Cardiovascular stent with Ag-TiO2 coating on surface and preparation method of cardiovascular stent

A cardiovascular and coating technology, applied in the field of cardiovascular stents with Ag-TiO2 coating on the surface and its preparation, can solve problems such as easy fracture or collapse, poor corrosion resistance of magnesium and magnesium alloys, loss of support, etc. , to achieve the effect of prolonging the service life, high use value and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

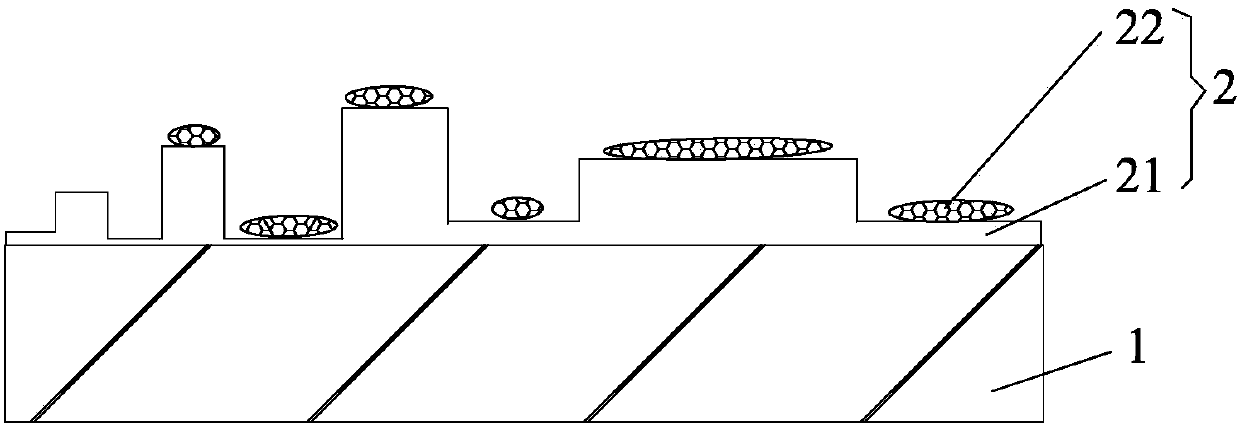

[0024] A surface with Ag-TiO 2 A coated cardiovascular stent, including a base layer 1 of the cardiovascular stent and an Ag coating 2 covered thereon, the Ag-TiO 2 The coating 2 includes an oxide film layer 21 , and the oxide film layer 21 contains nano-silver and / or silver oxide particles 22 .

[0025] The base layer 1 of the cardiovascular stent is one of magnesium-titanium alloy, magnesium-titanium-aluminum alloy, magnesium-aluminum-chromium alloy, magnesium-aluminum-chromium-nickel alloy, and magnesium-aluminum-cobalt-chromium alloy.

[0026] The main component of the oxide film layer 21 is TiO 2 , is the uneven film layer. Uniformly cover the base layer 1 of the cardiovascular stent with a thickness of 1-100um, preferably 10-100um, most preferably 20-40um.

[0027] The nano-silver and / or silver oxide particles 22 are unevenly deposited or embedded in the oxide film layer 21 , and the concentration thereof decreases as the depth of the oxide film layer 21 increases.

Embodiment 2

[0029] The preparation method of the above-mentioned cardiovascular stent comprises the following steps:

[0030] 1) prepare colloidal dispersion system, described colloidal dispersion system comprises pure water with zero electrical conductivity, disperse particle, electrolyte and additive; Wherein, described disperse particle concentration is 50mg / L, is nano-silver particle, and particle size is 10- 30nm; the concentration of the additive is 10mg / L, which is magnesium oxide; the formula of the electrolyte is Na 2 SiO 3 115g / L, NaOH 20g / L, organic amine 15g / L, peroxide 5g / L;

[0031] 2) Put the colloid dispersion system into an electrolytic cell, dip the cardiovascular stent into the colloid dispersion system, then connect the cardiovascular stent to the positive pole of the power supply, set the negative pole of the power supply in the electrolytic cell, The negative pole of the power supply is cup-shaped and surrounds the positive pole of the power supply, and generates ...

Embodiment 3

[0033] The preparation method of the above-mentioned cardiovascular stent comprises the following steps:

[0034] 1) Prepare a colloidal dispersion system, which includes ion-exchanged water with low conductivity, dispersed particles, electrolytes and additives; wherein, the dispersed particle concentration is 100mg / L, which is silver oxide particles and / or nano silver Particles, particle size is 10nm; The concentration of the additive is 1mg / L, selected from magnesium oxide; The formula of the electrolyte is Na 2 SiO 310g / L, NaOH20g / L, organic amine 20g / L, peroxide 2g / L;

[0035] 2) Put the colloidal dispersion system into the electrolytic cell, dip the cardiovascular stent into the colloidal dispersion system, then connect the cardiovascular stent to the positive pole of the power supply, set the negative pole of the power supply in the electrolytic cell, and the The negative pole of the power supply is cup-shaped and surrounds the positive pole of the power supply, and an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com