Method for electrodepositing nanocrystalline chromium-nickel alloy coating with carboxylic acid or its salt -urea impulse

A technology of pulse electrodeposition and nanocrystals, applied in the field of surface engineering and surface treatment, can solve the problems of high toxicity, high energy consumption, and high pollution of hexavalent chromium electroplating process, and achieve strong bonding, low energy consumption, and easy sewage treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

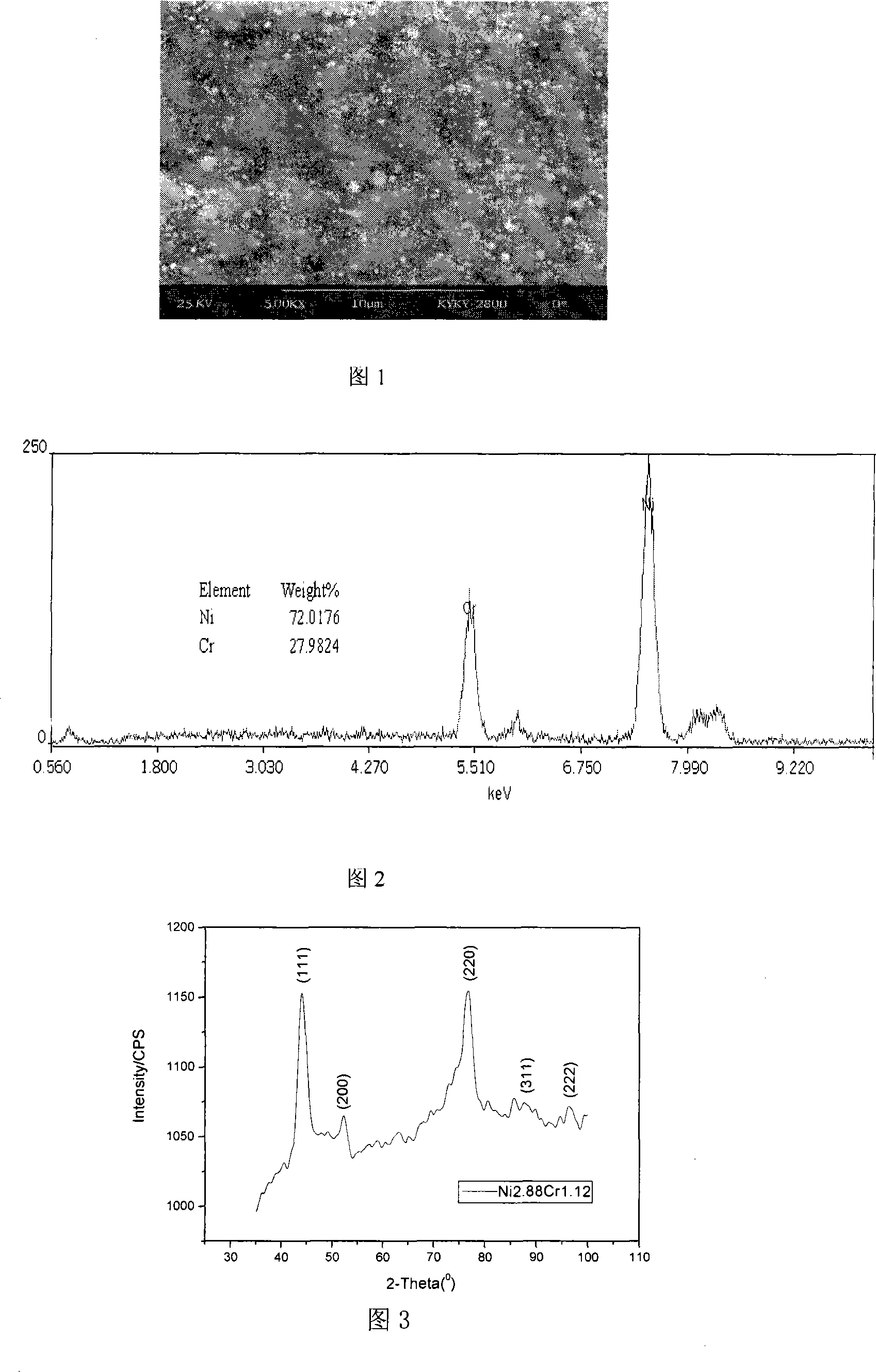

Embodiment 1

[0021] 1) Take an ordinary carbon steel sample with a dimension of 40mm×20mm×2mm, using 2 # 、4 # 、6 # Metallographic sandpaper is polished and polished sequentially, washed with tap water; and then treated with NaOH 40-60g / l 2 CO 3 60~80g / l, OP emulsifier 5~10ml / l alkaline degreasing liquid, degreasing at 60~70℃ for 8~12min, wash with tap water immediately after degreasing; 2 SO 4 100~200ml / l, HCl 40~70g / l, HNO 3 In 20-40ml / l polishing activation solution, the temperature is 40-60°C, activate for 2-3 minutes, and the pretreated sample to be plated can be obtained.

[0022] 2) Take the pretreated sample to be plated as the cathode and the insoluble anode (graphite) as the anode. Under the condition of stirring, directly insert the 3 ·6H 2 O 0.6mol L -1 , NiSO 4 ·6H 2 O 0.075mol L -1 , trisodium citrate 0.4mol L -1 , sodium oxalate 0.3mol L -1 , CH 3 COONa 0.2mol L -1 , Lactic acid 0.1mol L -1 , CO(NH 2 ) 2 2.0mol·L -1 , Cr 2 (SO 4 ) 3 ·6H 2 O 0.1mol L ...

Embodiment 2

[0024] 1) The pretreatment of the plated part is the same as "Example 1"

