Powder coating as well as preparation method and application thereof

A technology of powder coatings and coatings, applied in the field of coatings, which can solve the problems of non-abrasive coatings and achieve good adhesion, enhanced wear resistance, and good leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

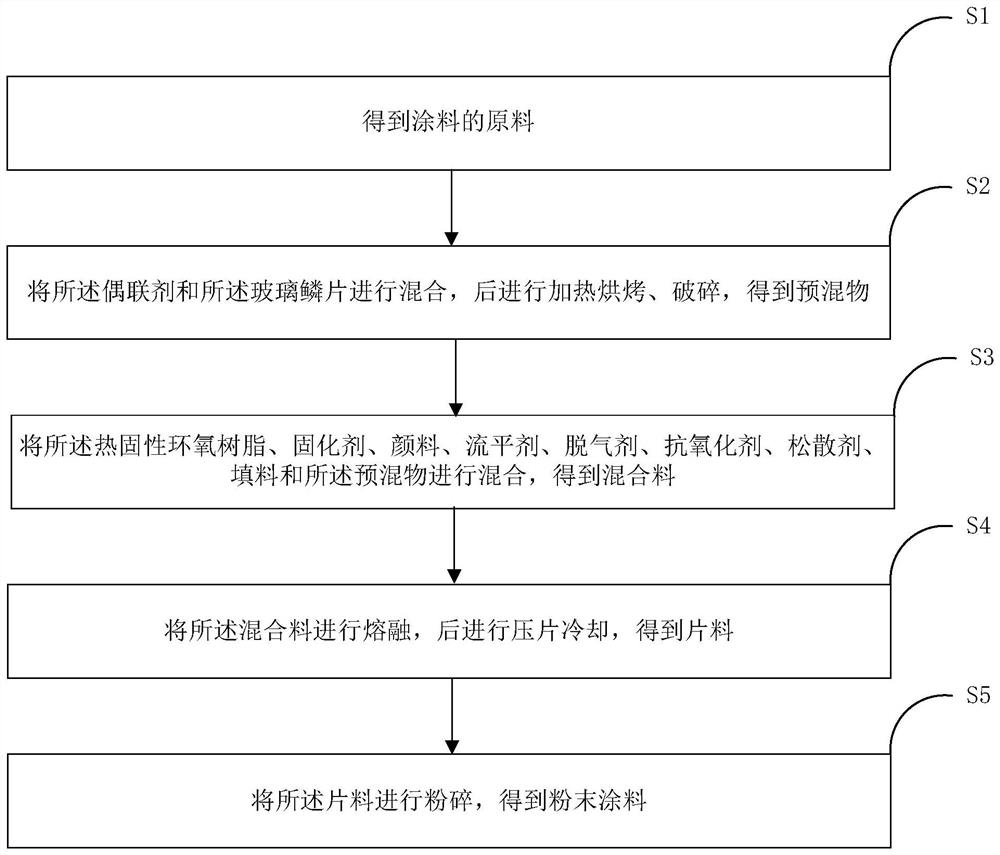

[0043] According to another typical embodiment of the present invention, a method for preparing a powder coating for railway wagon accessories is provided, comprising the following steps:

[0044] S1. Mix the coupling agent and glass flakes evenly in advance, spread out and heat to 105°C and bake for 3 hours, then use a mixer to crush into powder and sieve through a 50-mesh sieve;

[0045] S2. Stir the thermosetting epoxy resin, curing agent, pigment, leveling agent, degassing agent, antioxidant, loosening agent, filler and glass flake-coupling agent premix at a speed of 500 to 800r / min for 15 ~30min for full mixing;

[0046] S3. Send the mixed material into the melting machine from the feed port to melt, and press the tablet machine to obtain the tablet material, and cool to room temperature;

[0047] S4. The flakes are crushed and separated, and sieved with a 150-mesh sieve, and the obtained powder is the powder coating for railway wagon accessories.

[0048] According to ...

Embodiment 1-3

[0054] A kind of powder coating, the raw material of described coating is as shown in the table below in parts by mass:

[0055] Example 1 Example 2 Example 3 thermosetting epoxy resin 45 55 60 Hardener 13.5 14.5 15 pigment 1.5 1.5 1.5 glass flakes 30 25 20 leveling agent 0.5 0.5 0.5 Degasser 1.0 0.7 1.0 Antioxidants 0.3 0.3 0.3 Loosening agent 0.5 0.5 0.5 coupling agent 2 2 1.2 filler 5.7 0 0

[0056] Among them, the thermosetting epoxy resin is novolak epoxy resin; the curing agent is HT2844 modified dicyandiamide curing agent; the pigment is SW-160 carbon black from Quanzhou Sanwei Chemical; the glass flakes are the glass flakes of Shanghai Yipin Pigment; The leveling agent is polyvinyl alcohol-butyral leveling agent; the degassing agent is benzoin; the antioxidant is CHEMNOX1098 hindered phenolic antioxidant; the loosening agent is AEROSIL R972 fumed silica of Degussa Company...

experiment example

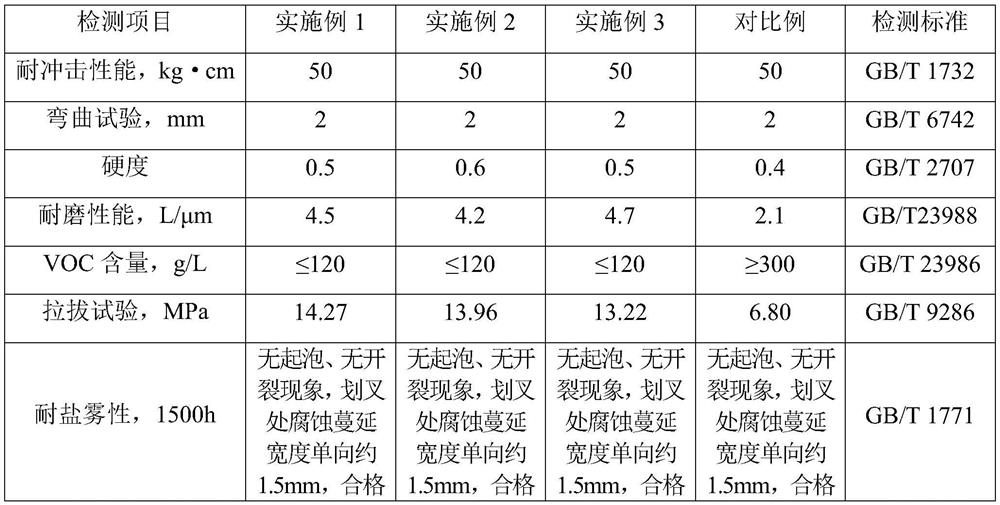

[0060] The coating or lacquer provided by embodiment 1-3 and comparative example 1 is carried out performance testing, and the results are shown in the table below:

[0061]

[0062] It can be seen from the above table that (1) the hardness and abrasion resistance of the powder coating are better than those of the comparative example; (2) the VOC content of the comparative example is significantly higher than that of the powder coating. (3) The salt spray resistance of both can reach 1500h.

[0063] One or more technical solutions in the embodiments of the present invention also have at least the following technical effects or advantages:

[0064] (1) The powder coating used for the body of the embodiment of the present invention has good wear resistance, so that the accessories can bear the abrasion of sand grains, prolonging the service life of the car body;

[0065] (2) The anticorrosion performance of the powder coating provided by the embodiment of the present inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com