High-silica magnesian fluxed pellet for blast furnace and production method of high-silica magnesian fluxed pellet

A production method, high-silicon-magnesium technology, applied to blast furnaces, blast furnace details, furnaces, etc., can solve problems such as immaturity, rotary kiln ring formation, etc., achieve low production costs, reduce powder rate, and increase the use ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

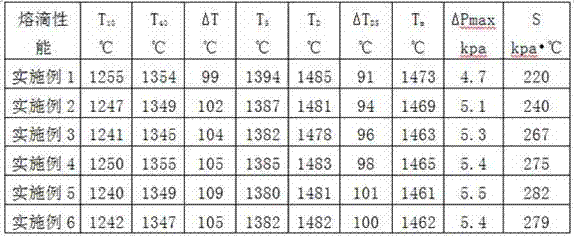

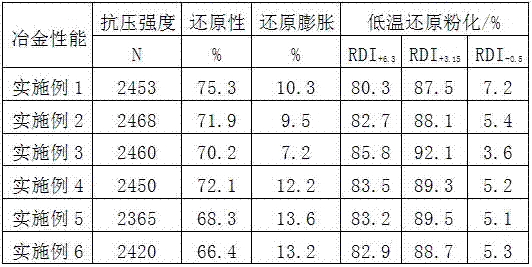

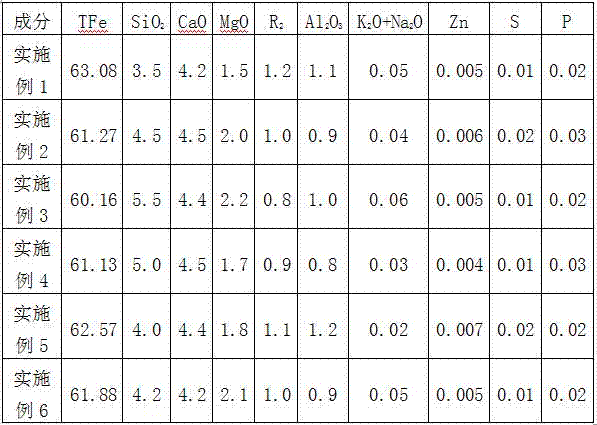

[0022] Example 1: The specific production process of the high-silicon magnesium flux pellets used in this blast furnace is as follows.

[0023] (1) Proportion according to the mass fraction required by the following ingredients: SiO 2 3.5%, MgO 1.5%, alkalinity 1.2; other ingredients must meet Al 2 o 3 ≤1.5%, K 2 O+Na 2 O≤0.1%, Zn≤0.02%, S≤0.05%, P≤0.07%. Among them, the proportion of laterite ore is 0.5wt%, the proportion of anthracite powder is 0.2wt%, and the proportion of other raw materials is calculated according to the above composition requirements.

[0024] (2) After the raw materials are mixed, they pass through the high-pressure roller mill, and the proportion of particle size less than 0.074mm reaches 88%; after that, they are mixed by a powerful mixer, and the mixture enters the disc pelletizer to form green pellets, with a particle size of 9-13.5mm.

[0025] (3) The raw balls enter the grate machine, go through blast drying, exhaust drying, preheating stage...

Embodiment 2

[0026] Example 2: The specific production process of the high-silicon magnesium flux pellets used in the blast furnace is as follows.

[0027] (1) Proportion according to the mass fraction required by the following ingredients: SiO 2 4.5%, MgO 2.0%, alkalinity 1.0; other ingredients must meet Al 2 o 3 ≤1.5%, K 2 O+Na 2 O≤0.1%, Zn≤0.02%, S≤0.05%, P≤0.07%. Among them, the proportion of laterite ore is 1.5wt%, the proportion of anthracite powder is 0.5wt%, and the proportion of other raw materials is calculated according to the above composition requirements.

[0028] (2) After the raw materials are mixed, they pass through the high-pressure roller mill, and the proportion of particle size less than 0.074mm reaches 92%; after that, they are mixed by a powerful mixer, and the mixture enters the disc pelletizer to form green pellets, with a particle size of 9-13.5mm.

[0029] (3) The raw balls enter the grate machine, go through blast drying, exhaust drying, preheating stage ...

Embodiment 3

[0030] Example 3: The specific production process of the high-silicon magnesium flux pellets used in the blast furnace is as follows.

[0031] (1) Proportion according to the mass fraction required by the following ingredients: SiO 2 5.5%, MgO 2.2%, alkalinity 0.8; other ingredients must meet Al 2 o 3 ≤1.5%, K 2 O+Na 2O≤0.1%, Zn≤0.02%, S≤0.05%, P≤0.07%. Among them, the proportion of laterite ore is 3.0wt%, the proportion of anthracite powder is 1.0wt%, and the proportion of other raw materials is calculated according to the above composition requirements.

[0032] (2) After the raw materials are mixed, they are passed through a high-pressure roller mill, and the proportion of particles smaller than 0.074mm reaches 86%; after that, they are mixed by a powerful mixer, and the mixture enters a disc pelletizer to form green pellets, with a particle size of 9-13.5mm.

[0033] (3) The raw balls enter the grate machine, go through blast drying, exhaust drying, preheating stage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com