Fine atomization flash tank

A flash tank, fine technology, applied in the field of fine atomization flash tank, can solve the problems of not emphasizing the impact of the flash tank flash effect, the decline of boiling vaporization capacity, etc., to improve the liquid vaporization efficiency and prolong the residence time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

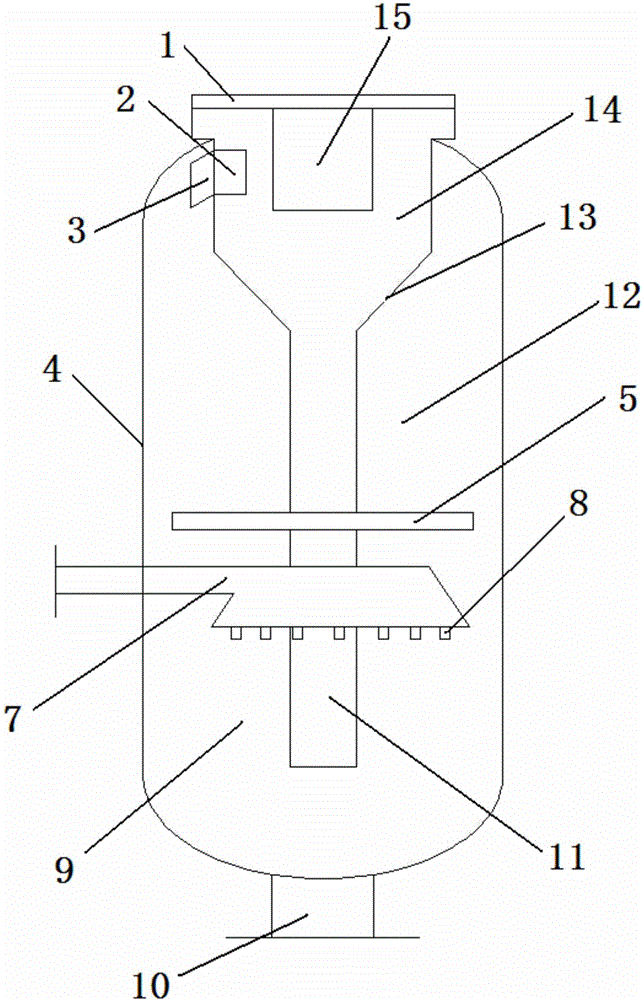

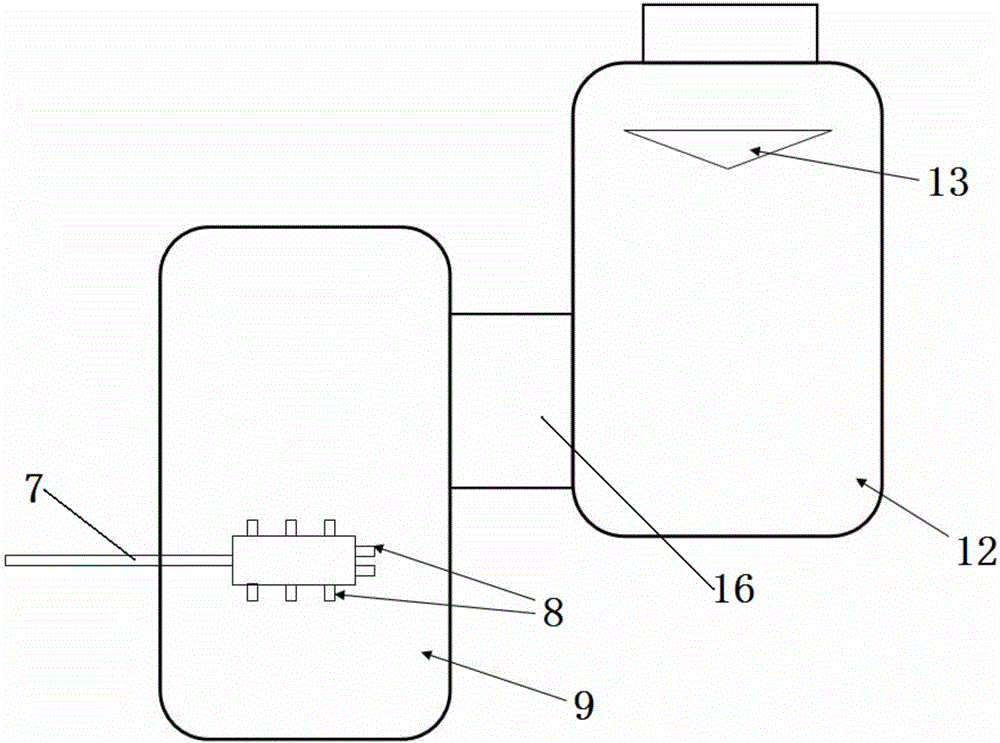

[0017] A kind of fine atomization flash tank, comprises the atomization chamber 9 that communicates with vaporization chamber 12, the feed pipe 7 of described fine atomization flash tank is installed in the atomization chamber 9, is installed on the feed pipe 7 A plurality of atomizing nozzles 8 and a vapor-liquid separator 13 of the fine atomizing flash tank are installed in the vaporization chamber 12 .

[0018] The tank body of the fine atomization flash tank is divided into two connected chambers by a partition 5 , above the partition 5 is a vaporization chamber 12 , and below the partition 5 is an atomization chamber 9 .

[0019] The two tank bodies are respectively used as the atomization chamber 9 and the vaporization chamber 12, and the two tank bodies are connected 16 by a communication channel.

[0020] The vapor-liquid separator 13 is provided with a plurality of evenly distributed steam outlets 2 .

[0021] The fine atomization flash tank described in this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com