Composite functional material capable of synchronously removing nitrogen and phosphorus and preparation method thereof

A technology of simultaneous denitrification and dephosphorization and composite function, which is applied in the field of composite functional materials for simultaneous denitrification and dephosphorization and its preparation, can solve the problems of insignificant phosphorus adsorption effect, poor dephosphorization effect, limitation of lanthanum load, etc. To achieve the effect of enhancing phosphorus adsorption, excellent size effect, and increasing loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a method for preparing a composite functional material for synchronous denitrification and phosphorus removal. The mixture is obtained by mixing powdered nitrogen adsorption components, penetration components, bonding components and rare earth components, wherein the rare earth components are mixed The mass proportion of the material is 0.5-5%. The mixed material is granulated in a granulator to obtain a spherical filter material, which is calcined to obtain a finished filter material. It is worth noting that the particle size of the rare earth component used is larger than that of the nitrogen adsorption component, and the particle size of the rare earth component is larger than that of the binding component. The rare earth component plays the role of "skeleton" and "ball core" in the pelletizing process, which can promote the formation of the cue ball and increase the strength of the green ball, and also enable the rare earth component to have a ...

Embodiment 1

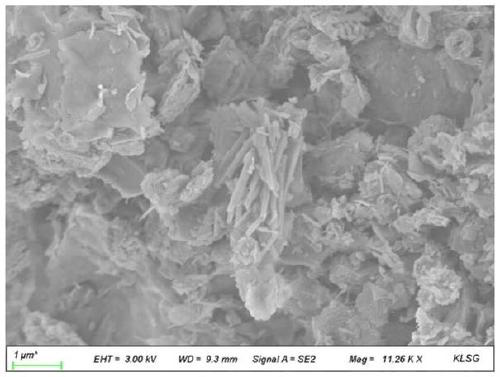

[0038] In this embodiment, 50% by weight of mordenite, 40% by weight of attapulgite, 5% by weight of diatomite powder, and 5% by weight of lanthanum oxide are formulated. Zeolite and attapulgite are crushed to 200 mesh (that is, the particle size is 75 μm), diatomaceous earth is crushed to 50 mesh (that is, the particle size is 270 μm), fully mixed, and rolled in the granulator while adding water to make the particle size A spherical filter material of about 5mm is calcined at a temperature of 500°C for 4 hours to produce a composite functional material 1 for synchronous denitrification and dephosphorization. Composite functional material 1 is characterized by BET=28.45m 2 / g, the particle strength is 43.15N / particle, the SEM scanning picture is as follows figure 1 shown.

[0039] Through the above preparation method, there is no need to use rare earth solution, the loading capacity of rare earth components is significantly increased, and the phosphorus adsorption effect of ...

Embodiment 2

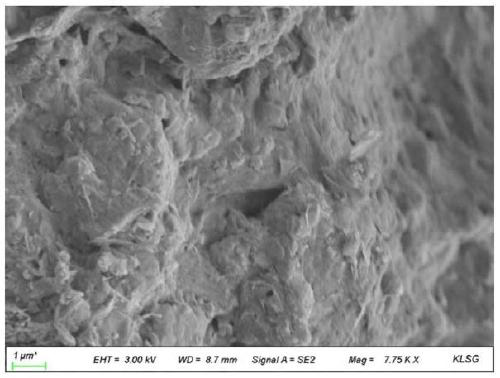

[0044] The basic content of the present embodiment is the same as that of Example 1, the difference being: the clinoptilolite of proportioning 58% by weight, the attapulgite of 35% by weight, the diatomite powder of 5% by weight, 2% Lanthanum hydroxide by weight. Zeolite and attapulgite are crushed to 200 mesh (that is, the particle size is 75 μm), diatomaceous earth is crushed to 50 mesh (that is, the particle size is 270 μm), fully mixed, and rolled in the granulator while adding water to make the particle size A spherical filter material of about 5mm is calcined at 600°C for 6 hours to make a composite functional material 2 for synchronous denitrification and phosphorus removal. Composite functional material 2 is characterized by BET=20.86m 2 / g, particle strength 68.21N / particle, SEM electron microscope scanning picture is as follows figure 2 shown.

[0045] Through the above preparation method, there is no need to use rare earth solution, the loading capacity of rare ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com