A kind of oxidized pellet binder made from low-rank coal and its preparation method and application

A technology for oxidizing pellets and binders, which is applied in the fields of oxidizing pellet binders and their preparation methods and applications, and can solve the problems of iron grade decline, increased energy consumption in steel production, and increased gangue content in pellets, etc. Achieve the effect of improving iron grade, reducing production cost and improving green pellet strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

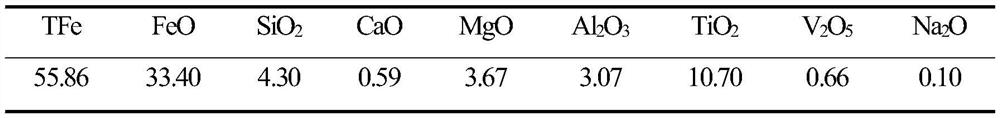

[0029] Using vanadium-titanium magnetite as raw material to make pellets, the raw material moisture is 5.0wt%, adding a binder accounting for 3.0wt% of its mass to the vanadium-titanium magnetite powder to keep the moisture at 8.0wt% during pelletizing, Mix thoroughly and evenly, then sieve the mixture to a size below 1mm, and use a disc pelletizer to make pellets. The pelletizing time is 10-12 minutes, and the pellet size is 10-12mm. The obtained iron ore green balls are tested, and the drop strength of the green balls is 3.5 times / (0.5m), and the compressive strength is 13.7N / piece.

Embodiment 2

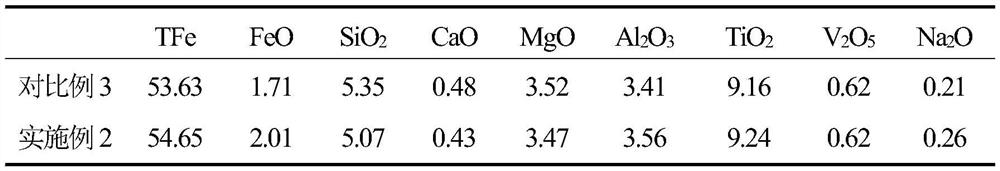

[0036] The vanadium-titanium magnetite is pretreated by high-pressure roller mill for 3 times and then pelletized, adding 1.0wt% water and 2.0wt% binder slurry to the iron ore powder to make the water Keep it at 8.0wt%, mix thoroughly and evenly, and then sieve the material to be less than 1mm, and use a disc pelletizer to pelletize. The pelletizing time is 10-12min, and the pellet size is 10-12mm. The obtained iron ore green balls are tested, and the drop strength of the green balls is 8.6 times / (0.5m), and the compressive strength is 21.3N / piece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com