Double-layer composite pellet for treating copper slag and preparation method thereof

A double-layer composite and copper slag technology, which is applied in the field of double-layer composite pellets for processing copper slag and its preparation, can solve the problem of less research on the removal of harmful elements or harmless treatment, the treatment effect needs to be improved, and environmental pollution, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention provides a method for preparing the double-layer composite pellets described in the above technical solution, comprising the following steps:

[0032] Pretreatment is carried out by mixing copper slag, potassium permanganate and part of water to obtain pretreated copper slag;

[0033] mixing the pretreated copper slag, iron powder, manganese dioxide, binder and remaining water, and then performing the first granulation to obtain a ball core;

[0034] spraying water glass on the surface of the ball core and mixing it with the cladding material, and then performing the second granulation to obtain green balls;

[0035] In an oxidizing atmosphere, the green balls are dried to obtain double-layer composite pellets.

[0036] The invention mixes copper slag, potassium permanganate and part of water for pretreatment to obtain pretreated copper slag. In the present invention, it is preferred to dissolve potassium permanganate with part of the water as a ...

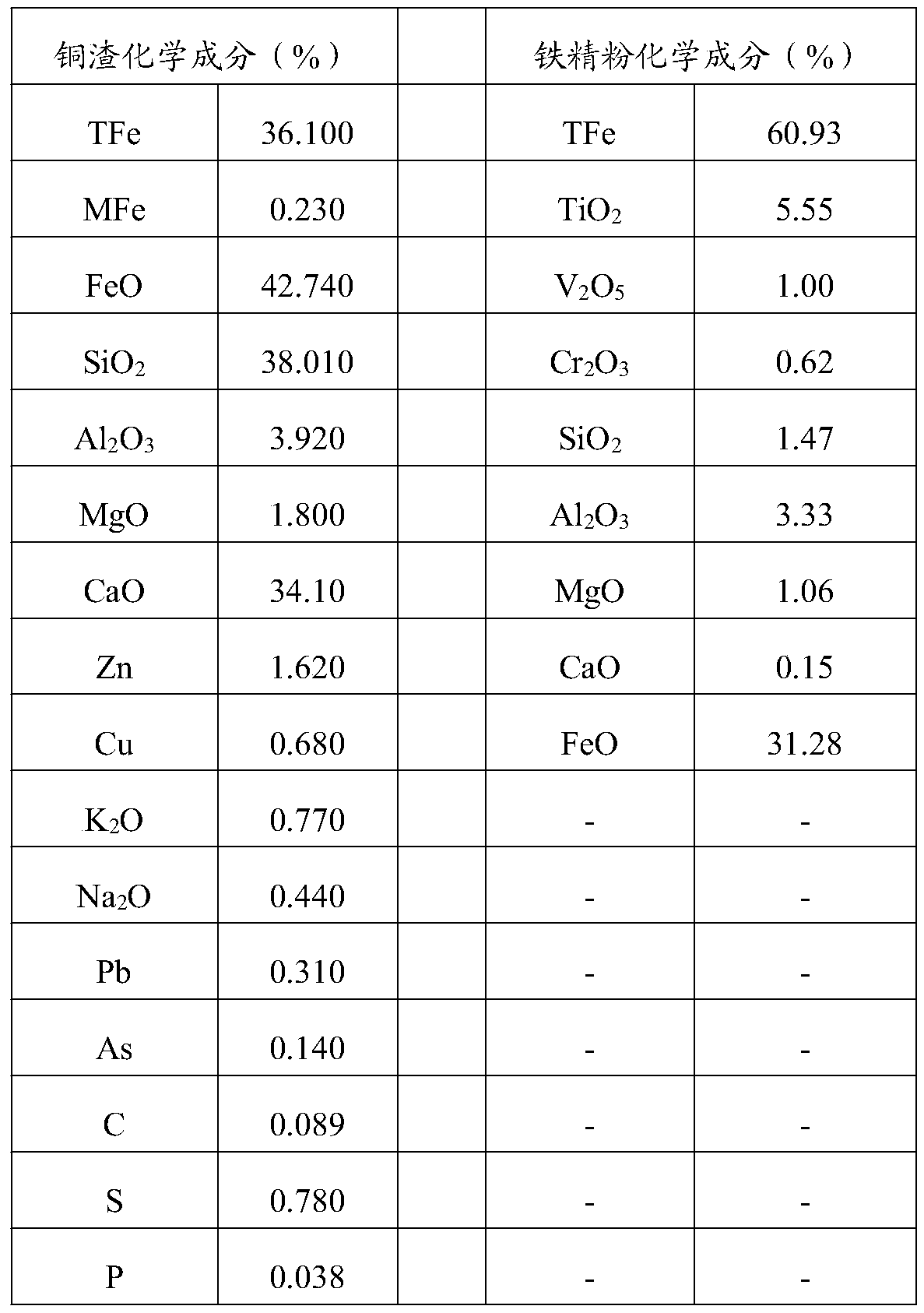

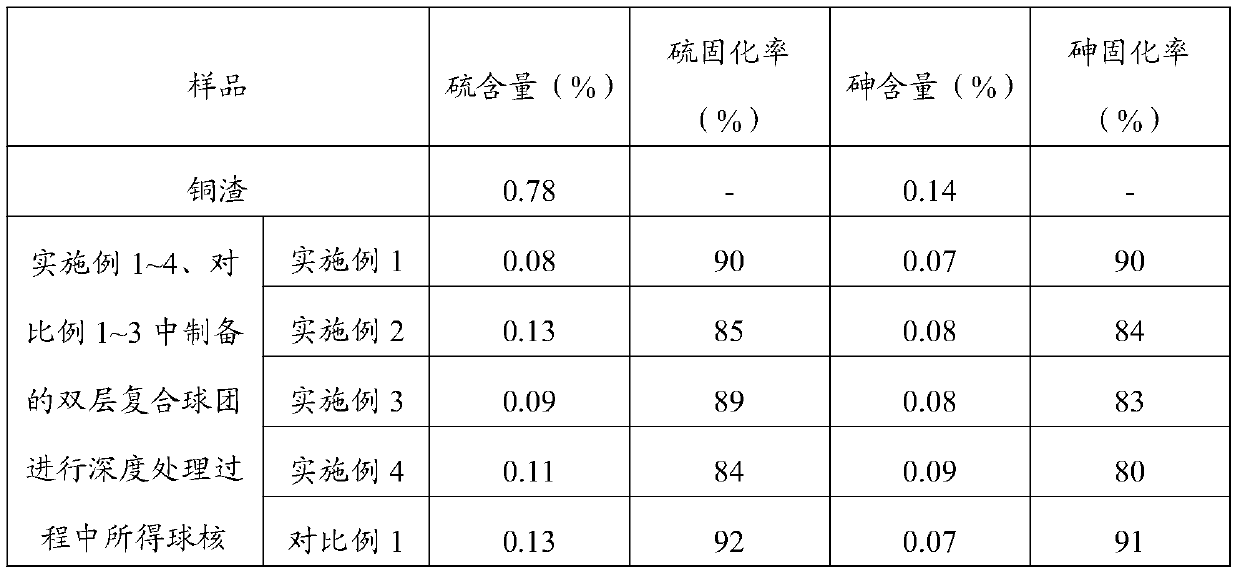

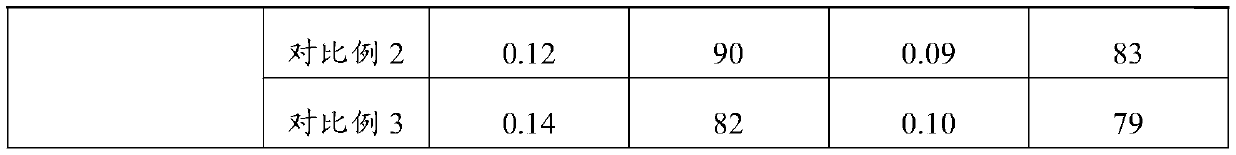

Embodiment 1

[0050] Spray 50°C potassium permanganate aqueous solution (mass concentration is 0.5%, dosage is 30g) on the surface of copper slag (particle size is 150~200 mesh, dosage is 1000g), after mixing uniformly, let it stand at 30°C for pretreatment Process 2h, obtain pretreatment copper slag;

[0051] With described pretreatment copper slag and fine iron powder (particle size is 200~300 order, grade is 60%, consumption is 100g), manganese dioxide (consumption is 30g), binding agent (carboxymethyl cellulose, consumption is 11.66g) were mixed, and then mixed with water, and the resulting mixture was placed in a disc pelletizer for the first granulation (the time was 7min) to obtain spherical cores (the particle size was 8-10mm, and the water content was controlled at 8-10mm). %);

[0052] Spray water glass (with a modulus of 1) on the surface of the ball core, mix it with the coating material (CaO, particle size 200-250 mesh) and place it in a disc pelletizer for the second granul...

Embodiment 2

[0055] Prepare double-layer composite pellets according to the method of embodiment 1, and difference is that binding agent is bentonite; Water glass modulus is 2; Covering material is Mg(OH) 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com