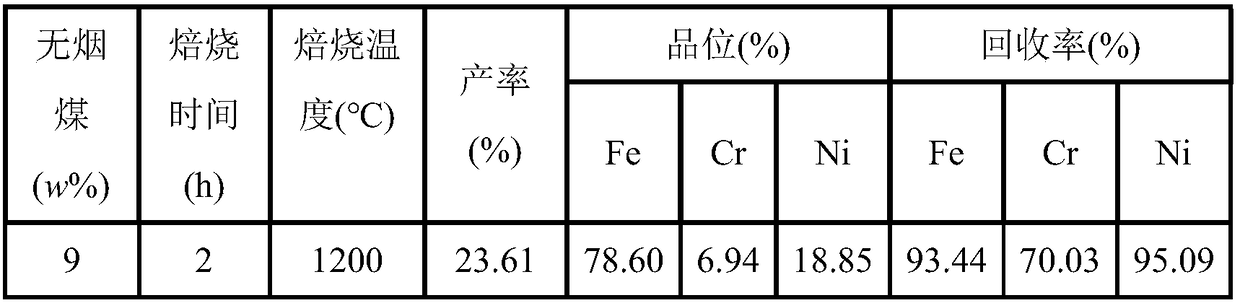

The invention discloses a method for recycling stainless steel pickling wastewater. The method comprises the following steps: 1) adding a neutralizing agent A to the stainless steel pickling wastewater to adjust a pH value to 3.0-8.0, then adding a neutralizing agent B to adjust the pH value to 9.0-12.0, respectively precipitating Fe, Cr, Ni and F in the wastewater in the forms of Fe(OH)3, Cr(OH)3, Ni(OH)2 and CaF2, and performing solid-liquid separation to obtain a solid phase sludge and a liquid phase; 2) drying the solid phase sludge obtained in the step 1) and adding a reducing agent for carbothermal reduction, and roasting the material in reducing atmosphere at 1150 DEG C to 1300 DEG C to obtain a calcined product; 3) performing fragmentation on the calcined product obtained in step 2) and performing ore dressing separation to obtain iron-chromium-nickel alloy powder and fluorine-containing tailings, and realizing separation of metal elements and fluorine elements; 4) performing flotation on the fluorine-containing tailings obtained in the step 3) to obtain a fluorite concentrate; and 5) performing NO3<-> removal on the liquid phase obtained in the step 1), and adjusting the material to neutrality, discharging while reaching the standard. The method can effectively treat the stainless steel pickling wastewater, and the discharge does not pollute the environment.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

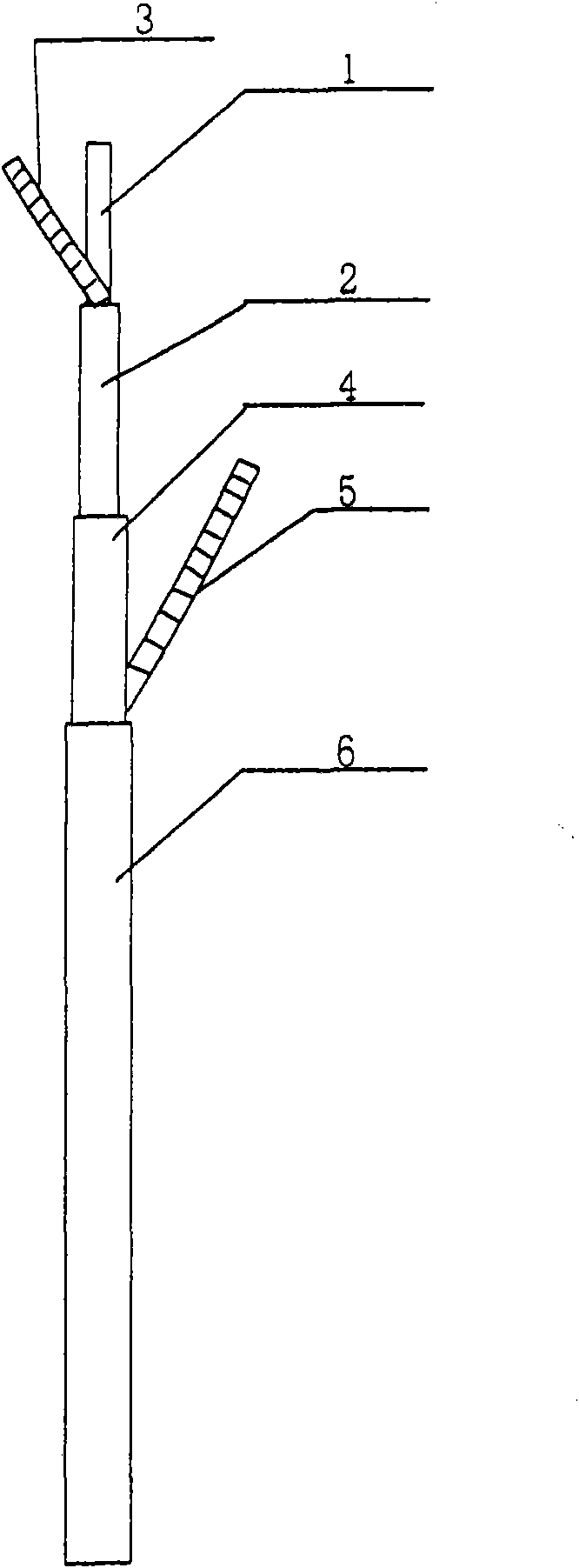

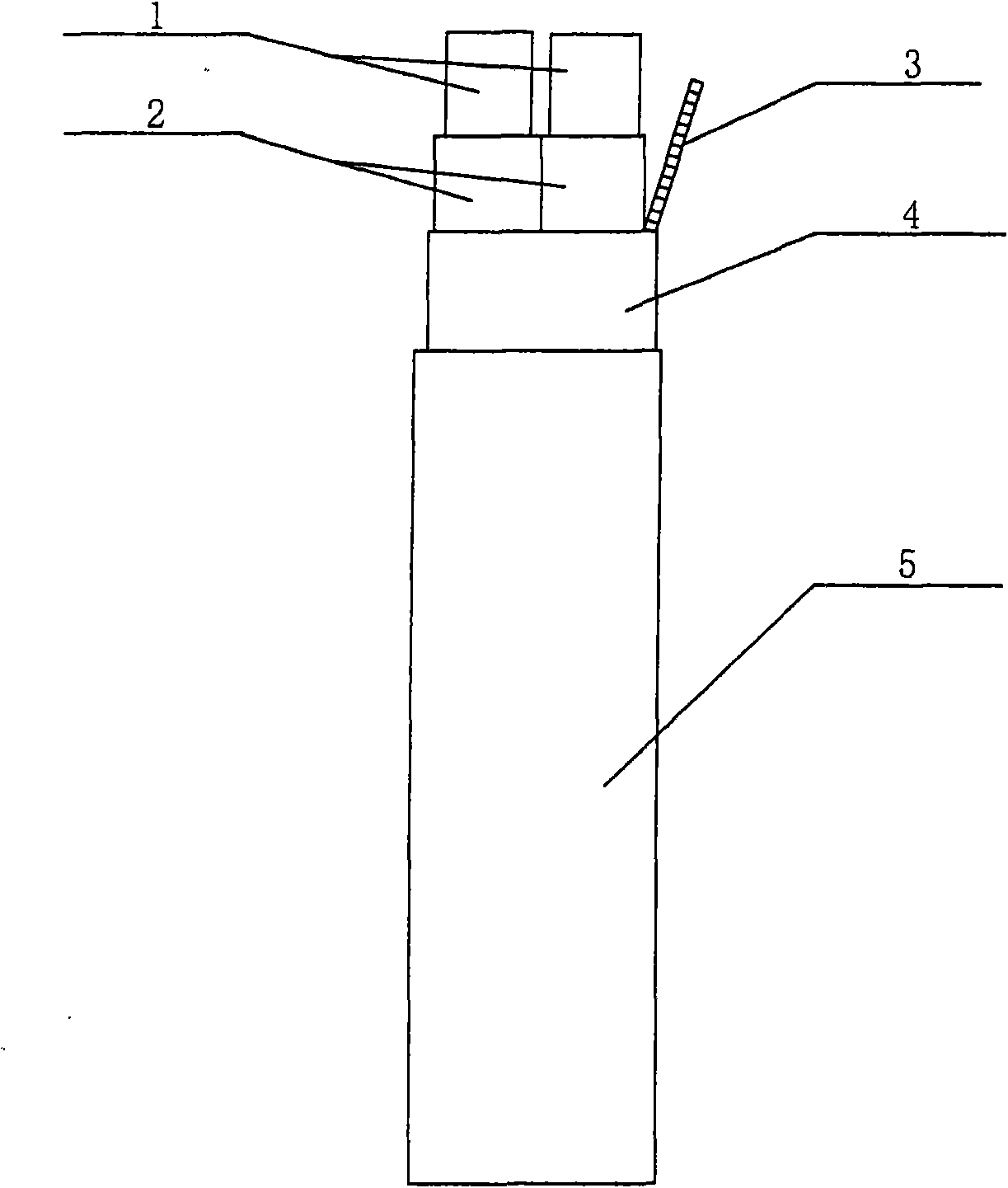

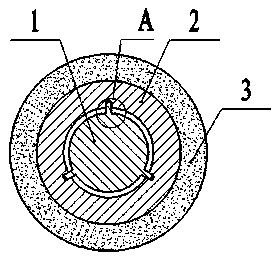

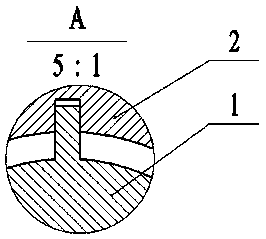

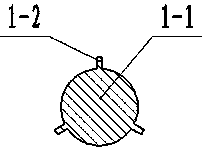

Heating cable

ActiveCN101902848AAdd ground protectionImprove securityMagnetic/electric field screeningHeating element shapesElectrical conductorChromium-Nickel Alloys

The invention discloses a heating cable. The heating cable is shaped as a thin long band, and an ultrathin chromium-aluminum or chromium-nickel alloy steel band is used as a heating conductor, wherein an insulating layer is coated outside the heating conductor, a shielding layer is coated outside the insulating layer, and an outer protection layer is coated outside the shielding layer. The heating cable comprises 7 products with different structures. The heating cable has the advantages of durability, safety, energy saving, difficult burnout after long-time high-temperature heating, stable heating temperature, simple and convenient mounting, small occupied space and optional selection of length. The invention is suitable for roads, pipelines and pots in cold areas for raising temperature and deicing as well as planting and breeding green houses, automobile engines, houses and places needing keeping warm and raising temperature.

