Aluminum ash pellet binder and preparation method thereof

A technology for aluminum ash pellets and a binder is applied in the field of aluminum ash pellet binder and its preparation, which can solve the problems of complex aluminum ash process, high energy consumption, unfriendly environment, etc. The effect of high product quality and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

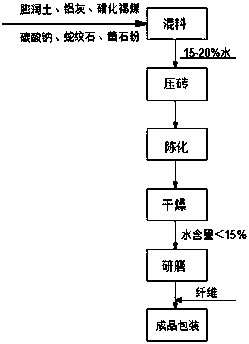

Method used

Image

Examples

Embodiment 1

[0021] Weigh 7 t of aluminum ash, 1.5 t of bentonite, 0.237 t of sodium carbonate, 0.0475 t of calcined serpentine, 0.0475 t of fluorite powder and 0.19 t of sulfonated lignite and put them into a mixer to mix evenly, then transfer the mixture to a vacuum brick press, and add 1.4 t water, the extrusion pressure is 3Mpa, extruded twice, then stacked and aged for 15 days under natural conditions, dried to a moisture content of 12%, and then the dried mixture was thrown into a Raymond machine for grinding to a particle size of 200 mesh For fine powder, add 0.0475t of glass wool to the finished product conveying duct of the Raymond machine to obtain the finished binder.

[0022] The aluminum ash pellet binder prepared in this example was mixed with iron ore powder at a ratio of 1%, and then mixed to form pellets. The ball forming rate of green balls is 65%, the drop strength of green balls is 4.3 times / 0.5m, and the compressive strength of green balls is 12.2N / piece; under the con...

Embodiment 2

[0024] Weigh 6 t of aluminum ash, 2 t of bentonite, 0.32 t of sodium carbonate, 0.12 t of calcined serpentine, 0.09 t of fluorite powder and 0.32 t of sulfonated lignite and put them into a mixer to mix evenly, then transfer the mixture to a vacuum brick press, and add 2 t of water , the extrusion pressure is 5Mpa, extruded 3 times, then stacked and aged for 7 days under natural conditions, dried to a moisture content of 10%, and then the dried mixture was thrown into a Raymond machine to be ground into a fine powder with a particle size of 200 mesh , add 0.16t basalt fiber to the conveying duct of the finished product of the Raymond machine to obtain the finished product of the binder.

[0025] The aluminum ash pellet binder prepared in this example was mixed with iron ore powder at a ratio of 1%, and then mixed to form pellets. The ball forming rate of green balls is 85%, the drop strength of green balls is 7.2 times / 0.5m, and the compressive strength of green balls is 16.2N...

Embodiment 3

[0027] Weigh 10t of aluminum ash, 2t of bentonite, 0.36t of sodium carbonate, 0.12t of calcined serpentine, 0.12t of fluorite powder and 0.48t of sulfonated lignite and put them into a mixer to mix evenly, then transfer the mixture to a vacuum brick press, and add 2.4t water, the extrusion pressure is 7Mpa, extruded twice, then stacked and aged for 3 days under natural conditions, dried to a moisture content of 11%, and then the dried mixture was thrown into a Raymond machine to be ground into a fine particle size of 200 mesh Powder, add 0.12t dolomite fiber in the finished product delivery duct of the Raymond machine to get the finished binder.

[0028] The aluminum ash pellet binder prepared in this example was mixed with iron ore powder at a ratio of 1%, and then mixed to form pellets. The ball forming rate of green balls is 81%, the drop strength of green balls is 6.5 times / 0.5m, and the compressive strength of green balls is 13.2N / piece; under the conditions of drying tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com