A kind of production method of low-carbon hot-rolled thin steel sheet with multi-layer structure

A hot-rolled thin steel plate and microstructure technology, applied in the field of metallurgy, can solve problems such as high cost, poor edge ductility of homogeneous steel plate, complex production process of composite plate or gradient material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for producing a low-carbon hot-rolled thin steel plate with a multi-layered structure, the chemical composition and mass percentage of the low-carbon hot-rolled thin steel plate: C: 0.05%, Si: 0.03%, Mn: 0.12%, P: 0.010 %, S: 0.003%, Als: 0.035%, and the balance is Fe and inevitable impurities.

[0020] The production method of the above-mentioned low-carbon hot-rolled thin steel sheet with a multi-layer structure comprises the following steps:

[0021] Continuous casting into billet → soaking in 1# heating furnace → rough rolling in rough rolling unit → heating in 2# heating furnace → high-pressure water dephosphorization → finishing rolling in finishing rolling group → cooling by layer cooling device → coiling by coiler;

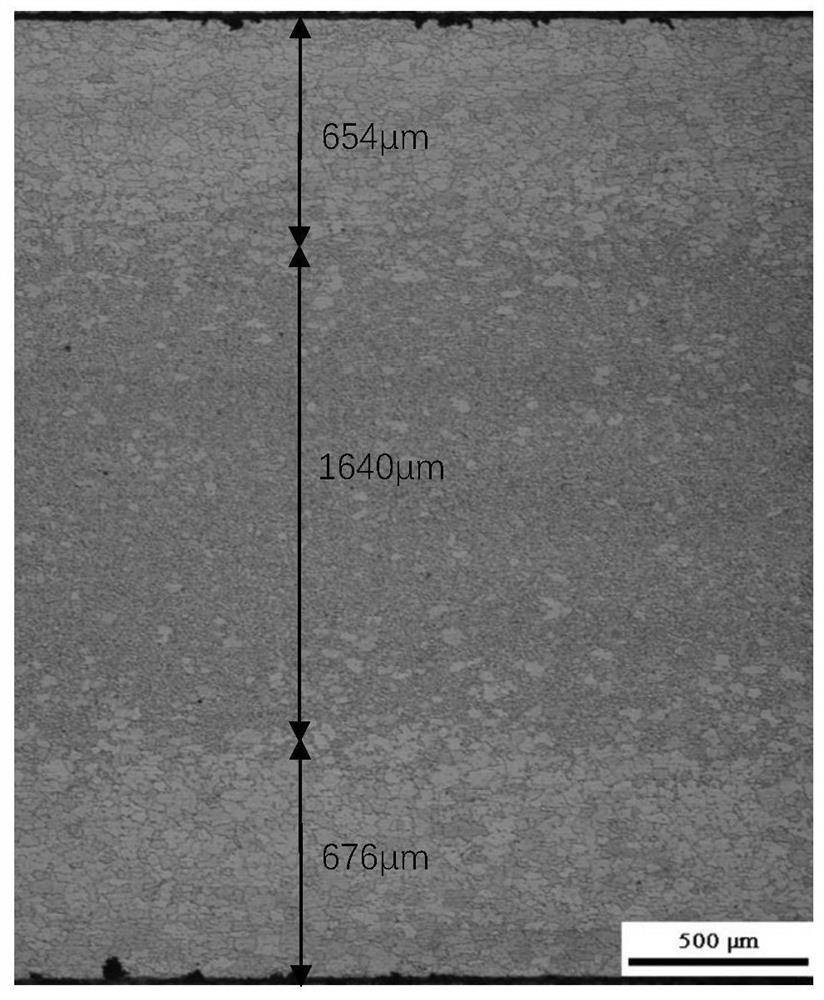

[0022] Through converter smelting→LF refining→slab continuous casting, qualified slabs with the above chemical composition are obtained, wherein the pulling speed is 5m / min, and the slab thickness is 95mm. Uniform heating was carried out i...

Embodiment 2

[0024] A method for producing a low-carbon hot-rolled steel sheet with a multi-layered structure, the chemical composition and mass percentage of the low-carbon hot-rolled steel sheet are: C: 0.03%, Si: 0.01%, Mn: 0.15%, P: 0.012 %, S: 0.001%, Als: 0.040%, B≤0.003%, Ti≤0.03%, and the balance is Fe and inevitable impurities.

[0025] The production method of the above-mentioned low-carbon hot-rolled thin steel sheet with multi-layer structure comprises the following steps:

[0026] Continuous casting into billet → soaking in 1# heating furnace → rough rolling in rough rolling unit → heating in 2# heating furnace → high-pressure water dephosphorization → finishing rolling in finishing rolling group → cooling by layer cooling device → coiling by coiler;