Owner:GUANGXI QUNXING CABLE CO LTD

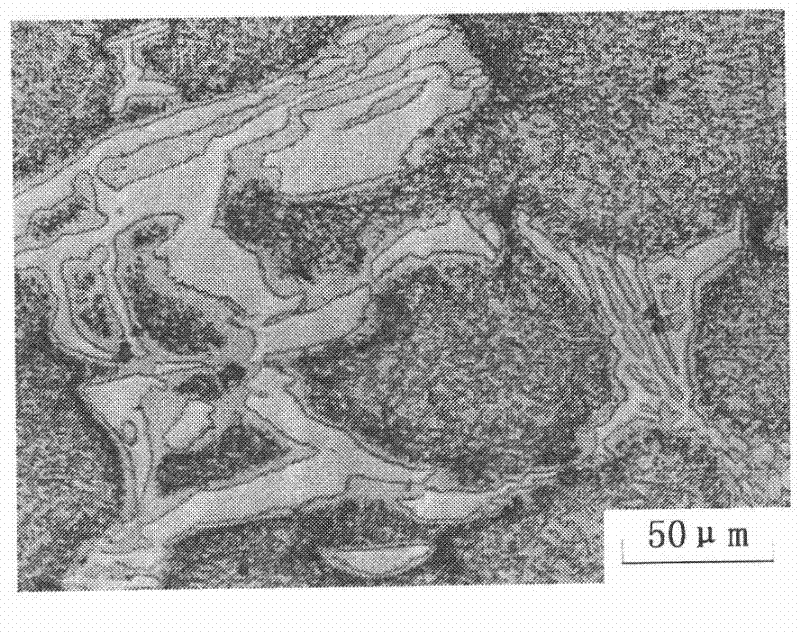

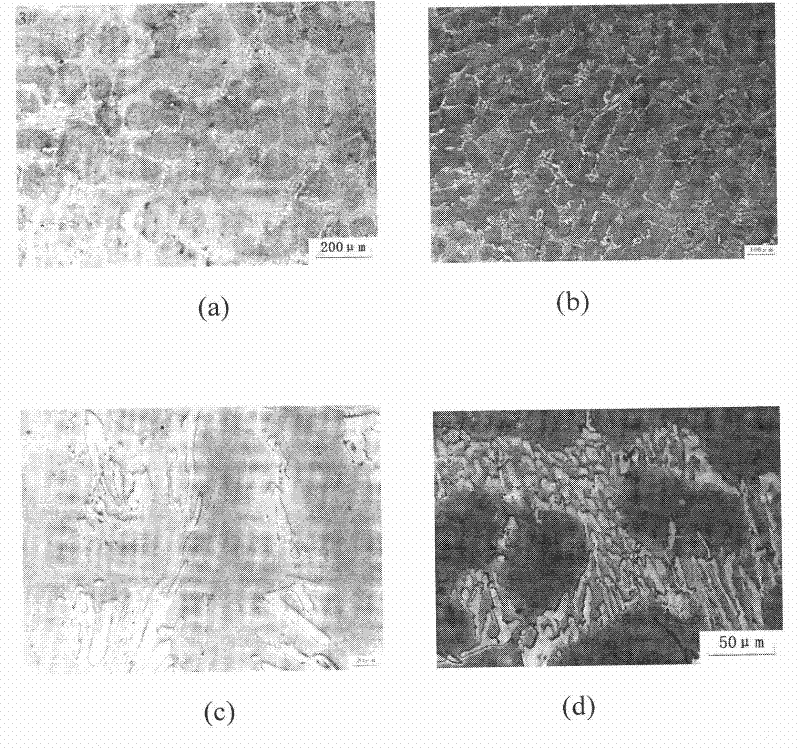

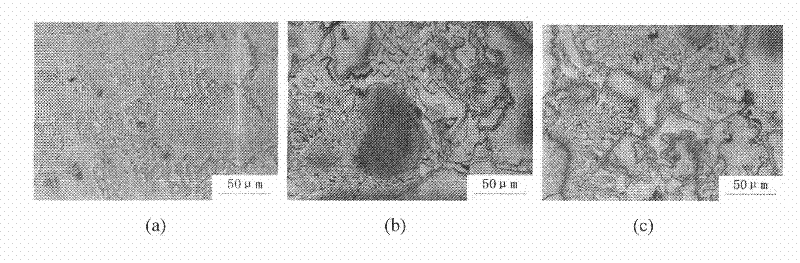

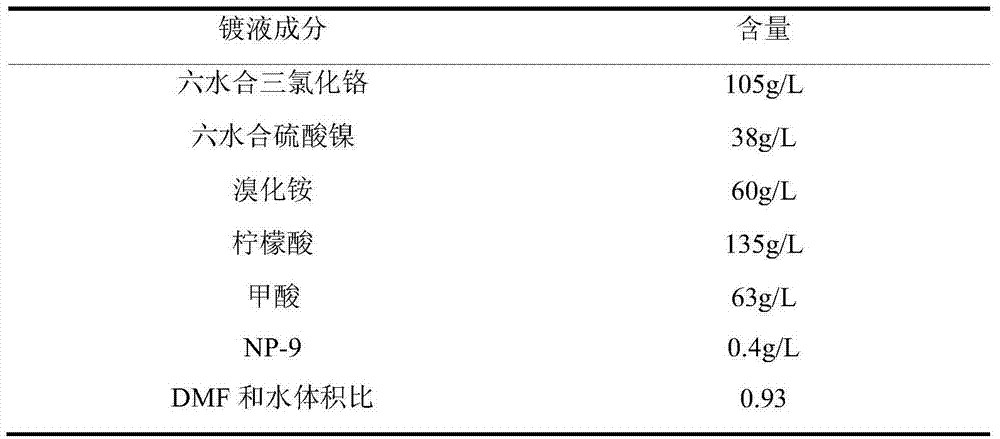

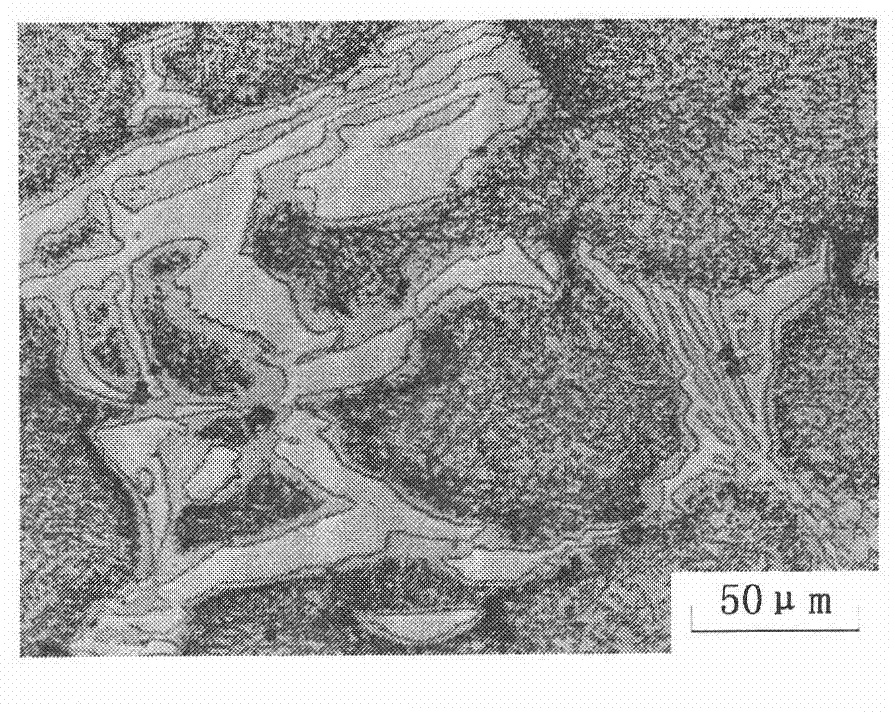

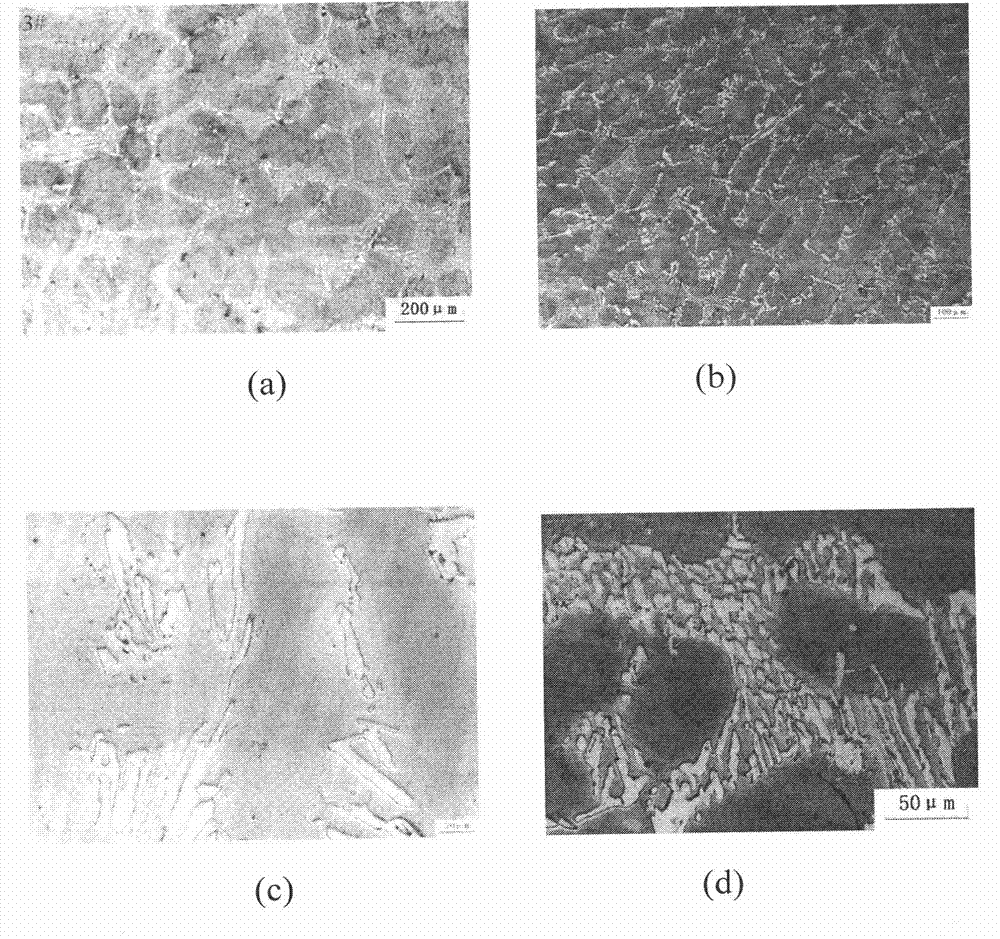

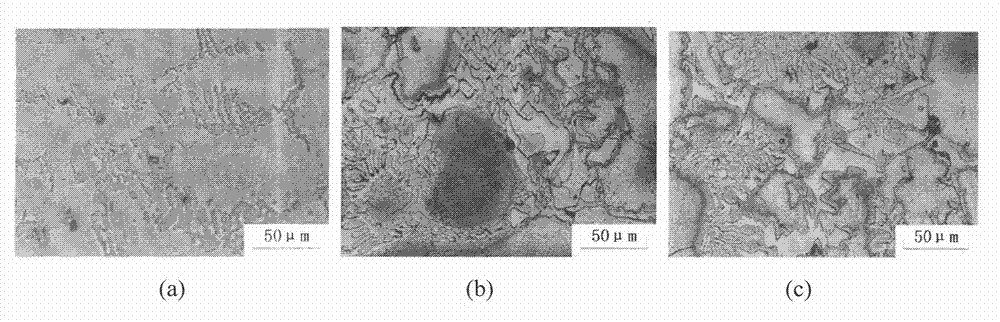

Rare earth modification and ageing processing method of high chromium-nickel alloy steel guide plate

The invention discloses a rare earth modification and ageing processing method of a high chromium-nickel alloy steel guide plate, belonging to the technical field of metallurgy. The rare earth modification and ageing processing method comprises the following steps of: enabling large blocky net primary carbides to be subjected to necking and spheroidizing through a rare earth modification process;and separating out secondary carbides after an ageing process in tiny dispersive small particles instead of a plurality of thick strips. Due to the change of size, form and amount of the primary carbides and the secondary carbides, the service life of the high chromium-nickel alloy steel guide plate is prolonged. After modification and ageing processes are carried out on the guide plate, the original fragmentation situation is largely reduced, the service life is prolonged by 43-50%, the service life of small series guide plate is prolonged to 1000 times per piece from the original average 700 times per piece, the service life of a large series guide plate is prolonged to 1500 times per piece from the original average 700 times per piece, the energy consumption per ton steel is reduced, and the production cost is saved.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

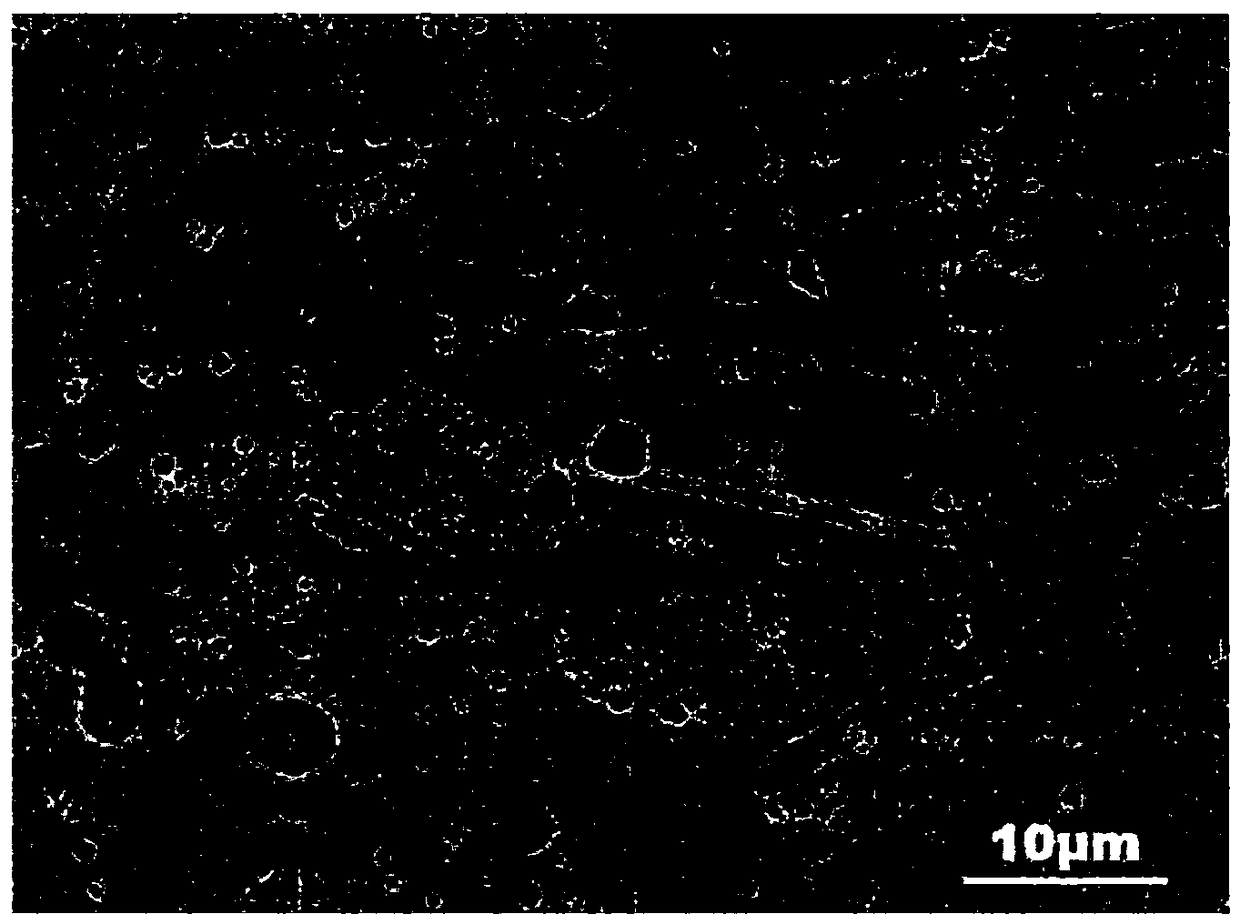

Cobalt-chromium-nickel alloy material and powder metallurgy preparation method thereof

The invention discloses a cobalt-chromium-nickel alloy material and a powder metallurgy preparation method thereof. The cobalt-chromium-nickel alloy material is prepared from Co-Cr-Ni-M-C original powder, wherein M is selected from one or more of Mo, W, Fe, Si and Mn. In the preparation process of the cobalt-chromium-nickel alloy material, negative-pressure dewaxing is carried out in advance, andsinter molding is carried out in a low-vacuum sintering manner within a sintering temperature range. The scheme that single-phase epsilon-hcp Co alloy and double-phase alpha-fcc and epsilon-hcp Co alloy are obtained through the powder metallurgy method by adjusting the content of the original material component Ni is given.

