Superfine ground calcium carbonate and preparation method thereof

A heavy calcium carbonate, mass ratio technology, applied in fibrous fillers, dyed high molecular organic compound treatment, dyed low molecular organic compound treatment, etc., can solve the problem of affecting the whiteness and electrical insulation of heavy calcium products, and low grinding efficiency , iron filings pollution and other issues, to achieve the effects of pollution-free fine production, improved grinding efficiency, and increased output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

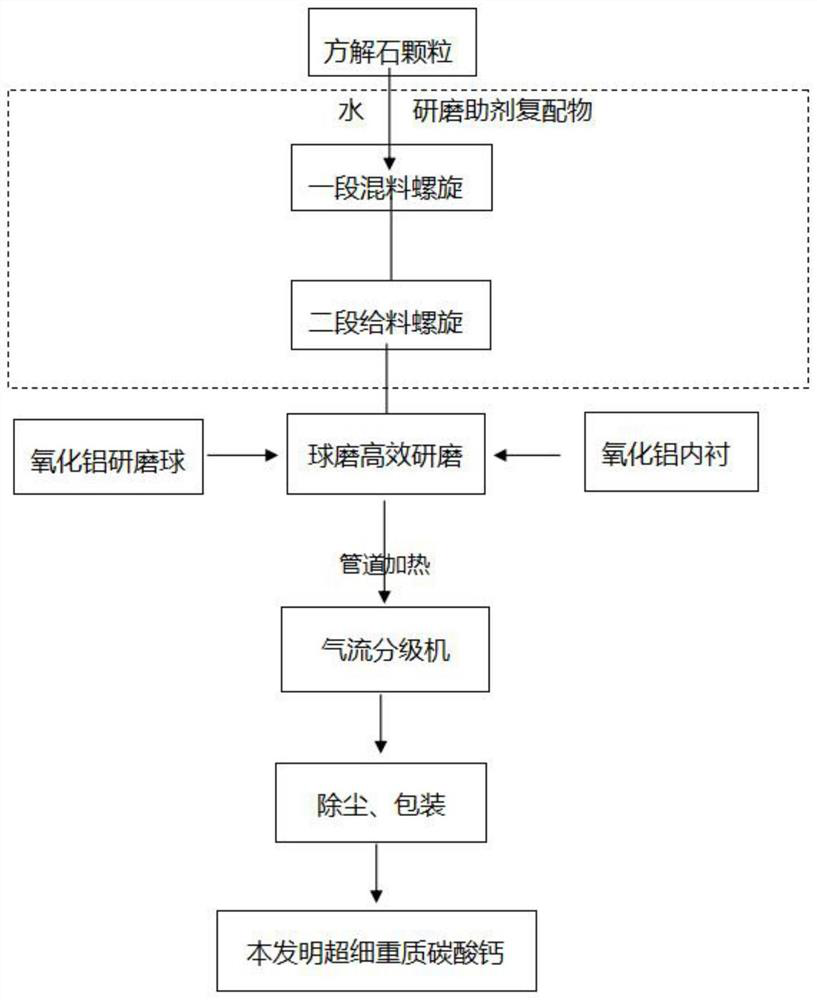

[0025] The invention provides a preparation method of ultrafine heavy calcium carbonate, comprising the following steps;

[0026] Mixing the calcite particles, water and a grinding aid to obtain a mixture; the grinding aid includes polyethylene glycol, diethylene glycol and a titanate coupling agent;

[0027] The mixture is ball-milled to obtain a ball-milled material; the grinding medium of the ball-milling is Al 2 O 3 Ceramic balls or zirconia balls, the lining of the ball mill is Al 2 O 3 Full ceramic lining or chrome-nickel alloy lining;

[0028] The ball milled material is classified to obtain the ultrafine heavy calcium carbonate.

[0029] In the present invention, unless otherwise specified, the raw materials used are all commercially available products in the field.

[0030] In the present invention, calcite particles, water and a grinding aid are mixed to obtain a mixture; the grinding aid includes polyethylene glycol, diethylene glycol and a titanate coupling ag...

Embodiment 1

[0060] The cleaned and crushed calcite particles (2-3mm) are first fed into a screw with a length of 1.5m for premixing. In this section of the feeding screw, 10wt% of the calcite input amount of water is metered at a constant speed, and at the same time, the pre-mixed water is metered. Good calcite particles feed 0.2% dry weight composite grinding aid, grinding aid ratio polyethylene glycol: diethylene glycol: triethanolamine chelate of bis(dioctyl pyrophosphate acyloxy) ethylene titanate The mixture is 1:1.5:0.1, in which the weight-average molecular weight of polyethylene glycol is 400. The premixed material is fed into a 2.5m-long two-stage helix so that the material particles are fully wetted and covered by water and grinding aids, and mixed. The uniform material is fed into the alumina ceramic-lined ball mill with a diameter of 2.2m and a length of 7m. The filling rate of alumina balls is 32%. :3:2:1, the ground material is drawn out of the mill by negative pressure air ...

Embodiment 2

[0074] The cleaned and crushed calcite particles (2-3mm) are first fed into a screw with a length of 1.5m for premixing. In this section of the feeding screw, the calcite feeding amount of 4wt% of water is metered at a constant speed, and at the same time, the pre-mixed water is metered. Good calcite particles feed 0.2% dry weight composite grinding aid, grinding aid ratio polyethylene glycol: diethylene glycol: triethanolamine chelate of bis(dioctyl pyrophosphate acyloxy) ethylene titanate The mixture is 1:1.5:0.1, in which the weight-average molecular weight of polyethylene glycol is 400. The premixed material is fed into a 2.5m-long two-stage helix so that the material particles are fully wetted and covered by water and grinding aids, and mixed. The uniform material is fed into the alumina ceramic-lined ball mill with a diameter of 2.2m and a length of 7m. The filling rate of alumina balls is 32%. :3:2:1, the ground material is drawn out of the mill by negative pressure air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com