Method for heightening two-stage roasting arsenic collecting efficiency and special equipment

A special equipment and two-stage roasting technology, which is applied in the field of metallurgy, can solve the problems of frequent parking and cleaning, low arsenic collection rate, etc., and achieve the effects of reducing labor intensity, easy operation, and increased gas extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

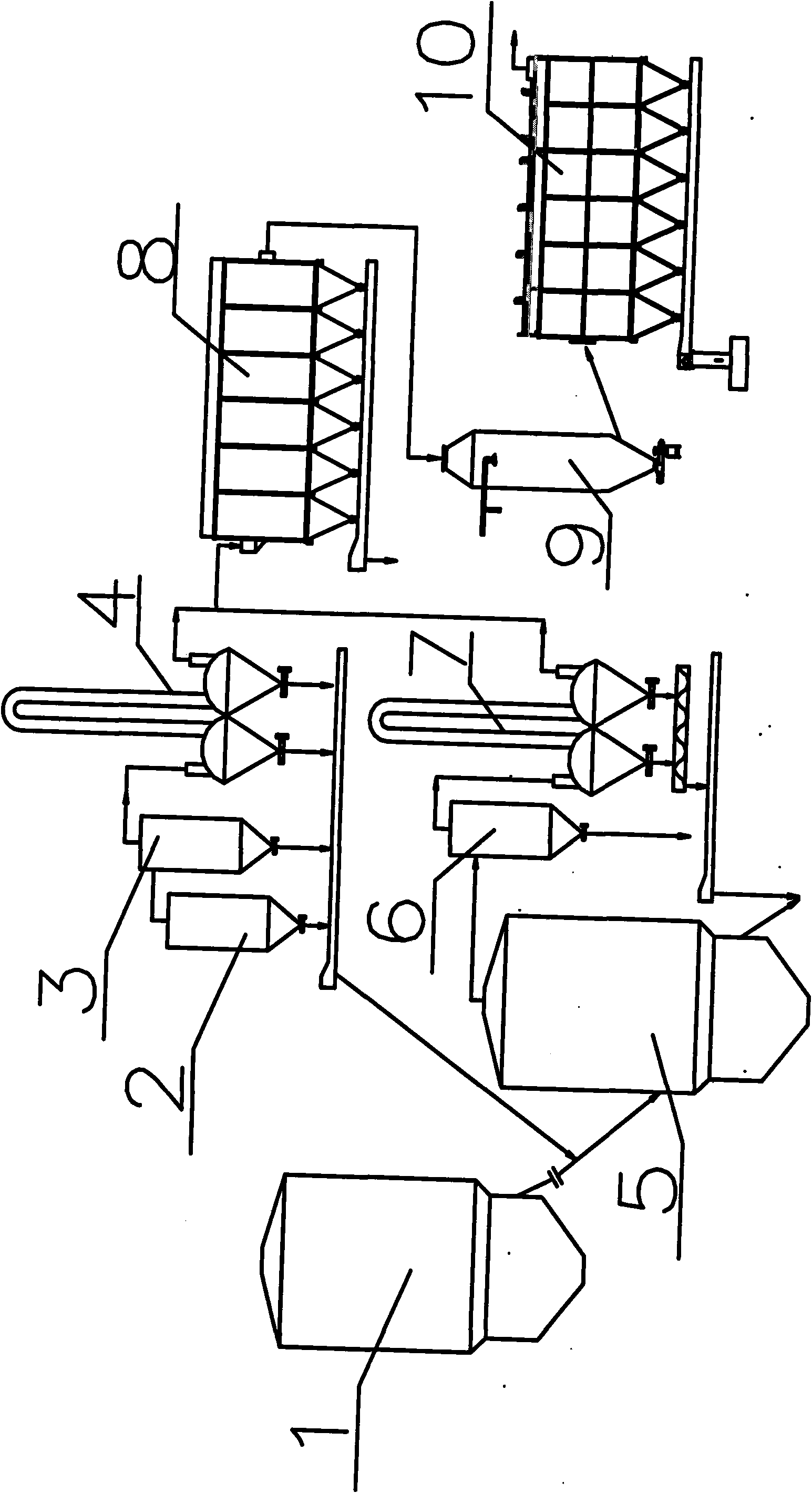

[0016] Example 1, see figure 1 , processed into 1-section roaster 1 and 2-section roaster 5, both roasters are cooled by cooling tube bundles, the top of 1-section roaster 1 is sealed and connected with the top of 1# cyclone device 2 through pipelines, and then the The top of 1# cyclone device 2 is sealed and connected with the upper part of 2# cyclone device 3 through the pipeline, the top of 2# cyclone device 3 is sealed and connected with the 1# furnace cooler 4 through the pipeline, and the 1# cyclone device 2, 2# The bottom ends of cyclone device 3 and 1# furnace cooler 4 are communicated with 2 sections of roasting furnace 5 by pipeline, and the top of 2 sections of roasting furnace 5 is sealed and connected with the top of cyclone device 6 by pipeline, and the top of cyclone device 6 The top is sealed and connected with the 2# furnace cooler 7 through the pipeline, and then the lower part of the second-stage roasting furnace 5 and the cyclone device 6 and the bottom end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com