Owner:湖北麦拓新材料科技股份有限公司

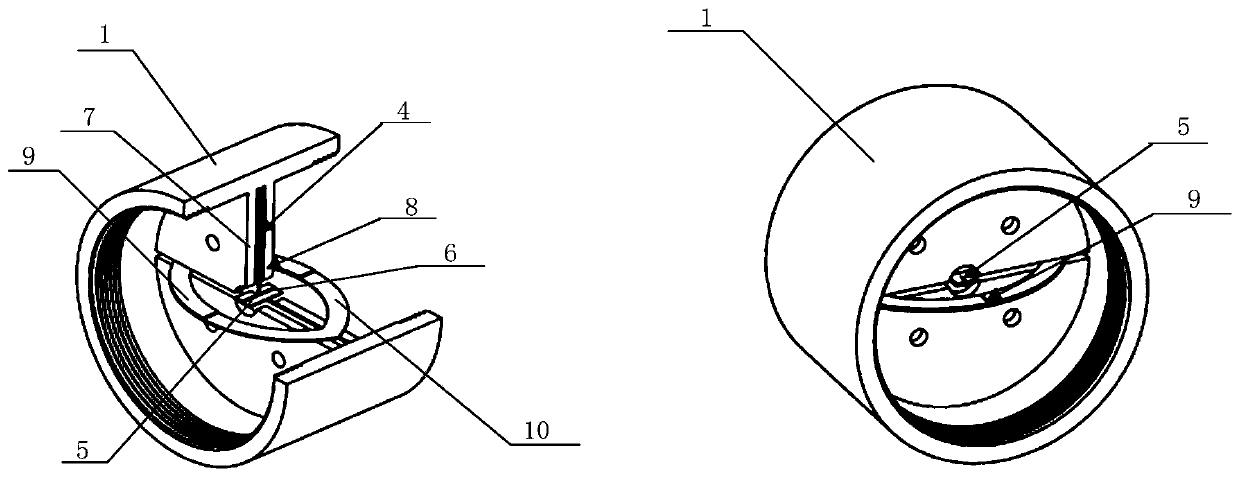

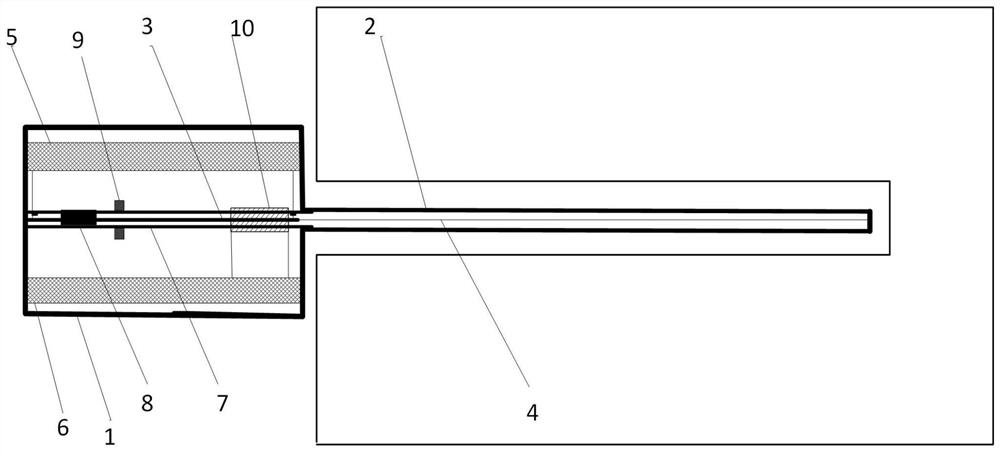

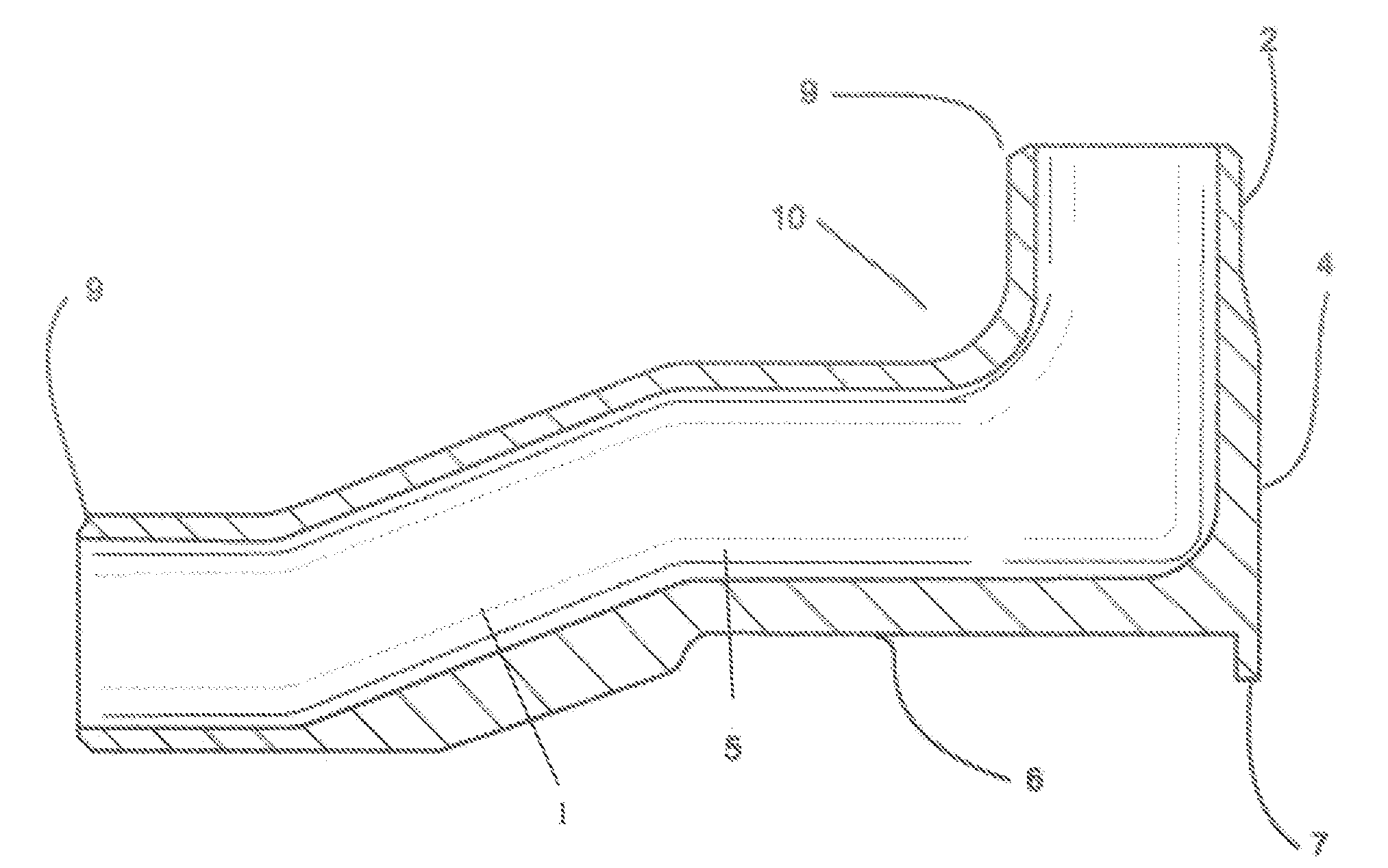

Differential pressure sensor based on optical fiber point type sensor

ActiveCN111272332ANo irreversible damage will occurDoes not hinder deformationPressure difference measurement between multiple valvesFluid pressure measurement by optical meansChromium-Nickel AlloysEngineering

The invention discloses a differential pressure sensor based on an optical fiber point type sensor, and the differential pressure sensor is provided with a first limiting diaphragm and a second limiting diaphragm, thereby guaranteeing that a pressure sensing diaphragm cannot be damaged irreversibly, and guaranteeing that the deformation of the pressure sensing diaphragm is not hindered in a measurement range. The fixing points of the pressure sensing diaphragm, the first arc-shaped metal sheet and the second arc-shaped metal sheet are located at the same position, so that measurement errors caused by deformation of the shell are avoided, and the measurement precision is improved. By arranging the first optical fiber point type sensor and the second optical fiber point type sensor, the pressure difference is converted into the change of the characteristic value of the optical fiber point type sensors, and the characteristics of high sensitivity and long-term stability are achieved. Dueto the fact that the limiting diaphragms are arranged, the pressure sensing diaphragm can be made of chromium-nickel alloy, the material of the pressure sensing diaphragm can be selected according tothe using environment, and the differential pressure sensor can be suitable for high-static-pressure and high-temperature environments.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Cardiovascular stent with Ag-TiO2 coating on surface and preparation method of cardiovascular stent

ActiveCN104189961AGood biocompatibilityImprove antibacterial propertiesAnodisationSurgeryCardiovascular stentChromium-Nickel Alloys

The invention provides a cardiovascular stent with an Ag-TiO2 coating on the surface. An Ag coating covers a base layer of the cardiovascular stent; the base layer of the cardiovascular stent refers to a magnesium-titanium alloy, a magnesium-titanium-aluminum alloy, a magnesium-titanium-chromium alloy, a magnesium-titanium-chromium-nickel alloy or a magnesium-titanium-cobalt-chromium alloy; the Ag-TiO2 coating comprises an oxide film layer; and the oxide film layer contains nano-silver and / or silver oxide particles. According to the Ag-TiO2 coating, the cardiovascular stent has high biocompatibility, antibacterial property and extremely high application value, and the service life of the cardiovascular stent in a human body is prolonged.

Owner:DONGGUAN REVOLUTION PROD DESIGN

Method for recycling acid regeneration iron powder pressed balls

InactiveCN102212679AHigh yieldReduce usageProcess efficiency improvementElectric furnaceIron powderChromium-Nickel Alloys

The invention discloses a method for recycling acid regeneration iron powder pressed balls, and belongs to comprehensive utilization of the steel making field. The method is characterized by comprising the following steps of: mixing 50 to 70 mass parts of acid regeneration iron powder and 50 to 30 mass parts of dust removing ash uniformly, adding 3 to 8 mass parts of MgCl2 solution, mixing uniformly, performing extrusion forming on a roll ball press, and adding the formed iron balls into an electric furnace for smelting. By the method, the metal yield is improved, the acid regeneration iron powder is utilized, the dust removing ash is also utilized, and meanwhile, the consumption of chromium-nickel alloy in the steel making process is reduced, so that the production cost of stainless steel is reduced.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

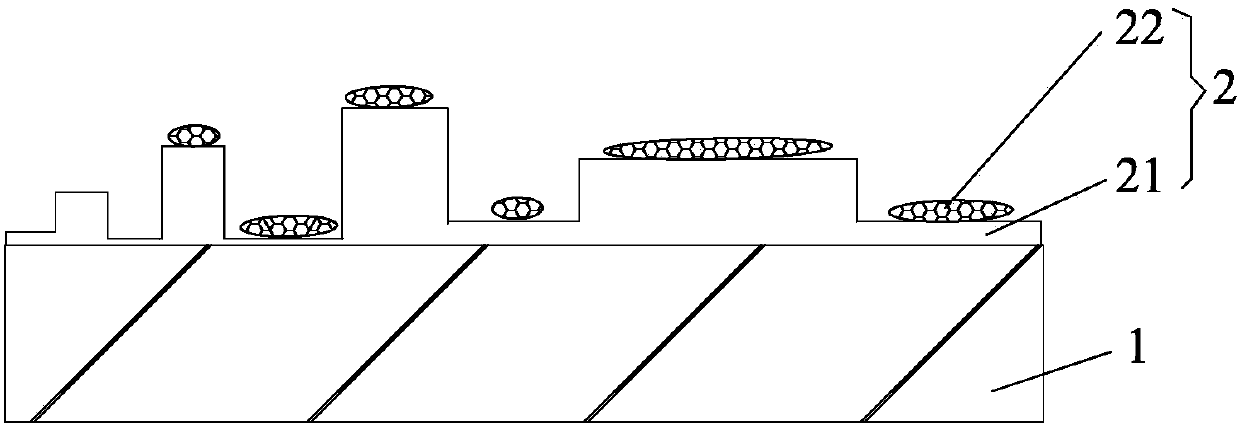

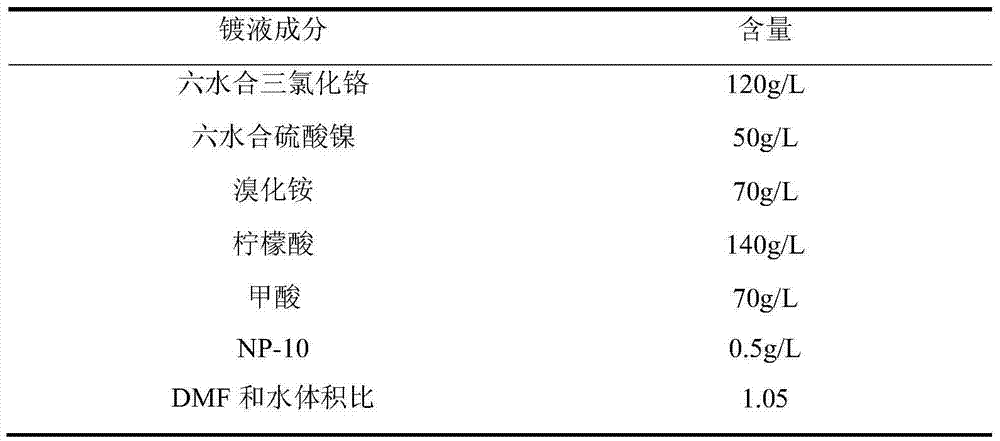

Chromium-nickel alloy electroplating solution and electroplating method

The invention discloses a chromium-nickel alloy electroplating solution and an electroplating method. The chromium-nickel alloy electroplating solution includes: 90-120g / L chromium chloride hexahydrate, 25-50g / L nickel sulfate hexahydrate, 50-70g / L ammonium bromide, 130-140g / L citric acid, 55-70g / L formic acid, 0.3-0.5g / L an emulsifier and the balance a solvent. The solvent is a mixed solution of DMF and water in a volume ratio of (0.8-1.05):1. The chromium-nickel alloy electroplating solution provided by the invention adopts the mixed solution of DMF and water as the solvent of the electroplating solution, citric acid and formic acid are taken as the compound complexing agent, citric acid and formic acid are selected as the buffering agent to replace boric acid, thus simplifying the formula, enhancing the hardness and corrosion resistance of the coating, and improving the dispersion ability and deep plating ability of the electroplating solution.

