Industrial natural gas synergist and preparation method thereof

A natural gas and synergist technology, which is applied in the petroleum industry, gas fuel, fuel, etc., can solve problems such as high toxicity, equipment, tool sealing, and human injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

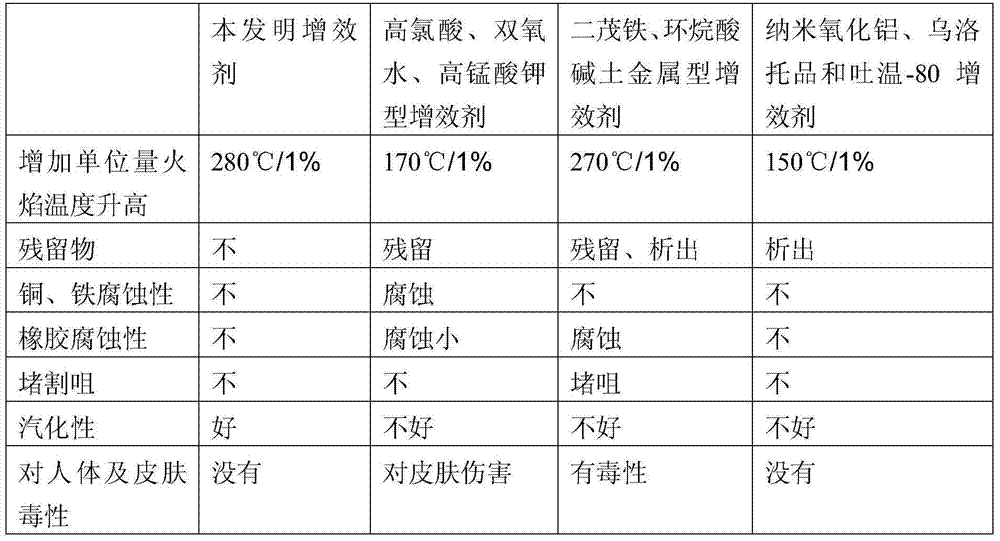

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Weigh the chemical raw material di-tert-butyl peroxide butane: terpane hydroperoxide: cyclohexane peroxide: isooctyl nitrate: C5~C9 linear alkane complex (weight) is 9 parts: 8 parts: 3 servings: 1 serving: 4 servings.

[0019] 2. Add the above-mentioned chemical raw materials into the tank one by one, stir slowly for 15 minutes, let it stand for 10 minutes, and then put it into the package, which is the finished product.

[0020] When the natural gas synergist is used with natural gas, the ratio of synergist:natural gas (weight) is 1:100 parts.

Embodiment 2

[0022] 1. Weigh the chemical raw material di-tert-butyl peroxide butane: terpane hydroperoxide: cyclohexane peroxide: isooctyl nitrate: C5~C9 linear alkane complex (weight) is 8 parts: 7 parts: 5 servings: 1 serving: 3 servings.

[0023] 2. Add the above-mentioned chemical raw materials into the tank one by one, stir slowly for 20 minutes, let it stand for 8 minutes, and then put it into the package, which is the finished product.

[0024] When the natural gas synergist is used with natural gas, the ratio of synergist: natural gas (weight) is 2 parts: 100 parts.

Embodiment 3

[0026] 1. Weigh the chemical raw material di-tert-butyl peroxide butane: terpane hydroperoxide: cyclohexane peroxide: isooctyl nitrate: C5~C9 linear alkane complex (weight) is 8.5 parts: 7.5 parts: 4 servings: 1 serving: 3.5 servings.

[0027] 2. Add the above-mentioned chemical raw materials into the tank one by one, stir slowly for 25 minutes, let it stand for 15 minutes, and then put it into the package, which is the finished product.

[0028] When the natural gas synergist is used with natural gas, the ratio of synergist: natural gas (weight) is 3 parts: 100 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com