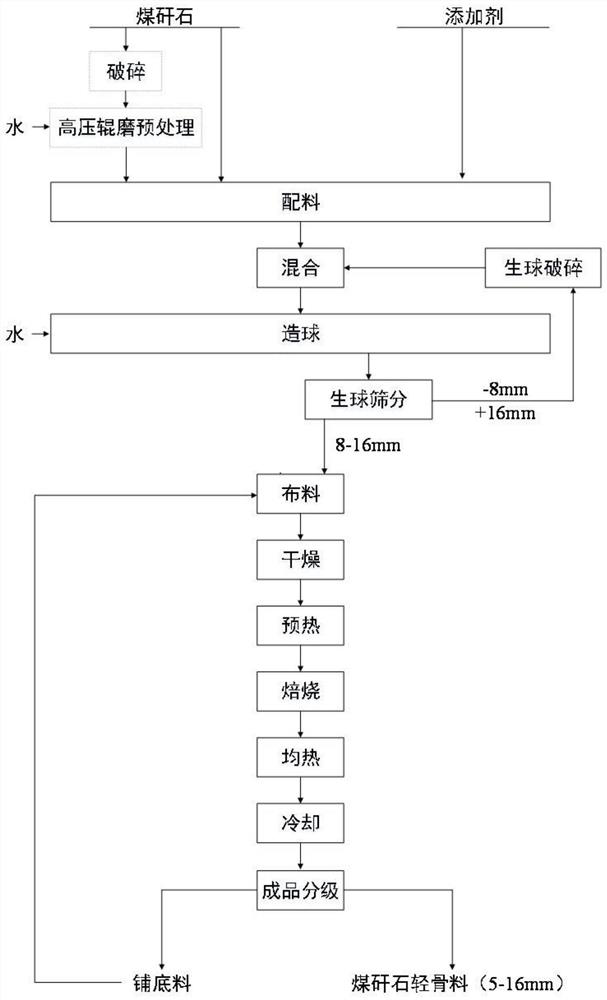

A process for preparing coal gangue lightweight aggregate by belt roaster pellet method

A technology of belt roasting machine and lightweight aggregate, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., to achieve the effects of uniform quality, optimized organizational structure, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] After the coal gangue is crushed to -1mm with a jaw crusher, it is ground to -0.074mm by a dry ball mill, accounting for 85%, and the finely ground coal gangue is rolled through a high-pressure roller mill, wherein the rolling pressure is 500KN / m , the rolling moisture is controlled at 6.5%, so that the specific surface area of coal gangue powder can be increased to 1450cm 2 / g.

[0036] Coal gangue powder (accounting for 96% by mass) is mixed with 3% multifunctional additives (sodium humate 30%, magnetite 20%, limestone 50%), and the mass ratio is 3% water. Mix in the mixer for 1.5min (speed 1600-2000rpm), and then pelletize in the disc pelletizer for 12min (a small amount of water needs to be added during the pelletizing process and sieved), and the water content of the obtained green pellets is 8.5 %, the particle size is 8-16mm, the drop strength of green balls is 4.2 times / 0.5m, the compressive strength of green balls is 10.3N / piece, and the bursting temperature...

Embodiment 2

[0040] After the coal gangue is crushed to -1mm with a jaw crusher, it is dry-grinded to -0.074mm, accounting for 85%. Control at 7.5%, increase the specific surface area to 1550cm 2 / g.

[0041] Coal gangue powder (accounting for 91% in mass ratio) is mixed with 5% multifunctional additives (sodium humate 40%, magnetite 20%, limestone 40%) in mass ratio, and 4% water in mass ratio. Mix in an intensive mixer for 2 minutes (rotation speed: 1600-2000rpm), and then pelletize in a disc pelletizer for 12 minutes (add a small amount of water and sieve during the pelletizing process), and finally obtain a particle size of 8-16mm , raw balls with a moisture content of 8.0%. The drop strength of green balls is 5.2 times / 0.5m, the compressive strength of green balls is 11.2N / piece, and the bursting temperature of green balls is 380°C.

[0042] Green balls are dried at 350°C for 4 minutes on a belt roaster (the height of the green ball layer is 250mm), preheated at 800°C for 15 minute...

Embodiment 3

[0045] After the coal gangue is crushed to -1mm with a jaw crusher, it is dry-grinded to -0.074mm, accounting for 85%. Control at 8.0%, increase the specific surface area to 1570cm 2 / g.

[0046] Then in coal gangue powder (mass ratio accounts for 93%), adding mass ratio is 3% multifunctional additive (sodium humate 45%, magnetite 15%, limestone 40%), and mass ratio is 4% water, in Mix in a strong mixer for 2 minutes (rotation speed: 1600-2000rpm), and then pelletize in a disc pelletizer for 11 minutes (a small amount of water needs to be added during the pelletizing process, and sieved), and the particle size is 8-16mm , raw balls with 8.5% water content. The drop strength of green balls is 5.9 times / 0.5m, the compressive strength of green balls is 13.2N / piece, and the bursting temperature of green balls is 440°C.

[0047] The green balls are dried at 400°C for 3.5 minutes on a belt roaster (the height of the green ball layer is 250mm), preheated at 850°C for 16 minutes, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com