Owner:WUXI HUAYE IRON & STEEL

Chromium nickel alloy powder for flux-cored wire, flux-cored wire and preparation method of flux-cored wire

ActiveCN107214435AAddressing physical propertiesHigh physical ductilityWelding/cutting media/materialsSoldering mediaMaterials scienceHeat treated

The invention relates to chromium nickel alloy powder for a flux-cored wire, the flux-cored wire and a preparation method of the flux-cored wire. The chromium nickel alloy powder comprises the following components of, by mass, 37-45% of Cr, 18-23% of Ni, 0.03% or less of C, 1.0% or less of the Si, 2.5% or less of Mn, 0.02% or less of S, 0.025% or less of P, 0.5% or less of Cu, 0.5% or less of Mo and the balance Fe. By adding the chromium nickel alloy powder in the flux-cored wire, drawing of a small-diameter welding wire is facilitated, and a large-diameter welding wire does not need to be subjected to heat treatment firstly; and meanwhile, in welding, the flux-cored wire is more even and stable, and splashing is effectively reduced.

Owner:JIANGSU JIUZHOU NEW MATERIAL TECH CO LTD

Flexible circuit base board and its manufacturing method

InactiveCN1406104AImprove bindingNo preprocessing requiredVacuum evaporation coatingSputtering coatingChromium-Nickel AlloysFlexible circuits

The invention relates to the method for manufacturing the soft circuit based plate. The base plate comprises the macromolecular thin film layer and the metal, the nickel alloy and the copper bond coat is sequence. The manufacturing method is as following steps. (1) The macromolecule thin film is as the basis material and the metal is as the sputter target material. The metal bond cost is sputtered on the surface of one side of the macromolecule thin film. (2) The nickel alloy is as the sputter target material. The nickel alloy bond cost is sputtered on the surface of the metal bond cost. (3) The copper bond coat is sputtered on the surface of the nickel alloy bond coat by using copper as the sputter target material. Chromium-nickel alloy layer with coefficient of expansion between the coefficients of chrome sputter layer.

Owner:黄堂杰

Rare earth modification and ageing processing method of high chromium-nickel alloy steel guide plate

The invention discloses a rare earth modification and ageing processing method of a high chromium-nickel alloy steel guide plate, belonging to the technical field of metallurgy. The rare earth modification and ageing processing method comprises the following steps of: enabling large blocky net primary carbides to be subjected to necking and spheroidizing through a rare earth modification process;and separating out secondary carbides after an ageing process in tiny dispersive small particles instead of a plurality of thick strips. Due to the change of size, form and amount of the primary carbides and the secondary carbides, the service life of the high chromium-nickel alloy steel guide plate is prolonged. After modification and ageing processes are carried out on the guide plate, the original fragmentation situation is largely reduced, the service life is prolonged by 43-50%, the service life of small series guide plate is prolonged to 1000 times per piece from the original average 700 times per piece, the service life of a large series guide plate is prolonged to 1500 times per piece from the original average 700 times per piece, the energy consumption per ton steel is reduced, and the production cost is saved.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

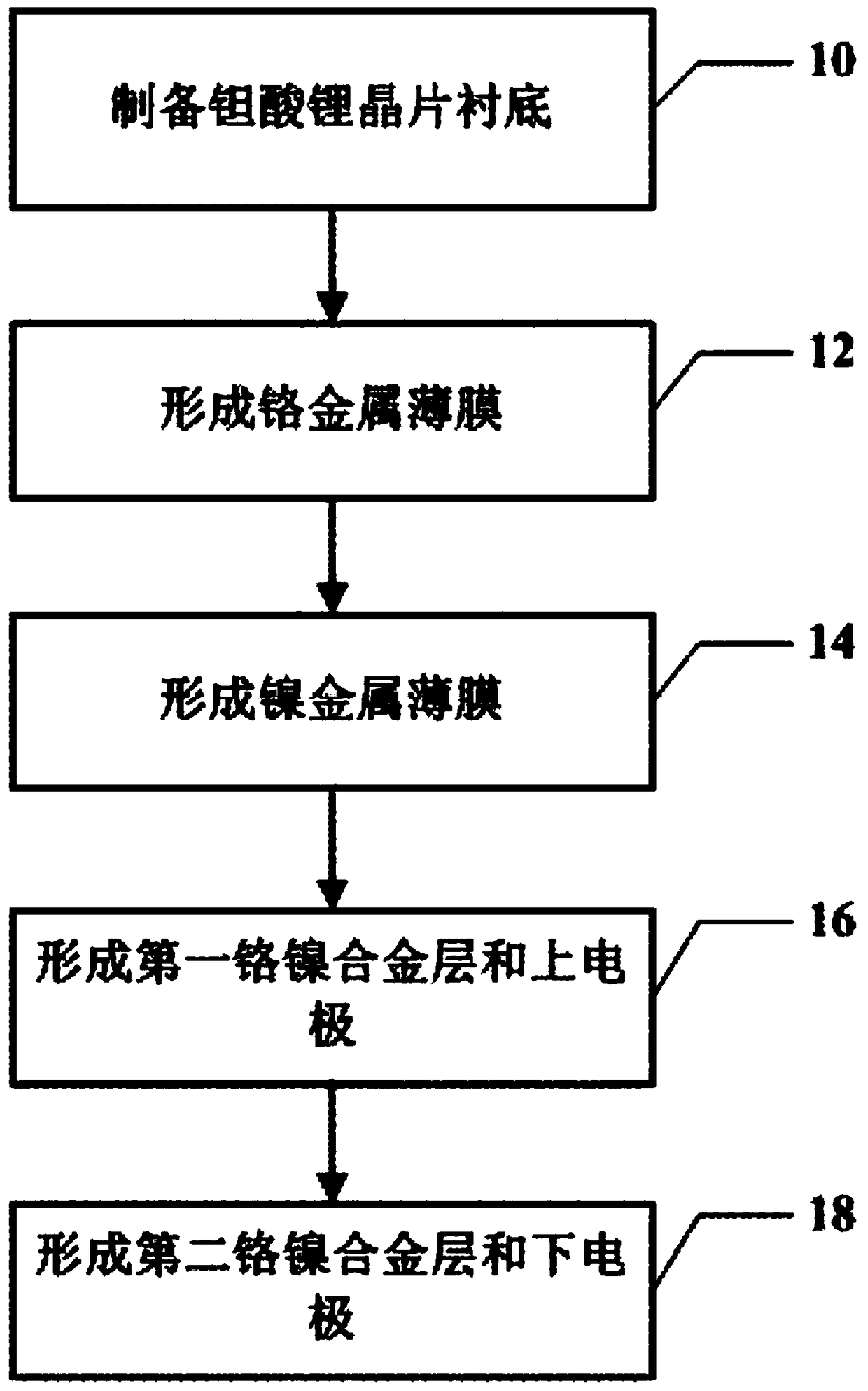

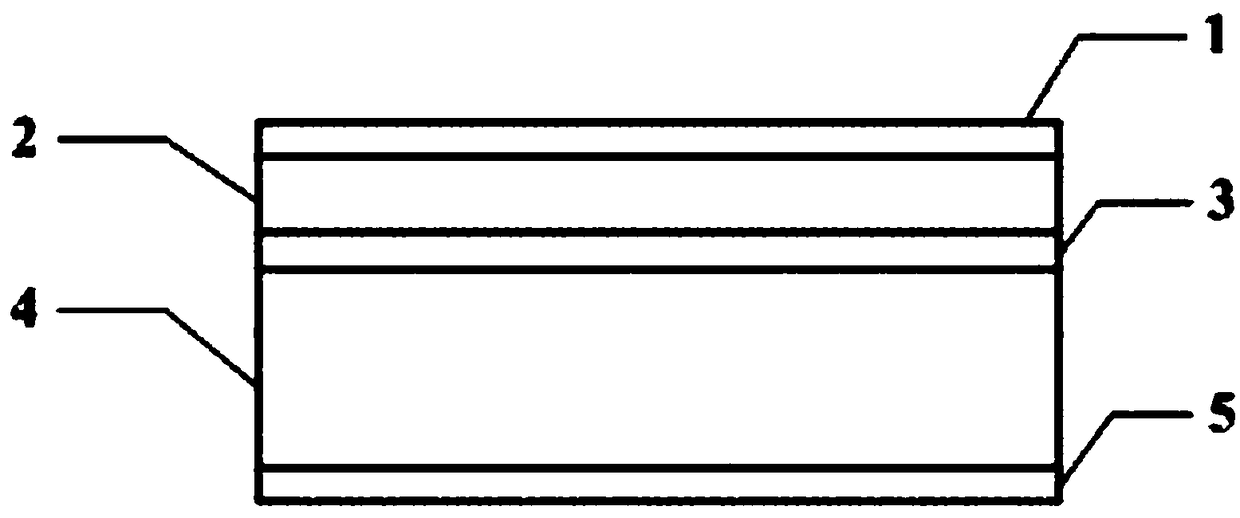

A method for manufacturing a pyroelectric infrared detector sensing unit

InactiveCN109216492AFirmly attachedGood repeatabilitySemiconductor devicesHigh absorptionChromium-Nickel Alloys

The invention discloses a method for manufacturing a pyroelectric infrared detector sensing unit, comprising the steps of: preparing a lithium tantalate wafer substrate; Forming a chromium metal filmon the first surface of the lithium tantalate wafer substrate; Forming a nickel metal film on the chromium metal film; Forming a first chromium-nickel alloy layer on the nickel metal film and etchingto form an upper electrode; A second chromium-nickel alloy layer is formed on the second surface of the lithium tantalate wafer substrate and etched to form a lower electrode. The absorption layer ofthe pyroelectric infrared detector sensing unit manufactured according to the method of the embodiment of the present invention has the advantages of firm adhesion, good repeatability, wide absorptionband, flat spectrum, high absorption rate, small specific heat capacity and excellent heat transfer performance. At the same time, the absorbing layer can also be used as the electrode, which is suitable for the pyroelectric infrared detector.

Owner:游代华

High-temperature wear resistant kilneye cap iron alloy and manufacturing method thereof

InactiveCN101476090BSolve non-wearable technical problemsReduce tensionFoundry mouldsFoundry coresChromium-Nickel AlloysWear resistant

The invention discloses a high-temperature wear-resistant kilneye protection iron alloy using the chromium-nickel alloy as the essential element. The kilneye protection iron alloy comprises the following components by weight percentage: C of 0.25-0.60, Cr of 26.00-30.00, Ni of 9.00- 12.00, Si of 0.80-1.50, Mn of 1.00-2.00, N of 0.15-0.30, Mo of 0.20-0.50, W of 0.50-1.00, Ti of 0.20-0.60, Nb of 0.20-0.60, V of 0.20-0.50, Re of 0.20-0.50, S<=0.04, P<=0.05, and Fe of the rest.The manufacturing process of the high-temperature wear-resistant kilneye protection iron alloy comprises steps of moulding preparation, smelting and pouring and thermal treatment. The invention solves the problem that the existing kilneye protection iron is un-wearable under a high temperature and the produced high-temperature wear-resistant kilneye protection iron alloy has three main advantages of high stretching and rigidity specific elongation index at normal temperature, strong oxidation resistance and antiwearquality at high temperature and service life longer than that of the existing products.

