SCR system control device

A technology of SCR system and control device, applied in the direction of muffler device, exhaust device, electronic control of exhaust gas treatment device, etc., can solve the problems of time delay, large deviation of urea injection amount and decrease of urea injection amount, etc. Achieve the effect of satisfying emissions, ensuring service life and improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific drawings.

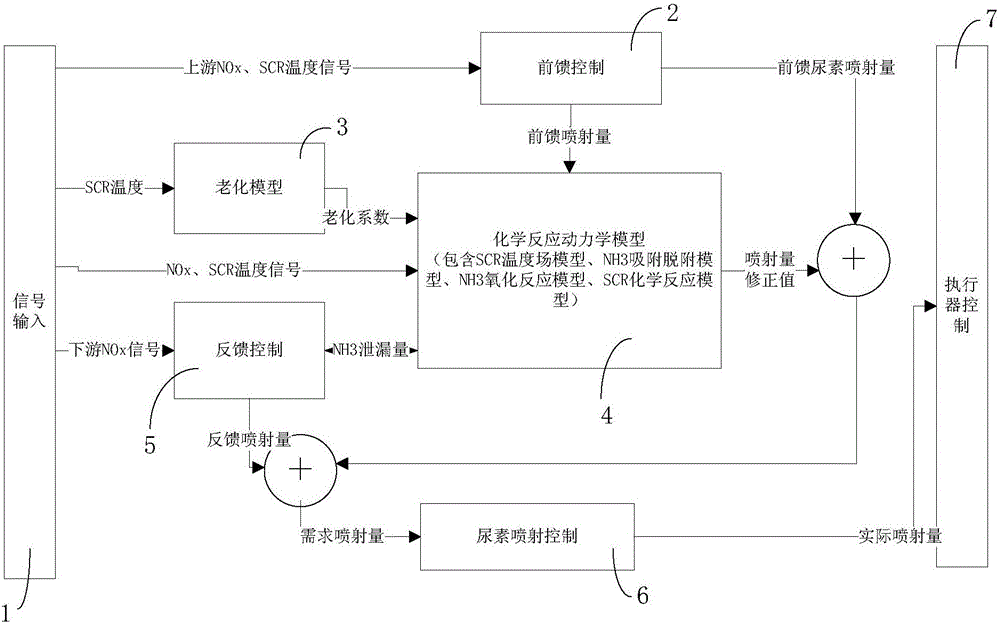

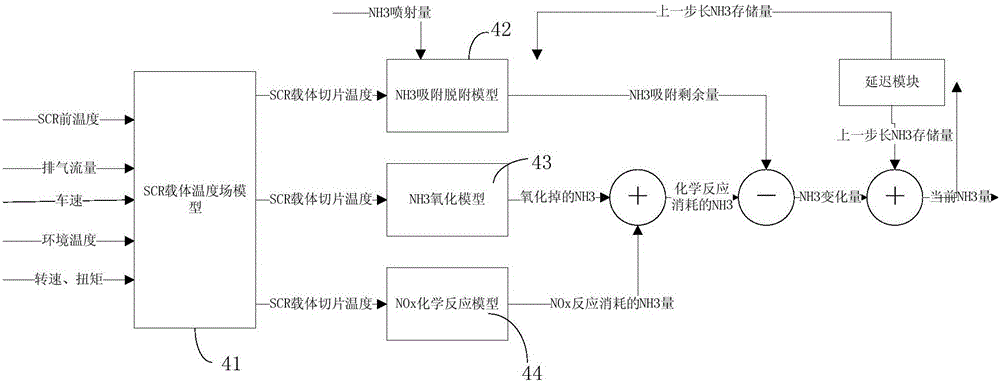

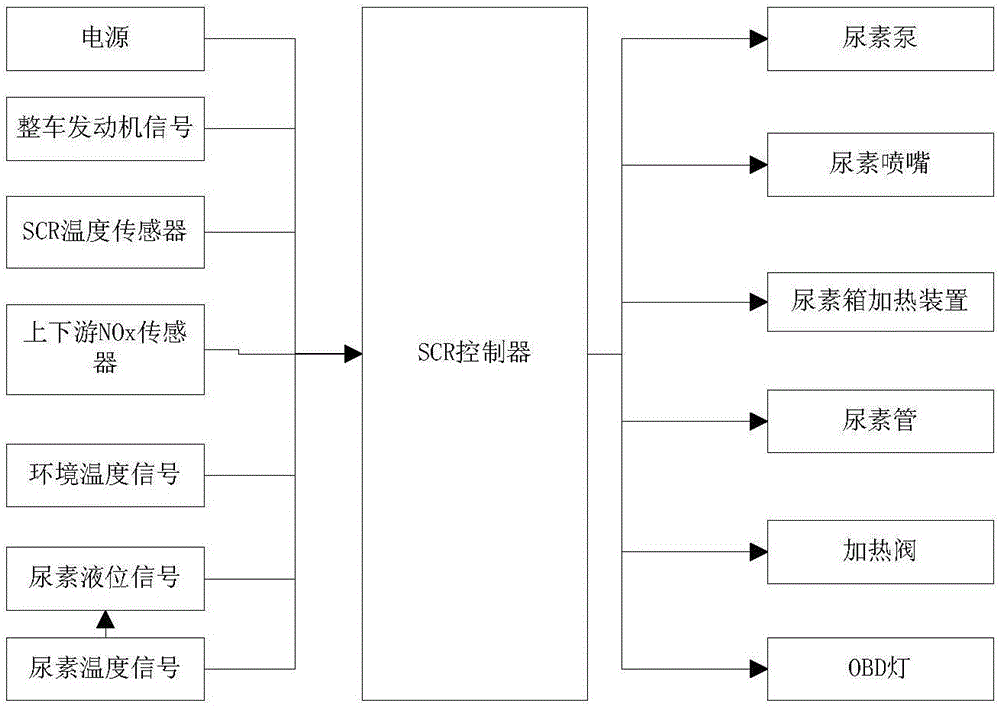

[0029] like figure 1 As shown, the SCR system control device of the present invention includes a signal module 1, a feedforward control module 2, an aging model module 3, a chemical reaction kinetic model module 4, a feedback module 5, a urea injection control module 6 and an actuator control module 7 .

[0030] The main function of the signal module 1 is to process and detect signals from vehicles and engines; to process and detect SCR system sensor signals; and to process and detect signals from external diagnostic instruments.

[0031] The main function of the feedforward control module 2 is to x The concentration value, exhaust gas mass flow rate, SCR temperature and catalyst temperature efficiency MAP are used to obtain the basic urea injection amount, which is used as the feedforward urea injection amount.

[0032] The main function of the aging model module 3 is to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com