Production process of organic composite bentonite for metallurgical pellet production

A production process and technology of bentonite, applied in the field of non-metallic mineral materials, can solve the problems of large amount of bentonite, increase of slag amount under the furnace, energy consumption of metallurgical smelting, and reduction of metallurgical pellet grade, so as to achieve smooth surface and reduce under-furnace The effect of reducing the amount of slag and reducing energy consumption in smelting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

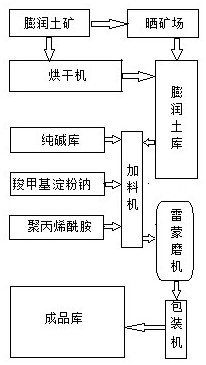

Image

Examples

Embodiment 1

[0023] Embodiment 1: The raw material is the finished sodium bentonite purchased.

[0024] Put a certain amount of sodium bentonite in a mixer, add (weight percentage) 1% organic bonding powder and stir thoroughly to prepare organic composite bentonite for metallurgical pellet production.

[0025] The organic composite bentonite and water used in the production of metallurgical pellets are adjusted to the organic composite bentonite slurry at a concentration of (weight percentage) 15%, and then the slurry is evenly sprayed on the rotating pelletizing disc by a slurry pump through the nozzle of the slurry pipe. Balling on metallurgical powder.

[0026] The metallurgical pellets prepared by this scheme can meet the application requirements in terms of drop strength, compressive strength and burst temperature.

Embodiment 2

[0027] Embodiment 2: The raw material is purchased finished sodium bentonite.

[0028] A certain amount of sodium bentonite is put in a mixer, and 1.5% organic bonding powder is added (weight percentage) for full stirring to obtain an organic composite bentonite for metallurgical pellet production.

[0029] The organic composite bentonite and water used in the production of metallurgical pellets are adjusted to the organic composite bentonite slurry at a concentration of (weight percentage) 10%, and then the slurry is evenly sprayed on the rotating pelletizing disc by a slurry pump through the nozzle of the slurry tube. The metallurgical powder is pelletized, and the obtained metallurgical pellets will not affect the next step of preheating, drying and other processes.

[0030] The parameters of drop strength, compressive strength and bursting temperature of the metallurgical pellets prepared by the scheme of Example 2 are all improved.

Embodiment 3

[0031] Embodiment 3: Get the raw ore calcium-based bentonite to dry in the sun or dehydrate with a dryer, then enter the Raymond mill for grinding, add 2.5-3.5% of soda ash, 0.8% of carboxymethyl starch sodium (CMS-Na), polyacrylamide (PAM) 0.2%, mixed and ground, and the 200-mesh fine powder obtained by winnowing is the organic composite bentonite used in the production of metallurgical pellets.

[0032] The organic composite bentonite and water used in the production of metallurgical pellets are adjusted to the organic composite bentonite slurry at a concentration of 10-15% by weight, and then the slurry is evenly sprayed on the rotating pelletizing disc by a slurry pump through the nozzle of the slurry pipe. Balling on metallurgical powder.

[0033] The parameters of drop strength, compressive strength and burst temperature of the metallurgical pellets prepared according to the scheme of Example 3 are all further improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com