Owner:HENAN HONGYU SPECIAL CASTINGS

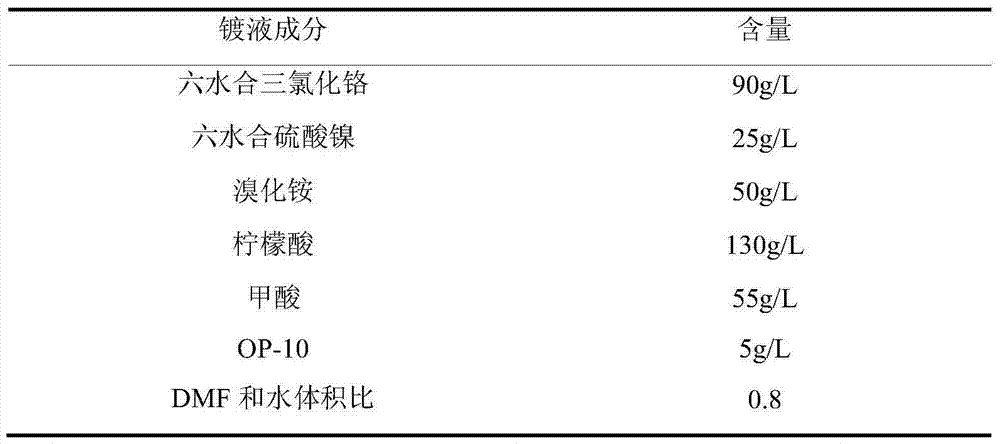

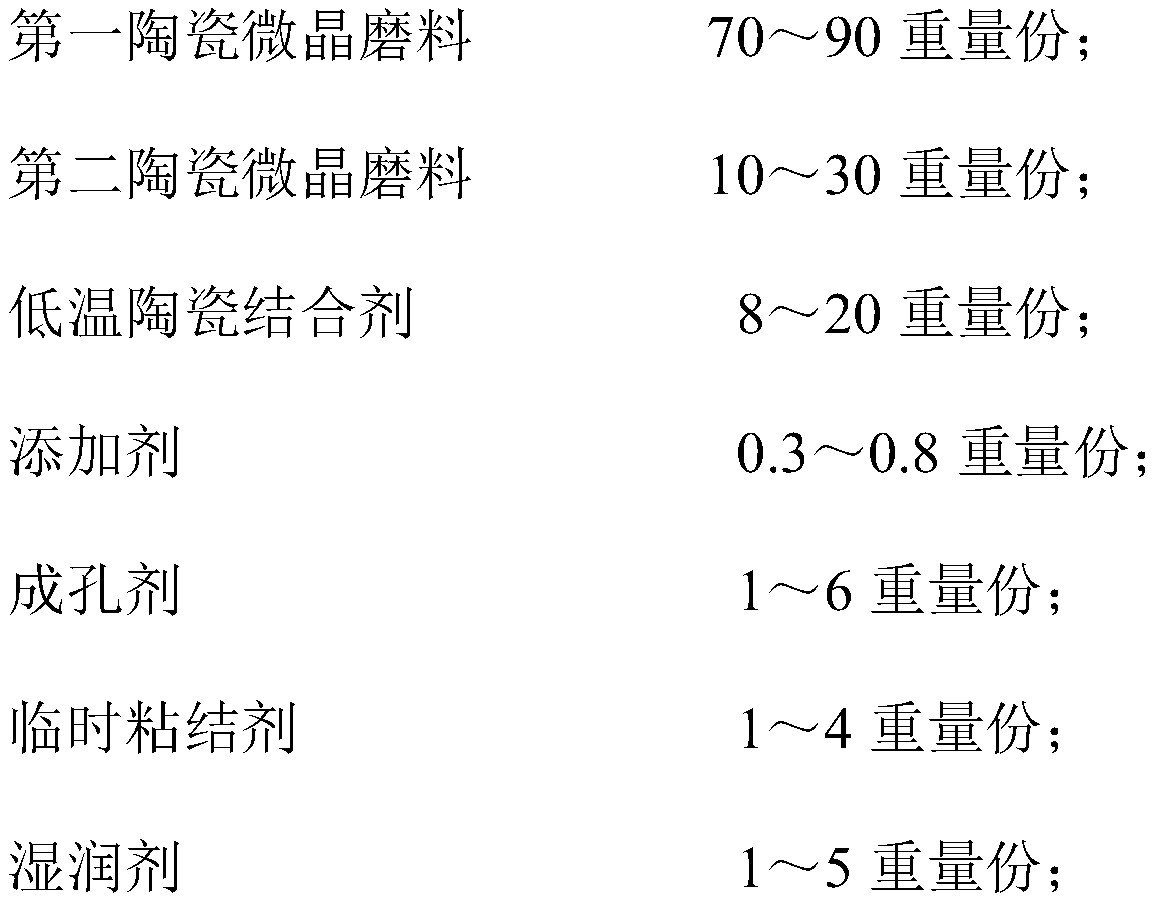

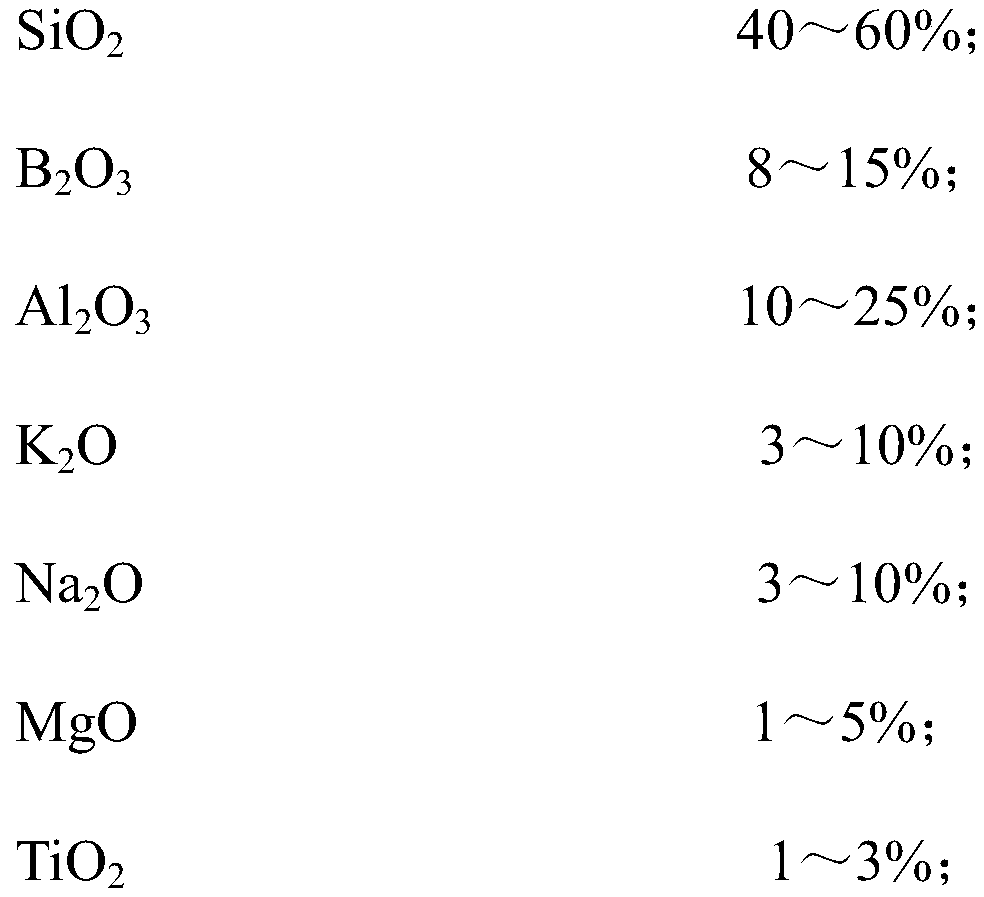

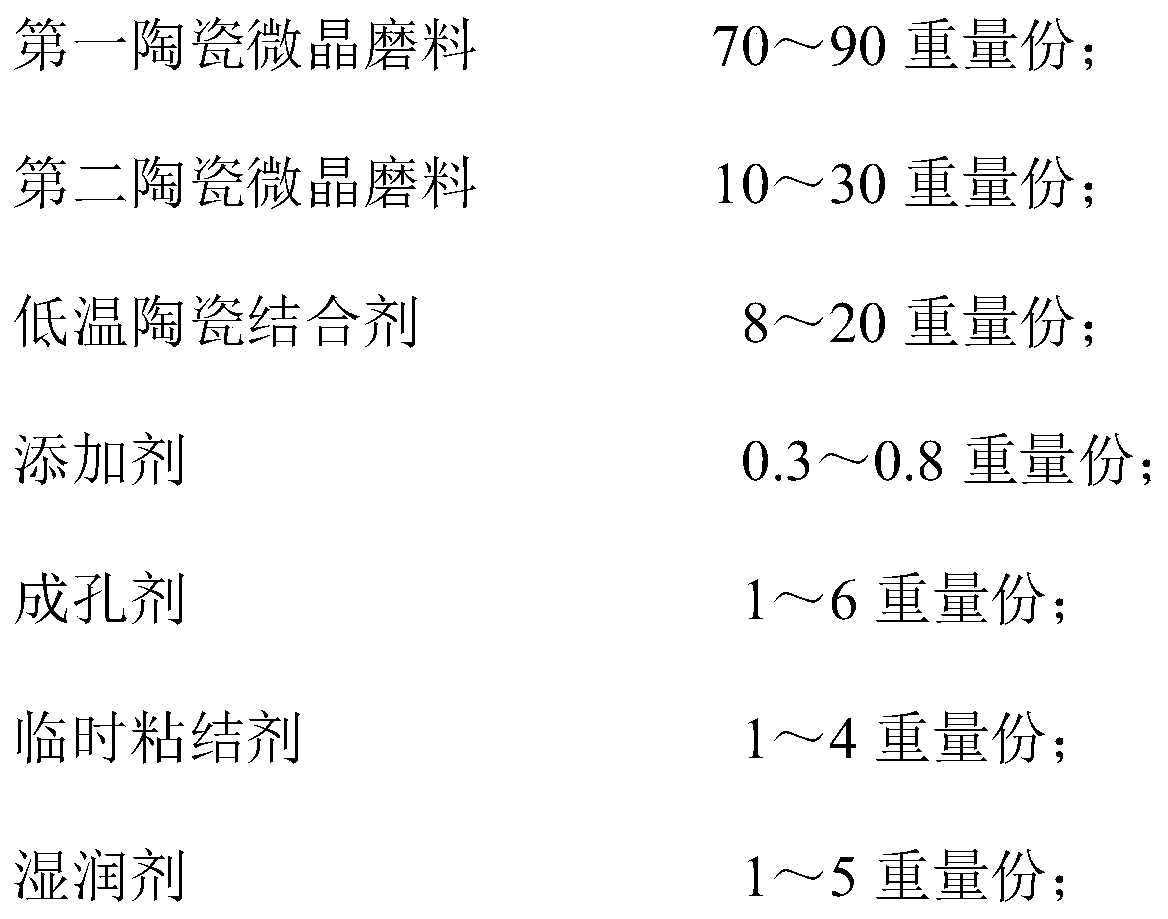

Ceramic microcrystalline grinding wheel for grinding cobalt-chromium-nickel alloy sealing block and manufacturing method of ceramic microcrystalline grinding wheel

ActiveCN109759963AGood self-sharpeningPlay a cohesiveAbrasion apparatusGrinding devicesChromium-Nickel AlloysGrinding wheel

The invention belongs to the technical field of grinding machining, and particularly relates to a ceramic microcrystalline grinding wheel for grinding cobalt-chromium-nickel alloy sealing block and amanufacturing method of the ceramic microcrystalline grinding wheel. The ceramic microcrystalline grinding wheel comprises a first ceramic microcrystalline abrasive, a second ceramic microcrystallineabrasive, a low-temperature ceramic binding agent, an additive, a pore-forming agent, a temporary binder and a wetting agent. The coarse-grain-sized first ceramic microcrystalline abrasive is taken asthe main abrasive; the fine-grain-sized second ceramic microcrystalline abrasive is taken as the auxiliary abrasive; the low-temperature ceramic binding agent which is prepared from the raw materialsof SiO2, B2O3, Al2O3, K2O, Na2O, MgO, and TiO2 in a certain ratio and through high-temperature smelting is selected to be matched with the additive (MnO2) in a certain ratio; and the shortage of workpiece burning and the grinding wheel surface retentivity conflict when an existing ceramic microcrystalline grinding wheel grinds and machines a cobalt-chromium-nickel alloy is overcome.

