Trivalent Chromium Electroplating Solution and an Operational Method Thereof

a technology of trivalent chromium and electroplating solution, applied in the field of trivalent chromium electroplating solution, can solve the problem that hexavalent chromium-based solution is not suitable for application, and achieve the effect of high current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

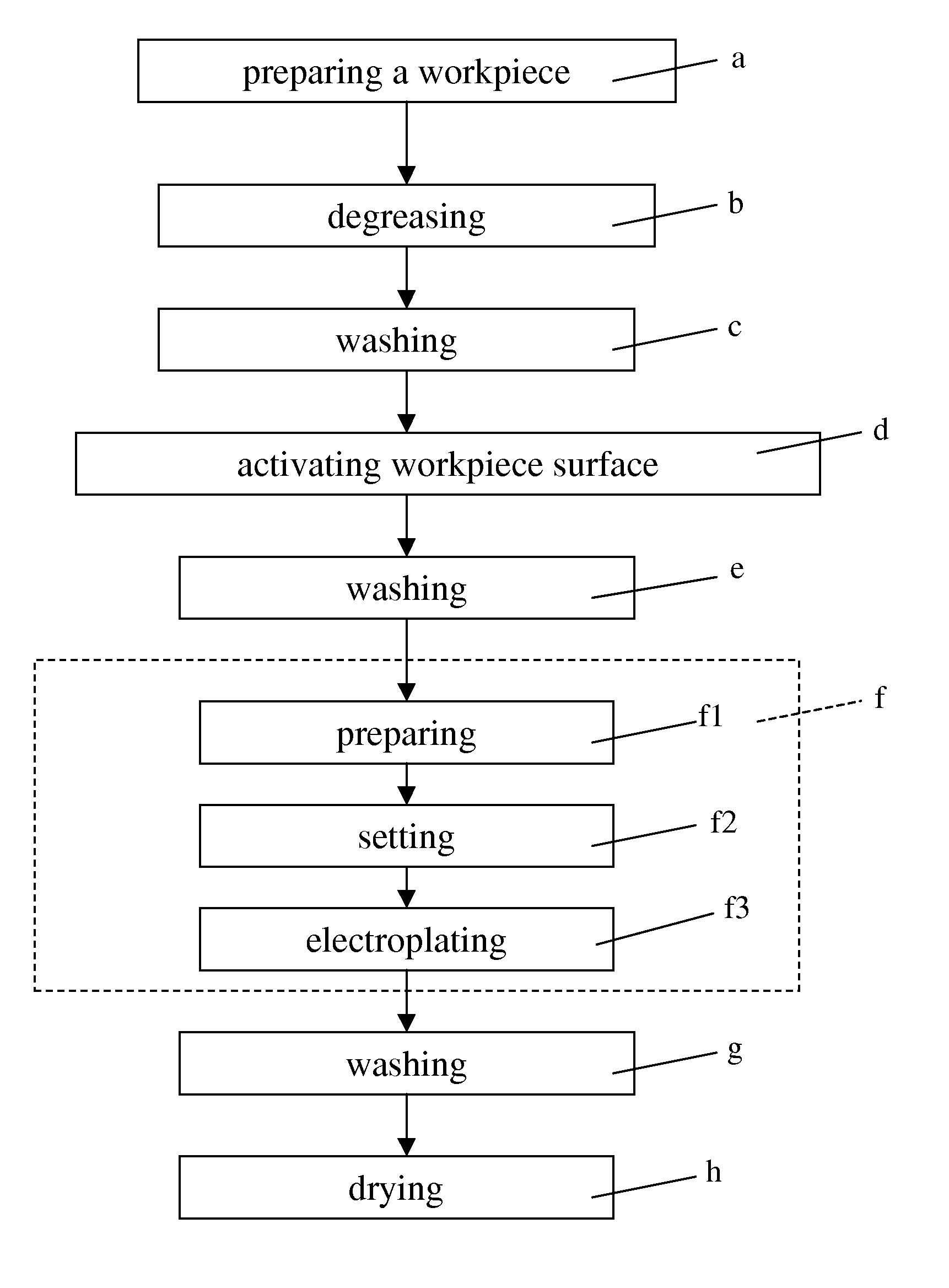

Method used

Image

Examples

Embodiment Construction

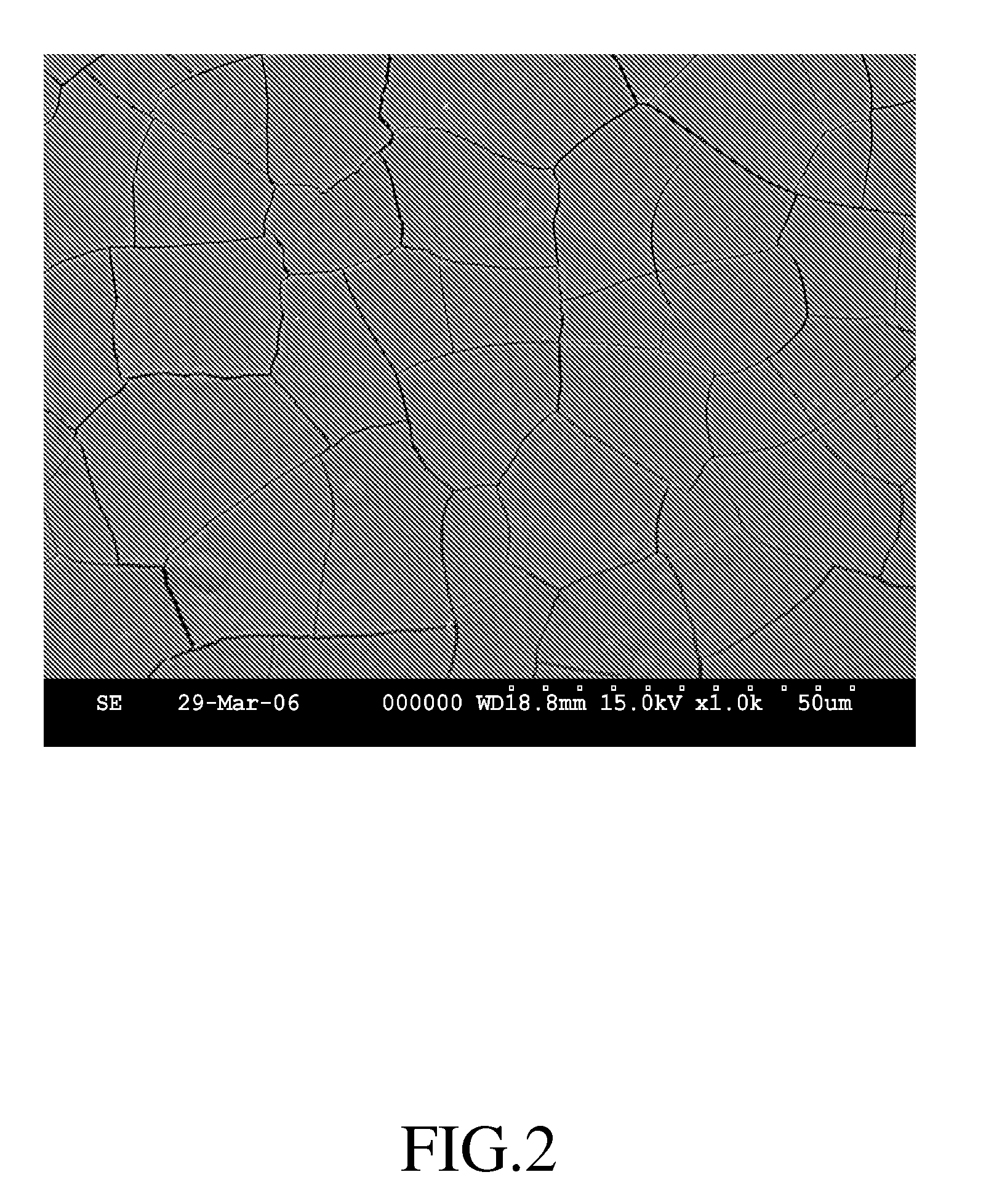

[0013]A trivalent chromium-based electroplating solution in accordance with the present invention contains a trivalent chromium salt, a bivalent nickel salt, a complex agent, a conductive salt, a buffering agent and an additive for electroplating a chromium-nickel deposit on a metal component. By using the lowly toxic trivalent chromium ion to substitute highly toxic hexavalent chromium ion, the present trivalent chromium-based electroplating solution has much less pollution and high current efficiency to obtain chromium-nickel deposits with different ratios of chromium and nickel concentrations. Moreover, the electroplating can be conducted at room temperature.

[0014]The trivalent chromium-based solution comprises: 0.1-1.2 mole / L of the trivalent salt that is selected from the group consisting of chromium chloride, chromium sulfate, or a hydrate of each forgoing salts; 0.1-0.8 mole / L of the bivalent salt that is selected from the group consisting of nickel chloride, nickel sulfate, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com