Process of adopting vanadium titano-magnetite or titanium middling as raw material to produce titanium dioxide

A vanadium-titanium magnetite and raw material technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, vanadium oxide, etc., can solve the problems of waste acid and waste discharge, restricted development, and highly toxic chlorine gas, etc. Environmental pollution, easy industrial production, and less time-consuming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

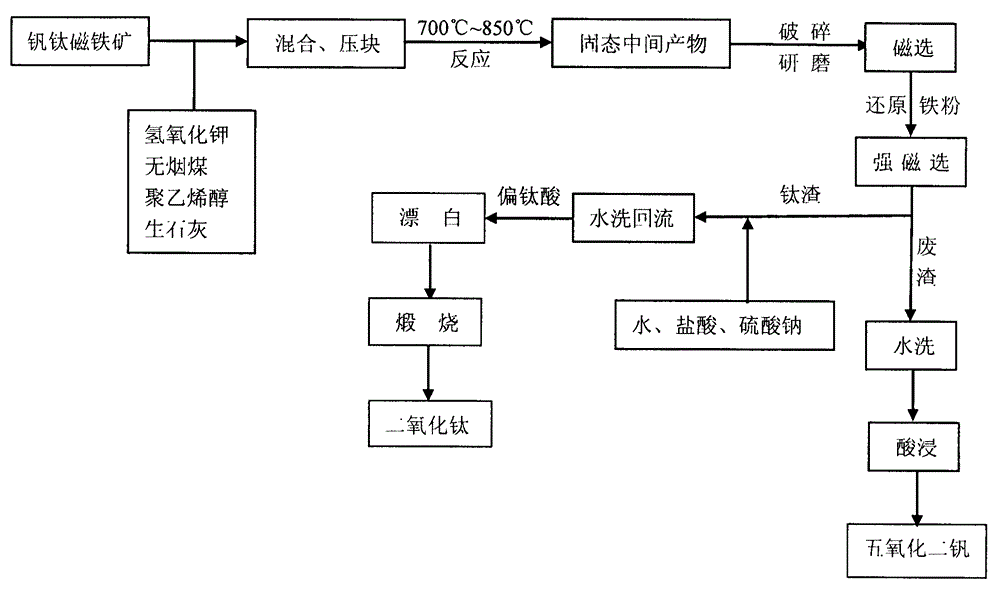

Image

Examples

Embodiment Construction

[0017] For example, transport 1000Kg vanadium-titanium magnetite to the pre-powder process, crush and grind to 150 mesh, add 100Kg~150Kg potassium hydroxide, grind to 150 mesh anthracite 100Kg~200Kg, polyvinyl alcohol 10Kg~30Kg, quicklime 20Kg~40Kg evenly Mix, then press into a block with a diameter of 2 to 3 cm and a thickness of 1 cm, and react at 700°C to 850°C for 0.5 to 1 hour to obtain a solid intermediate product. The solid intermediate product is crushed and ground to 200 meshes, and the magnetic separator is used for magnetic separation to magnetically select reduced iron powder, and the remaining residue is then strongly magnetically selected to obtain titanium slag; the remaining residue is reserved for building materials. The titanium slag is reflux washed by adding water, hydrochloric acid, and sodium sulfate, and the mass ratios are 1: (5-10), 1: (0.5-1), 1: (1-1.5) at a temperature of 40°C, and the time is 2-3 hours, solid metatitanic acid is obtained, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com