Owner:SUZHOU FAR EAST ABRASIVES

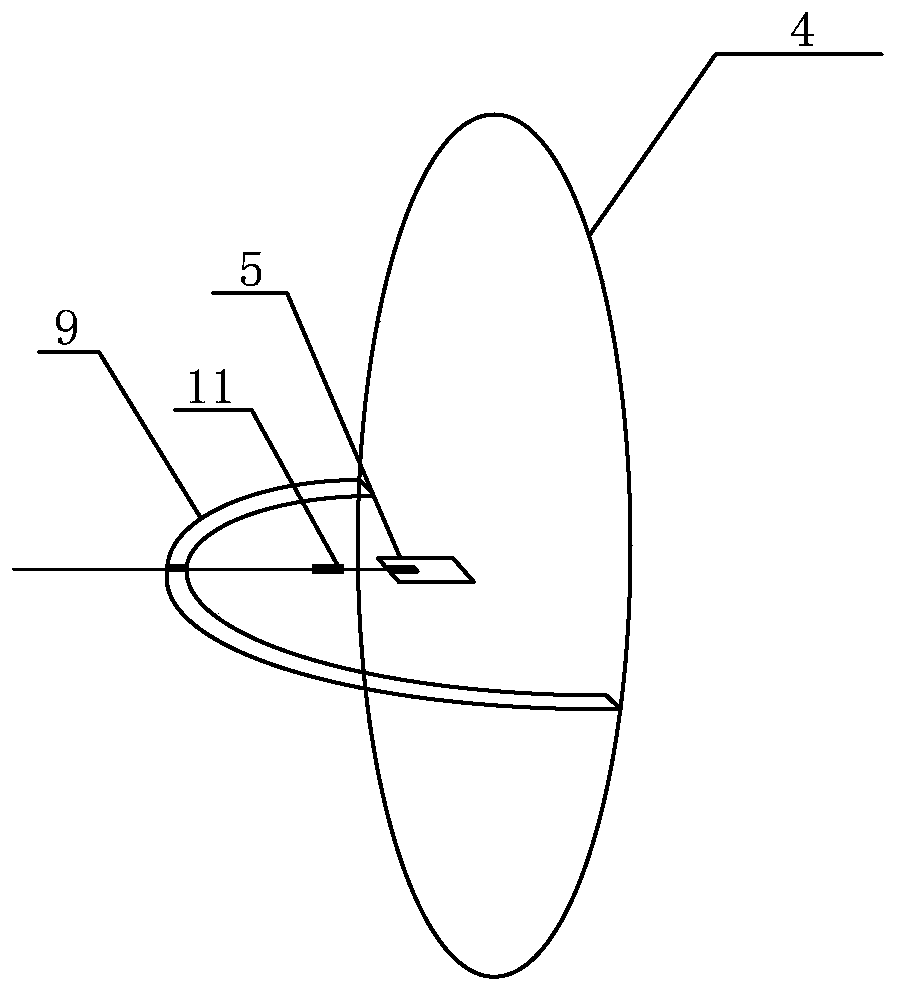

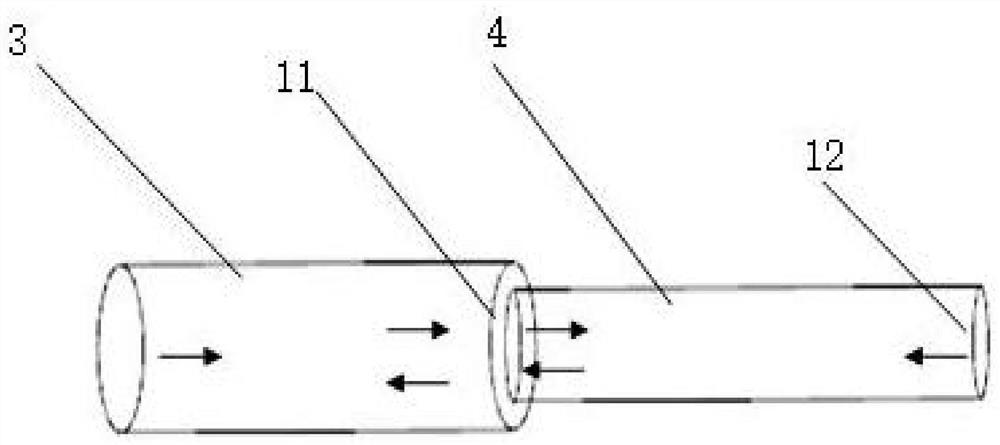

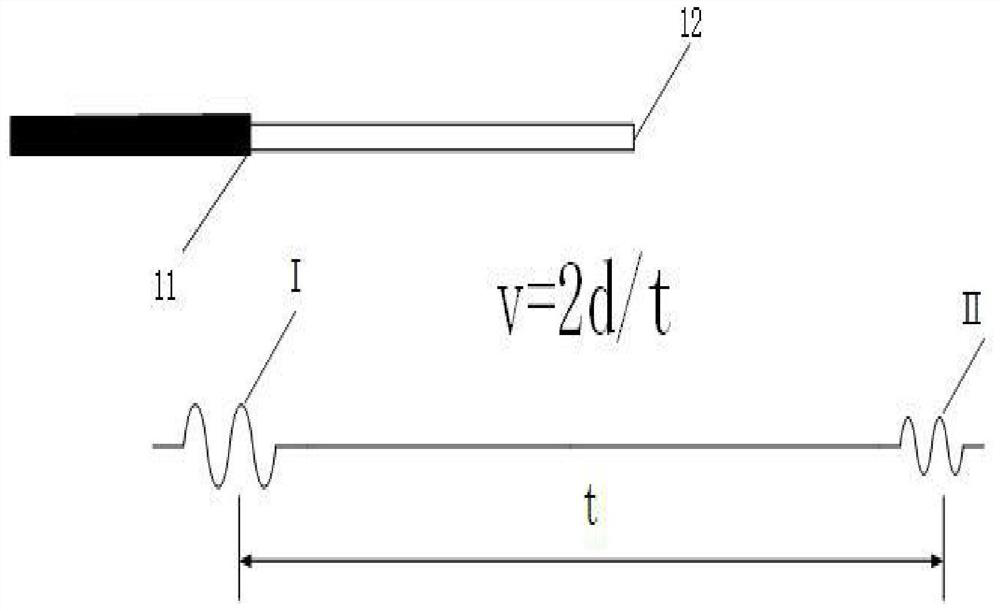

Ni-Cr alloy temperature sensor based on magnetostrictive torsional waves

ActiveCN112834069AReduce noise signal effectsGood non-dispersive propertiesThermometers using physical/chemical changesCircular discChromium-Nickel Alloys

The invention relates to a Ni-Cr alloy temperature sensor based on magnetostrictive torsional waves. The sensor comprises a cylindrical shell, a measuring rod, a Fe-Ga wire, a chromium-nickel alloy wire, a pulse signal generation module, a control sampling module, a ceramic sleeve, a damper, a permanent magnet and a detection coil; the right end of the measuring rod is closed, one end of the chromium-nickel alloy wire is fixed to the center of the inner wall of the right end of the measuring rod, the other end of the chromium-nickel alloy wire penetrates through the measuring rod, enters the shell and is connected with the right end of the Fe-Ga wire at the right portion in the ceramic sleeve, and the left end of the Fe-Ga wire passes through the interior of the ceramic sleeve, penetrates through the damper and is fixed to the center of the inner wall of the left end of the shell; and the appearance of the measuring rod is a linear measuring rod and a planar disc-shaped measuring rod. According to the invention, the noise signal influence caused by high voltage, high frequency and vibration in ultrasonic temperature measurement can be effectively reduced.

Owner:HEBEI UNIV OF TECH

Novel chromium-nickel alloy and method for centrifugally casting and producing high-temperature dusting corrosion resistant furnace tube by using alloy

ActiveCN103409664AOvercoming the problem of poor water flowAvoid chalkingBoiler flue tubes/fire tubesBoiler water tubesChromium-Nickel AlloysChemical composition

The invention discloses a novel chromium-nickel alloy and a method for centrifugally casting and producing a high-temperature dusting corrosion resistant furnace tube by using the alloy. The contents of chemical ingredients of the novel chromium-nickel alloy are as follows: 0.3-0.5% of Si, 0.3-0.5% of Mn, not more than 0.02% of P, not more than 0.01% of S, 24-26% of Cr, 59.3-65.5% of Ni, not more than 0.5% of Mo, 0.03-0.05% of Cu, 1.8-2.4% of Al, and the balance of micro alloying elements, including Ti, Zr and Re. The novel chromium-nickel alloy is adopted to produce the high-temperature dusting corrosion resistant furnace tube through a centrifugal casting method, the produced high-temperature dusting corrosion resistant furnace tube can replace an imported rolled 602CA alloy furnace tube, the requirement of a petrochemical high temperature device on an alloy furnace tube with metal powder dusting corrosion resistance and hydrogen resistance can be met, and a methanol device can produce methanol through recycled waste gases and tail gases.

Owner:QINGDAO NPA IND

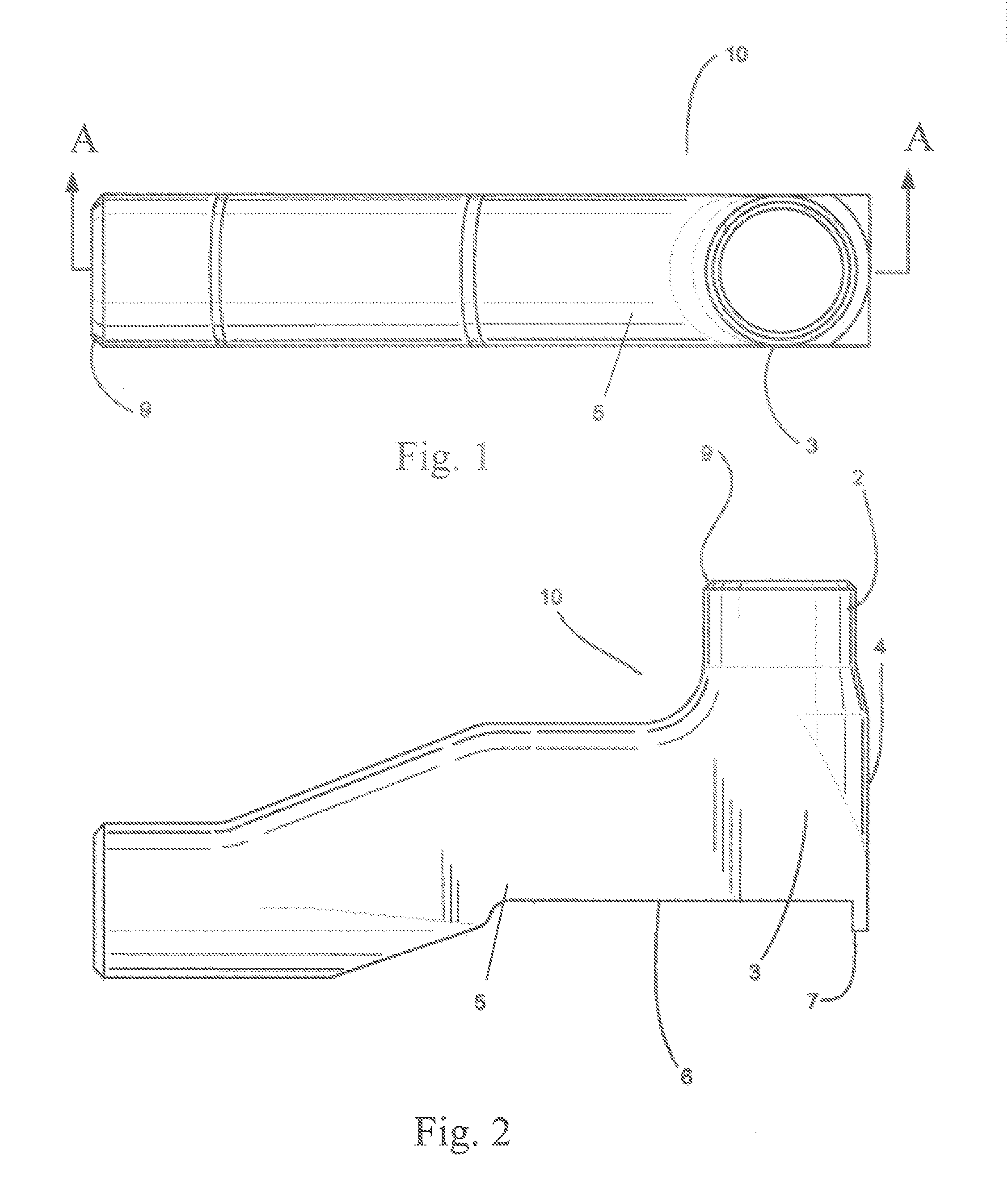

End Support Configuration for Steam Tubes of a Superheater or Reheater

InactiveUS20080264358A1Boiler supporting/setting arrangementsBoiler flue tubes/fire tubesChromium-Nickel AlloysSuperheater

End support for parallel tubes of a superheater or reheater with a bend tubular portion, a linear tubular portion extending away from each end of the bend tubular portion, and a supporting member formed on a curved section of the bend tubular portion. The tubular portions form a connection between two consecutive parts of a fluid passage. In a preferred embodiment, the tubular portions and the supporting member are integrally formed, molded or cast of a suitable material, such as carbon steel, stainless steel, chromium-nickel alloy, or other suitable alloys that have high temperature strength and oxidation resistance. The supporting member is configured to securely attach the end support configuration to the wall support brackets on the wall support tube. Preferably, the supporting member and the wall support bracket slide on one another to provide relative movement between the superheater tubes and the wall support or boiler tubes.

