Multipolymer organosilicon finishing agent and its preparation method

A multi-copolymerization, silicone technology, used in fiber processing, textiles and papermaking, plant fibers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

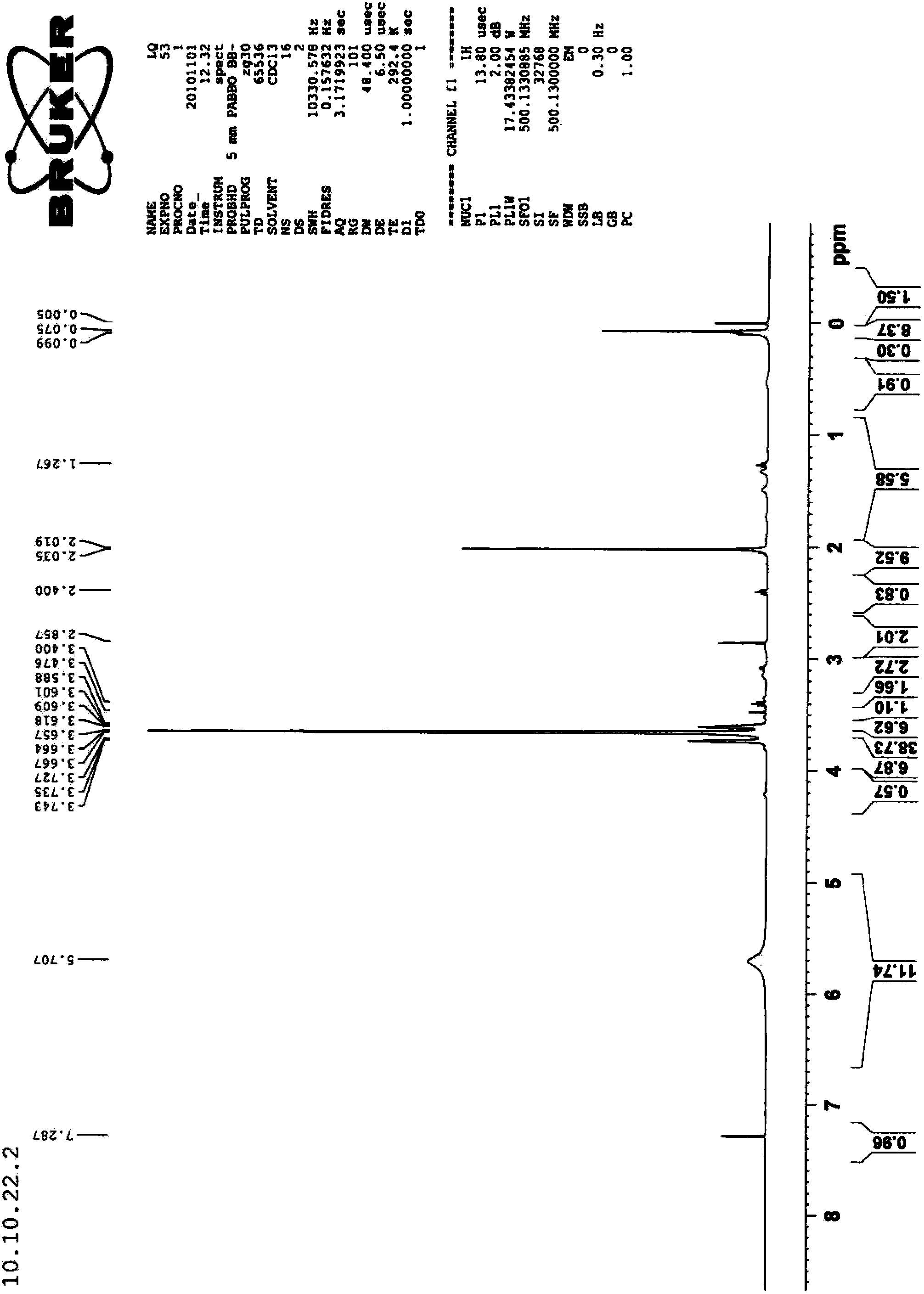

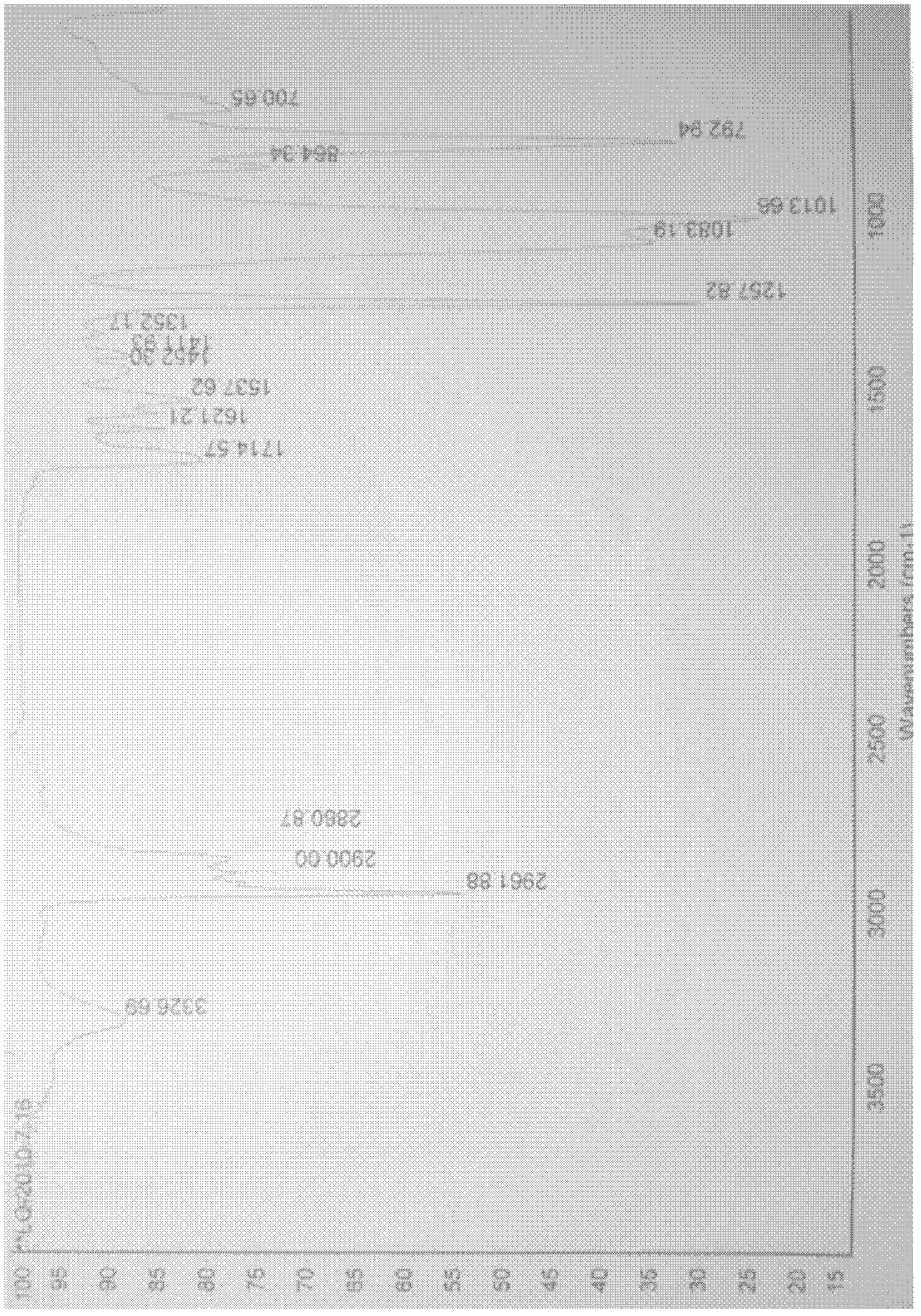

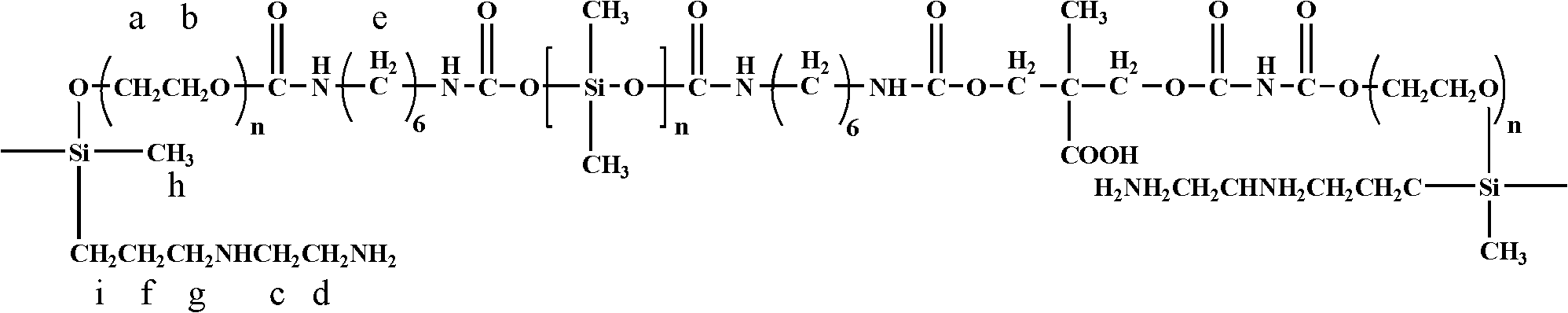

Image

Examples

Embodiment 1

[0057] Add 33.4g (0.01069mol) of terminated dihydroxypolydimethylsiloxane (the brand name is WS-62M, molecular weight is 3125g / mol), 90.7g (0.2267mol) polyethylene glycol (molecular weight is 400g) to the dry there-necked flask / mol), 2.5g (0.01864mol) DMPA (dissolved in 7.5g N-methylpyrrolidone), pass N 2 Under air protection, the temperature of the water bath was raised to 65°C and stirred evenly, then 10.7g (0.0637mol) HDI was added dropwise thereto, and then the temperature was raised to 70°C, dibutyltin dilaurate catalyst was added dropwise, and the reaction was carried out at constant temperature for 2 hours. Then cool down to 50°C, add 1.9g of triethylamine to the reaction system, neutralize for 30min, raise the temperature to 90°C, add