High-temperature wear resistant kilneye cap iron alloy and manufacturing method thereof

A high-temperature wear-resistant and production method technology, which is applied in metal processing equipment, casting molding equipment, casting molds, etc., to achieve the effects of reducing production costs, strong oxidation resistance, and strong oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

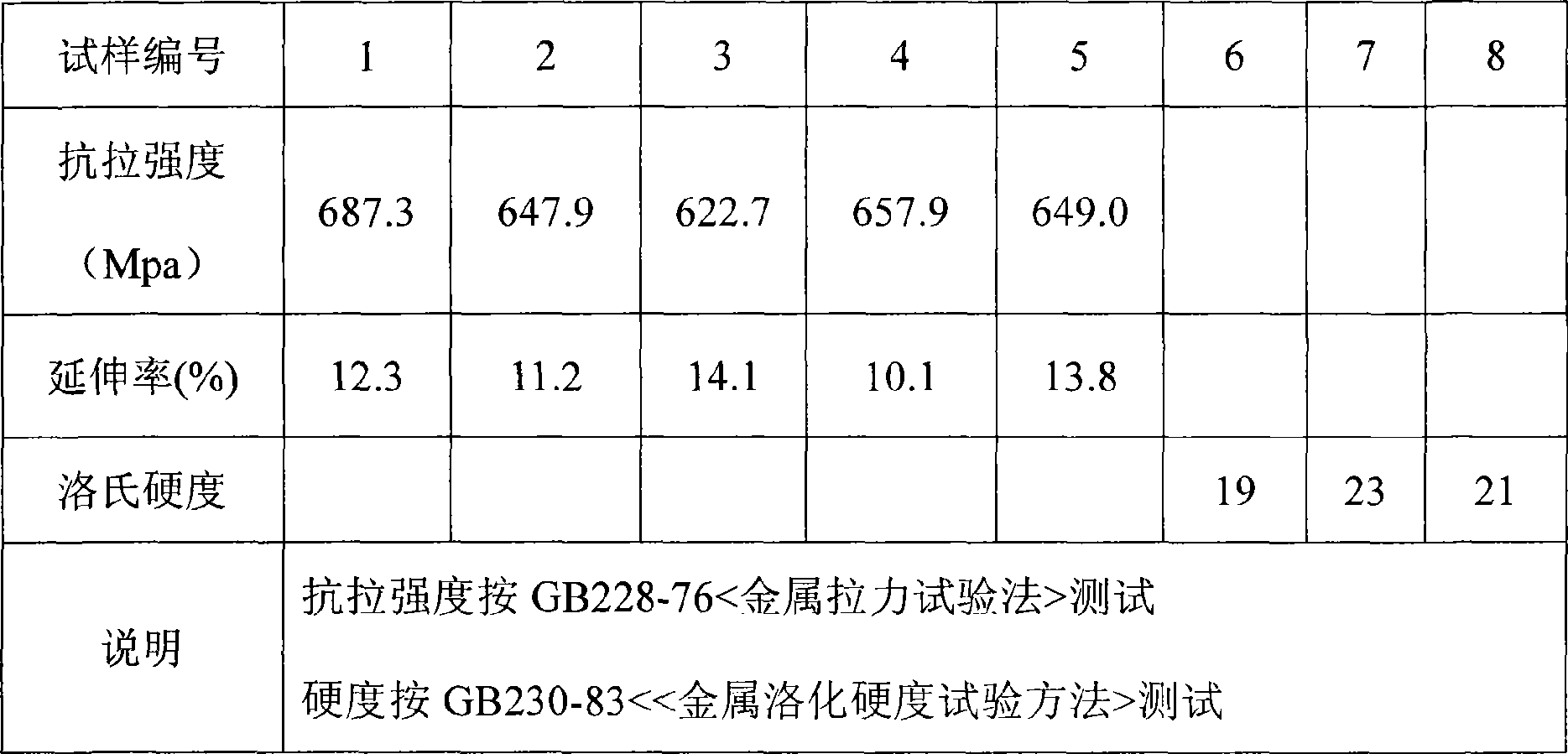

Examples

Embodiment Construction

[0024] For better understanding of the present invention, below in conjunction with specific embodiment is further described:

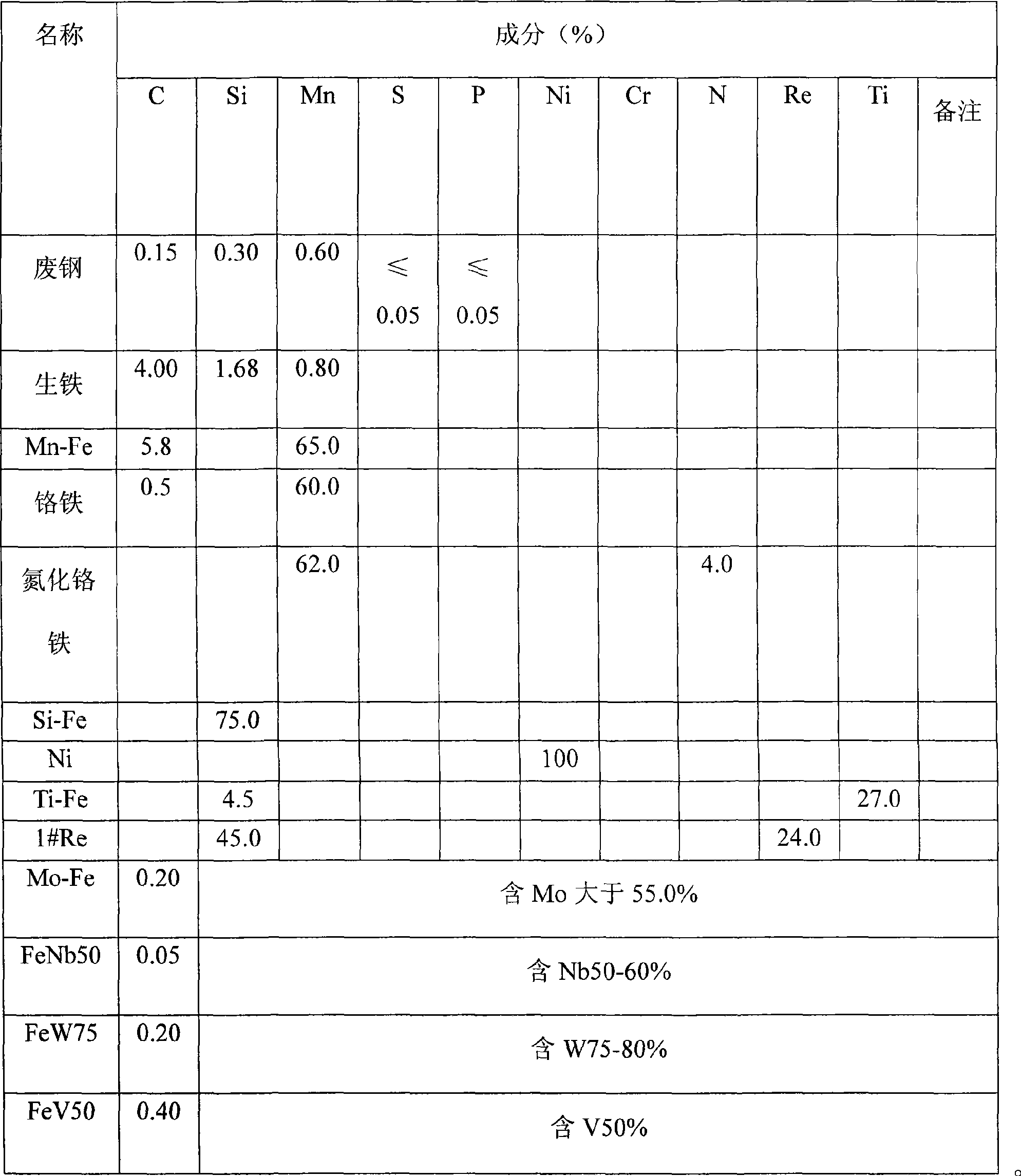

[0025] 1. Chemical composition design of high-temperature wear-resistant kiln mouth guard iron:

[0026] Chemical composition is the key factor determining the performance of alloys. To solve the problem of metal wear resistance under high temperature conditions, a reasonable composition design must be carried out first. Through comprehensive comparison and analysis, the present invention is determined to be based on chromium and nickel alloys, and adopts the combination of dominant alloying factors (chromium, nickel) and auxiliary elements (nitrogen, titanium, niobium, tungsten, rare earth) to form alloy materials. One is to obtain the austenite matrix, and the other is to form MC carbide and reduce M 23 C 6 Type compounds to ensure the oxidation resistance, creep resistance and wear resistance of alloy materials at high temperatures.

[0027] Chr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com