Owner:THE BABCOCK & WILCOX CO

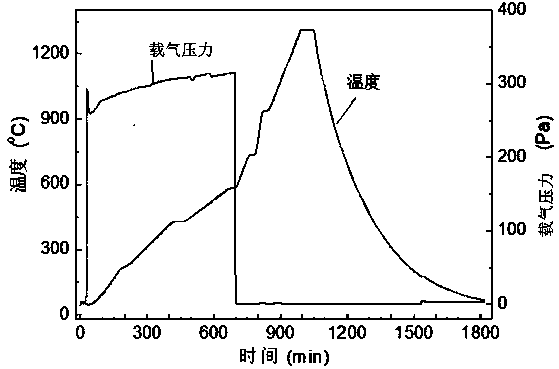

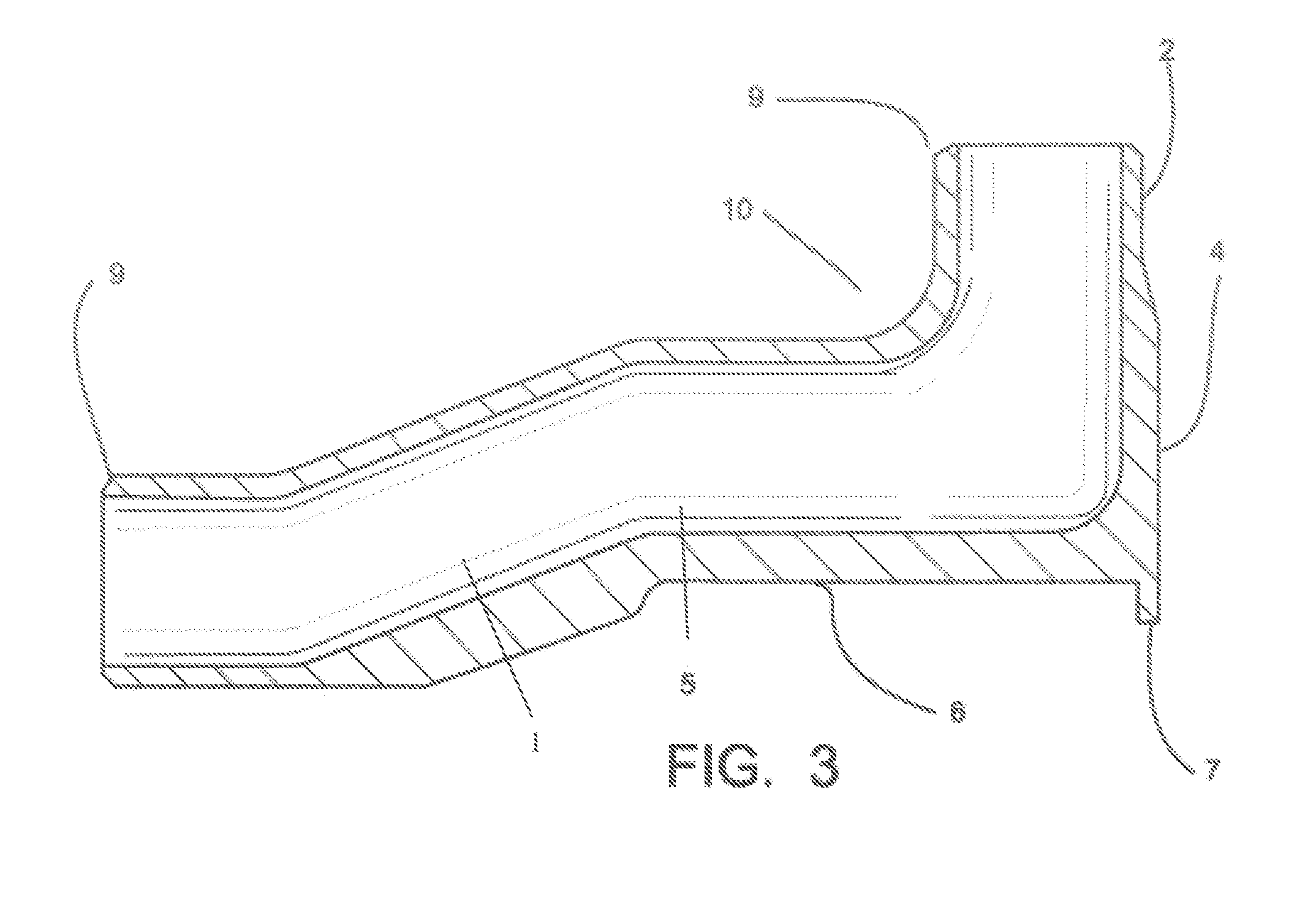

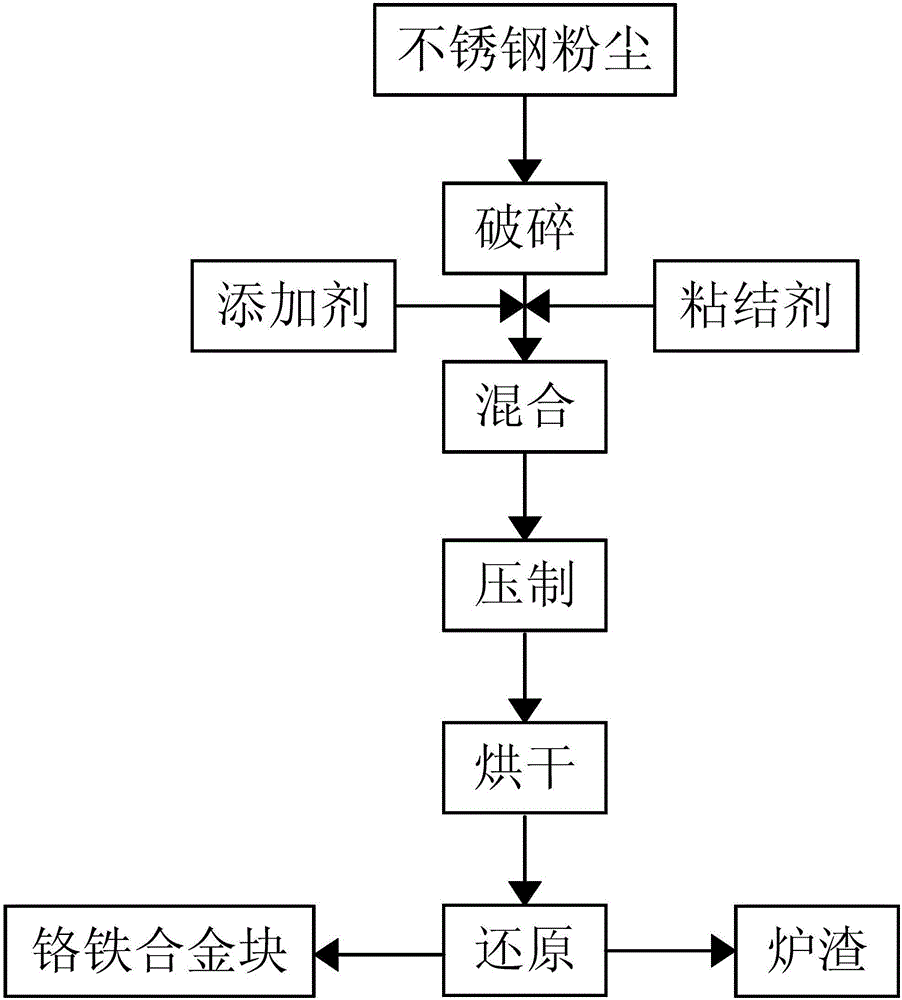

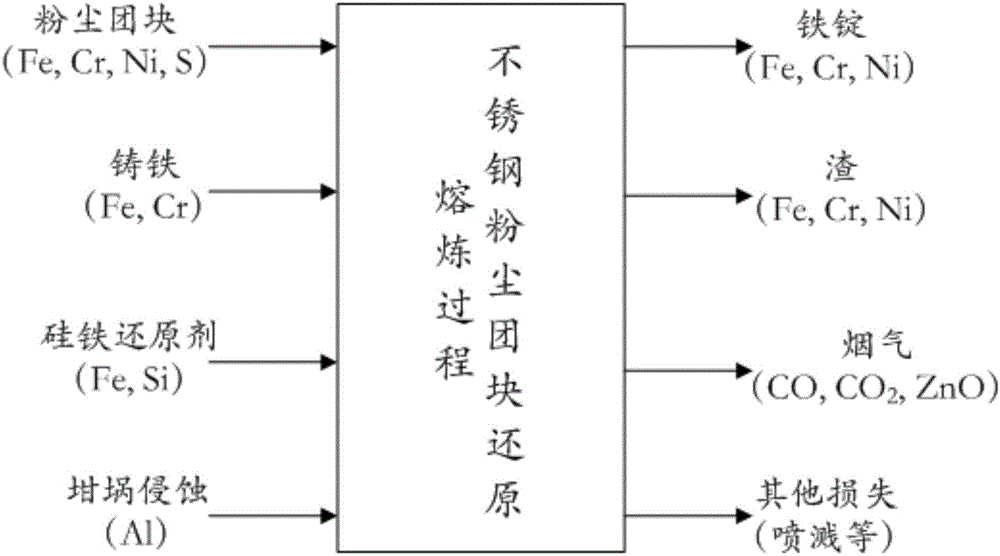

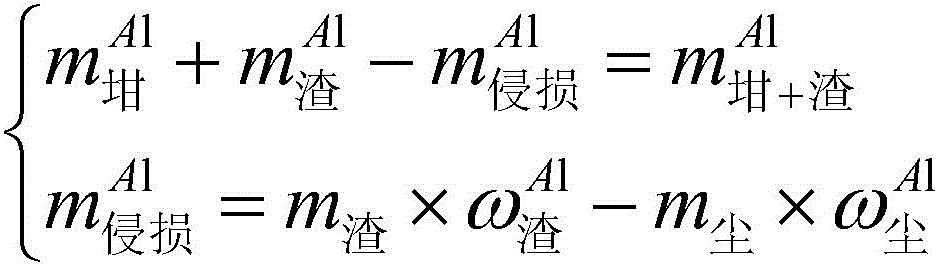

Method for preparing low-sulfur iron-chromium-nickel alloy block through stainless steel dust

ActiveCN106755976AHigh purity iron chromium nickelHigh purityProcess efficiency improvementChromium-Nickel AlloysSulfur

The invention discloses a method for preparing a low-sulfur iron-chromium-nickel alloy block through stainless steel dust. The method is conducted according to the following steps that firstly, a bonding agent and an additive are added into stainless dust after the stainless dust is broken, and the stainless dust is prepared into a mixed raw material; secondly, the mixed raw material is put into a die to be pressed into a block, the block is dried to reach constant weight, and a cold consolidation block is obtained; and thirdly, the cold consolidation block and cast iron are put into an alumina crucible in a reducing furnace to be heated to 1400 DEG C to 1600 DEG C and are reduced for 40 min to 50 min, and the iron-chromium-nickel alloy block and slag are obtained in the alumina crucible. By means of the method, the stainless steel dust can be directly used for preparing the iron-chromium-nickel alloy block needed in stainless steel production, the production technology is relatively simple, rough products have the beneficial effects that impurities are few and purity is high; and stainless steel other liquid source supply in the stainless steel production process can be achieved on the premise that high additional value utilization of stainless steel dust of a steel making enterprise is achieved.