N-β-(aminoethyl)-γ-aminopropylmethyl dimethoxy 27.1 g (0.1315 mol) of base silane (brand name: DL-602) and catalyst KOH were reacted at constant temperature for 5 hours. The temperature was lowered to 65°C, and an appropriate amount of ...

Embodiment 2

[0060] Add 20.1g (0.00643mol) end-dihydroxy polydimethylsiloxane (brand name is WS-62M, molecular weight is 3125g / mol), 112.0g (0.28mol) polyethylene glycol (molecular weight is 400g) to the dry there-necked flask / mol), 3.0g (0.02236mol) DMPA (dissolved in 9.0g N-methylpyrrolidone), pass N 2 Under air protection, the water bath was heated to 75°C and stirred evenly, then 17.3g (0.1029mol) HDI was added dropwise thereto, and then the temperature was lowered to 70°C, dibutyltin dilaurate catalyst was added dropwise, and the reaction was carried out at constant temperature for 2 hours. Then cool down to 50°C, add 2.3g of triethylamine to the reaction system, neutralize for 30min, raise the temperature to 90°C, add N-β-(aminoethyl)-γ-aminopropylmethyl dimethoxy 34.4 g (0.167 mol) of base silane (brand name: DL-602) and catalyst KOH were reacted at constant temperature for 5 hours. The temperature was lowered to 65°C, and an appropriate amount of acetic acid was added dropwise to...

Embodiment 3

[0062] Add 14.8g (0.004736mol) end-dihydroxy polydimethylsiloxane (brand name is WS-62M, molecular weight is 3125g / mol), 129.2g (0.323mol) polyethylene glycol (molecular weight is 400g) to dry there-necked flask / mol), 2.9g (0.02164mol) DMPA (dissolved in 9.0g N-methylpyrrolidone), through N 2 Under gas protection, the water bath was heated to 65°C and stirred evenly, then 19.6g (0.1166mol) HDI was added dropwise thereto, and then the temperature was raised to 70°C, dibutyltin dilaurate catalyst was added dropwise, and the reaction was carried out at constant temperature for 2 hours. Then cool down to 50°C, add 2.2g of triethylamine to the reaction system, neutralize for 30min, raise the temperature to 90°C, add N-β-(aminoethyl)-γ-aminopropylmethyl dimethoxy 26.5 g (0.1286 mol) of base silane (brand name is DL-602) and catalyst KOH, constant temperature reaction for 6 hours. The temperature was lowered to 65°C, and an appropriate amount of acetic acid was added dropwise to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com