SNCR denitrification system and denitrification method

A technology of denitrification and denitrification agent, applied in the direction of separation method, chemical instrument and method, lighting and heating equipment, etc., can solve the problems of high ammonia escape, high operating cost, low NOx removal efficiency, etc., and achieve improved contact area, vaporization Good effect, the effect of increasing the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

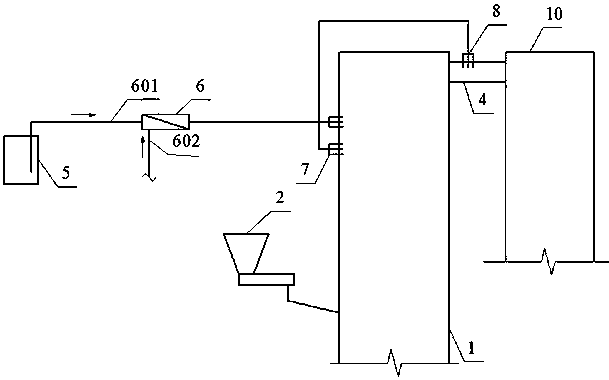

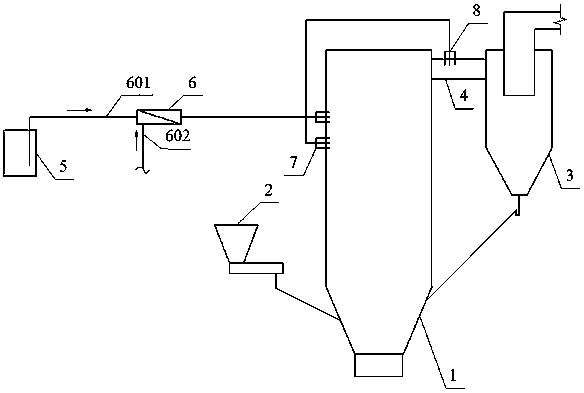

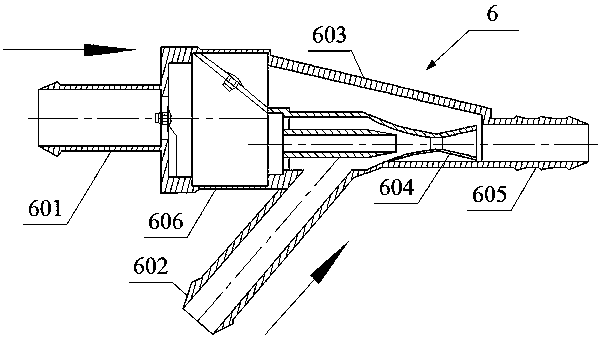

[0042] Example 1: 2×130t / h circulating fluidized bed boiler denitrification project of a chemical company.

[0043] Furnace flue gas volume is 340000Nm 3 / h, the original NOx emission concentration is 300~350 mg / Nm 3 . The mixed ammonia vapor enters the boiler through the nozzle group, and the nozzle group is arranged in 4 groups, of which two groups are arranged on the flue before the cyclone inlet, and the other two groups are arranged in the middle of the furnace, near the return point. NOx emission concentration dropped to 30mg / Nm 3 the following. The denitrification rate reaches 90%,

example 2

[0044] Example 2: A chemical company's 2×35t / h circulating fluidized bed boiler denitrification project.

[0045] Single boiler flue gas volume 50000 Nm 3 / h. NOx original emission concentration 450~480 mg / Nm 3 . The mixed ammonia vapor enters the boiler through the nozzle group, and the nozzle group is arranged in 2 groups, which are arranged at the lower part of the secondary air inlet of the side wall of the boiler. NOx emission concentration dropped to 30mg / Nm 3 the following. The denitrification rate is over 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com