Novel method for producing iron ore pellet binder

A production method and binder technology, which is applied in the field of iron ore pellet production binder, can solve problems affecting the quality of pellets that affect economic benefits, reduce the taste of blast furnace, increase the amount of blast furnace smelting slag, etc., so as to shorten the drying time time, improve the grade, and improve the effect of green ball strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

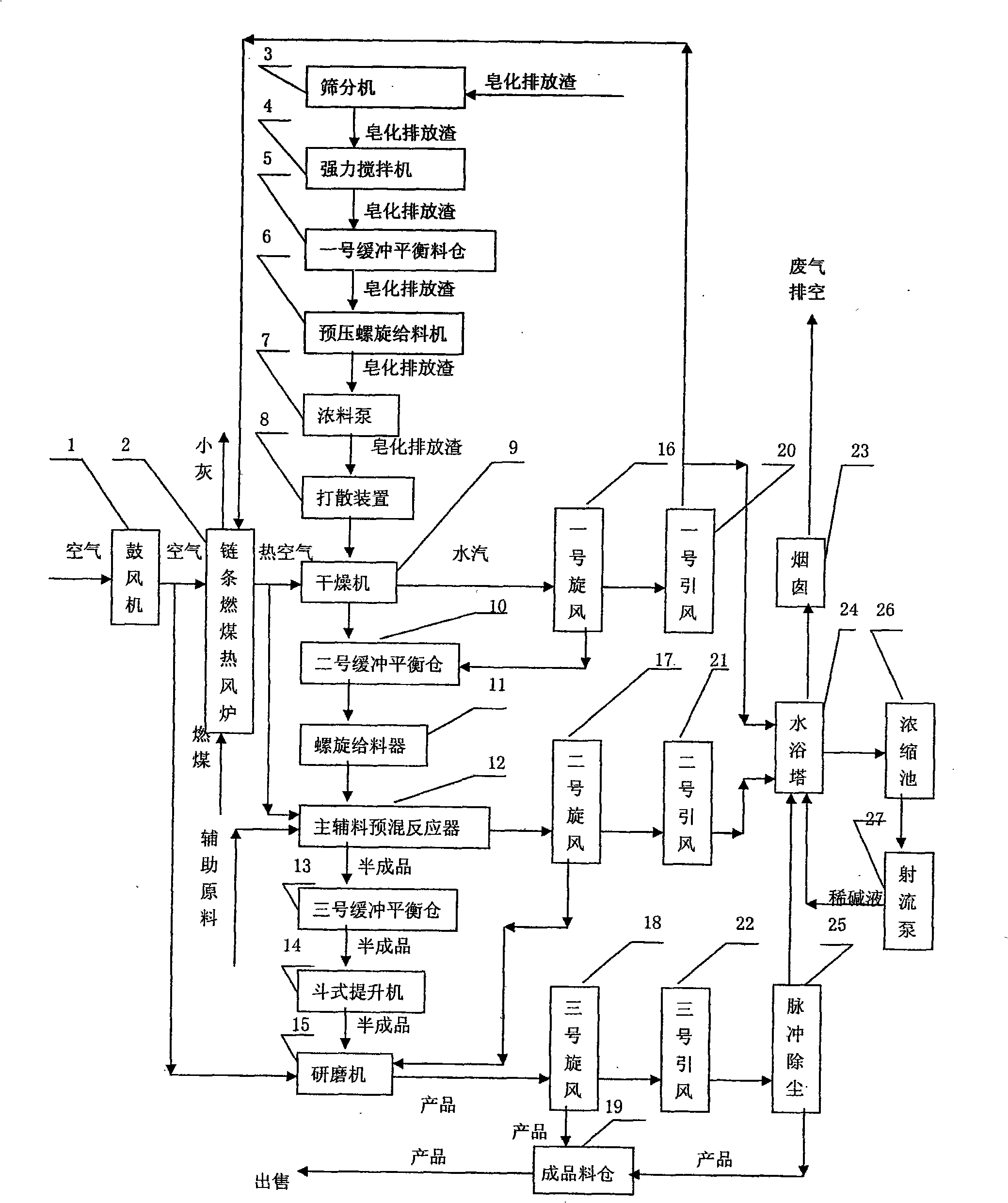

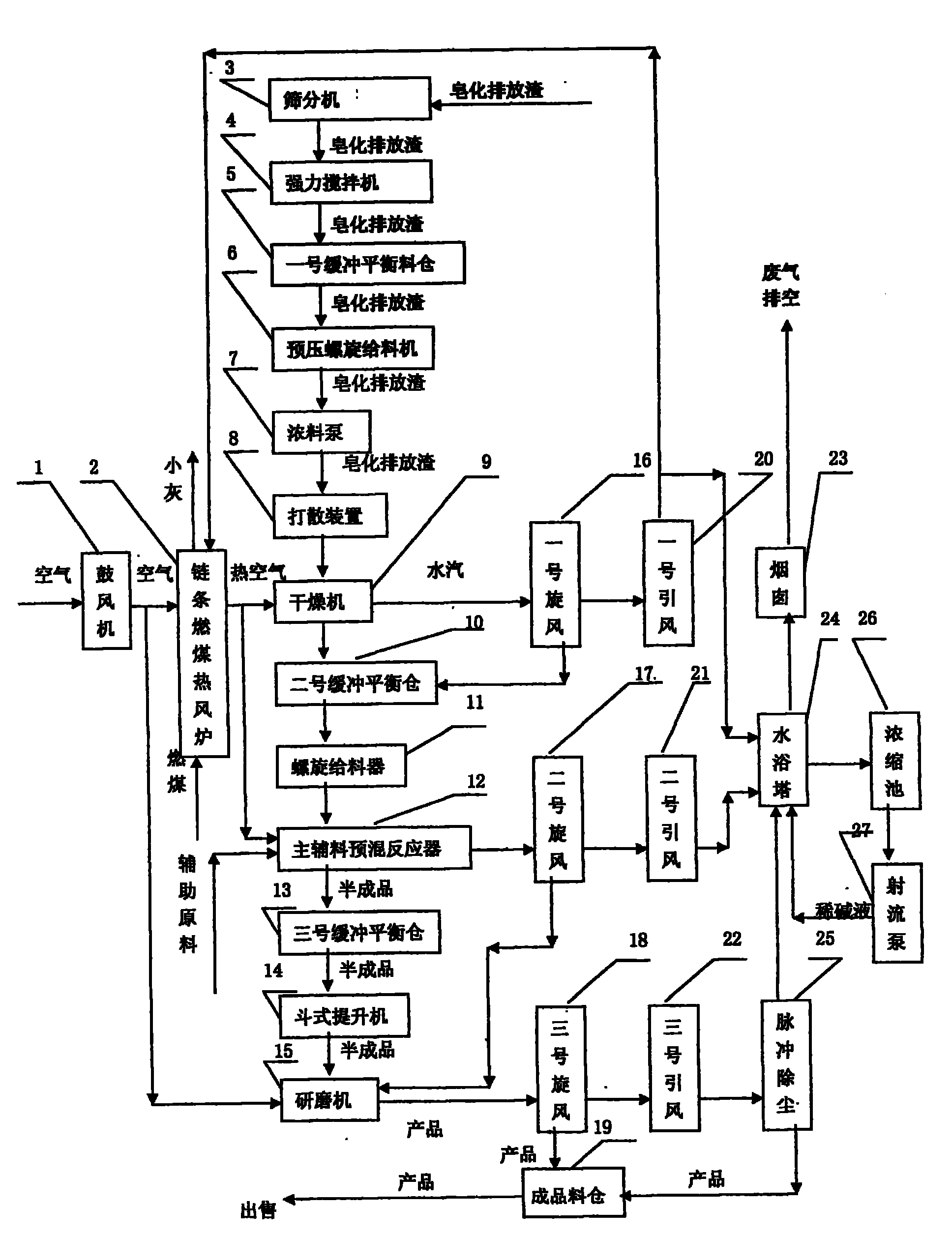

Method used

Image

Examples

Embodiment 1

[0030] The specific ratio of raw materials used in the production of the iron ore pellet binder of the present invention is all in mass percentages, as follows: 75% of saponification discharge slag with 10% water content after drying, 20% of calcium oxide, 4% of magnesium oxide, and 0.7% of reinforcing agent borax , stabilizer active molybdenum oxide 0.3%, the above-mentioned raw materials are fully mixed in the main and auxiliary material premixing reactor 13 with the device and process method adopted by the present invention, and then reacted at 550 ° C for 20 min under normal pressure conditions, Then use the grinding machine 15 to finely grind to make a powder with a particle size distribution of 80-300 mesh, which is the iron ore pellet binder product of the present invention.

[0031] Adopt iron ore pellet binder product produced by the present invention to produce pellets, raw material composition is mass percentage, as follows:

[0032] (1) High-quality Shuangda iron p...

Embodiment 2

[0053] The specific proportioning of raw materials used in the production of iron ore pellet binder of the present invention is all in mass percentages, as follows: the raw materials taken include 63.5% of saponification discharge slag containing 20% water, 30% of calcium oxide, 5% of magnesium oxide, and 1.0% of reinforcing agent borax %, stabilizer active molybdenum oxide 0.5%; the above-mentioned raw materials are fully mixed in the main and auxiliary material premixing reactor 12 with the device and process method adopted in the present invention, then at 650 ° C, reacted for 30min under normal pressure conditions, and then Finely grind with a grinder 15 to make a powder with a particle size distribution of 80-300 mesh, which is the iron ore pellet binder product of the present invention.

[0054] Adopt the iron ore pellet binder product that the present invention produces to produce pellet ore, raw material composition is as follows:

[0055] (1) High-quality Shuangda i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| burst temperature | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com