High-strength double-doped mineral powder

A high-strength, blast-furnace slag powder technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the environmental impact of steel slag being difficult to utilize and accumulate, so as to improve wear resistance and reduce heat of hydration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

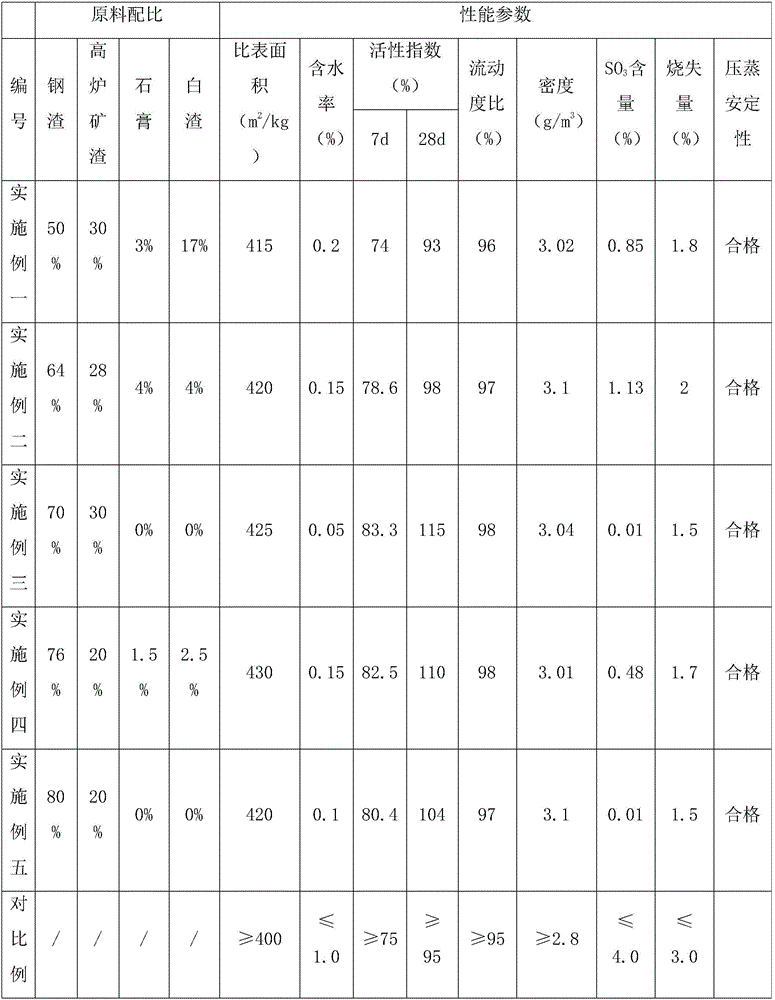

Embodiment 1

[0033] Embodiment 1, the high-strength double-mixed slag powder is composed of 50% steel slag, 30% blast furnace slag powder, 3% gypsum powder, and 17% white slag.

Embodiment 2

[0034] Embodiment 2, the high-strength double-mixed slag is composed of 64% steel slag, 28% blast furnace slag powder, 4% gypsum powder and 4% white slag.

Embodiment 3

[0035] Embodiment 3, the high-strength double-doped slag powder is composed of 70% steel slag and 30% blast furnace slag powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com