Owner:JIANGXI UNIV OF SCI & TECH

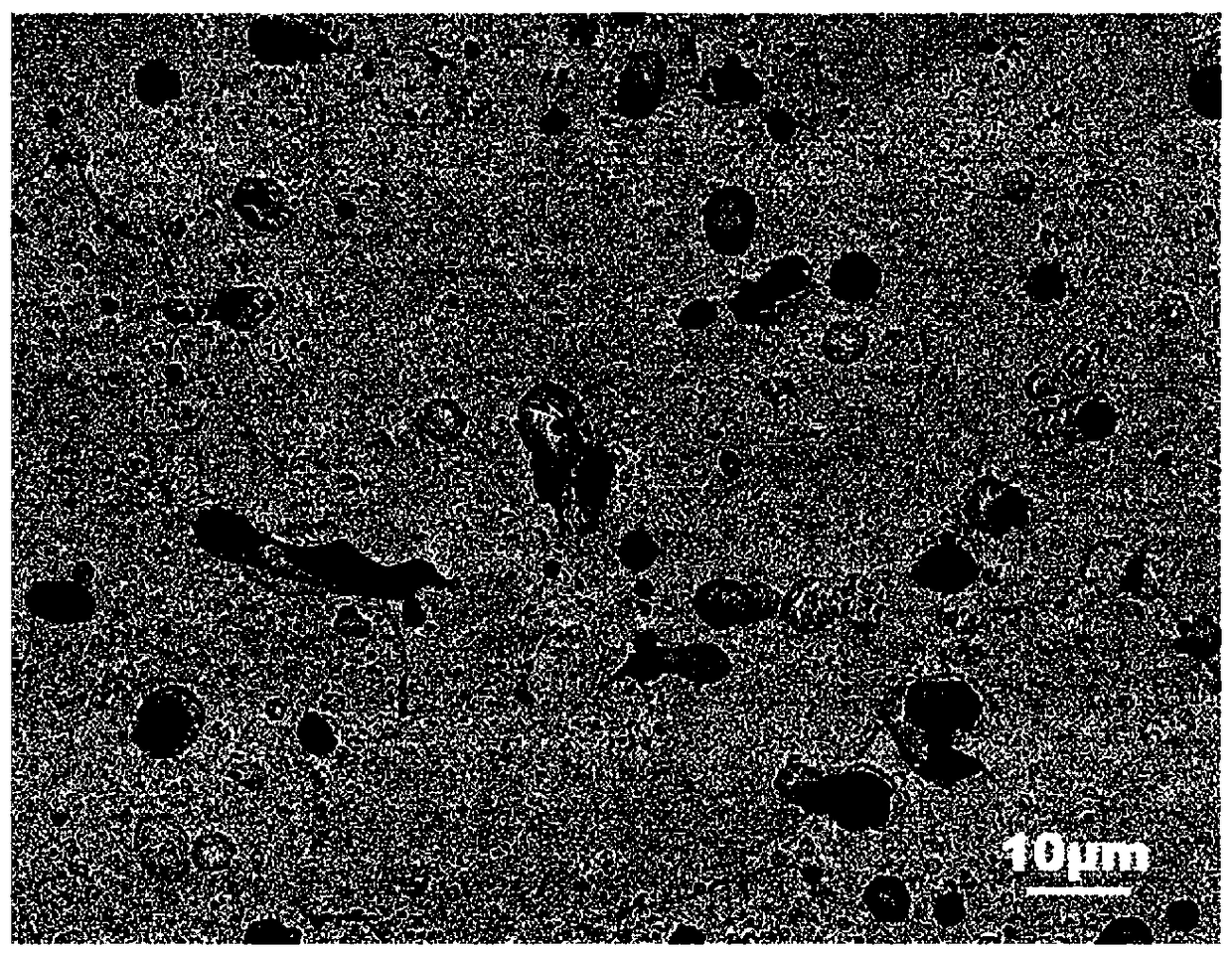

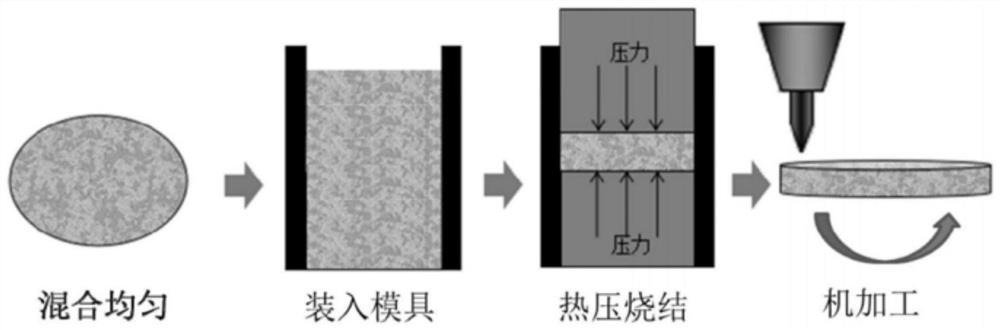

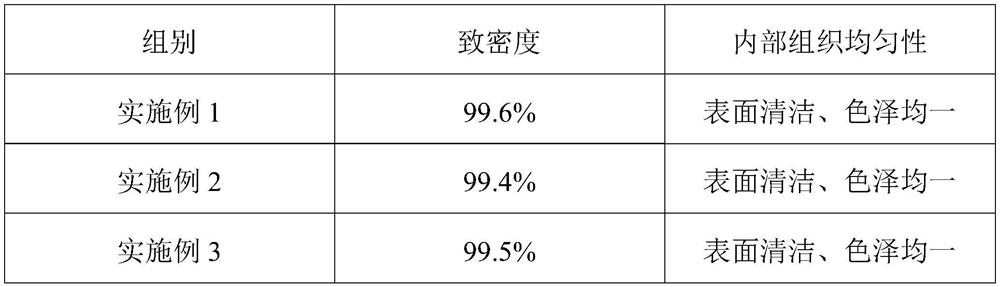

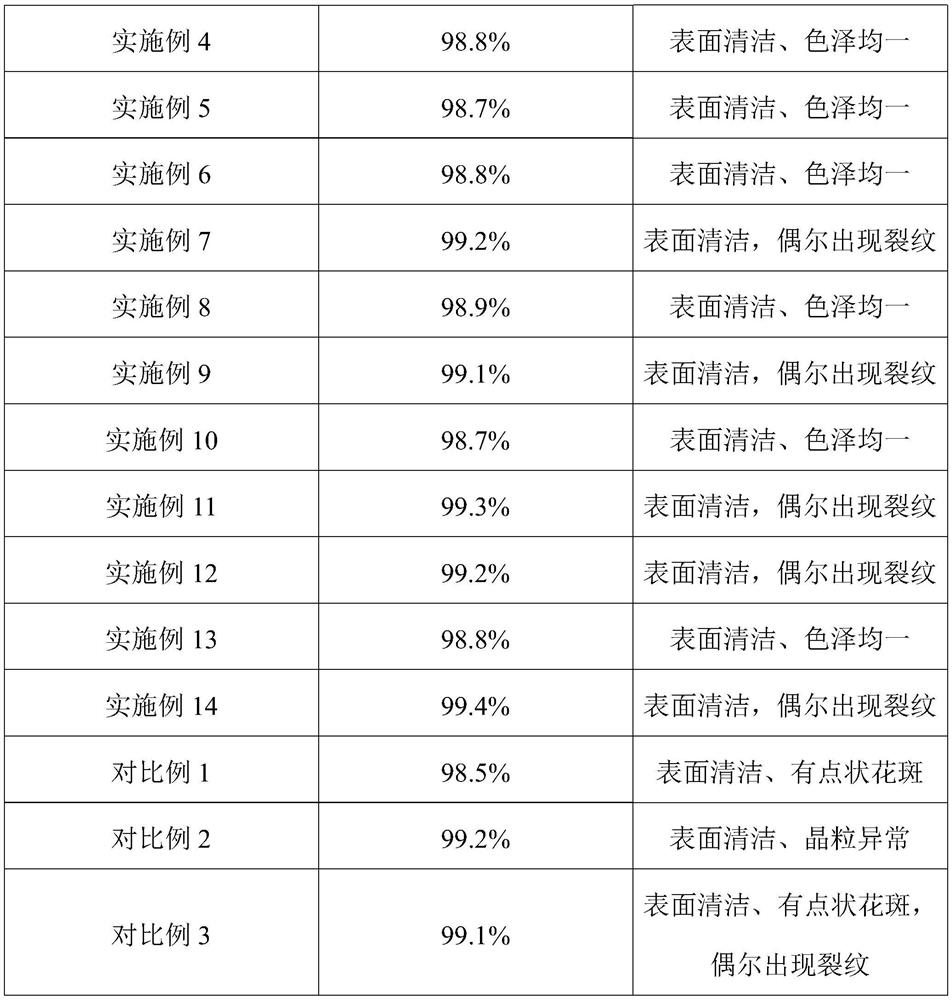

Chromium-nickel alloy sputtering target material and preparation method and application thereof

PendingCN112853283AHigh densityUniform structureVacuum evaporation coatingSputtering coatingChromium-Nickel AlloysNickel alloy

The invention provides a chromium-nickel alloy sputtering target material and a preparation method and application thereof. The preparation method comprises the following steps: (1) mixing chromium powder and nickel powder to obtain chromium-nickel powder; (2) filling and compacting the chromium-nickel powder obtained in the step (1) to obtain a chromium-nickel green body; (3) conducting vacuum hot pressing sintering treatment on the chromium-nickel green body obtained in the step (2) at the temperature of 850-1200 DEG C to obtain a chromium-nickel blank; and (4) machining the chromium-nickel blank obtained in the step (3) to obtain the chromium-nickel alloy sputtering target material. According to the preparation method provided by the invention, the compactness and microstructure uniformity of a target product are improved, and internal defects are eliminated.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

High-resistance chromium-nickel electrothermal alloy material for electric heating elements

InactiveCN106349776AExcellent abrasion resistanceAntioxidant is goodAnti-corrosive paintsHigh resistanceChromium-Nickel Alloys

The invention discloses a high-resistance chromium-nickel electrothermal alloy material for electric heating elements. The alloy material comprises a chromium-nickel alloy main body, wherein the chromium-nickel alloy main body is subjected to film coating treatment; the film coating treatment comprises the following steps: (1) sequentially adding 1-2 parts (by weight) of sodium silicate, 1.1 parts (by weight) of hydrolytic polymaleic anhydride, 2.8 parts (by weight) of polyethylene glycol and 0.7 part (by weight) of sodium alkylarylsulfonate into 40 parts (by weight) of deionized water, and carrying out uniform stirring; (2) then, sequentially adding 5.9 parts (by weight) of methyl laurate, 3.1 parts (by weight) of methacrylic acid, 1.3 parts (by weight) of sodium alpha-cyclohexylsulfamate and 0.8 part (by weight) of N-phenyl-2-naphthylamine into the solution, and continuing to carry out stirring until thorough and uniform mixing is achieved, so as to prepare a film coating treatment solution; (3) dipping the chromium-nickel alloy main body in the film coating treatment solution, taking out the chromium-nickel alloy main body, and then, baking the chromium-nickel alloy main body. According to the high-resistance chromium-nickel electrothermal alloy material for the electric heating elements, disclosed by the invention, the surface of the chromium-nickel alloy main body is coated with a protective film, so that the performance is good, and the surface smoothness is good.

Owner:CHANGSHU MEILI ALLOY MATERIAL CO LTD

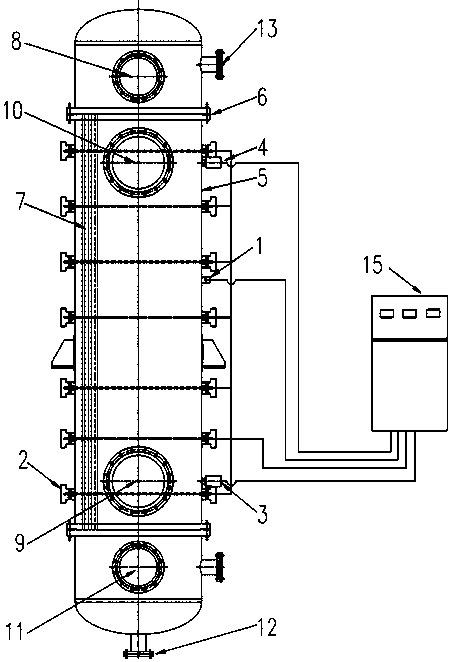

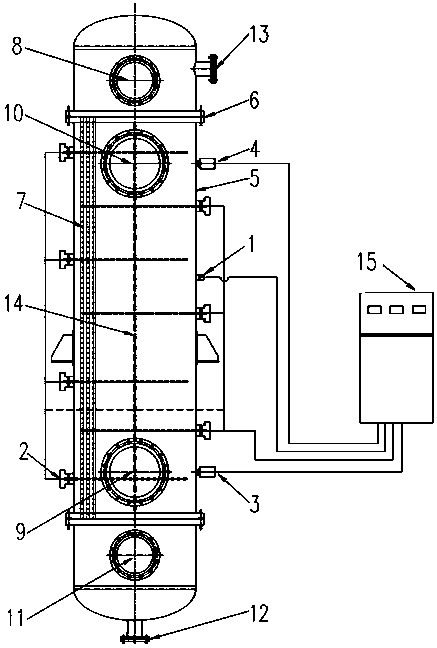

Application of chrome-nickel containing alloy vertical concentrated sulfuric acid cooler in low-temperature-position waste heat recycling device and power generation system comprising same

PendingCN108441709AEnvironmental protection is goodIncrease profitSulfur compoundsSteam useAcid concentrationSmall footprint

The invention discloses application of a chrome-nickel containing alloy vertical concentrated sulfuric acid cooler in a low-temperature-position waste heat recycling device and a power generation system comprising the same. The chrome-nickel containing alloy is composed of 19-30% of Cr, 5-50% of Ni and greater than or equal to 0.5 and less than or equal to 3 of (Cr+Si) / (Ni+Mo) or 19-30% of Cr, 5-50% of Ni and greater than or equal to 0.54 and less than or equal to 2.9, and the vertical concentrated sulfuric acid cooler has an anode protection system. The cooler has wider application range andbetter environment-friendly performance than existing concentrated sulfuric acid. The cooler has the main advantages that on an acid side, usable sulfuric acid concentration range is 93-100%, usable temperature range is 40-130 DEG C, equipment corrosion rate is lower than or equal to 0.1mm per year, and service life of the concentrated sulfuric acid cooler is longer than or equal to 8 years; shell-side acid concentration of the cooler is 93-100%, and temperature range is 40-130 DEG C; circulating water on a tube side is 0-130 DEG C; a cathode of the vertical protection concentrated sulfuric acid cooler is arranged perpendicular to a barrel, so that the defect of cathode replacement at the top end of equipment is avoided. The cooler is compact in structure, small in occupied area and suitable for existing anode protection concentrated sulfuric acid coolers realizing cooling through circulating water and organic working media.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

Chromium-nickel electrothermal alloy material

InactiveCN107760178AExcellent abrasion resistanceAntioxidant is goodAnti-corrosive paintsPolyether coatingsChromium-Nickel AlloysGlutaric acid

The invention discloses a chromium-nickel electrothermal alloy material which comprises a chromium-nickel alloy main body, wherein the chromium-nickel alloy main body is subjected to filming treatment; the filming treatment comprises the following steps: (1) sequentially putting 1-2 parts by weight of alkylolamides polyoxy ethane ether, 1.2 parts by weight of sodium xylene sulfonate, 2.3 parts byweight of vinyl acetate and 2.8 parts by weight of potassium sodium tartrate into 35 parts by weight of deionized water, and uniformly stirring; 92) further sequentially adding 2.6 parts by weight of2-phosphate-1,2,4-tricarboxylic acid butane, 1.9 parts by weight of sodium hexametaphosphate, 3.7 parts by weight of 1,3 glutaric acid morpholine and 2.8 parts by weight of 2-aminoethyl heptadecene imidazoline, continuously stirring till sufficient and uniform mixing is achieved so as to obtain a filming treatment solution; and (3) soaking the chromium-nickel alloy main body into the filming treatment solution, taking out, and drying. As the surface of the chromium-nickel alloy main body is covered by a protection film, the chromium-nickel electrothermal alloy disclosed by the invention is good in performance and good in surface smoothness.

Owner:CHANGSHU MEILI ALLOY MATERIAL CO LTD

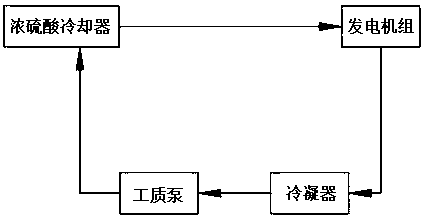

Superfine ground calcium carbonate and preparation method thereof

ActiveCN114773880ALittle effect on whitenessImprove technical levelPigment treatment with macromolecular organic compoundsPigment physical treatmentChromium-Nickel AlloysDiethylene glycol

The invention provides superfine ground calcium carbonate and a preparation method thereof, and belongs to the technical field of ground calcium carbonate. Mixing calcite particles, water and a grinding aid to obtain a mixture; the grinding aid comprises polyethylene glycol, diethylene glycol and a titanate coupling agent; carrying out ball milling on the mixture to obtain a ball-milled material; a grinding medium of the ball mill is an Al2O3 ceramic ball or a zirconia ball, and a lining of the ball mill is an Al2O3 full-ceramic lining or a chromium-nickel alloy lining; and grading the ball-milled material to obtain the superfine heavy calcium carbonate. The ball-milled lining is an Al2O3 full-ceramic lining or a chromium-nickel alloy lining, so that the situation that the product is polluted due to the fact that scrap iron of a traditional iron lining and a steel ball is brought in is effectively avoided, the whiteness of the product and the low iron impurity content are guaranteed, the influence on the whiteness of calcium carbonate is small, the iron impurity content is low, and the problems that the whiteness is influenced by a traditional dry ball-milling process, and the product quality is poor are solved. And the product has high magnetic substance content (iron scrap pollution).

Owner:JIANGXI GUANGYUAN CHEM +1

Anti-coating reddening and anti-cracking double-core flux-coated electrode for stainless steel welding

InactiveCN110936057ADoes not cause rednessWill not cause crackingWelding/cutting media/materialsSoldering mediaChromium-Nickel AlloysNichrome

The invention belongs to the field of welding materials, and particularly relates to an anti-coating reddening and anti-cracking double-core flux-coated electrode for stainless steel welding. The coreis formed by connecting a solid core with beads and a hollow core with grooves through matching the beads with the grooves, a gap of 0.8-1.2mm is reserved between the solid core and the hollow core,and the outer surface of the hollow core is coated with a coating. The hollow core is made of carbon steel, the volume expansion is small after the hollow core is heated, the generated resistance heatis little, and the phenomena of reddening and cracking of the coating are avoided. The solid core is made of chromium-nickel alloy, the volume expansion is large after the solid core is heated, and much resistance heat is generated. Due to the gap between the solid core and the hollow core, the outer circle of the hollow core does not expand, the heat generated by the solid core can be rapidly dissipated from the gap, and the phenomena of reddening and cracking of the coating are avoided. After the electrode is melted, elements such as nickel and chromium can be uniformly mixed with other parts of a molten pool under the action of electric arc blowing force, and chemical components of a formed weld joint meet the requirements of stainless steel deposited metal.

Owner:ZHENGZHOU UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com