Chromium-nickel alloy sputtering target material and preparation method and application thereof

A technology of sputtering target and chromium-nickel alloy, which is applied in the field of sputtering target, can solve the problems of unsuitable chromium-nickel alloy sputtering target, rolling cracking, and uneven composition, so as to achieve uniform internal structure and reduce energy consumption. Consumption and cost, the effect of improving density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

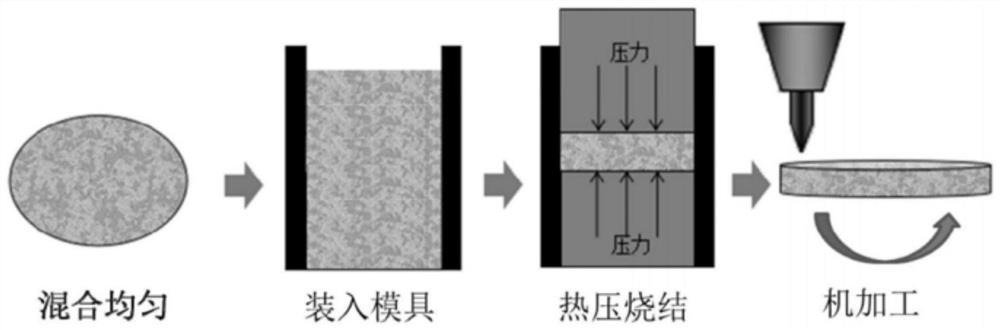

[0078] This embodiment provides a chromium-nickel alloy sputtering target and its preparation method, such as figure 1 Shown, described preparation method comprises the following steps:

[0079] (1) In a powder mixer, the chromium powder with a particle size of 3 μm and the nickel powder with a particle size of 10 μm are added, and zirconia balls are added to dry mix for 24 hours to obtain chromium-nickel powder; the chromium powder accounts for the total amount of chromium-nickel powder. 65% of the mass, the mass ratio of the zirconia ball to the chromium-nickel powder is 1:10;

[0080] (2) packing in the graphite mold with a flatness of 5mm, and carrying out the compaction step (1) gained chromium-nickel powder with a flatness of 0.5mm to obtain a chromium-nickel green body;

[0081] (3) Putting the chromium-nickel green body and the graphite mold obtained in step (2) into a vacuum furnace to carry out 900-1100°C vacuum hot-pressing sintering treatment to obtain the chromiu...

Embodiment 2

[0091] This embodiment provides a chromium-nickel alloy sputtering target and its preparation method, such as figure 1 Shown, described preparation method comprises the following steps:

[0092] (1) In a powder mixer, the chromium powder with a particle diameter of 1 μm and the nickel powder with a particle diameter of 8 μm are added, and zirconia balls are added to dry mix for 22 hours to obtain chromium-nickel powder; the chromium powder accounts for the total amount of chromium-nickel powder. 60% of the mass, the mass ratio of the zirconia ball to the chromium-nickel powder is 1:8;

[0093] (2) packing in the graphite mold with a flatness of 4mm, and carrying out the compaction step (1) gained chromium-nickel powder with a flatness of 0.4mm to obtain a chromium-nickel green body;

[0094](3) putting the chromium-nickel green body and the graphite mold obtained in step (2) into a vacuum furnace to carry out 850-1000°C vacuum hot-pressing sintering treatment to obtain the ch...

Embodiment 3

[0104] This embodiment provides a chromium-nickel alloy sputtering target and its preparation method, such as figure 1 Shown, described preparation method comprises the following steps:

[0105] (1) In the powder mixer, the chromium powder with a particle size of 5 μm and the nickel powder with a particle size of 12 μm are mixed, and zirconia balls are added to dry mix for 26 hours to obtain chromium-nickel powder; the chromium powder accounts for the total amount of chromium-nickel powder. 70% of the mass, the mass ratio of the zirconia ball to the chromium-nickel powder is 1:12;

[0106] (2) packing in the graphite mold with a flatness of 3 mm, and carrying out the compaction step (1) gained chromium-nickel powder with a flatness of 0.3 mm to obtain a chromium-nickel green body;

[0107] (3) putting the chromium-nickel green body and the graphite mold obtained in step (2) into a vacuum furnace to carry out 950-1200°C vacuum hot-pressing sintering treatment to obtain the chr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com