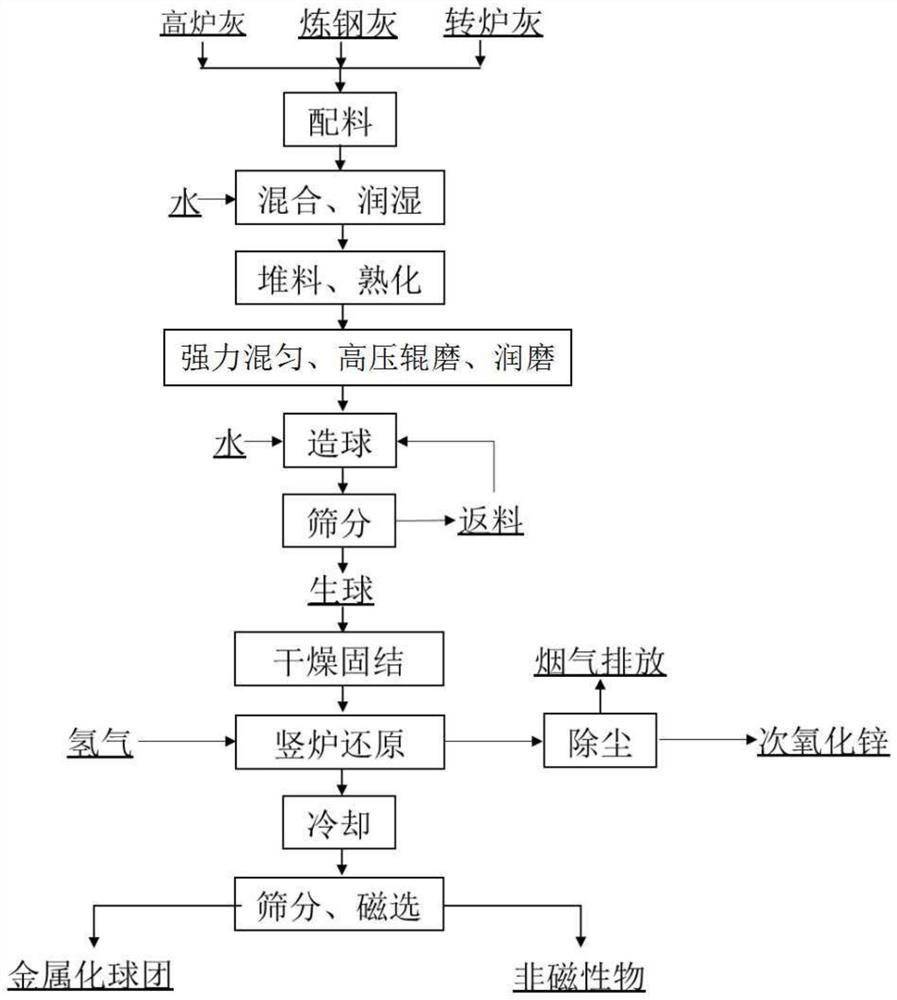

Method for dezincification of zinc-containing dust through hydrogen reduction

A dust and dezincification technology, applied in the field of iron and steel metallurgy, can solve the problems of large carbon emissions, low product quality, and high energy consumption, and achieve the effects of no carbon emissions, high pellet strength, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The reduction dezincification pellet obtained in Example 1 has a metallization rate of 91.33%, and the reduction process dezincification rate is as high as 91.2%. reduction

Embodiment 2

[0056] The metallization rate of the reduced dezincification pellets obtained in Example 2 was 94.55%, and the dezincification rate in the reduction process was as high as 94.6%. reduction

Embodiment 3

[0063] The metallization rate of the reduced dezincification pellets obtained in Example 3 is 96.72%, and the dezincification rate in the reduction process is as high as 97.4%. reduction

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| burst temperature | aaaaa | aaaaa |

| burst temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com