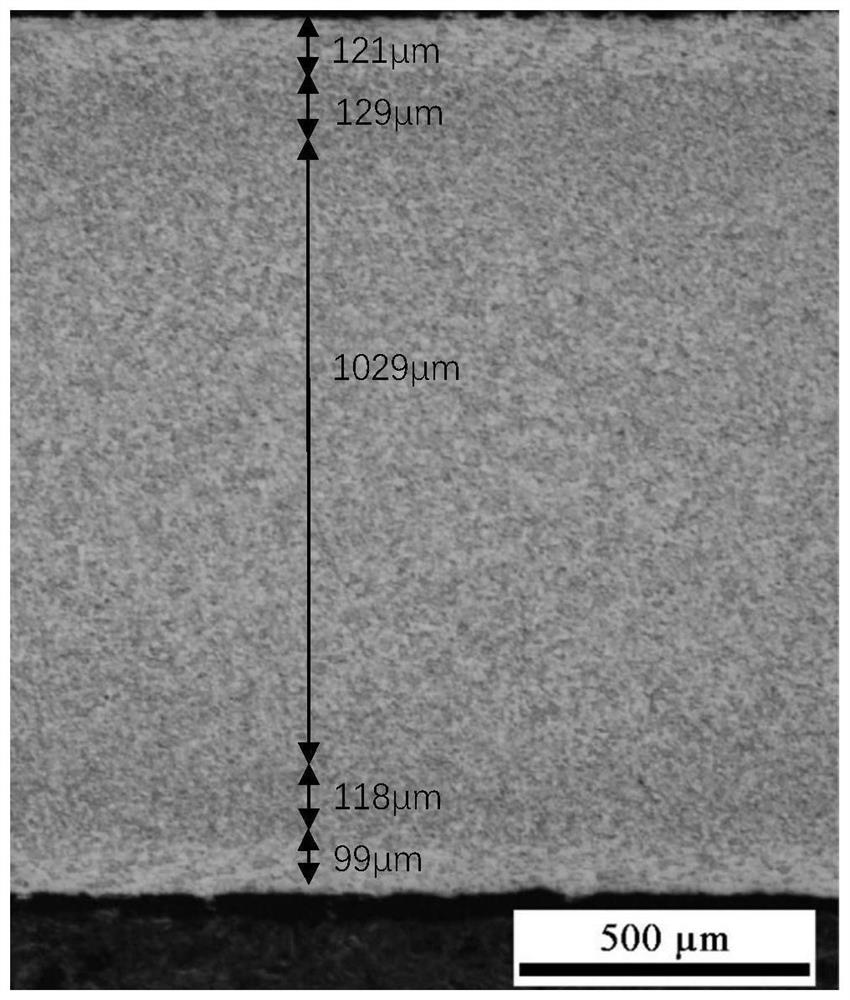

[0027] The qualified slab with the above chemical composition is obtained by converter smelting→LF refining→slab continuous casting, wherein the pulling speed is 6m / min and the slab thickness is 80mm. Uniform heating was carrie...

Embodiment 3

[0029]A method for producing a low-carbon hot-rolled steel sheet with a multi-layered structure. The chemical composition and mass percentage of the low-carbon hot-rolled steel sheet are: C: 0.01%, Si: 0.02%, Mn: 0.09%, P: 0.012 %, S: 0.001%, Als: 0.040%, Nb+V+Ti+Cr≤0.10%, the balance is Fe and inevitable impurities.

[0030] The production method of the above-mentioned low-carbon hot-rolled thin steel sheet with multi-layer structure comprises the following steps:

[0031] Continuous casting into billet → soaking in 1# heating furnace → rough rolling in rough rolling unit → heating in 2# heating furnace → high-pressure water dephosphorization → finishing rolling in finishing rolling group → cooling by layer cooling device → coiling by coiler;

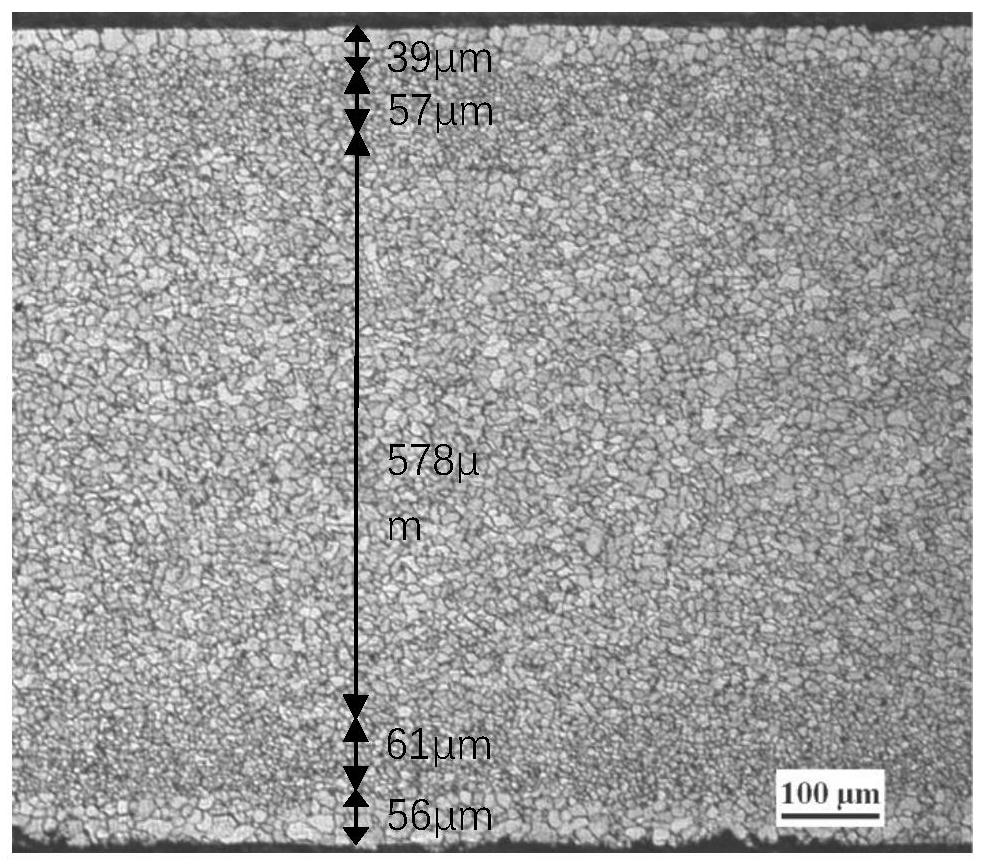

[0032] Qualified slabs with the above chemical composition were obtained by converter smelting→LF refining→slab continuous casting, wherein the pulling speed was 7m / min and the slab thickness was 110mm. Uniform heating was carried out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com