[0025] 2) Take the pretreated sample to be plated as the cathode and the insoluble anode (graphite) as the anode. Under the condition of stirring, directly insert the 3 ·6H 2 O 0.6mol L -1 , NiCl 2 ·6H 2 O 0.075mol L -1 , citric acid 0.4mol L -1 , oxalic acid 0.3mol L -1 , CH 3 COOH 0.2mol L -1 , CO(NH 2 ) 2 2.0mol·L -1 , Cr2(SO 4 ) 3 ·6H 2 O 0.1mol L -1 , H 3 BO 3 0.72mol·L -1 , NaCl 2.0mol·L -1 In the plating solution, the temperature of the plating solution is 35°C, and the current density is 8A·dm -2 , the pH of the plating solution is 2.0, the pulse working ratio is 0.3, the reversing time is 2ms, the pulse frequency is 50Hz, and the pulse electrodeposition time is 60min, the nanocrystalline chromium-nickel coating sample is obtained, and the coating thickness is about 14.45 μm, the average particle size of coating crystal particles is about 65nm.

Embodiment 3

[0027] 1) The pretreatment of the plated part is the same as "Example 1"

[0028] 2) Take the pretreated sample to be plated as the cathode and the insoluble anode (graphite) as the anode. Under the condition of stirring, directly insert the 3 ·6H 2 O 0.6mol L -1 , NiSO 4 ·6H 2 O 0.075mol L -1 , trisodium citrate 0.8mol L -1 , sodium oxalate 0.6mol L -1 , CH 3 COONa 0.1mol L -1 , Lactic acid 0.0mol·L -1 , CO(NH 2 ) 2 2.0mol·L -1 , H 3 BO 3 0.72mol·L -1 , NaCl 2.0mol·L -1 In the plating solution, the temperature of the plating solution is 35°C, and the current density is 8A·dm -2 , the pH of the plating solution is 2.0, the pulse working ratio is 0.3, the reversing time is 2ms, the pulse frequency is 50Hz, and the pulse electrodeposition time is 60min, the nanocrystalline chromium-nickel coating sample is obtained, and the coating thickness is about 13.25 μm, the average particle size of coating crystal particles is about 53nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com